Regular fuel lines are not designed for diesel engines and can lead to performance issues and potential safety hazards. Diesel fuel has a higher pressure and temperature requirement compared to gasoline, and the fuel lines must be able to withstand these conditions. Using regular fuel lines for diesel engines can result in fuel leaks, reduced performance, and even engine damage over time. It is crucial to use the appropriate fuel lines designed specifically for diesel engines to ensure optimal performance and safety.

What You'll Learn

- Fuel Compatibility: Regular gasoline fuel lines may not withstand diesel's higher pressure and temperature

- Material Differences: Diesel fuel requires fuel lines made from materials resistant to fuel degradation

- Performance Impact: Using regular fuel lines can lead to reduced engine performance and potential damage

- Safety Concerns: Incorrect fuel lines can cause fuel leaks, increasing the risk of fire or explosion

- Longevity: Diesel fuel lines are designed for longer lifespan and durability compared to gasoline lines

Fuel Compatibility: Regular gasoline fuel lines may not withstand diesel's higher pressure and temperature

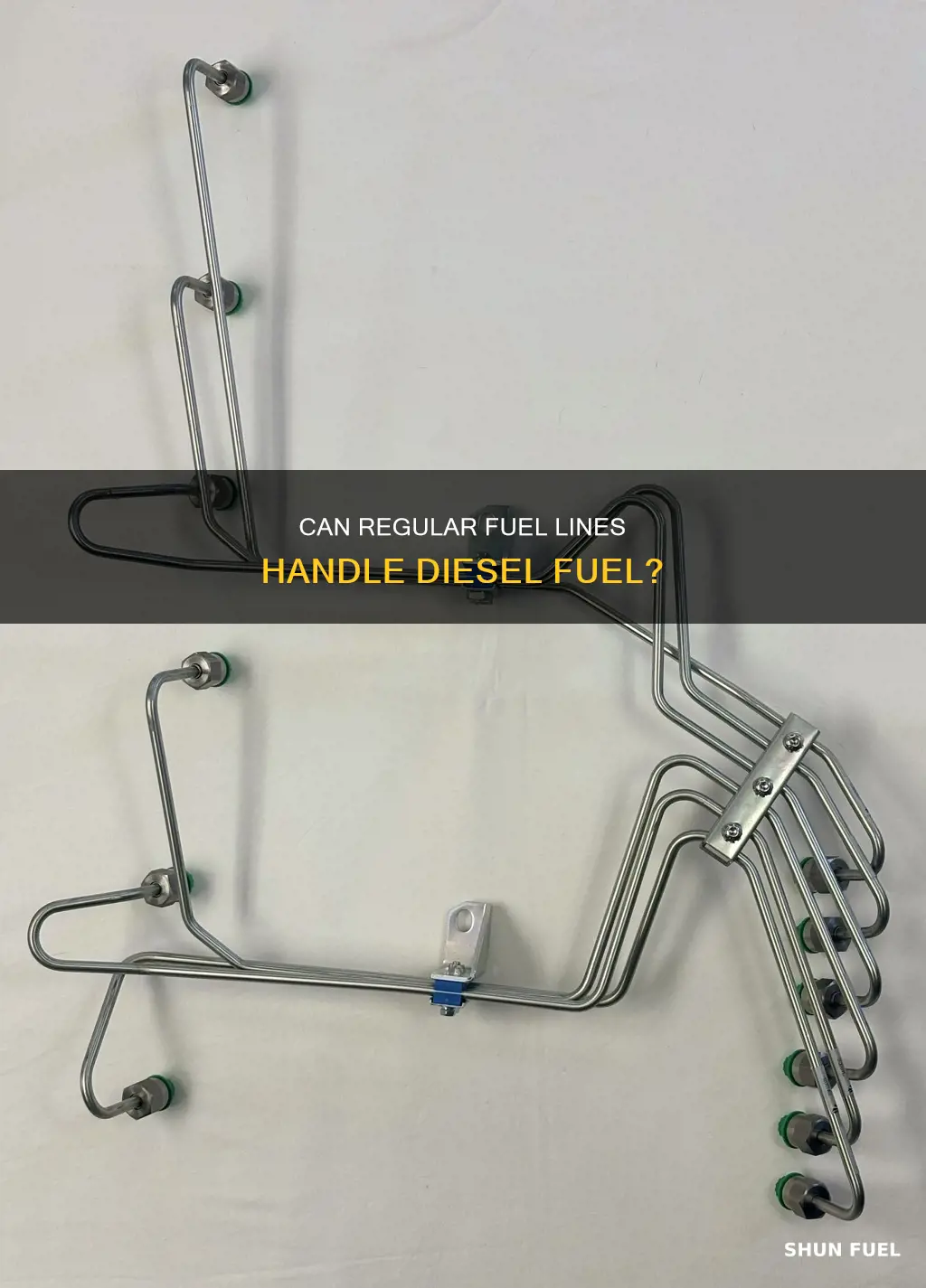

When considering the compatibility of fuel lines for diesel engines, it is crucial to understand the inherent differences between gasoline and diesel fuel systems. Regular gasoline fuel lines, designed for the lower pressure and temperature requirements of gasoline engines, may not be suitable for diesel applications. Diesel fuel operates under significantly higher pressure and temperature conditions compared to gasoline, which can lead to potential issues if the fuel lines are not designed to handle these demands.

The primary concern lies in the construction and material of regular gasoline fuel lines. These lines are typically made from materials like rubber or plastic, which may not be able to withstand the increased stress and heat generated by diesel fuel. Over time, the higher pressure and temperature can cause the fuel lines to degrade, leading to potential leaks, reduced performance, or even fuel system failures.

In diesel engines, the fuel injection process involves precise timing and high-pressure fuel delivery. This high-pressure environment requires fuel lines with enhanced structural integrity and heat resistance. Regular gasoline fuel lines may lack the necessary reinforcement to handle these conditions, potentially resulting in premature failure or reduced efficiency.

