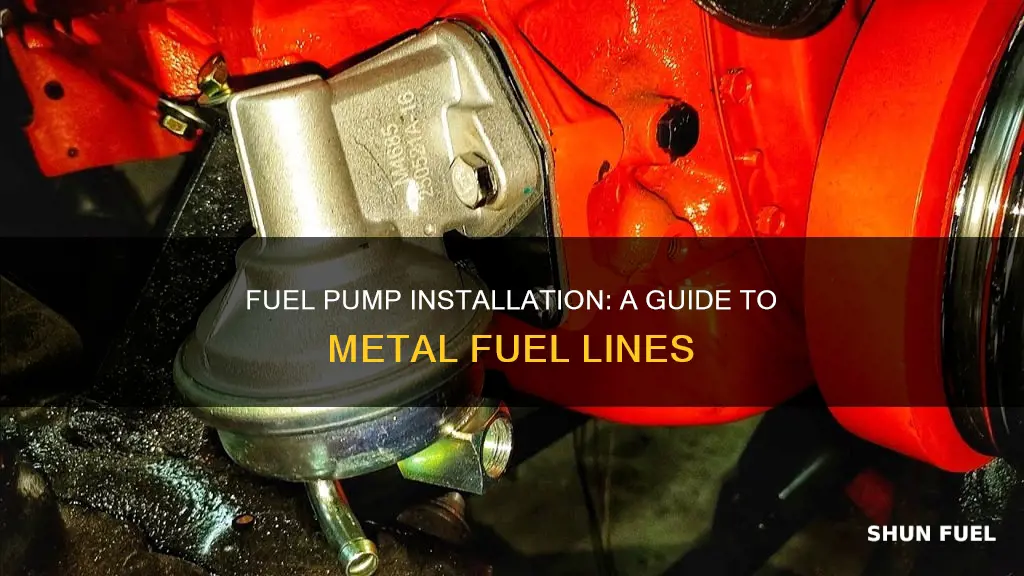

Installing a fuel pump into a metal fuel line is a crucial process for ensuring the efficient and safe operation of a vehicle's fuel system. This procedure involves carefully replacing the existing fuel line with a new one that can accommodate the fuel pump, which is essential for delivering fuel to the engine. The process requires precision and attention to detail to avoid any potential issues, such as fuel leaks or damage to the fuel pump. By following a step-by-step guide, you can ensure a successful installation, enhancing the vehicle's performance and reliability.

What You'll Learn

- Prepare Tools and Materials: Gather necessary tools like wrenches, pump, and line cutters

- Locate and Remove Old Pump: Identify the old pump's position and disconnect fuel lines

- Install New Pump: Secure the new pump with brackets and connect fuel lines

- Test and Adjust: Ensure proper fuel flow, check for leaks, and fine-tune settings

- Safety Checks: Verify pump functionality, fuel line integrity, and vehicle performance

Prepare Tools and Materials: Gather necessary tools like wrenches, pump, and line cutters

Before you begin the installation process, it's crucial to gather all the necessary tools and materials to ensure a smooth and efficient job. Here's a detailed guide on what you need to prepare:

Wrenches and Pliers: Start by collecting a set of wrenches and pliers of various sizes. You'll need these to tighten the connections and secure the fuel pump in place. Wrenches are essential for turning nuts and bolts, especially when dealing with the fuel line fittings. Opt for a combination of adjustable and fixed-size wrenches to accommodate different bolt sizes. Pliers will be handy for gripping and manipulating smaller components.

Fuel Pump: The primary component you'll be installing is the fuel pump itself. Ensure you have the correct model that fits your vehicle's specifications. Check the manufacturer's recommendations or consult your vehicle's manual to identify the compatible pump.

Fuel Line Cutters: You'll require specialized tools to cut the metal fuel line. Line cutters are designed to make clean, precise cuts without damaging the surrounding metal. These cutters often feature a sharp blade and a handle for comfortable operation. Having a pair of line cutters will enable you to remove any excess fuel line and prepare it for the new pump.

Pipe Threads and Fittings: Gather the necessary pipe threads and fittings to connect the fuel pump to the existing fuel line. You might need adapters, elbows, or straight fittings, depending on your vehicle's setup. Ensure you have the correct thread sizes and materials compatible with your fuel system.

Safety Gear: Don't forget to prioritize safety. Wear safety goggles to protect your eyes from any potential fuel splashes. Gloves will also provide a better grip and protect your hands during the installation process.

