Installing fuel lines for a 545081855 carb can seem daunting, but with the right tools and a systematic approach, it's a manageable task. This guide will walk you through the process step-by-step, ensuring a successful installation. From preparing the necessary tools to connecting the fuel lines securely, you'll learn how to make the most of your engine's performance. Whether you're a seasoned mechanic or a DIY enthusiast, this detailed tutorial will help you achieve a professional-looking installation.

| Characteristics | Values |

|---|---|

| Product Type | Carburetor |

| Application | Universal |

| Fuel Type | Gasoline |

| Engine Type | Carbureted |

| Fitment Type | Direct Replacement |

| Includes | Fuel Lines, Carburetor |

| Color | Black |

| Material | Plastic, Metal |

| Notes | Designed for specific vehicle models; consult compatibility chart |

| Package Includes | Fuel Lines, Carburetor, Mounting Hardware |

| Brand | Various (depending on the specific model) |

| Part Number | 545081855 |

What You'll Learn

- Prepare Tools and Materials: Gather fuel line, carb, wrenches, and fuel filter for installation

- Remove Old Fuel Lines: Disconnect and carefully remove old fuel lines from the carb

- Install New Fuel Line: Route new fuel line through engine compartment, securing with clips

- Connect to Carb: Attach fuel line to carb's inlet and outlet ports, ensuring proper alignment

- Test and Adjust: Check for leaks, start engine, and fine-tune fuel mixture as needed

Prepare Tools and Materials: Gather fuel line, carb, wrenches, and fuel filter for installation

Before you begin the installation process, it's crucial to gather all the necessary tools and materials to ensure a smooth and efficient job. Here's a breakdown of what you'll need:

Fuel Line and Carburetor: Start by acquiring the specific fuel line designed for your engine model, identified by the part number 545081855. This fuel line is crucial for directing fuel from the tank to the carburetor, where it mixes with air for combustion. Ensure you get the correct size and length to fit your engine's requirements. Additionally, you'll need the carburetor itself, which is the component responsible for regulating and mixing the air-fuel mixture.

Wrenches: A set of wrenches is essential for tightening and loosening various components during the installation. You'll likely require different sizes, including metric and standard, to accommodate different bolt and nut sizes. Having a variety of wrenches will make it easier to access tight spots and ensure proper torque application.

Fuel Filter: A clean and functional fuel filter is vital to prevent contaminants from entering your engine. It should be compatible with your fuel line and carburetor setup. Check the specifications of your fuel system to ensure you select the correct filter size and type.

Additional Tools: Consider having a few extra tools on hand, such as a fuel pump primer bulb, if your engine requires priming. You might also want a fuel gauge and sender assembly, especially if you're replacing an old or faulty one. These additional tools can make the installation process more comprehensive and ensure your engine's optimal performance.

By gathering these tools and materials, you'll be well-prepared to tackle the installation of your fuel lines and carburetor. Remember to double-check compatibility and specifications to ensure a successful and safe installation process.

Cruise Ship Fuel: Can It Be Delivered from the Shore?

You may want to see also

Remove Old Fuel Lines: Disconnect and carefully remove old fuel lines from the carb

When it comes to replacing fuel lines, a crucial step is removing the old ones to ensure a smooth transition to the new setup. Here's a detailed guide on how to safely and effectively disconnect and remove the old fuel lines from the carburetor:

Step 1: Identify the Fuel Lines: Before you begin, locate the fuel lines connected to the carburetor. These lines are typically made of rubber or flexible material and carry fuel from the fuel tank to the carburetor. There might be two or more lines, each serving a specific purpose, such as the primary and secondary fuel supply lines.

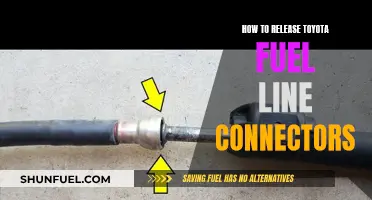

Step 2: Disconnect the Fuel Lines: Carefully inspect each fuel line for any connections or fittings. These connections are usually quick-release clips or screws. Loosen the clips or screws to release the fuel lines from their attachments. Be gentle to avoid damaging the lines or the carburetor. Take note of the positions of the lines to ensure proper reinstallation later.

