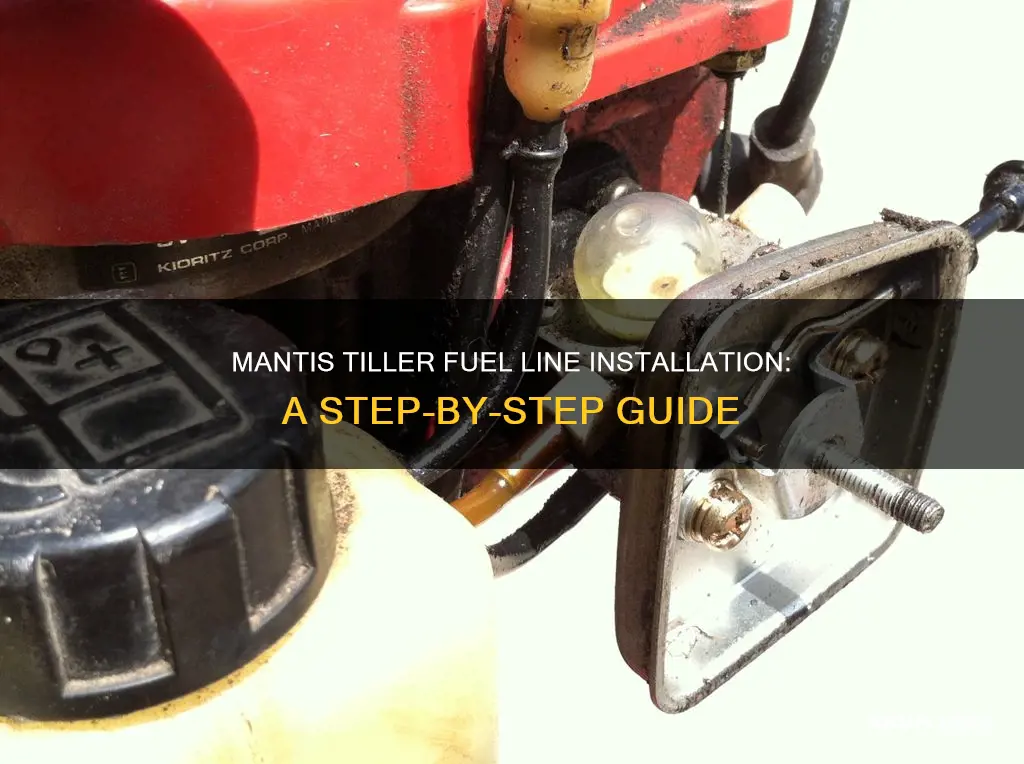

Understanding how to properly install fuel lines on a Mantis tiller is essential for ensuring optimal performance and longevity. The process involves carefully routing the fuel lines to the engine, connecting them to the fuel tank and carburetor, and securing them to prevent damage. This guide will provide a step-by-step breakdown of the installation process, highlighting important considerations such as fuel line material, routing, and proper connections to ensure your tiller runs smoothly and efficiently.

| Characteristics | Values |

|---|---|

| Fuel Line Routing | The fuel lines on a Mantis tiller are typically routed from the fuel tank to the carburetor or fuel injection system. This may involve a fuel pump and lines to ensure proper fuel delivery. |

| Fuel Filter | A fuel filter is often installed to prevent contaminants from entering the fuel system, ensuring clean fuel delivery to the engine. |

| Fuel Pump | Some tiller models may have an electric or manual fuel pump to ensure a steady fuel supply to the engine. |

| Fuel Injectors (if applicable) | In fuel-injected tiller engines, fuel injectors precisely deliver fuel into the combustion chamber, optimizing performance. |

| Engine Type | The specific fuel line configuration can vary depending on the engine type (e.g., two-stroke, four-stroke). |

| Maintenance | Regular maintenance, including fuel line inspection and replacement, is essential to ensure the tiller's longevity and performance. |

What You'll Learn

- Fuel Tank Location: Identify the fuel tank's position on the tiller

- Fuel Line Routing: Follow the manufacturer's diagram for optimal routing

- Fuel Filter Installation: Securely attach the fuel filter to the line

- Fuel Pump Connection: Connect the pump to the fuel lines

- Fuel Line Protection: Use protective sleeves to prevent damage

Fuel Tank Location: Identify the fuel tank's position on the tiller

The fuel tank on a Mantis tiller is typically located on the right side of the machine, often near the operator's seat. It is a small, cylindrical tank designed to hold the fuel for the tiller's engine. Identifying the exact position of the fuel tank is crucial for anyone working on the tiller, as it provides easy access for refilling and maintenance.