By gathering these tools and materials, you'll be well-prepared to tackle the fuel pump installation. Remember to work in a well-ventilated area and follow safety guidelines throughout the project.

Fuel Line Swap: EFI to Carb Conversion Guide

You may want to see also

Locate and Remove Old Pump: Identify the old pump's position and disconnect fuel lines

To begin the process of installing a new fuel pump into a metal fuel line, you must first locate and remove the old pump. This step is crucial to ensure a smooth and efficient installation. Start by inspecting the fuel system and identifying the old pump's position. The fuel pump is typically located near the engine, often in the fuel tank or along the fuel line, where it can efficiently draw fuel from the tank and supply it to the engine.

Once you've identified the pump's location, carefully inspect the surrounding area. You'll need to disconnect the fuel lines that are connected to the old pump. These lines are usually made of metal and can be quite delicate. Use the appropriate tools to carefully loosen and remove the nuts or clips that hold the fuel lines in place. Be cautious not to damage the fuel lines during this process.

With the fuel lines disconnected, you can now access the old pump. Carefully lift and remove the pump from its position, ensuring you don't drop or damage any components. Take note of the pump's orientation and any specific connections or attachments it had. This information will be crucial when installing the new pump.

When removing the old pump, it's essential to handle it with care. The pump may contain sensitive components, and improper handling could lead to damage. If possible, use a soft cloth or gloves to avoid leaving fingerprints or marks on the pump's surface. Once the old pump is removed, you can proceed with cleaning and inspecting the fuel lines to ensure they are in good condition before installing the new pump.

Mastering Fuel Cell Efficiency: The Art of Running Return Lines

You may want to see also

Install New Pump: Secure the new pump with brackets and connect fuel lines

When installing a new fuel pump into a metal fuel line, securing the pump with brackets is a crucial step to ensure a stable and reliable setup. Start by locating the appropriate brackets that match the dimensions of your pump and fuel line. These brackets are typically made of sturdy materials like steel or aluminum to withstand the pressure and vibrations associated with the fuel system. Carefully align the brackets with the pump's mounting points, ensuring they are secure and tight. Use the provided screws or bolts to fasten the brackets in place, taking care not to overtighten to avoid damage to the pump or fuel line.

Once the brackets are firmly attached, it's time to connect the fuel lines. Carefully inspect the new pump to identify the inlet and outlet ports, as these will need to be connected to the respective fuel lines. Ensure that the fuel lines are the correct size and material for the application, as using the wrong size or material can lead to leaks or performance issues. Start by inserting the inlet line into the pump's inlet port, ensuring a snug fit. Then, connect the outlet line to the pump's outlet port, again confirming a secure connection.

To ensure a tight seal, you can use fuel line connectors or clamps to secure the lines to the pump and brackets. Wrap the connectors or clamps around the fuel lines and tighten them according to the manufacturer's instructions. This step is essential to prevent any fuel leaks and to maintain the integrity of the fuel system. Take your time with this process, as a proper connection is critical to the overall performance and safety of the fuel pump installation.

After connecting the fuel lines, double-check all connections to ensure they are secure and leak-free. You can use a fuel line inspection mirror or a small camera to visualize the connections and identify any potential issues. If everything looks good, start the engine and check for any unusual noises or vibrations. Properly securing the pump with brackets and connecting the fuel lines will contribute to a smooth and efficient operation of the fuel system.

Unraveling the Mystery: Can Fuel Lines Withstand Heat?

You may want to see also

Test and Adjust: Ensure proper fuel flow, check for leaks, and fine-tune settings

After installing the fuel pump into the metal fuel line, it's crucial to test and adjust the system to ensure optimal performance and safety. Here's a step-by-step guide to help you through this process:

Fuel Flow Testing: Begin by starting the engine and allowing it to idle. Monitor the fuel flow rate to ensure it meets the required specifications. You can use a fuel flow meter or a pressure gauge to measure the output. The flow rate should be consistent and within the recommended range for your vehicle's engine. If the flow is insufficient, you might need to adjust the pump's settings or check for any blockages in the fuel line.

Leak Detection: Inspect the entire fuel system for any signs of leaks. Check all connections, including the pump, fuel lines, and the fuel tank. Look for any wet spots or drips, especially around the pump's mounting area and the fuel line connections. Leaks can lead to fuel wastage, engine performance issues, and potential safety hazards. If you notice any leaks, tighten connections or replace damaged components.

