Bleed fuel lines on a Yanmar 3JH engine can be a straightforward process if you follow the right steps. This guide will provide a step-by-step approach to ensure a successful bleed, allowing you to maintain optimal fuel flow and engine performance. By following these instructions, you can efficiently remove air bubbles from the fuel lines, ensuring a smooth and reliable operation of your Yanmar engine.

What You'll Learn

- Preparation: Ensure engine is off, and fuel lines are cool before starting

- Safety Gear: Wear gloves and goggles to protect from fuel splashes

- Locate Lines: Identify fuel lines and their connections using diagrams

- Bleeding Process: Open fuel line bleeder valves and release pressure gradually

- Testing: Check for leaks and ensure fuel flow is clear and clean

Preparation: Ensure engine is off, and fuel lines are cool before starting

Before attempting to bleed the fuel lines on a Yanmar 3JH engine, it is crucial to prioritize safety and preparation. Firstly, ensure that the engine is completely shut off and has had sufficient time to cool down. Working on a hot engine can be dangerous and may cause fuel to spray unexpectedly. Allow the engine to idle for a few minutes after turning it off to allow the fuel to return to the tank. This step is essential to prevent any potential hazards.

Additionally, locate the fuel lines and inspect them for any visible damage or blockages. Clean and inspect the fuel lines to ensure they are in good condition. This process helps identify any potential issues that might hinder the bleeding process. It is also recommended to wear protective gear, such as gloves and safety goggles, to safeguard against any potential fuel splashes or spills.

Once the engine and fuel lines are ready, you can proceed with the bleeding process. It is important to have a clear understanding of the engine's fuel system layout to locate the correct bleeder valves. These valves are typically located near the fuel tank or along the fuel lines. Have a suitable container ready to collect any fuel that is drained during the bleeding process.

Remember, the key to a successful fuel line bleed is patience and a systematic approach. Take your time to carefully follow the steps, ensuring that all fuel lines are properly bled and any air bubbles are eliminated. This preparation phase is critical to the overall success of the task and helps prevent any complications during the bleeding process.

Fuel Line Valves: Direction Matters for Effective Shut-Off

You may want to see also

Safety Gear: Wear gloves and goggles to protect from fuel splashes

When working on fuel systems, especially on a Yanmar 3JH engine, prioritizing safety is crucial. One essential aspect of ensuring your safety during this process is wearing the appropriate protective gear. Fuel lines can be under pressure, and any fuel leaks or splashes can be hazardous. Here's why and how to stay safe:

Gloves: Working with fuel lines requires a pair of heavy-duty gloves designed to withstand the potential heat and pressure. Leather or synthetic leather gloves are ideal as they provide a good grip and protect your hands from any sharp edges or debris that might be present. Ensure the gloves fit well to allow for dexterity when handling small components. This simple gear choice can prevent skin irritation, cuts, and potential chemical burns from fuel contact.

Goggles: Eye protection is equally important. Fuel can be a corrosive substance, and any splashes or spills can cause severe irritation or even blindness. Goggles should be impact-resistant and provide a secure seal to protect your eyes from any potential hazards. Look for goggles that offer side protection as well, as fuel can spray in various directions. This safety measure is critical to avoid any long-term damage to your vision.

The process of bleeding fuel lines can be intricate, and it's essential to have your hands and eyes protected. By wearing gloves and goggles, you create a barrier between the fuel and your skin and eyes, reducing the risk of injury. This simple safety gear checklist is often overlooked but is a fundamental part of engine maintenance and repair, ensuring your well-being and the success of the task at hand. Remember, taking these precautions will make your work more efficient and safe.

