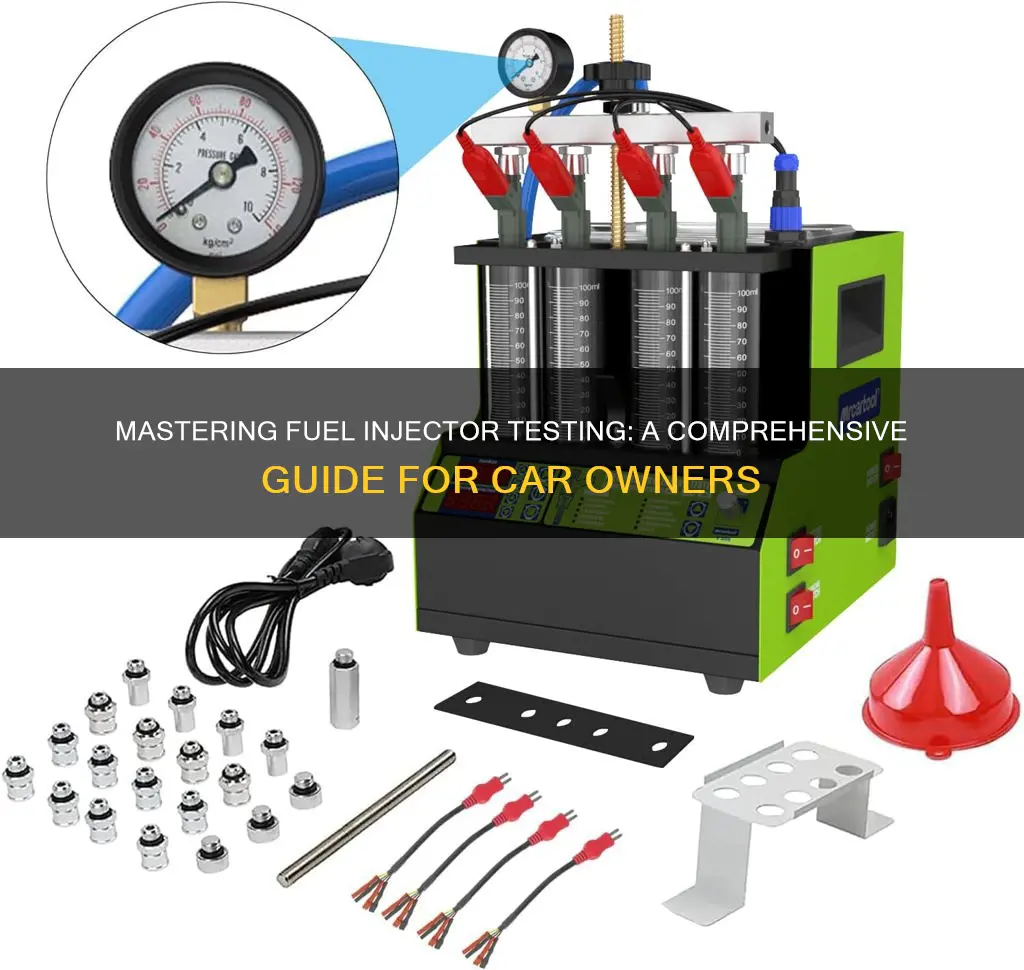

Testing fuel injectors in a car is a crucial process to ensure optimal engine performance and fuel efficiency. It involves a systematic approach to diagnose and verify the functionality of the fuel injectors, which are responsible for delivering the precise amount of fuel required for combustion. This guide will provide a step-by-step process to test fuel injectors, including the use of specialized tools and techniques to measure fuel pressure, flow rate, and spray patterns. By following these methods, you can identify and address any issues with the fuel injectors, ensuring your vehicle operates efficiently and reliably.

