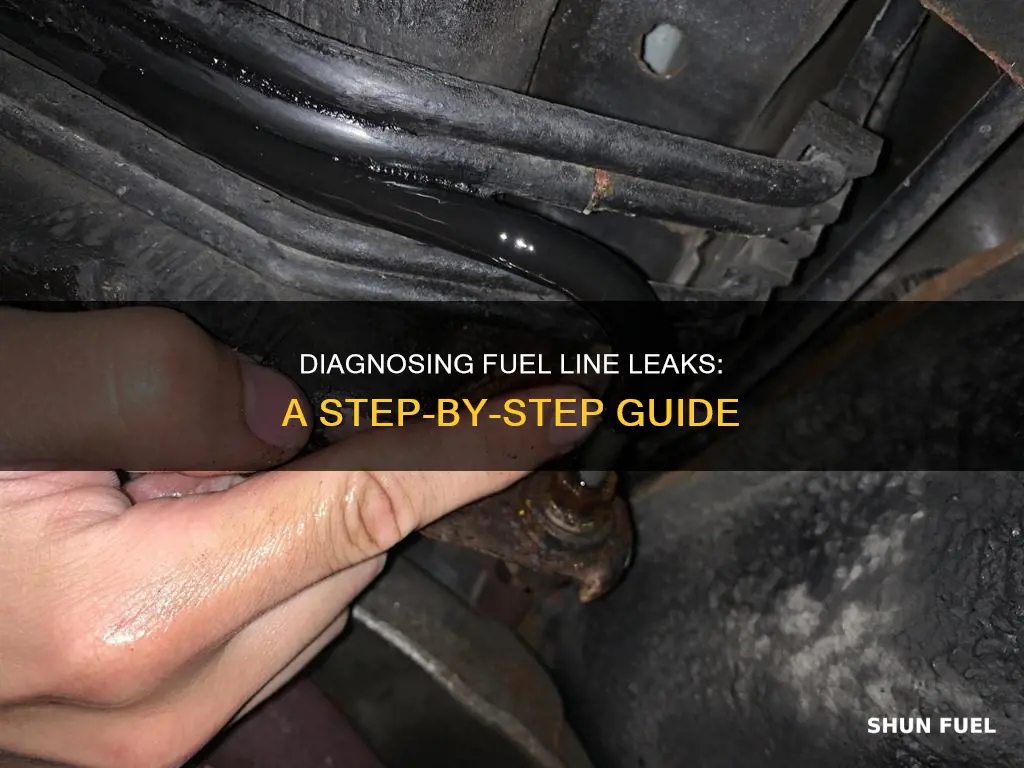

Checking for fuel line leaks is an essential part of vehicle maintenance to ensure safety and optimal performance. It involves a systematic approach to identify any potential issues with the fuel system. This process typically includes inspecting the fuel lines for visible damage, such as cracks or punctures, and using specialized tools like a fuel line inspection kit or a pressure gauge to detect leaks. Additionally, technicians often use a method called fuel pressure testing to measure the pressure in the fuel lines and identify any discrepancies that might indicate a leak. Regular maintenance and prompt identification of leaks can prevent costly repairs and ensure the longevity of the vehicle's fuel system.

What You'll Learn

- Visual Inspection: Look for fuel stains, wet spots, or fuel accumulation around the lines

- Bubble Test: Use a soapy solution to create bubbles and check for leaks

- Pressure Test: Measure fuel pressure to detect leaks or blockages

- Gasoline Dye: Add a fuel dye to the system and inspect for color changes

- Professional Diagnostic Tools: Utilize specialized equipment to identify leaks accurately

Visual Inspection: Look for fuel stains, wet spots, or fuel accumulation around the lines

A visual inspection is a crucial step in identifying potential fuel line leaks, and it can be performed by any vehicle owner or mechanic with a keen eye and a basic understanding of vehicle components. This method is non-invasive and can often reveal issues before they become major problems. Here's a detailed guide on how to conduct a visual inspection to check for fuel line leaks:

When performing a visual inspection, the primary goal is to look for any signs of fuel leakage around the fuel lines. Fuel lines are typically made of rubber or plastic and carry gasoline or diesel from the fuel tank to the engine. Over time, these lines can deteriorate, crack, or become damaged, leading to leaks. Here's what you should look out for:

- Fuel Stains and Wet Spots: One of the most obvious indicators of a fuel line leak is the presence of fuel stains or wet spots. These can appear as dark, oily marks or puddles of liquid around the vehicle, especially under the engine bay. Look for any unusual moisture or discolored patches on the ground or on the engine components. If you notice these stains, it's essential to investigate further, as they could be a sign of a leaking fuel line.