Step 3: Remove the Old Fuel Lines: Once the lines are disconnected, you can start removing them. Gently pull the fuel lines away from the carburetor, ensuring you don't force anything to avoid damage. If the lines are stubborn, you can use a small tool like a screwdriver or a flathead to carefully pry them loose. Take your time and be patient, as rushing might lead to issues.

Step 4: Inspect for Damage: As you remove the fuel lines, inspect them for any signs of wear, cracks, or damage. Old fuel lines may have deteriorated over time, especially if they've been exposed to heat, cold, or fuel contaminants. If you notice any significant damage, it's best to replace the entire line rather than just the section that's been removed.

Step 5: Clean the Carburetor (Optional): While you have the carburetor exposed, you might want to clean it to ensure optimal performance. This step is optional but recommended for a thorough maintenance routine. Use a carburetor cleaner and follow the manufacturer's instructions to remove any built-up deposits or residue.

Deep Clean Your 4Runner's Fuel System: A Step-by-Step Guide

You may want to see also

Install New Fuel Line: Route new fuel line through engine compartment, securing with clips

When replacing or installing a new fuel line for a 545081855 carb, proper routing and securement are crucial to ensure optimal performance and prevent fuel leaks. Here's a step-by-step guide to help you through the process:

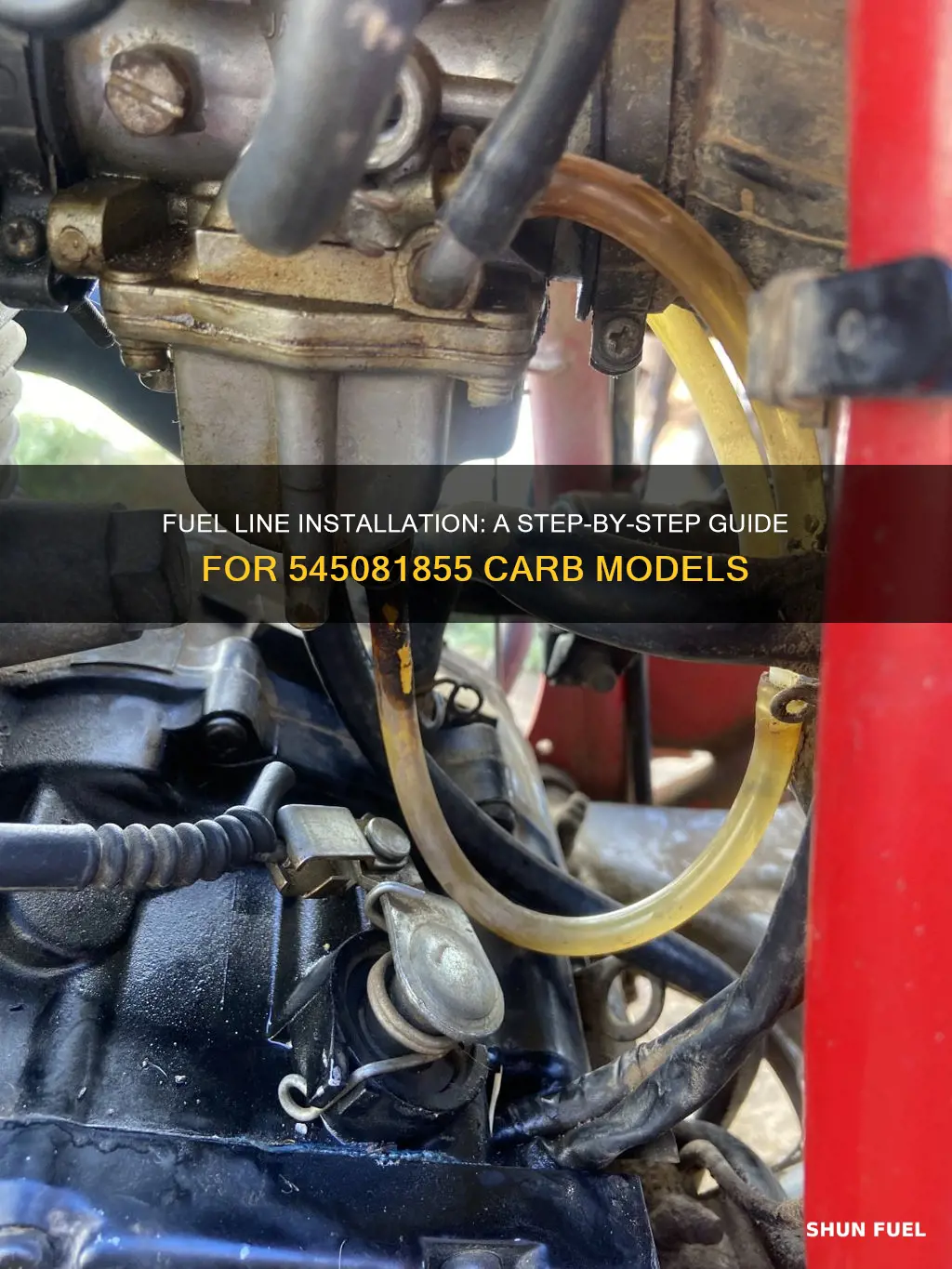

Start by locating the old fuel line and carefully removing it from the engine compartment. Take note of the path it took to reach the carburetor, as you'll need to replicate this route for the new line. Ensure you have the necessary tools, such as fuel line clips, a fuel line cutter, and a fuel line primer, readily available.

Begin routing the new fuel line through the engine compartment, following the same path as the old line. Ensure that the new line is not twisted or kinked, as this can restrict fuel flow and cause issues. Use the fuel line clips to secure the line at regular intervals, typically every 6-8 inches, to keep it organized and prevent tangling.

As you near the carburetor, carefully feed the fuel line through the appropriate openings and ensure it is properly aligned. Double-check that the line is not caught or pinched in any moving parts. Once the line reaches the carburetor, attach the fuel line to the carburetor's fuel inlet using the appropriate fittings or clips.