What You'll Learn

- Visual Inspection: Check for any visible damage or debris in the fuel injectors

- Pressure Testing: Use a fuel pressure gauge to measure injector output

- Flow Rate Measurement: Assess the fuel flow rate using a flow meter

- Spray Pattern Analysis: Examine the spray pattern of the fuel injectors

- Performance Comparison: Compare injector performance with a known good injector

Visual Inspection: Check for any visible damage or debris in the fuel injectors

When performing a visual inspection of the fuel injectors, it's important to start by understanding the basic structure and location of these components. Fuel injectors are typically found near the engine's intake manifold, and they are responsible for spraying fuel into the engine's cylinders to facilitate combustion. Given their position and function, they can be susceptible to various issues, including damage from debris or contaminants.

The first step in the visual inspection is to locate the fuel injectors. These are usually small, cylindrical components with a small nozzle at the end. They are often connected to the fuel rail or the fuel pump via a series of hoses and lines. Once located, carefully inspect each injector for any signs of damage or malfunction. Look for any cracks, warping, or visible corrosion on the injector body. Also, check for any signs of melting or burning, especially if the vehicle has been exposed to high temperatures or if there have been previous engine issues.

Debris and contaminants can also cause significant problems for fuel injectors. Over time, small particles of dirt, dust, or even metal shavings can accumulate inside the injectors, leading to blockages or damage. To check for debris, remove the fuel injectors from the engine (if possible) and examine them closely. Use a magnifying glass or a small flashlight to help you see inside the injector body. Look for any foreign matter, such as small pieces of metal, carbon deposits, or even insect parts. If you notice any debris, it's crucial to clean the injectors to prevent further issues.

In addition to physical damage, also look for any signs of corrosion or oxidation. Fuel injectors are often made of metal, which can corrode over time, especially if they are not properly sealed or maintained. Corrosion can lead to reduced performance or even failure of the injectors. Check for any discolored areas or a powdery substance on the injector surfaces, which could indicate corrosion. If corrosion is present, it may be necessary to clean or replace the injectors to ensure optimal performance.

Remember, the goal of this visual inspection is to identify any potential issues before they cause significant problems. By carefully examining the fuel injectors for visible damage, debris, and corrosion, you can take proactive steps to maintain your vehicle's performance and longevity. If any issues are found, further testing or professional assistance may be required to ensure the injectors are functioning correctly.

Flex Fuel or Not? Signs to Identify Your Car's Flexibility

You may want to see also

Pressure Testing: Use a fuel pressure gauge to measure injector output

Pressure testing is a crucial method to assess the performance of fuel injectors in a vehicle's engine. This technique involves using a fuel pressure gauge to measure the output of each injector, ensuring they deliver the correct amount of fuel at the right pressure. Here's a step-by-step guide on how to perform this test:

Preparation: Before starting, ensure you have the necessary tools, including a fuel pressure gauge, a set of injector clips or adapters, and a fuel pressure regulator. It is recommended to work on a level surface, preferably in a well-ventilated area, to ensure safety and ease of operation.

Step-by-Step Process: Begin by disconnecting the negative battery terminal to prevent any electrical issues during the test. Locate the fuel rail, which is the component where the fuel injectors are connected. Securely attach the fuel pressure gauge to the fuel rail using the appropriate adapter or clip. Make sure the gauge is calibrated and functioning correctly. Start the engine and allow it to idle for a few minutes to reach a stable operating temperature. This step is essential as it ensures the fuel system is ready for testing.

Now, the critical part: measuring the injector output. Set the fuel pressure gauge to the desired measurement unit (usually psi or bar) and record the initial reading. Then, for each fuel injector, slowly increase the engine speed while monitoring the fuel pressure. The ideal pressure should be within the manufacturer's specified range. If the pressure drops significantly or remains low, it indicates a potential issue with the injector or its related components. Repeat this process for all fuel injectors, comparing their outputs to ensure they are functioning symmetrically.

Troubleshooting: If any injector fails the pressure test, further investigation is required. Check for clogged or restricted fuel lines, as they can cause pressure drops. Inspect the injectors for any signs of damage or malfunction. In some cases, cleaning or replacing the injector may be necessary. It is important to address these issues promptly to prevent further engine problems.

