Bleed air fuel lines on an ATV is a crucial process to ensure optimal performance and fuel efficiency. This guide will provide a step-by-step process to safely and effectively bleed the air fuel lines on your ATV, covering the necessary tools, safety precautions, and techniques to achieve a smooth and efficient fuel flow.

What You'll Learn

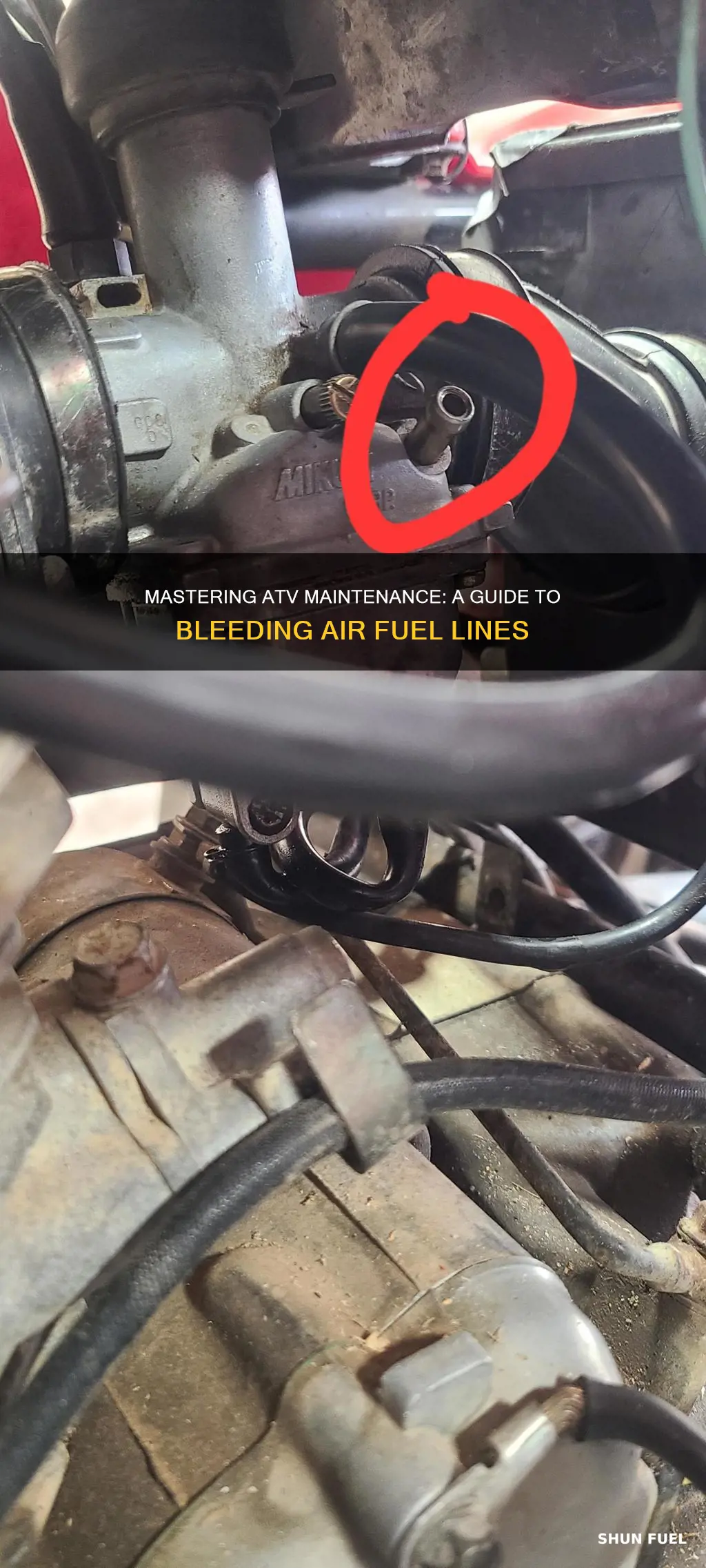

Locate the air/fuel mixture screw and remove it

To bleed the air/fuel mixture in your ATV, you'll need to locate the air/fuel mixture screw, which is typically found on the carburetor. This screw controls the air/fuel ratio, and by adjusting it, you can ensure that your engine is getting the correct mixture of air and fuel. Here's a step-by-step guide on how to locate and remove this screw:

Start by locating the carburetor, which is usually positioned near the engine's intake manifold. It is often a small, rectangular or cylindrical component with a series of openings and passages. Carefully inspect the carburetor to find the air/fuel mixture screw. This screw is typically a small, Phillips-head or flat-head screw, and it might be marked with a label or a small indentation to indicate its purpose. If you're having trouble finding it, consult your ATV's manual or online resources for a visual representation.