Finally, inspect the entire fuel line system to ensure there are no sharp bends or excessive tension. Test the fuel line by starting the engine and checking for any leaks. If all is well, you've successfully installed the new fuel line. Remember to dispose of the old fuel line responsibly and consider using a fuel line primer to ensure a clean and secure connection.

Unleash Power: 8 Fuel Lines, Horsepower Limits, and Engine Potential

You may want to see also

Connect to Carb: Attach fuel line to carb's inlet and outlet ports, ensuring proper alignment

When connecting fuel lines to the carburetor (carb) inlet and outlet ports, it's crucial to follow a systematic approach to ensure a proper and secure installation. This process requires attention to detail and a methodical step-by-step execution. Here's a comprehensive guide to help you through this task:

Start by locating the carburetor on your engine and identifying the inlet and outlet ports. These ports are typically marked with small notches or indentations on the carburetor body. The inlet port is where the fuel enters the carburetor, and the outlet port is where it exits to supply the engine. Ensure you have the correct fuel lines, as different engines may require specific sizes and types.

Now, take the fuel line and align it with the inlet port. The line should fit snugly over the port, ensuring a tight seal. Use your hands or a small tool to gently push the line onto the port until it is firmly in place. Repeat this process for the outlet port, connecting the fuel line accordingly. Make sure the line is not kinked or twisted, as this can affect the fuel flow and engine performance.

Proper alignment is key to a successful installation. When attaching the fuel lines, ensure they are straight and not bent at odd angles. Bending the lines can restrict fuel flow and potentially damage the carburetor. Take your time to carefully position each line, ensuring it is secure and free from any obstructions.

After attaching the fuel lines to both ports, double-check your work. Verify that the lines are tightly sealed and there are no gaps or leaks. You can use a small amount of fuel on the carburetor and observe if any leaks occur, indicating a potential misalignment or faulty connection. If everything looks good, your next step is to secure the fuel lines with the appropriate clamps or fasteners to prevent any movement or disconnection during engine operation.