By following this pressure testing procedure, you can effectively diagnose and ensure the optimal performance of your car's fuel injectors. Regular maintenance and testing are vital to keeping your vehicle's engine in top condition.

Car Fuel Type: Quick Guide to Knowing What Your Vehicle Needs

You may want to see also

Flow Rate Measurement: Assess the fuel flow rate using a flow meter

To accurately assess the fuel flow rate of a car's fuel injectors, a flow meter is an essential tool. This measurement is crucial as it directly relates to the injector's performance and the engine's overall efficiency. Here's a step-by-step guide on how to measure flow rate using a flow meter:

Step 1: Preparation

Before beginning the test, ensure the car's engine is cool and has been off for at least 30 minutes. This step is important to prevent any residual heat from affecting the flow meter readings. Additionally, locate the fuel rail, which is the component that houses the fuel injectors. It is typically found near the engine's intake manifold.

Step 2: Connect the Flow Meter

Attach the flow meter to the fuel rail. The flow meter should be securely connected to ensure accurate measurements. Different types of flow meters are available, such as volumetric or mass flow meters. For this test, a volumetric flow meter is commonly used due to its simplicity and ease of installation. Ensure the flow meter is calibrated and compatible with the fuel type in your vehicle.

Step 3: Set Up the Measurement

Start the engine and allow it to idle for a few minutes to reach a stable operating temperature. Connect the flow meter to a data logging device or a scope to record the flow rate over time. This step is crucial for analyzing the injector's performance under different conditions.

Step 4: Measure and Record

With the engine idling, record the flow rate readings from the flow meter. Note the values at different engine speeds and loads. A typical test involves varying the engine speed to simulate different driving conditions. The flow rate should be consistent and within the expected range for the specific fuel injector and engine configuration.

Step 5: Compare and Analyze

Compare the measured flow rates with the manufacturer's specifications or previous test results. Any significant deviations may indicate issues with the fuel injectors or the fuel system. For instance, a lower-than-expected flow rate could suggest a clogged or malfunctioning injector. This analysis is vital for diagnosing fuel injection problems and ensuring optimal engine performance.

By following these steps, you can effectively measure and assess the fuel flow rate of a car's fuel injectors, providing valuable insights into the overall health of the engine's fuel delivery system.

Indy Car Fuel Capacity: Unlocking the Secrets of Speed

You may want to see also

Spray Pattern Analysis: Examine the spray pattern of the fuel injectors

Spray pattern analysis is a crucial method for evaluating the performance of fuel injectors in a vehicle. This technique involves visually inspecting the fuel spray as it exits the injector nozzles to assess the quality and distribution of the fuel-air mixture. By examining the spray pattern, you can gain valuable insights into the injector's functionality and identify potential issues. Here's a detailed guide on how to perform this analysis:

When conducting spray pattern analysis, it is essential to have a well-lit and controlled environment. Park your vehicle in a garage or a shaded area to ensure optimal visibility. Start by disconnecting the fuel line from the injector you want to test. This step allows you to observe the spray pattern directly from the injector outlet. Use a high-speed camera or a smartphone with a fast shutter speed to capture the fuel spray in action. Aim for a close-up shot, focusing on the injector tip. The goal is to capture the spray's shape, size, and dispersion.

Examine the captured images or videos frame-by-frame to analyze the spray pattern. Look for uniformity in the spray's shape and size. Ideal spray patterns should be consistent, forming a smooth, even sheet of fuel that covers the entire cross-section of the intake manifold. If the spray appears uneven, with large droplets or a mist-like consistency, it may indicate a problem with the injector's atomization capability. Atomization is the process of breaking down fuel into tiny droplets, and a poor atomization can lead to inefficient combustion.

Additionally, observe the spray's dispersion. The fuel should spread evenly across the intake manifold, covering a wide area. If the spray is concentrated in a small area or forms multiple distinct streams, it could suggest a misaligned injector or a blockage within the nozzle. Misalignment can cause uneven fuel distribution, affecting engine performance.