Once you've identified the screw, use a screwdriver to carefully remove it. It might be secured with a small retaining clip, so be gentle to avoid damaging it. After removing the screw, set it aside in a safe place. You may want to take a picture of the screw's original position and orientation for reference during the bleeding process.

With the screw removed, you can now proceed to the next step of bleeding the air/fuel mixture. This process involves introducing a fuel source into the carburetor and adjusting the screw to achieve the correct air/fuel ratio. However, it's important to note that this step should be done with caution and preferably under the guidance of a professional or an experienced mechanic to avoid any potential engine damage.

Remember, the air/fuel mixture screw is a critical component in your ATV's engine, and adjusting it incorrectly can lead to poor performance or even engine failure. Always exercise caution and refer to your vehicle's manual for specific instructions tailored to your ATV model.

Moisture in Fuel Lines: A Recipe for Power Loss

You may want to see also

Connect a fuel gauge or pressure gauge to the line

To ensure your ATV's fuel system is functioning optimally, it's crucial to bleed the air fuel line. Once the line is bled, you can connect a fuel gauge or pressure gauge to monitor the fuel levels and pressure in the system. Here's a step-by-step guide on how to do this:

First, locate the fuel line that connects the fuel tank to the engine. This line is typically made of rubber or plastic and is often black or dark in color. You'll need to disconnect the fuel line from the fuel tank and the engine. Use a fuel line disconnect tool or a pair of pliers to carefully remove the fittings. Make sure to label or mark the positions of the fittings so you can reconnect them later in the correct order.

Next, you'll need to find a suitable location to mount the gauge. This could be on the fuel tank, the frame, or any other convenient spot that provides easy access. Ensure the gauge is positioned where the fuel line connects to the engine or the fuel tank. Use a suitable mounting bracket or secure the gauge with tape or straps to keep it in place.

Now, you can connect the fuel gauge or pressure gauge to the fuel line. Start by threading the gauge's hose into the fuel line. Ensure a tight connection by twisting the hose until it locks into place. Check the gauge's instructions or manufacturer's guidelines for the correct orientation and connection method. Once connected, secure the gauge with tape or a clamp to prevent it from coming loose.

After connecting the gauge, it's essential to test the system to ensure proper functionality. Start the ATV's engine and allow it to run for a few minutes. Check the gauge readings to confirm that the fuel levels or pressure are accurate. If the gauge shows incorrect readings, you may need to adjust the gauge's settings or calibrate it according to the manufacturer's instructions.

Remember, when working with fuel lines and gauges, it's crucial to follow safety precautions. Always wear protective gear, such as gloves and safety goggles, to prevent any potential fuel-related hazards. Additionally, ensure the ATV is in a well-ventilated area, and never smoke or use open flames when working on the fuel system.

Mysterious Moisture: Unraveling the Mystery of Water in John Deere Fuel Lines

You may want to see also

Start the engine and allow it to run for a few minutes

Once you've located the air/fuel line, you can begin the bleeding process. Start by ensuring the engine is in a stable running condition. It's crucial to have a steady engine before attempting to bleed the lines, as any sudden changes in the fuel-air mixture can cause the engine to stall or misfire.

With the engine running, you'll want to observe the behavior of the engine. Pay close attention to the idle speed and stability. The engine should maintain a steady idle without any noticeable fluctuations or hesitations. If the engine stumbles or the idle speed fluctuates, it indicates that there might be an issue with the fuel-air mixture, and you may need to adjust the fuel-air ratio or address other related components.

During this process, you might also want to check for any unusual noises or vibrations. These could provide valuable insights into the engine's performance and help identify potential issues. A well-behaved engine during this stage is a good sign that the bleeding process is proceeding correctly.

The duration of this step can vary depending on the specific ATV model and its engine characteristics. Generally, allowing the engine to run for 5-10 minutes should be sufficient to ensure the air/fuel mixture is properly distributed and any air bubbles have been dispersed.

Remember, the goal is to ensure an even and consistent fuel-air mixture, and this step is a crucial part of the overall bleeding process.