- Fuel Accumulation: In some cases, fuel may accumulate in specific areas, such as the wheel wells or under the car near the fuel lines. This accumulation can be a result of a small leak that has gone unnoticed. Over time, the fuel can seep out and collect in these hidden areas. Inspect these regions carefully, as fuel accumulation can lead to corrosion and further damage if left unattended.

- Visual Damage: While fuel stains are a clear sign, you should also inspect the fuel lines themselves for any visible damage. Look for cracks, tears, or bulges in the rubber or plastic lines. These defects can be caused by age, wear and tear, or previous damage. If you notice any physical damage, it's a strong indicator of a potential leak. Additionally, check for any signs of corrosion or rust around the fuel lines, especially if they are exposed.

- Engine Bay Inspection: The engine bay is a critical area to inspect for fuel line leaks. Lift the hood and carefully examine the fuel lines for any signs of leakage. You might need to use a flashlight to get a better view, especially if the lines are located in hard-to-reach places. Look for any discolored fuel or moisture around the lines, as this could indicate a breach. Also, check the fuel filter and the area around it for any fuel accumulation or stains.

Remember, during this visual inspection, it's essential to be thorough and methodical. Take your time to cover all the relevant areas, and if you notice any suspicious signs, it's advisable to consult a professional mechanic for further diagnosis and repair. Regular visual inspections can help prevent costly repairs and ensure your vehicle's fuel system remains in good condition.

Powerful Engine, Right Fuel Line? Size Matters!

You may want to see also

Bubble Test: Use a soapy solution to create bubbles and check for leaks

The Bubble Test is a simple and effective method to identify fuel line leaks, especially for those who prefer a visual approach to troubleshooting. This test is based on the principle that fuel lines that are leaking will release small amounts of fuel into the surrounding air, which can then react with the soap solution to create bubbles. Here's a step-by-step guide on how to perform this test:

Preparation: Before you begin, ensure that the engine is cool to the touch. This is important because hot engines can cause fuel to expand and potentially create false positives during the test. Gather the necessary materials: a soapy solution (you can use a store-bought soap or create your own by mixing dish soap with water), a spray bottle, and a clean cloth. It's also a good idea to have a helper with you to make the process easier.

Step-by-Step Process: Start by spraying the soapy solution onto the fuel lines, focusing on the connections and joints where leaks are most likely to occur. You can use the spray bottle to direct the solution onto the lines. Allow the soap to sit on the fuel lines for a few minutes to ensure it has a chance to react with any potential fuel leaks. Then, use the cloth to wipe away the excess soap, leaving a thin layer on the fuel lines. Now, the visual inspection begins. Look for any bubbles forming on the fuel lines, especially at the points where the lines connect to the fuel tank, pump, or engine. Bubbles indicate the presence of fuel vapor, which is a sign of a potential leak.

Interpreting the Results: If you notice bubbles forming and expanding on the fuel lines, it's a strong indication of a leak. The bubbles will typically appear as small, white, or translucent spheres along the line. The more bubbles you see, the more severe the potential leak. It's important to note that this test is not definitive, and further investigation may be required. If you find a leak, it's best to consult a professional mechanic to ensure proper repair.

Safety Precautions: When performing this test, always exercise caution. Fuel is flammable, so ensure the engine is off and the vehicle is in a well-ventilated area. Avoid any open flames or sparks during the test. Additionally, be mindful of the fuel lines' location to prevent accidental damage during the inspection.

This Bubble Test is a quick and accessible way to check for fuel line leaks, providing a visual indication of potential issues. It is a valuable tool for vehicle owners who want to ensure their fuel system's integrity and address any leaks promptly.