Remember, spray pattern analysis is just one aspect of testing fuel injectors. It should be complemented with other diagnostic techniques, such as pressure testing and flow rate measurements, to ensure a comprehensive evaluation of the injector's performance. By combining these methods, you can accurately assess the health of your fuel injectors and address any issues to optimize engine efficiency.

Unraveling the Mystery: Common Causes of Low Fuel Pressure in Cars

You may want to see also

Performance Comparison: Compare injector performance with a known good injector

When comparing the performance of a fuel injector under test with a known good injector, the goal is to identify any discrepancies that might indicate a faulty injector. Here’s a step-by-step guide to help you through this comparison:

Step 1: Prepare the Test Equipment

Before you begin, ensure you have the necessary tools and equipment. This includes a fuel pressure gauge, a fuel flow meter, a diagnostic scanner, and a known good injector for comparison.

Step 2: Measure Fuel Pressure

Fuel pressure is a critical factor in injector performance. Use the fuel pressure gauge to measure the pressure at the injector rail. Note the reading and compare it to the expected value for your vehicle. A known good injector should provide a consistent and within-spec pressure.

Step 3: Measure Fuel Flow

Next, measure the fuel flow rate through the injectors. Use the fuel flow meter to capture the flow rate at different engine speeds and loads. Compare these readings with the known good injector’s performance. A faulty injector might show a lower flow rate or inconsistent flow.

Step 4: Monitor Injector Pulse Width

Use the diagnostic scanner to monitor the injector pulse width. This is the duration for which the injector is active, delivering fuel to the engine. Compare the pulse width of the under-test injector with that of the known good injector. A faulty injector might have a shorter or longer pulse width, leading to poor engine performance.

Step 5: Perform a Visual Inspection

While not a definitive test, a visual inspection can provide valuable insights. Check for any signs of damage, clogging, or debris in the injector nozzle. A known good injector should be clean and free of any obstructions.

Step 6: Compare Performance Data

Compile the data from the fuel pressure, fuel flow, and injector pulse width measurements. Compare these readings with the known good injector’s performance. Any significant deviations could indicate a faulty injector.

Step 7: Document and Analyze

Document all the test results and analyze them. Look for patterns or anomalies that could help diagnose the issue. If the under-test injector consistently performs differently from the known good injector, it is likely the source of the problem.

By following these steps, you can systematically compare the performance of a fuel injector under test with a known good one, helping you identify and address any issues efficiently.

Summer or Winter: Which Season Drains Your Car's Fuel More?

You may want to see also

Frequently asked questions

Fuel injectors can become clogged or malfunction over time, leading to poor engine performance. Signs that your fuel injectors may need testing include a noticeable decrease in engine power, fuel efficiency, or a check engine light illumination. If you've recently replaced the fuel filter and still experience these issues, it's a good indicator that the fuel injectors might be the problem.

Testing fuel injectors typically requires a fuel pressure gauge, a multimeter, and a fuel injector tester (also known as a scan tool). These tools help measure fuel pressure, voltage, and current to diagnose any issues with the injectors. Some mechanics may also use a fuel flow meter to assess the volume of fuel being delivered.

While some basic checks can be performed at home, it's generally recommended to have a professional mechanic test the fuel injectors. They have the expertise and specialized equipment to accurately diagnose and repair any issues. However, if you're comfortable with car maintenance, you can start with simple visual inspections and basic testing using a multimeter.

The testing process involves connecting the fuel pressure gauge to the fuel rail and measuring the fuel pressure. It should be within the specified range for your vehicle. Then, using the multimeter, you can check the voltage and current at the injector control circuit. A fuel injector tester can also be used to read error codes and simulate injector operation.

If testing reveals clogged fuel injectors, you can try cleaning them using a fuel injector cleaner or a high-pressure fuel injector cleaning machine. If cleaning doesn't resolve the issue, it may be necessary to replace the injectors. This is a specialized task that requires precise tools and knowledge, so it's best left to a professional mechanic.