Modern cars are equipped with sophisticated fuel management systems that play a crucial role in optimizing fuel efficiency and performance. These systems utilize a combination of sensors, algorithms, and real-time data to calculate fuel consumption and ensure optimal engine operation. By monitoring various parameters such as engine speed, vehicle speed, and driver input, the car's computer can estimate the amount of fuel required for different driving conditions. This calculation takes into account factors like vehicle weight, aerodynamics, and road conditions, allowing for precise fuel management and helping drivers make informed decisions about their vehicle's fuel usage. Understanding these intricate processes can empower car owners to make the most of their vehicles' fuel efficiency.

What You'll Learn

- Engine Control Unit (ECU): Processes sensor data to optimize fuel injection

- Fuel Injection System: Delivers precise fuel amounts to the engine

- Oxygen Sensors: Monitor exhaust to adjust fuel-air mixture in real-time

- Mass Airflow Sensor: Measures air intake to calculate fuel requirements accurately

- Engine Management: Software controls fuel economy and performance

Engine Control Unit (ECU): Processes sensor data to optimize fuel injection

The Engine Control Unit (ECU) is the brain of a modern vehicle's fuel injection system, playing a crucial role in optimizing fuel consumption and performance. It is an electronic control unit that processes data from various sensors and makes real-time decisions to ensure the engine operates efficiently. The ECU's primary function is to calculate the precise amount of fuel required for optimal combustion, considering factors such as engine speed, load, and temperature.

When a car is in motion, the ECU receives input from multiple sensors, including the crankshaft position sensor, camshaft position sensor, mass airflow sensor, and oxygen sensors. These sensors provide critical data about the engine's current state, such as the position of the pistons, the amount of air flowing into the engine, and the oxygen levels in the exhaust. By analyzing this information, the ECU can make informed decisions about fuel injection.

The ECU's sophisticated algorithms and mapping tables enable it to determine the ideal fuel-air mixture for different driving conditions. It calculates the required fuel injection based on the engine's speed and load, ensuring that the air-fuel mixture is neither too rich (wasting fuel and producing excessive emissions) nor too lean (leading to poor performance and potential engine damage). This precise control is achieved through a process called 'fuel mapping', where the ECU learns and adjusts the fuel injection parameters based on various driving scenarios.

One of the key advantages of the ECU's role is its ability to adapt to changing conditions. For instance, when the driver accelerates rapidly, the ECU increases the fuel injection to meet the sudden demand for power. Conversely, during steady cruising, it reduces the fuel injection to optimize fuel economy. This dynamic adjustment ensures that the engine operates efficiently across a wide range of speeds and loads.

Furthermore, the ECU's processing power allows it to consider other factors that influence fuel efficiency. It can account for external conditions like ambient temperature and barometric pressure, which affect the density of the air. By making these adjustments, the ECU ensures that the fuel injection is tailored to the specific environmental conditions, further optimizing fuel consumption. This level of control and precision is a testament to the ECU's importance in modern vehicle technology.

Fixing Flex Fuel: Protect Your Car's Engine with These Tips

You may want to see also

Fuel Injection System: Delivers precise fuel amounts to the engine

The fuel injection system is a critical component in modern vehicles, responsible for delivering the precise amount of fuel required for optimal engine performance. This system has evolved significantly over the years, moving from mechanical fuel injection to the more advanced electronic fuel injection (EFI) systems found in contemporary cars. The primary function of the fuel injection system is to ensure that the engine receives the correct fuel-air mixture, which is essential for efficient combustion and power generation.

At its core, the fuel injection system operates on the principle of precise fuel metering. It calculates the exact amount of fuel needed for each cylinder based on various engine parameters. These parameters include engine speed, load, temperature, and even the driver's input through the throttle position. The system uses sophisticated sensors and electronic controls to gather this data and make real-time adjustments to the fuel delivery. For instance, when the driver presses the accelerator, the system increases the fuel flow to meet the higher power demand, ensuring a smooth and responsive drive.

The process begins with the engine control unit (ECU), which acts as the brain of the fuel injection system. The ECU receives input from various sensors, such as the crankshaft position sensor, which monitors the engine's rotation, and the mass airflow (MAF) sensor, which measures the amount of air entering the engine. By analyzing this data, the ECU can determine the engine's air density and calculate the required fuel injection accordingly. This calculation is based on the engine's specific fuel consumption, which varies with speed and load.

In the fuel injection system, high-pressure fuel injectors play a crucial role. These injectors are designed to spray fuel into the engine's intake manifold or directly into the combustion chamber. The fuel is delivered at a precise pressure and rate, ensuring that the correct amount of fuel is injected during each engine cycle. This precision is vital for maintaining optimal engine performance, fuel efficiency, and emissions control. Modern fuel injectors are capable of delivering fuel in micro-liter increments, showcasing the advanced technology employed in these systems.