When you locate the fuel tank, you'll notice a small opening or filler neck on the top. This is where you'll add fuel to ensure the tiller has enough power for operation. It's important to check the fuel level regularly, especially before starting the tiller, to avoid running out of fuel during use.

The fuel tank's position is strategically placed for easy access and convenience. By having it on the right side, it allows the operator to quickly reach for the filler neck without having to stretch or reach too far, ensuring a smooth and efficient fueling process.

In some models, the fuel tank might be slightly lower than the operator's seat, providing a stable base for the tiller. This design ensures that the fuel remains secure and doesn't spill during operation. Always ensure that the fuel tank is properly sealed and that there are no leaks or damage to the tank or filler neck.

Understanding the fuel tank's location is essential for proper maintenance and fueling procedures. It allows users to quickly identify and access the tank, ensuring the tiller is always ready for use with the correct fuel levels.

Understanding Fuel Injection Lines: A Comprehensive Guide

You may want to see also

Fuel Line Routing: Follow the manufacturer's diagram for optimal routing

When it comes to installing or replacing fuel lines on a Mantis tiller, following the manufacturer's diagram is crucial for optimal performance and safety. This diagram provides a detailed layout of the fuel system, ensuring that the fuel lines are routed correctly to deliver fuel efficiently to the engine. Here's a step-by-step guide on why and how to follow the manufacturer's diagram for fuel line routing:

Understanding the Importance: The manufacturer's diagram is a critical resource as it is designed with the specific tiller model in mind. It takes into account the engine's layout, the fuel tank's position, and the various components of the fuel system. By adhering to this diagram, you ensure that the fuel lines are correctly positioned, avoiding potential issues such as kinks, restrictions, or damage during operation. Proper routing also helps maintain a consistent fuel flow, preventing engine performance issues and potential breakdowns.

Step-by-Step Process: Begin by carefully examining the diagram provided by the manufacturer. It will illustrate the path the fuel lines should take from the fuel tank to the engine. Locate the fuel tank, which is typically a small reservoir, and identify the fuel lines connected to it. These lines will have specific routes marked on the diagram, leading to various engine components like the carburetor or fuel injectors. Ensure that you understand the connections and the order in which the lines need to be connected.

Routing the Fuel Lines: Start routing the fuel lines according to the diagram. Maintain a clear path, avoiding any sharp bends or kinks that could restrict fuel flow. Secure the lines using appropriate clamps or ties to prevent movement and potential damage. Pay close attention to any bends or turns, ensuring they are gradual and do not create stress points that could lead to line failure. Keep the lines away from moving parts or areas where they might get caught or damaged during operation.

Testing and Verification: Once the fuel lines are installed, it is essential to test the system. Start the tiller and check for any leaks or unusual noises. Ensure that the engine runs smoothly and that there is no disruption in fuel supply. Verify that the fuel lines are securely connected and that the routing allows for optimal performance. If any issues arise, refer back to the manufacturer's diagram and the installation instructions to identify and rectify the problem.

By strictly following the manufacturer's diagram, you can ensure a proper and safe fuel line installation on your Mantis tiller. This approach minimizes the risk of engine problems and promotes the longevity of your equipment. Remember, each tiller model may have unique fuel line routing requirements, so always consult the provided diagram for the best results.

Fuel Line Removal Guide: 87 Crown Victoria Edition

You may want to see also

Fuel Filter Installation: Securely attach the fuel filter to the line

To begin the fuel filter installation process, ensure you have the necessary tools and components ready. You will need the fuel filter itself, a suitable fuel line that matches the specifications of your tiller, and some basic hand tools such as wrenches and pliers. Before proceeding, locate the fuel line that connects the fuel tank to the tiller's engine. Identify the section of the line where the filter will be attached.

Start by cutting the fuel line to the desired length, ensuring there is enough length to accommodate the filter and allow for a secure connection. Use a clean, sharp blade to make a precise cut, taking care not to damage the surrounding components. Once the line is cut, prepare the fuel filter by removing any protective caps or seals. Clean the filter's mounting surface to ensure a tight fit.

Now, carefully slide the fuel filter onto the prepared fuel line. Ensure that the filter is aligned correctly and that there is no kinking or bending of the line. Use your hands or a gentle tool to push the filter onto the line until it is fully seated. The filter should fit snugly, creating a secure connection. Check that the filter is firmly in place and there are no gaps or leaks.

To secure the fuel filter, locate the mounting points on the tiller's frame or housing. These points are typically designed to hold the filter in place. Attach the filter to these points using the appropriate fasteners, such as screws or clips. Tighten the fasteners securely but be careful not to overtighten, as this can damage the filter or the fuel line. Ensure that the filter is positioned in a way that allows for easy access during future maintenance.