Honda vs Mercury: Unraveling the Outboard Fuel Line Connector Mystery

You may want to see also

Open the bleeder valve and release any excess pressure

When performing an air fuel line bleed on your ATV, opening the bleeder valve is a crucial step to ensure the process is done correctly. This valve is typically located near the fuel tank or the fuel pump, and it allows you to release any built-up air or pressure from the system. Here's a step-by-step guide on how to do this:

Start by locating the bleeder valve, which is usually a small screw or bolt that can be turned by hand. It might be covered with a small cap or be part of a fuel line fitting. Carefully remove any covers or caps to access the valve. Once you have the valve exposed, you'll need to turn it counterclockwise to open it. Be gentle but firm in your application of force to avoid stripping the threads.

After opening the bleeder valve, you should hear a hissing sound as air is released from the system. This is a good sign that the bleed process is working. Continue to hold the valve open for a few seconds to ensure a steady flow of air. You might also notice some fuel being released, which is normal. If this happens, it indicates that the line is almost bled, and you should proceed with caution to avoid fuel wastage.

It's important to note that the bleeder valve should be opened slowly and controlled. Rapidly opening it can cause a sudden rush of air and fuel, which might be dangerous and could lead to engine misfires or stalling. Take your time and be patient during this process. If you hear a continuous hissing sound without any fuel release, it might indicate a blocked line, and you should check for any obstructions.

Once you've released the excess pressure and air from the system, carefully close the bleeder valve by turning it clockwise. Ensure it is securely tightened to prevent any leaks. After closing the valve, you can proceed to the next step of the bleeding process, which might involve adjusting the fuel mixture or testing the engine's performance. Remember, this process requires patience and a gentle touch to avoid any potential issues.

Mastering Fuel Line Maintenance: Spring Decoupling Tool Techniques

You may want to see also

Tighten the screw and check for any leaks

After you have bled the air from the fuel line, it's crucial to ensure that the system is functioning correctly and there are no leaks. This step is essential to guarantee that your ATV's engine receives the correct fuel-air mixture for optimal performance. Here's a detailed guide on how to tighten the screw and check for any leaks:

Locate the fuel line screw, which is typically found near the fuel tank or the engine's fuel inlet. This screw is designed to regulate the fuel flow and pressure. Use a wrench or a pair of adjustable pliers to tighten the screw. Apply firm pressure in a clockwise direction until the screw is snug and secure. Be careful not to overtighten it, as this can damage the fuel line or create unnecessary tension. The goal is to ensure a tight seal without causing any damage.

Once the screw is tightened, it's time to inspect for any potential leaks. Start by turning the ATV's engine on and allowing it to idle. Pay close attention to the fuel line connections and the area around the screw. Look for any signs of fuel escaping, such as a hissing sound or a visible stream of fuel. If you notice any leaks, immediately tighten the screw further or adjust the connection to seal the leak. Ensure that all connections are secure and tight.

After tightening the screw and addressing any leaks, it's a good practice to test the engine's performance. Start the ATV and let it run for a few minutes. Observe if there are any unusual noises or vibrations, which could indicate a persistent leak. If everything seems normal, you can proceed with the rest of the bleeding process or ride the ATV to ensure the fuel system is functioning as intended.

Remember, taking the time to properly tighten the fuel line screw and check for leaks is vital for the overall health of your ATV's engine. It ensures that the fuel system operates efficiently, providing the engine with the correct fuel-air mixture for optimal power and performance. Always exercise caution when working on your vehicle and consult the ATV's manual for specific instructions tailored to your model.

Fixing a Flooded Fuel Line: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Bleeding the air/fuel line is a process to remove air bubbles from the fuel system, ensuring a smooth and efficient fuel-air mixture delivery to the engine. This process helps to prevent engine performance issues and ensures optimal power output.

It is recommended to bleed the air/fuel line whenever you notice any signs of air in the system, such as a sputtering or hesitating engine, poor performance, or a noticeable drop in power. Regular maintenance, especially after adding fuel or making fuel system modifications, is advised.

Air bubbles can be detected by observing the engine's behavior. If the engine stalls or runs roughly when you start it, it might indicate the presence of air in the fuel system. Additionally, a hissing sound near the fuel tank or lines could be a sign of air bubbles.

You will need a fuel pump primer bulb, a fuel filter, and a fuel line. Start by removing the fuel line from the fuel filter and priming the fuel pump to create a vacuum. Then, slowly open the fuel valve and allow the air to escape. Reattach the fuel line and filter, ensuring a secure connection. This process may require repetition to fully remove all air bubbles.