To ensure optimal performance and longevity, it is recommended to use fuel lines specifically designed for diesel applications. These lines are engineered to withstand the higher pressure and temperature requirements, often made from more robust materials such as high-temperature-resistant rubber compounds or specialized plastics. By investing in compatible fuel lines, diesel engine owners can maintain the integrity of their fuel system and avoid potential issues related to fuel line compatibility.

In summary, while it might be tempting to reuse regular gasoline fuel lines for diesel engines, the increased demands of diesel fuel make this practice risky. The potential consequences of using incompatible fuel lines can lead to costly repairs and performance issues. Therefore, it is essential to prioritize fuel line compatibility to ensure the reliable operation of diesel engines.

Automotive Fuel Line: A Viable Option for Outboard Motor?

You may want to see also

Material Differences: Diesel fuel requires fuel lines made from materials resistant to fuel degradation

When considering the compatibility of fuel lines for diesel engines, it is crucial to understand the material requirements to ensure optimal performance and longevity. Diesel fuel has distinct properties that set it apart from regular gasoline, and these differences are reflected in the choice of materials used for fuel lines.

One of the primary concerns with diesel fuel is its higher sulfur content compared to gasoline. Sulfur in diesel can lead to the formation of acidic compounds when the fuel is burned, which can cause corrosion and degradation of the fuel lines over time. Therefore, the materials used for diesel fuel lines must be resistant to this corrosive effect. Common materials for fuel lines include rubber, plastic, and metal hoses. However, not all of these materials are suitable for diesel applications.

Rubber, for instance, is often used in fuel lines due to its flexibility and durability. But, natural rubber is susceptible to degradation when exposed to the higher temperatures and sulfur content of diesel fuel. This degradation can result in cracks, leaks, and reduced fuel efficiency. To combat this, synthetic rubbers, such as neoprene or butyl rubber, are preferred for diesel fuel lines as they offer improved resistance to heat and sulfur compounds.

Plastic fuel lines, such as those made from polyvinyl chloride (PVC) or polyethylene, are also an option. These materials are generally more resistant to the corrosive effects of diesel fuel compared to rubber. However, it is essential to choose the right type of plastic to ensure compatibility. Some plastics may become brittle or crack when exposed to diesel fuel over extended periods.