Bleed Fuel Lines: A Comprehensive Guide for Car Owners

You may want to see also

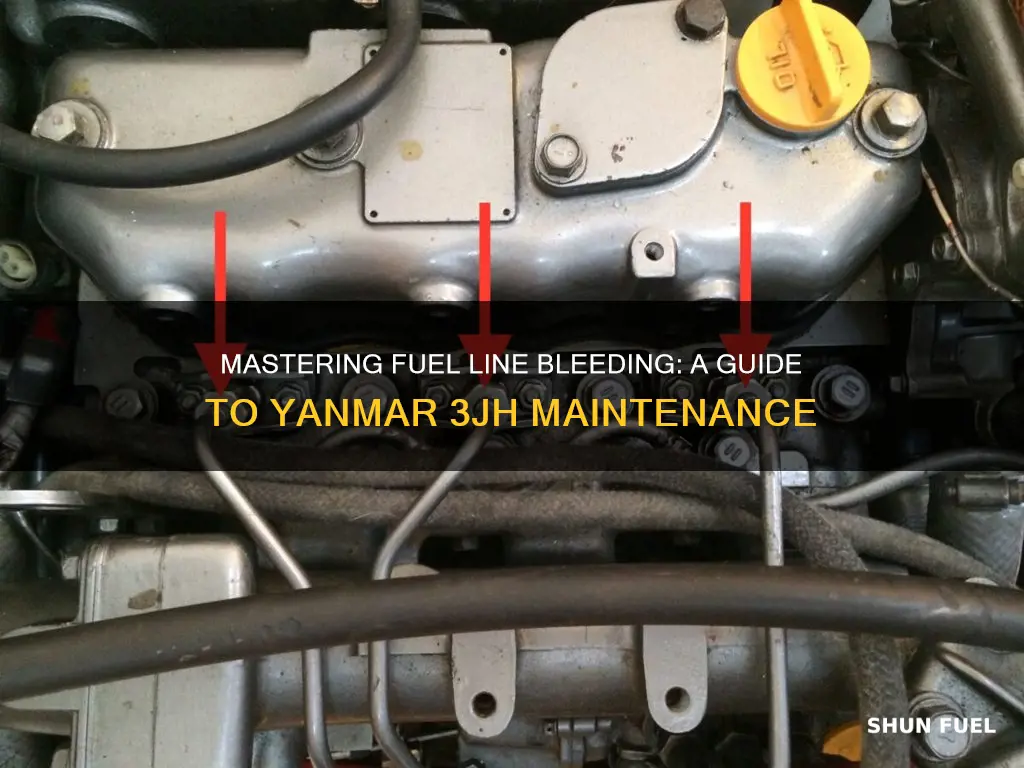

Locate Lines: Identify fuel lines and their connections using diagrams

To effectively bleed the fuel lines on a Yanmar 3JH engine, you must first locate the fuel lines and their connections. This process is crucial to ensure you have access to the necessary components and can perform the bleeding procedure accurately. Here's a step-by-step guide to help you identify the fuel lines and their connections:

Consult the Engine Manual: Start by referring to the engine's manual, which should provide detailed diagrams and illustrations specific to your Yanmar 3JH model. These diagrams will show the layout of the fuel system, including the fuel lines, injectors, and various connections. Look for diagrams that depict the engine's top view or a detailed breakdown of the fuel system.

Identify Fuel Lines: Fuel lines are typically made of rubber or plastic and carry fuel from the tank to the engine's injectors. They are often color-coded or labeled for easy identification. Common colors include red, blue, and black. Locate the fuel tank, which is usually positioned at the rear or side of the engine. Follow the lines that connect the tank to the engine, as these will lead you to the injectors.

Locate Connections: The fuel lines will have various connections, such as fittings, clamps, and unions. These connections are critical points for bleeding. Look for any visible fittings or unions where the fuel lines are connected to the engine block, injectors, or other components. These connections might be secured with screws, bolts, or clamps, so ensure you have the necessary tools to release them.

Use Diagrams for Precision: Diagrams will be your best friend in this process. Compare the diagram with the actual engine to ensure you identify the correct fuel lines and connections. Pay attention to the labels and markings on the diagram, as they will guide you to the specific locations of the fuel lines and their respective connections.

Safety Precautions: Before proceeding, ensure the engine is cool to the touch to avoid any burns. Additionally, locate the fuel shut-off valve and ensure it is in the 'off' position to prevent accidental fuel release during the bleeding process.

By following these steps and using the provided diagrams, you can accurately locate the fuel lines and their connections, making the subsequent bleeding process more efficient and effective.

Solid Fuel Safety: Can It Be Used in Fuel Lines?

