Sprint cars, a popular form of racing, have evolved significantly over the years, with advancements in technology playing a crucial role in their performance. One of the key areas of development is the fuel injection system, which has become a standard feature in modern sprint cars. This paragraph will explore the topic of whether sprint cars are fuel injected, delving into the benefits and challenges of this technology in the high-performance world of racing.

| Characteristics | Values |

|---|---|

| Engine Type | Carburetor |

| Fuel Injection | Not Fuel-Injected |

| Power Output | Typically around 400-500 horsepower |

| Engine Displacement | Usually 350-400 cubic inches (5.7-6.6 liters) |

| Transmission | Manual (sequential) |

| Weight | Lightweight, often under 1,500 pounds (680 kg) |

| Aerodynamics | Highly streamlined bodies and wings for downforce |

| Tires | Small and narrow, providing excellent traction |

| Brakes | Powerful and responsive |

| Safety Features | Roll cages, fire suits, and helmet systems |

What You'll Learn

- Engine Performance: Sprint cars often use fuel injection for precise power output

- Fuel Efficiency: Injection systems can improve fuel economy in high-performance engines

- Tuning: Adjusting fuel injection settings is crucial for optimal sprint car performance

- Reliability: Fuel injection provides consistent power delivery, enhancing sprint car reliability

- Maintenance: Regular fuel injection maintenance ensures long-term engine health and performance

Engine Performance: Sprint cars often use fuel injection for precise power output

Sprint cars, known for their high-performance and compact design, have evolved significantly over the years, particularly in terms of engine technology. One of the most notable advancements in sprint car engines is the adoption of fuel injection systems. Fuel injection is a critical component that has revolutionized the way these powerful machines deliver performance on the track.

In the context of engine performance, fuel injection plays a pivotal role in ensuring precise power output. Sprint cars demand a high level of control and responsiveness, and fuel injection systems are designed to meet these requirements. These systems deliver fuel to the engine in a highly controlled manner, allowing for precise adjustments to the air-fuel mixture. This level of control is essential for achieving optimal performance, especially during high-speed races where split-second decisions can make a significant difference.

The benefits of fuel injection in sprint cars are numerous. Firstly, it enables the engine to produce a consistent and reliable power output. By precisely managing the fuel delivery, the engine can maintain a steady power level, ensuring that the car accelerates smoothly and responds instantly to driver inputs. This is crucial in sprint car racing, where quick bursts of speed are required to gain an advantage over competitors.

Secondly, fuel injection systems provide the ability to fine-tune the engine's performance. Mechanics and engineers can adjust the fuel injection parameters to optimize power output for different track conditions and driving styles. This level of customization allows for a tailored approach to engine management, ensuring that the car is set up for maximum performance in various racing scenarios.

Furthermore, fuel injection contributes to improved fuel efficiency and reduced emissions. By optimizing the air-fuel mixture, these systems can minimize fuel consumption without sacrificing power. This is a significant advantage in the highly competitive world of sprint car racing, where every ounce of efficiency matters. Additionally, the reduced emissions from fuel injection systems align with modern environmental standards, making them a more sustainable choice for racing applications.

In summary, the use of fuel injection in sprint cars is a strategic decision that significantly enhances engine performance. It provides precise power output, instant responsiveness, and the ability to fine-tune the engine for various racing conditions. With fuel injection, sprint cars can achieve a balance between power, control, and efficiency, making it a vital technology in the pursuit of victory on the track.

Fuel Injector Cleaner: Friend or Foe for Your Car?

You may want to see also

Fuel Efficiency: Injection systems can improve fuel economy in high-performance engines

The evolution of fuel injection technology has played a pivotal role in enhancing the performance and efficiency of high-performance engines, particularly in the world of sprint cars. These powerful vehicles demand precise and efficient fuel delivery systems to meet their demanding performance requirements. Injection systems have become a cornerstone in the quest for improved fuel economy, offering a myriad of benefits that contribute to the overall success of these high-speed machines.

In the context of sprint cars, where engines are pushed to their limits, fuel injection systems offer a significant advantage. These systems deliver fuel directly to the engine's cylinders, ensuring optimal combustion and power output. By precisely controlling the fuel-air mixture, injection systems enable engines to operate at their most efficient levels, resulting in improved fuel economy. This is especially crucial in the highly competitive world of sprint car racing, where every second counts, and fuel efficiency can make a substantial difference in performance.

The process begins with the fuel injection system's ability to meter and inject fuel with unparalleled accuracy. Unlike traditional carburetors, fuel injectors provide a consistent and precise fuel supply, ensuring that the engine receives the exact amount of fuel required at any given moment. This precision is vital for maintaining optimal combustion, especially during high-performance driving conditions. By optimizing the fuel-air mixture, injection systems enable the engine to burn fuel more efficiently, reducing waste and improving overall fuel economy.