In addition to the choice of material, the construction of the fuel line is also vital. Diesel fuel lines should be designed to withstand the high pressure and temperature fluctuations that occur during engine operation. Reinforced fuel lines with multiple layers or braids can provide additional strength and durability, ensuring a reliable fuel supply to the engine.

In summary, when using diesel fuel, it is imperative to select fuel lines made from materials that can withstand the unique challenges posed by diesel's higher sulfur content and operating temperatures. Proper material selection and construction will help prevent fuel line degradation, ensuring a reliable and efficient fuel supply to the diesel engine.

KTM 640 Fuel Line Size: Ultimate Guide

You may want to see also

Performance Impact: Using regular fuel lines can lead to reduced engine performance and potential damage

The use of regular fuel lines for diesel engines can have significant performance implications and may result in various issues over time. Firstly, regular fuel lines are not designed to withstand the higher pressure and temperature requirements of diesel fuel. Diesel engines operate at much higher pressures compared to gasoline engines, and the fuel lines must be able to handle these conditions to ensure optimal performance. When regular fuel lines are used, they may not provide the necessary pressure resistance, leading to a decrease in engine power and efficiency. This can result in a noticeable drop in performance, with the engine feeling less responsive and potentially losing its ability to reach peak power output.

In addition to reduced performance, the use of regular fuel lines can also lead to potential damage to the engine's fuel system. Diesel fuel contains higher levels of lubricity and additives compared to gasoline, which can cause issues if the fuel lines are not compatible. Regular fuel lines may not have the necessary flexibility and resistance to the corrosive properties of diesel fuel, leading to potential degradation of the fuel lines over time. This can result in fuel leaks, blockages, or even damage to the fuel injectors, causing further performance issues and potentially requiring expensive repairs.

The impact on engine performance is often immediate and noticeable. Engine misfires, rough idling, and reduced acceleration are common symptoms when using regular fuel lines with a diesel engine. These issues arise from the fuel lines' inability to deliver the precise fuel-air mixture required for optimal combustion. As a result, the engine may struggle to maintain stable operation, leading to increased fuel consumption and reduced overall efficiency.

Furthermore, the potential for long-term damage is a significant concern. Regular fuel lines may not withstand the continuous high-pressure environment, leading to cracks, leaks, or even complete failure. This can result in fuel spilling onto hot engine components, causing potential fires or further damage to the engine's internal parts. The consequences of using regular fuel lines for diesel engines can be severe, requiring extensive repairs or even premature engine replacement.

To ensure optimal performance and longevity of the engine, it is crucial to use fuel lines specifically designed for diesel applications. These specialized fuel lines are engineered to withstand the unique demands of diesel fuel, providing the necessary pressure resistance and compatibility. By investing in the right fuel lines, engine owners can avoid performance degradation, potential damage, and the associated costs, ensuring their diesel engine operates efficiently and reliably.

Cub Cadet Mower Fuel Line Switch: Unlocking the Mystery

You may want to see also

Safety Concerns: Incorrect fuel lines can cause fuel leaks, increasing the risk of fire or explosion

When it comes to vehicle maintenance, one of the critical aspects often overlooked is the fuel lines. These seemingly simple components play a vital role in ensuring the safe and efficient operation of your engine. However, using the wrong type of fuel line can lead to a host of problems, with safety being the primary concern.

Regular fuel lines, designed for gasoline engines, are not suitable for diesel engines. The primary safety concern arises from the different fuel properties of gasoline and diesel. Gasoline is less dense and has a lower flash point compared to diesel. This means that regular fuel lines, which are typically made of materials like rubber or plastic, may not withstand the higher pressure and temperature of diesel fuel. Over time, these materials can degrade, leading to cracks, leaks, and potential fuel spills.

The consequences of using incorrect fuel lines can be severe. Fuel leaks, especially when combined with the high temperatures and sparks present in the engine compartment, pose a significant fire hazard. A small leak can quickly escalate into a dangerous situation, especially if the fuel comes into contact with hot engine components or electrical systems. In extreme cases, a fuel leak can lead to a fire or even an explosion, causing severe damage to the vehicle and endangering the lives of those nearby.