You may want to see also

Bleeding Process: Open fuel line bleeder valves and release pressure gradually

To begin the bleeding process for your Yanmar 3JH engine's fuel lines, you'll need to locate the bleeder valves. These valves are typically found along the fuel lines, often near the engine's fuel tank or the fuel filter. It's important to consult your engine's manual or a reliable online resource for specific valve locations, as they can vary depending on the model and year of your Yanmar engine.

Once you've identified the bleeder valves, it's time to open them. Start by ensuring that the engine is cool and that you have a suitable container or drain pan to catch any fuel that may bleed out. Then, using a suitable tool (often a small spanner or wrench), carefully turn the bleeder valves counterclockwise to open them. Be cautious, as the fuel lines may contain residual pressure, and opening the valves too quickly could lead to a sudden release of fuel.

With the bleeder valves open, you can now begin the gradual release of pressure. This step is crucial to ensure that air bubbles are removed from the fuel lines, allowing for proper fuel flow. Slowly turn the bleeder valves in a counterclockwise direction, allowing fuel to flow out of the lines. As you do this, you should hear the air being expelled, and you may see fuel in the container below. The process might take a few minutes, so be patient and continue to turn the valves slowly.

As you release the pressure, keep an eye on the fuel that drains out. If you notice any air bubbles or if the fuel flow becomes inconsistent, you may need to adjust the valve opening slightly. Remember, the goal is to remove air bubbles and ensure a smooth, continuous flow of fuel. Once you've reached a steady flow and no more air bubbles are evident, you can close the bleeder valves.

After closing the bleeder valves, it's essential to start the engine and check for any leaks or unusual behavior. Run the engine for a few minutes, ensuring that the fuel system is functioning correctly. If everything is in order, you've successfully bled the fuel lines on your Yanmar 3JH engine. This process is a critical maintenance step to ensure optimal engine performance and longevity.

Polyurethane's Potential as an Alternative Fuel Line Material

You may want to see also

Testing: Check for leaks and ensure fuel flow is clear and clean

When it comes to testing the fuel system on a Yanmar 3JH engine, ensuring that the fuel lines are clear and free of any leaks is crucial. This process involves a series of checks and procedures to verify the integrity of the fuel system and its performance. Here's a step-by-step guide to help you through this testing process:

Leak Detection: Begin by inspecting the fuel lines for any signs of damage, cracks, or corrosion. Pay close attention to connections, fittings, and areas where the lines might be susceptible to wear. Use a soapy water solution to test for leaks. Apply the solution to the fuel lines and observe for any bubbles or foam. Bubbles indicate the presence of air or fuel vapor, while foam suggests a fuel leak. If any leaks are found, repair or replace the affected parts accordingly.

Fuel Flow Assessment: After ensuring the lines are leak-free, it's time to check the fuel flow. Start the engine and monitor the fuel pressure gauge, if available. The gauge should read within the specified range for the engine model. If the pressure is too low, it may indicate a restriction or blockage in the fuel lines or injectors. Check for any clogs or obstructions that could be causing this issue. Additionally, listen for any unusual noises while the engine is running, as this could indicate a problem with the fuel pump or injectors.

Fuel Quality and Filtration: Ensure that the fuel being supplied to the engine is clean and of good quality. Check the fuel filter regularly and replace it if it appears clogged or dirty. Contaminated fuel can lead to engine performance issues and potential damage. Consider using a fuel stabilizer if the fuel has been sitting for an extended period, especially during storage.

Engine Performance Testing: Once the fuel system is confirmed to be in good condition, it's time to test the engine's performance. Run the engine through its operating range, including idling, cruising, and high-load conditions. Monitor for any unusual vibrations, noises, or changes in performance. A well-functioning fuel system should provide smooth and consistent power delivery without any hiccups.

Remember, regular maintenance and testing of the fuel system are essential to keep your Yanmar 3JH engine running efficiently and reliably. By following these steps, you can ensure that the fuel lines are properly bled, free of leaks, and delivering clean fuel, contributing to the overall performance and longevity of your engine.

Solder Bosch Steel Fuel Line: A Comprehensive Guide

You may want to see also