Furthermore, injection systems offer advanced control over the fuel injection timing and rate. This level of control allows for better engine management, especially during rapid acceleration and high-speed maneuvers. By adjusting the fuel injection parameters, engineers can fine-tune the engine's performance, ensuring that it delivers maximum power without compromising fuel efficiency. This is particularly important in sprint cars, where drivers often need to make split-second decisions, and maintaining optimal fuel economy is essential for consistent performance.

The benefits of fuel injection systems in high-performance engines are evident in the improved power-to-weight ratio and overall performance of sprint cars. With efficient fuel delivery, these vehicles can achieve higher top speeds, improved acceleration, and enhanced handling capabilities. The precision of injection systems also contributes to reduced emissions, making these cars more environmentally friendly without sacrificing performance. As technology advances, the integration of fuel injection in sprint car engineering will continue to drive innovation, pushing the boundaries of what these high-performance machines can achieve on the track.

Smart Cars: Fuel Efficiency Myth or Reality?

You may want to see also

Tuning: Adjusting fuel injection settings is crucial for optimal sprint car performance

Tuning sprint cars to optimize their performance is an intricate process, and one of the most critical aspects is adjusting the fuel injection settings. Sprint cars, known for their high-performance and compact design, rely on precise fuel injection systems to deliver the right amount of fuel to the engine at the right time. This ensures optimal power output, fuel efficiency, and overall engine health.

The fuel injection system in a sprint car is designed to provide a precise mixture of air and fuel to the engine's cylinders. This mixture is crucial for efficient combustion, which directly impacts the car's performance. When tuning the fuel injection, mechanics aim to fine-tune the fuel-air ratio to match the engine's requirements. This involves adjusting the fuel pressure, spray patterns, and the timing of fuel delivery.

One key factor in this process is the use of a fuel injection controller or a programmable engine management system. These tools allow mechanics to make real-time adjustments to the fuel injection settings. By monitoring various engine parameters such as temperature, speed, and load, the system can automatically adjust the fuel-air ratio to maintain optimal performance. For instance, during high-speed runs, the system might increase the fuel injection to provide more power, while during low-speed maneuvers, it might reduce the fuel to improve efficiency.

Mechanics also consider the specific requirements of the engine and the type of fuel being used. Different engines may have unique characteristics, and the fuel injection settings need to be tailored accordingly. For example, a naturally aspirated engine might require a different approach compared to a turbocharged one. Additionally, the type of fuel, whether it's ethanol-blended or pure gasoline, can also influence the tuning process.

In summary, tuning the fuel injection settings is a critical step in optimizing sprint car performance. It involves a detailed understanding of the engine's characteristics and the ability to make precise adjustments. By fine-tuning the fuel-air ratio, mechanics can ensure that the engine operates at its peak, delivering the power and efficiency required for successful sprint car racing. This process showcases the intricate relationship between engine management and vehicle performance in the high-speed world of sprint cars.

Optimizing Fuel Efficiency: Understanding Ideal Car Consumption

You may want to see also

Reliability: Fuel injection provides consistent power delivery, enhancing sprint car reliability

Fuel injection technology has revolutionized the world of sprint cars, offering a significant advantage in terms of reliability and performance. Sprint cars, known for their high-speed and intense racing conditions, demand a reliable power source to ensure optimal performance and safety. This is where fuel injection comes into play, providing a consistent and efficient power delivery system.

In the high-octane world of sprint car racing, reliability is paramount. Fuel injection systems offer a precise and controlled method of fuel delivery, ensuring that the engine receives the exact amount of fuel required at any given moment. This level of control is crucial, as it eliminates the inconsistencies and fluctuations that can occur with traditional carburetors. By providing a steady and reliable fuel supply, fuel injection enhances the overall reliability of the vehicle, reducing the chances of engine misfires, stalls, or performance degradation during critical racing moments.

The benefits of fuel injection in sprint cars are twofold. Firstly, it allows for a more efficient combustion process. The precise fuel-air mixture delivered by the fuel injectors ensures complete combustion, maximizing power output and engine efficiency. This results in improved performance, enabling sprint cars to accelerate faster, maintain higher speeds, and deliver consistent power delivery throughout the entire rev range. Secondly, fuel injection contributes to better engine management. Modern fuel injection systems are equipped with advanced sensors and computer controls, monitoring various engine parameters in real-time. This enables the system to make instant adjustments, optimizing fuel delivery and ensuring the engine operates at its peak performance, even under extreme racing conditions.