Remember, a well-connected fuel system is vital for optimal engine performance. Take your time, follow these steps, and ensure every connection is secure and properly aligned. This will contribute to a reliable and efficient fuel supply to your engine.

Dodge 2500 Fuel Line Connection: A Comprehensive Guide

You may want to see also

Test and Adjust: Check for leaks, start engine, and fine-tune fuel mixture as needed

Once you've installed the fuel lines and connected the carburetor, it's crucial to test and adjust the system to ensure optimal performance. This process involves checking for leaks, starting the engine, and fine-tuning the fuel mixture to achieve the right balance. Here's a step-by-step guide to help you through this critical phase:

Leak Check: Before starting the engine, inspect the entire fuel system for any signs of leaks. Look for any wet spots or fuel residue around the connections, especially where the fuel lines attach to the carburetor and the engine. If you notice any leaks, tighten the connections or replace the gaskets as necessary. Ensure that all fittings are secure and properly sealed to prevent fuel loss during operation.

Engine Start-Up: With the fuel system ready, it's time to start the engine. Ensure that the ignition system is functioning correctly, and the spark plugs are in good condition. When you turn the key, the engine should start promptly and run smoothly. Pay attention to any unusual noises or vibrations, as these could indicate issues with the fuel delivery or engine components.

Fine-Tuning the Fuel Mixture: Adjusting the fuel mixture is a delicate process and may require some trial and error. Start by referring to your vehicle's manual for the recommended fuel-to-air ratio. You can often find this information in the carburetor's adjustment specifications. Use a fuel mixture gauge or a timing light to measure the air-fuel ratio. If the mixture is too rich (too much fuel), the engine may misfire or run poorly. If it's too lean (too much air), the engine might not start at all. Adjust the carburetor's throttle plate or fuel screw to fine-tune the mixture until you find the optimal setting.

Testing and Adjusting: After starting the engine, let it idle for a few minutes to allow the carburetor to stabilize. Then, perform a test drive, monitoring the engine's performance. Check for any signs of hesitation, stalling, or rough idling, as these could indicate further adjustments are needed. If the engine runs smoothly, you've successfully tested and adjusted the fuel system. However, if issues persist, you may need to make additional fine-tunings to the carburetor settings.

Remember, this process requires patience and a methodical approach. Take your time to make small adjustments and test the engine's response. Fine-tuning the fuel mixture is an art that can be mastered with practice, ensuring your engine runs efficiently and performs optimally.

Reverse-Engineer Your Mustang: Fuel Line Swap Guide

You may want to see also

Frequently asked questions

Installing fuel lines for a 545081855 carb involves several steps. First, ensure you have the necessary tools and components, including the fuel lines, fittings, and any required adapters. Then, locate the carb on your engine and identify the fuel inlet and outlet ports. Carefully route the fuel lines from the fuel pump or tank to the carb, ensuring they are not twisted or kinked. Secure the lines with the appropriate fittings and clamps, making sure they are tight and won't come loose during operation. Finally, check for any leaks and ensure the lines are properly aligned and protected from damage.

While it is possible to install fuel lines yourself, especially if you have some mechanical experience, it is generally recommended to have a professional mechanic perform this task. Fuel lines require precise installation to ensure optimal performance and safety. Professionals have the knowledge and tools to ensure a proper fit and can identify any potential issues that might arise during the installation process. DIY installation can be challenging, especially if you're not familiar with engine mechanics, and may lead to costly mistakes.

During the installation of fuel lines, several problems can arise. One common issue is leaks, which can be caused by improper fitting or sealing. These leaks can lead to fuel wastage and potential engine performance issues. Another problem is kinking or twisting of the fuel lines, which can restrict fuel flow and cause engine misfires. Additionally, if the lines are not properly secured, they may become loose over time, leading to potential disconnection and engine starting issues. It's crucial to follow the manufacturer's guidelines and ensure all connections are secure and leak-free.