Pressure Check: Measure the fuel system pressure to ensure it is within the specified limits. You can use a fuel pressure gauge for this test. The pressure should be sufficient to supply fuel to the engine efficiently. If the pressure is too low, it may indicate a restricted fuel line or a faulty pump. Adjust the pump's settings or consider replacing the fuel pump if necessary.

Fine-Tuning Settings: Adjust the pump's settings to optimize fuel delivery. This might involve calibrating the pump's voltage or current to match the engine's requirements. Refer to the manufacturer's guidelines or consult a mechanic to determine the correct settings. Fine-tuning ensures that the fuel pump delivers the right amount of fuel at the right pressure, promoting efficient combustion and engine performance.

Safety and Maintenance: Regularly maintain the fuel system to prevent issues. Keep the fuel tank and lines clean to avoid contamination. Check for any signs of corrosion or damage to the fuel lines and replace them if necessary. Additionally, ensure that all fuel-related components are properly grounded to prevent electrical issues.

By thoroughly testing and adjusting the fuel pump installation, you can guarantee a reliable and safe fuel supply to your engine, optimizing its performance and longevity.

Spray Test: A Simple Way to Check Fuel Line Leaks

You may want to see also

Safety Checks: Verify pump functionality, fuel line integrity, and vehicle performance

Before attempting to install a new fuel pump into a metal fuel line, it's crucial to prioritize safety and ensure that all components are functioning correctly. Here's a step-by-step guide to performing the necessary safety checks:

- Verify Pump Functionality: Start by confirming that the new fuel pump is operational. This can be done by temporarily disconnecting the pump from the fuel line and using a fuel pressure gauge to measure the pressure. Apply the appropriate pressure to the gauge and check if it matches the manufacturer's specifications. If the pressure is insufficient, the pump may need to be replaced or adjusted. Ensure that the pump operates without any unusual noises or vibrations, as these could indicate potential issues.

- Inspect Fuel Line Integrity: Carefully examine the metal fuel line for any signs of damage, corrosion, or leaks. Look for cracks, bends, or kinks that could compromise the line's integrity. Check for any visible corrosion along the length of the line, especially where it connects to the pump and the fuel tank. If any damage is found, it's essential to replace the affected section of the fuel line to prevent fuel leaks and potential fire hazards.

- Test Fuel Flow: After confirming the pump's functionality, test the fuel flow to ensure a continuous supply. Temporarily disconnect the fuel line from the pump and observe the flow rate. The fuel should flow smoothly and consistently without any interruptions. If the flow is inconsistent or ceases, it may indicate a blockage or a faulty pump, requiring further investigation.

- Evaluate Vehicle Performance: Once the pump and fuel line are installed, start the vehicle and monitor its performance. Check for any unusual noises, especially during acceleration, as this could indicate issues with the fuel system. Ensure that the engine starts and runs smoothly, without stalling or misfiring. Test the vehicle's performance over various speeds and loads to ensure it meets the manufacturer's specifications.

- Final Safety Inspection: After the vehicle has been driven for a short period, perform a final safety inspection. Check for any signs of fuel leaks around the pump installation points and the fuel tank. Inspect the engine compartment for any unusual odors or smoke, which could indicate a fuel-related issue. Verify that all connections are secure and that there is no excessive heat or damage to the fuel system components.

By following these safety checks, you can ensure that the fuel pump installation is done correctly and safely. It's essential to address any issues identified during these checks to prevent potential failures and maintain the overall performance and safety of the vehicle. Regular maintenance and inspections of the fuel system are recommended to avoid unexpected breakdowns and ensure optimal vehicle operation.

Mastering the Art of Fuel Line Removal: A Guide to Push Lock Fuel Line Extraction

You may want to see also

Frequently asked questions

You will need a fuel pump, a metal fuel line (if not already installed), a fuel filter, a fuel pressure regulator, and various tools such as wrenches, screwdrivers, and a fuel line cutter. It's also recommended to have a fuel system flush and cleaner to ensure a clean installation.

Start by cutting the metal fuel line to the desired length using a fuel line cutter. Ensure a clean cut and deburr the edges if necessary. Then, use a fuel line adapter or a female-to-male adapter to connect the fuel line to the fuel pump. Tighten the connections securely, but be careful not to overtighten to avoid damage.

Yes, it is possible to install a fuel pump without completely removing the existing fuel line. You can cut the fuel line slightly above the fuel tank and install the pump's inlet and outlet lines into the existing line. However, it's crucial to ensure a proper seal and secure all connections to prevent fuel leaks. It is recommended to consult a professional or refer to the specific instructions for your fuel pump model.