To mitigate these risks, it is crucial to use fuel lines specifically designed for diesel engines. These lines are typically made of more robust materials that can withstand the higher pressure and temperature of diesel fuel. They are also often reinforced to prevent cracks and leaks. When replacing or upgrading fuel lines, always consult the vehicle's manual or seek professional advice to ensure you are using the correct type of fuel line for your diesel engine.

In summary, while it might seem convenient to use regular fuel lines for diesel engines, it is a practice that should be avoided due to the potential safety hazards. Always prioritize safety by using the correct components for your vehicle, ensuring that your engine operates efficiently and securely.

Fuel Line Sizing for Optimal Performance: Lohler Lawnmower Guide

You may want to see also

Longevity: Diesel fuel lines are designed for longer lifespan and durability compared to gasoline lines

When it comes to vehicle fuel systems, the choice of fuel lines is crucial for optimal performance and longevity. One common question that arises is whether regular fuel lines can be used for diesel engines. The answer is a resounding no, and here's why.

Diesel fuel lines are specifically engineered to withstand the unique demands of diesel fuel. These lines are designed with enhanced durability and longevity in mind. Diesel fuel often contains higher levels of ethanol and water, which can be more corrosive to certain materials compared to gasoline. Additionally, diesel fuel typically has a higher pressure and temperature range, requiring fuel lines that can handle these extreme conditions. Regular fuel lines, typically made from standard materials like rubber or plastic, may not possess the necessary strength and resistance to withstand the rigors of diesel fuel.

The primary reason for the specialized design of diesel fuel lines is their longer lifespan. Diesel engines are known for their robust nature and can operate for hundreds of thousands of miles with proper maintenance. The fuel lines, being a critical component, need to endure the constant flow of fuel, high pressure, and potential contaminants in diesel. Standard fuel lines may not have the same level of flexibility, resistance to abrasion, or ability to withstand temperature fluctuations, leading to premature wear and potential fuel leaks over time.

Furthermore, diesel fuel lines often incorporate materials that are more resistant to corrosion and degradation. For instance, some diesel fuel lines are made from high-density polyethylene (HDPE) or specialized rubber compounds that can handle the unique properties of diesel fuel. These materials ensure that the fuel lines remain flexible, durable, and less prone to cracking or deterioration, even under prolonged exposure to diesel's harsher characteristics.

In summary, using regular fuel lines for diesel engines can compromise the overall performance and reliability of the vehicle. Diesel fuel lines are an essential investment to ensure the longevity and safety of your diesel vehicle. They are specifically engineered to handle the unique demands of diesel fuel, providing the necessary durability and resistance to ensure a longer-lasting and more efficient fuel system.

Kreem Fuel Tank Liner: A Comprehensive Guide to Installation and Benefits

You may want to see also

Frequently asked questions

No, it is not recommended to use regular gasoline fuel lines for diesel engines. Diesel fuel lines are designed to withstand the higher pressure and temperature requirements of diesel fuel, which is more volatile than gasoline. Using the wrong type of fuel line can lead to performance issues and potential safety hazards.

Diesel fuel lines are typically made from materials that can handle the higher pressure and temperature ranges of diesel fuel. They often use materials like high-pressure rubber or synthetic compounds. Gasoline fuel lines, on the other hand, are designed for lower-pressure applications and may not be suitable for diesel engines.

Yes, using regular fuel lines for diesel can result in reduced engine performance and potential damage. Diesel fuel requires a more robust fuel system, including lines, to ensure proper atomization and injection into the engine. Regular fuel lines may not provide the necessary pressure and flow characteristics, leading to poor fuel delivery and engine misfires.

Absolutely. Using the wrong type of fuel line can lead to fuel leaks, which pose a significant safety risk. Diesel fuel lines are designed to be more flexible and durable to withstand the fuel's properties. If regular fuel lines are used, there is a higher chance of leaks, potential fires, or engine damage due to the increased pressure and temperature of diesel fuel.

Modifying existing fuel lines is not recommended without professional advice. It is best to consult a qualified mechanic or diesel specialist who can provide the appropriate fuel lines for your diesel engine. Attempting to modify lines yourself may void warranties and could lead to further complications if not done correctly.