Furthermore, the fuel injection system's ability to adapt to changing conditions is a key feature. It can adjust the fuel-air mixture in real-time, optimizing performance across various driving scenarios. For example, during high-load conditions like hill climbing or towing, the system increases the fuel injection to provide the necessary power. Conversely, during low-load situations, it reduces the fuel amount to improve fuel economy. This dynamic adjustment ensures that the engine operates efficiently and effectively, regardless of the driving conditions.

Is Age a Factor? Uncovering Fuel Efficiency Myths

You may want to see also

Oxygen Sensors: Monitor exhaust to adjust fuel-air mixture in real-time

Oxygen sensors play a crucial role in modern vehicle engines, enabling precise fuel-air mixture management for optimal performance and fuel efficiency. These sensors are strategically positioned in the exhaust system, typically near the catalytic converter, and their primary function is to monitor the oxygen content in the exhaust gases. By providing real-time data on the oxygen levels, these sensors allow the engine control unit (ECU) to make immediate adjustments to the fuel-air mixture, ensuring it remains within the optimal range for combustion.

The operation of an oxygen sensor involves a simple yet effective principle. It consists of a ceramic sensor element with a thin, electrically conductive layer on its surface. This layer is typically made of a material like platinum or palladium, which has a strong affinity for oxygen. When the sensor is exposed to exhaust gases, the oxygen molecules in the gas bind to the conductive layer, causing a change in its electrical resistance. This resistance change is then measured and converted into an electrical signal, which is sent to the ECU.

The ECU uses this oxygen sensor data to calculate the air-fuel ratio, which is the ratio of air to fuel in the combustion chamber. The ideal air-fuel ratio for complete combustion is approximately 14.7:1, meaning 14.7 parts air to 1 part fuel by volume. If the air-fuel ratio is too rich (more fuel than air), it can lead to inefficient combustion, increased emissions, and potential engine damage. Conversely, a too lean mixture (more air than fuel) can result in incomplete combustion, reduced power, and potential engine misfires.

By continuously monitoring the exhaust oxygen levels, the oxygen sensor provides the ECU with the necessary feedback to adjust the fuel injection timing and amount accordingly. If the sensor detects a lean mixture, the ECU will increase the fuel injection to enrich the mixture, ensuring complete combustion. Conversely, if the sensor indicates a rich mixture, the ECU will reduce the fuel supply to prevent excessive burning. This real-time adjustment process is known as closed-loop fuel control and is essential for maintaining optimal engine performance and fuel economy.

In summary, oxygen sensors are vital components in modern vehicles, enabling the engine to maintain the precise air-fuel ratio required for efficient combustion. Their ability to monitor exhaust gases in real-time allows for immediate adjustments to the fuel-air mixture, ensuring optimal engine performance, reduced emissions, and improved fuel efficiency. This technology showcases the sophistication of modern automotive engineering, where sensors and electronic controls work in harmony to provide a seamless driving experience.

The Hidden Fossil Fuel Connection: Electric Cars' Surprising Impact

You may want to see also

Mass Airflow Sensor: Measures air intake to calculate fuel requirements accurately

The mass airflow sensor (MAF) is a crucial component in modern vehicle engines, playing a vital role in the fuel management system. Its primary function is to measure the mass of air entering the engine, which is essential for determining the precise fuel requirements for optimal combustion. This sensor provides an accurate and real-time measurement of the air intake, allowing the engine control unit (ECU) to calculate the exact amount of fuel needed for efficient operation.

Located in the air intake system, typically near the throttle body, the MAF sensor operates by using a hot wire or a heated element. As air flows over the sensor, it cools the heated element, causing a change in its electrical resistance. This resistance variation is directly proportional to the mass of the air passing through. By measuring this change, the sensor can calculate the mass airflow rate, which is then used by the ECU to adjust the fuel injection accordingly.

The MAF sensor's output is critical for the engine's performance and efficiency. It provides the ECU with the necessary data to calculate the air-fuel ratio, ensuring the engine operates at its optimal level. This sensor's accuracy is vital, as it directly impacts the engine's power output, fuel consumption, and emissions. Modern vehicles often use this sensor in conjunction with other sensors, such as the oxygen sensors, to fine-tune the fuel injection and achieve the best possible performance.

In the event of a faulty MAF sensor, the engine's performance can be significantly affected. A failing sensor may provide inaccurate readings, leading to improper fuel injection. This can result in reduced power, increased fuel consumption, and even engine misfires. Therefore, regular maintenance and timely replacement of the MAF sensor are essential to ensure the engine operates efficiently and reliably.

In summary, the mass airflow sensor is a critical component in a car's fuel calculation system. It measures the air intake accurately, allowing the engine control unit to precisely calculate fuel requirements. This sensor's role in optimizing engine performance and fuel efficiency cannot be overstated, making it a vital part of modern vehicle technology.