The reliability of fuel injection is further enhanced by its ability to adapt to varying driving conditions. Sprint car racing involves rapid changes in speed, load, and temperature. Fuel injection systems can quickly respond to these changes, adjusting the fuel-air mixture accordingly. This adaptability ensures that the engine maintains its performance and reliability, even when faced with the challenges of high-speed cornering, rapid acceleration, or extreme weather conditions.

In summary, fuel injection technology has significantly contributed to the reliability and performance of sprint cars. By providing consistent power delivery, fuel injection ensures that sprint cars can maintain their speed, acceleration, and overall performance throughout the race. This technology's ability to adapt to varying conditions and optimize fuel usage makes it an invaluable asset for sprint car drivers, allowing them to focus on the track and deliver their best performance.

Fuel Additives: Friend or Foe for Your Car?

You may want to see also

Maintenance: Regular fuel injection maintenance ensures long-term engine health and performance

Regular maintenance of fuel injection systems is crucial for maintaining the performance and longevity of sprint cars. These high-performance vehicles rely on precise fuel injection to deliver the optimal amount of fuel to the engine, ensuring efficient combustion and maximum power output. Over time, fuel injection components can accumulate deposits, experience wear, or develop issues that impact their functionality. Therefore, a proactive maintenance approach is essential to keep these systems operating at their best.

One critical aspect of fuel injection maintenance is the regular cleaning and inspection of the injectors. Sprint car engines operate under extreme conditions, with high temperatures and pressures, which can lead to the buildup of carbon deposits and contaminants in the injectors. These deposits can restrict fuel flow, leading to poor engine performance, reduced power, and even potential engine damage. Cleaning the injectors involves using specialized cleaning agents and procedures to remove these deposits, ensuring that the fuel is injected accurately and efficiently.

Additionally, checking and replacing the fuel filter is a fundamental part of fuel injection maintenance. The fuel filter plays a vital role in preventing contaminants from entering the fuel injection system. Over time, the filter can become clogged or damaged, allowing dirt, water, or other impurities to pass through and potentially cause issues. Regularly replacing the fuel filter ensures that the fuel supply remains clean and free-flowing, promoting optimal engine operation.

Another essential task is the calibration and adjustment of the fuel injection system. This process involves fine-tuning the system to match the specific requirements of the sprint car engine. Proper calibration ensures that the engine receives the correct fuel-air mixture, optimizing performance and fuel efficiency. It may include adjusting the fuel pressure, spray angles, and other parameters to achieve the desired power output while maintaining engine health.

Furthermore, monitoring and addressing any fuel-related issues promptly is crucial. This includes checking for leaks in the fuel lines, ensuring proper fuel pressure, and verifying the functionality of the fuel pump. Regular maintenance helps identify and rectify problems before they escalate, preventing potential engine failures and costly repairs. By investing time and effort into fuel injection maintenance, sprint car owners can ensure their engines remain reliable, powerful, and durable over the long term.

Flex Fuel Cars: A Comprehensive Guide to Compatibility

You may want to see also

Frequently asked questions

No, not all sprint cars use fuel injection. While many modern sprint cars have adopted this technology for improved performance and efficiency, some older models still utilize carburetors. The transition to fuel injection has been gradual, and it varies depending on the car's age, make, and model.

Fuel injection offers several benefits for sprint cars. It provides precise fuel control, allowing for better engine management and performance. This technology can enhance power output, improve throttle response, and optimize fuel efficiency. Additionally, it reduces the need for manual adjustments, making the car more reliable and easier to maintain.

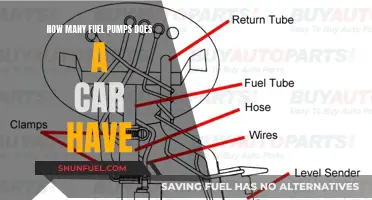

Fuel injection systems in sprint cars use electronic sensors to monitor various parameters like engine speed, temperature, and load. These sensors send data to a computer, which calculates the optimal fuel-air mixture and injects the precise amount of fuel required for each cylinder. This process ensures a consistent and efficient combustion process.

Yes, fuel injection systems can be retrofitted to older sprint cars. This process involves replacing the existing carburetor with a fuel injection setup, which may require modifications to the engine and wiring harness. Retrofitting can be complex and costly, but it can significantly improve the car's performance and longevity.

A A: While fuel injection offers numerous advantages, there are a few potential drawbacks. The initial cost of installation and maintenance can be higher compared to carburetors. Additionally, the complexity of the system may require specialized knowledge for troubleshooting and repairs. However, these challenges are often outweighed by the performance gains and long-term benefits.