Finally, reconnect the fuel line to the tiller's engine and fuel tank, ensuring all connections are tight and secure. Double-check that there are no leaks at any point in the system. With the fuel filter now installed, your tiller is ready for operation. Remember to regularly inspect and maintain the fuel filter to ensure optimal performance and prevent any potential issues.

Fuel Line Removal: Guide for 99 Yukon Intake Pump

You may want to see also

Fuel Pump Connection: Connect the pump to the fuel lines

To connect the fuel pump to the fuel lines on a Mantis tiller, follow these steps:

First, ensure you have the necessary tools and components, including the fuel pump, fuel lines, and any fittings or adapters required for your specific tiller model. It is crucial to have a clear understanding of the tiller's fuel system layout to ensure proper connections.

Locate the fuel pump, which is typically mounted near the fuel tank or the engine. Identify the input and output ports of the pump. The input port is where the fuel lines will connect to the pump, and the output port will be connected to the engine or the rest of the fuel system.

Now, take the fuel lines and carefully connect one end to the input port of the fuel pump. Ensure a secure and tight fit using appropriate fittings or clamps. The fuel lines should be routed in a way that allows for easy access and avoids any obstructions during the tiller's operation.

Next, connect the other end of the fuel lines to the engine's fuel injection system or the carburetor, depending on the tiller's engine type. Again, use the appropriate fittings and ensure a tight connection. Double-check that the fuel lines are securely fastened and that there are no leaks.

Finally, test the fuel system by starting the engine and observing its performance. Ensure that the fuel pump is delivering fuel efficiently to the engine. If everything is connected correctly, the tiller should start and run smoothly. If any issues arise, carefully inspect the connections and address any leaks or malfunctions before proceeding.

Mastering Fuel Line Routing: Essential Tips for Optimal Performance

You may want to see also

Fuel Line Protection: Use protective sleeves to prevent damage

The fuel lines on a Mantis tiller are crucial components that require careful attention to ensure optimal performance and longevity. One of the primary concerns when dealing with these lines is the potential for damage, which can lead to fuel leaks, engine issues, and even safety hazards. To mitigate these risks, a simple yet effective solution is to use protective sleeves.

Protective sleeves, also known as fuel line covers or boots, are designed to encapsulate the fuel lines, providing a barrier against potential sources of damage. These sleeves are typically made from durable materials such as rubber or plastic, ensuring they can withstand the rigors of outdoor use. By installing these sleeves, you create a physical barrier that safeguards the fuel lines from various threats.

One of the primary benefits of using protective sleeves is the prevention of damage from sharp objects. In outdoor environments, fuel lines can be exposed to rocks, debris, or even accidental impacts from tools or equipment. The sleeves act as a buffer, absorbing the force of potential impacts and protecting the fuel lines from punctures or tears. This is especially important in areas where the tiller is used frequently or in rugged terrain.

Additionally, protective sleeves offer defense against UV radiation and extreme temperatures. Prolonged exposure to sunlight can cause the fuel lines to degrade, leading to cracks or leaks. The sleeves provide a shield, blocking harmful UV rays and preventing premature aging of the fuel lines. Similarly, in colder climates, the sleeves insulate the lines, reducing the risk of freezing and maintaining the integrity of the fuel system.

Installing fuel line protective sleeves is a straightforward process. It typically involves sliding the sleeve over the fuel line, ensuring a snug fit. Some sleeves may require adhesive or clips for a secure attachment. By taking this simple precaution, you can significantly extend the lifespan of your Mantis tiller's fuel lines and ensure reliable performance for years to come. Regular inspection and replacement of the sleeves when necessary will further enhance the protection and maintain the overall health of your tiller's fuel system.

Fuel Line Adventure: Lines to Go's Real-World Test

You may want to see also

Frequently asked questions

The fuel lines are typically connected to the fuel tank and the engine or tiller mechanism. You'll find a fuel inlet or a small port on the tiller's engine, where the lines are attached.

To guarantee a steady fuel supply, ensure the fuel lines are securely connected and free from any kinks or obstructions. Check for any clogs or blockages in the lines and maintain the fuel tank's cleanliness to prevent contamination.

It's recommended to use fuel lines specifically designed for garden equipment or agricultural machinery. These lines are often made of durable materials like rubber or vinyl and can withstand the pressure and temperature variations associated with fuel.

If you notice any damage, cracks, or leaks in the fuel lines, it's crucial to replace them immediately. Contact the manufacturer or a qualified technician to obtain the correct replacement parts and ensure proper installation to maintain the tiller's performance and safety.