Fuel Cells vs. Gas: The Green Car Debate

You may want to see also

Engine Management: Software controls fuel economy and performance

The engine management system, often referred to as the Engine Control Unit (ECU), is a sophisticated piece of software that plays a pivotal role in optimizing a vehicle's fuel economy and overall performance. This system is the brain behind the scenes, making real-time decisions to ensure the engine operates efficiently and effectively. At its core, the ECU is a small computer that receives input from various sensors within the engine and vehicle, processes this data, and then makes adjustments to the fuel injection and ignition timing accordingly.

One of the primary functions of the engine management software is to calculate the optimal fuel-air mixture for the engine's current operating conditions. This calculation is based on a multitude of factors, including engine speed, load, temperature, and even the type of fuel being used. By precisely controlling the amount of fuel injected into the engine, the software ensures that the combustion process is efficient, producing the desired power output while minimizing fuel consumption. This level of control is crucial for achieving the best possible fuel economy, especially in modern vehicles with high-performance engines.

The software's ability to adapt to changing conditions is a key feature. For instance, when the vehicle is idling, the ECU might instruct the fuel pump to deliver a smaller amount of fuel, reducing emissions and fuel usage. Conversely, during high-performance driving or when towing heavy loads, the software increases the fuel injection to meet the higher power demands while maintaining optimal engine performance. This dynamic adjustment ensures that the engine always operates at its most efficient level, providing a seamless driving experience.

Furthermore, the engine management system contributes to the overall longevity of the vehicle. By monitoring engine parameters, it can detect and prevent potential issues before they become major problems. For example, if the engine is running too rich (excessive fuel), the software can adjust the fuel-air mixture to leaner conditions, which helps in preventing engine damage over time. This proactive approach to engine management not only improves fuel economy but also enhances the overall reliability and lifespan of the vehicle.

In summary, the engine management software is a critical component in modern vehicles, responsible for fine-tuning fuel economy and performance. Its ability to process sensor data and make real-time adjustments ensures that the engine operates at its peak efficiency, delivering the desired power output while consuming fuel optimally. This sophisticated system is a testament to the advancements in automotive technology, providing drivers with a seamless and efficient driving experience.

Will Your Car's Fuel Freeze in Winter?

You may want to see also

Frequently asked questions

Modern vehicles use sophisticated fuel injection systems that rely on a combination of sensors and electronic controls. The engine control unit (ECU) continuously monitors various parameters like engine speed, load, temperature, and air intake. It then calculates the precise fuel-air mixture required for optimal combustion, ensuring the engine runs efficiently and with the right amount of power.

The fuel pump is a critical component in the fuel system. It delivers the required amount of fuel to the engine under pressure. The pump's operation is controlled by the ECU, which adjusts the pump's speed and pressure to match the engine's demands. This ensures a consistent fuel supply and enables accurate fuel management.

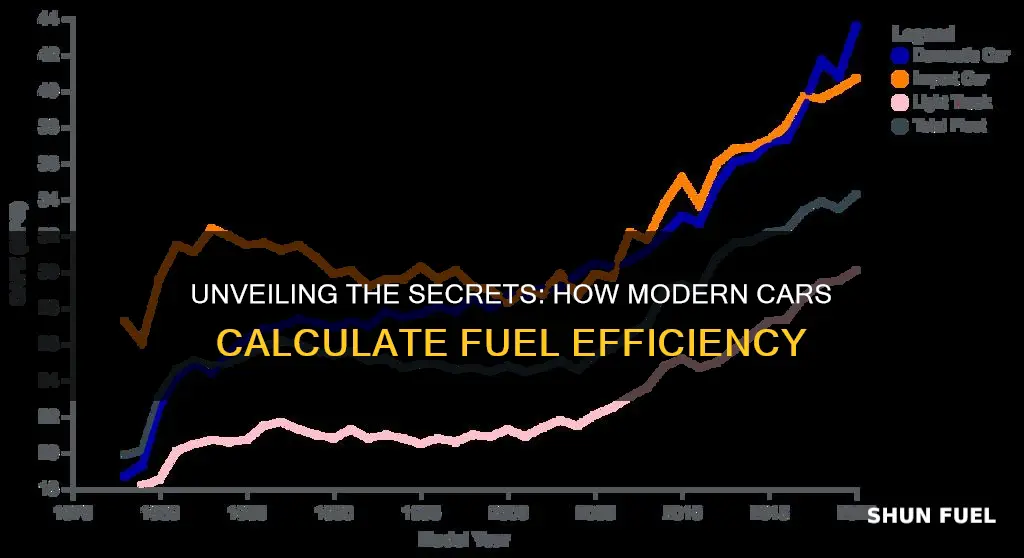

Fuel efficiency is calculated by dividing the distance traveled by the amount of fuel consumed. Modern cars often use on-board computers or trip computers to display this information in real-time. These systems monitor fuel levels and can provide estimates of fuel efficiency, helping drivers understand their vehicle's performance and make informed decisions about fuel usage.