QFT SL600 Fuel Line Compatibility: HR600 to SL600 Upgrade

You may want to see also

Pressure Test: Measure fuel pressure to detect leaks or blockages

A pressure test is a crucial method to identify fuel line leaks or blockages, ensuring the efficient and safe operation of your vehicle's fuel system. This test involves measuring the fuel pressure at various points along the fuel lines to detect any abnormalities. Here's a step-by-step guide on how to perform this test:

First, you'll need a fuel pressure gauge, which can be connected to the fuel line to measure the pressure. It's important to choose a gauge suitable for the fuel system type in your vehicle. Ensure you have the necessary tools, including a fuel line disconnect tool and a fuel pump primer, if required. Park your vehicle on a level surface and allow the engine to cool down to ensure accurate readings.

Locate the fuel pressure sensor or port, which is typically found near the fuel tank or along the fuel lines. Disconnect the fuel line from the sensor/port using the appropriate tool. Make sure to have a container or rag ready to catch any fuel that may spill during the process. Carefully connect the fuel pressure gauge to the disconnected fuel line, ensuring a secure connection.

Start the engine and allow it to idle for a few minutes to stabilize the fuel pressure. Then, slowly prime the fuel pump using the primer bulb (if applicable) to create a vacuum in the fuel system. This step is crucial as it simulates the engine's operation and helps detect any pressure drops. Observe the gauge to measure the fuel pressure. The ideal pressure should be within the manufacturer's specified range, usually indicated on a sticker inside the fuel tank or in the vehicle's manual.

If the pressure is below the recommended range, it may indicate a leak or a problem with the fuel pump. Conversely, if the pressure is significantly higher, it could suggest a blockage or a faulty pressure regulator. In both cases, further investigation is required to identify the exact cause. Remember, this test should be conducted with the engine off to avoid confusion with the idle pressure.

By following these steps, you can effectively use a pressure test to diagnose fuel line issues. It is a valuable technique for vehicle owners and mechanics alike, ensuring the proper functioning of the fuel system and preventing potential safety hazards associated with fuel leaks.

Finding the Perfect Fuel Line Fit for Your 2006 Scion TC

You may want to see also

Gasoline Dye: Add a fuel dye to the system and inspect for color changes

Checking for fuel line leaks can be a crucial step in maintaining your vehicle's performance and safety. One effective method to identify these leaks is by using a fuel dye, a simple yet powerful tool. Here's a step-by-step guide on how to use gasoline dye to detect leaks:

Preparation: Begin by ensuring you have the necessary materials. You'll need a fuel dye, which is typically a concentrated liquid, and a container to mix it. It's recommended to use a dye specifically designed for gasoline or diesel fuel, as these products are formulated to be stable in the fuel system. Additionally, have some rags or paper towels ready for cleaning up any spills.

Adding the Dye: Park your vehicle on a level surface and turn it off. Locate the fuel tank, which is usually accessible from under the car or in the trunk. Carefully pour the specified amount of fuel dye into the fuel tank. The instructions on the dye packaging will guide you on the correct dosage. After adding the dye, start the engine and let it run for a few minutes to ensure the dye circulates throughout the fuel system.

Inspection: With the engine running, carefully inspect the fuel lines for any signs of color change. The dye will be visible in the fuel lines, allowing you to identify potential leak points. Look for discolored areas, especially where the fuel lines connect to the engine, the fuel pump, or the tank. The dye might also appear in other components, such as the fuel filter or the carburetor, if there are leaks in those areas.

Troubleshooting: If you notice a color change, it indicates a potential leak. Start by checking for any visible damage or corrosion around the affected area. Tighten any loose connections and ensure all components are properly secured. If the leak persists, it may require further investigation or professional assistance. In some cases, the dye might not be visible in all fuel lines, so a thorough inspection is essential.

Remember, this method is a visual inspection, and it's crucial to be thorough. If you're unsure about any step, consulting a professional mechanic is always an option. Using gasoline dye is a cost-effective and efficient way to identify fuel line issues, ensuring your vehicle remains reliable and safe.

Fuel Line Freeze-Up: Myth or Reality?

You may want to see also

Professional Diagnostic Tools: Utilize specialized equipment to identify leaks accurately

Professional mechanics and technicians have access to a range of specialized tools and equipment designed to accurately identify fuel line leaks, ensuring prompt and effective repairs. These diagnostic tools are crucial for professionals as they provide precise and reliable information about the fuel system's integrity. Here's an overview of how these tools are utilized:

Pressure Testers and Gauges: One of the primary methods to detect fuel line leaks is through pressure testing. Technicians use specialized pressure gauges and testers that are connected to the fuel system. By applying a controlled amount of pressure to the fuel lines, they can identify any drops in pressure, indicating a potential leak. These tools are highly sensitive and can detect even the smallest breaches in the fuel lines. When a leak is suspected, the gauge will show a rapid decrease in pressure, allowing the mechanic to pinpoint the exact location.

Fuel System Analyzers: Modern diagnostic equipment includes fuel system analyzers, which are comprehensive tools for fuel line diagnostics. These devices can measure various parameters such as fuel pressure, temperature, and flow rate. By connecting the analyzer to the fuel lines, technicians can gather real-time data and identify any anomalies. For instance, a sudden drop in fuel pressure or an abnormal temperature reading could indicate a leak. Analyzers often provide visual representations of the data, making it easier to interpret and diagnose issues.

Leak Detection Fluids: Another professional approach is the use of specialized leak detection fluids. These fluids are carefully injected into the fuel system, and their presence is monitored. If a leak occurs, the fluid will escape and can be detected through various methods, such as visual inspection or specialized sensors. Technicians may use ultraviolet (UV) lights to identify the fluid's trail, as it will glow under UV illumination, making it visible in areas where a leak might be hidden. This method is particularly useful for hard-to-reach areas and provides a quick and effective way to pinpoint leaks.

Electronic Diagnostic Scanners: Advanced electronic diagnostic scanners are also employed by professionals. These scanners can communicate with the vehicle's onboard computer systems, providing detailed information about fuel system performance. By connecting to the engine control unit (ECU), technicians can access error codes and sensor data related to fuel injection and delivery. If a leak is detected, the scanner may trigger error codes, alerting the mechanic to potential issues. This method is especially valuable for modern vehicles with complex fuel systems and computer-controlled components.

Utilizing these professional diagnostic tools ensures that fuel line leaks are identified accurately and efficiently. Each tool plays a unique role in providing valuable insights into the fuel system's health, allowing mechanics to perform targeted repairs and maintain optimal vehicle performance. With these specialized equipment, professionals can deliver reliable solutions, ensuring vehicles remain safe and efficient on the road.

Solder Bosch Steel Fuel Line: A Comprehensive Guide

You may want to see also

Frequently asked questions

You can perform a simple visual inspection by following these steps: First, ensure the engine is cool to the touch to avoid any burns. Then, locate the fuel lines under the hood and inspect them for any signs of damage, cracks, or corrosion. Look for puddles of fuel or any unusual stains around the fuel lines, as these could indicate a leak. If you notice any issues, it's best to consult a professional mechanic for further diagnosis and repair.

Yes, there are a few methods to help identify leaks. One common tool is a fuel line pressure tester, which can measure the pressure in the fuel system and detect any leaks. You can also use a fuel line dye or a leak detection fluid, which is added to the fuel system and makes any leaks visible. These products are safe to use and can help pinpoint the exact location of the leak.

Fuel lines can develop leaks due to several reasons. Age and wear and tear are common factors, as fuel lines can degrade over time. Extreme temperatures, both hot and cold, can also cause fuel lines to crack or become brittle. Additionally, physical damage from accidents, road debris, or improper installation can lead to leaks. Regular maintenance and inspections can help prevent and identify these issues early on.

Preventative measures are key to avoiding fuel line leaks. Regularly checking the fuel lines for any signs of damage or wear is essential. Keeping the fuel system clean and free of contaminants can also help. Using high-quality fuel and ensuring proper fuel storage conditions can extend the life of the fuel lines. It's recommended to have a professional mechanic inspect the fuel system during routine maintenance checks to identify and address any potential issues.