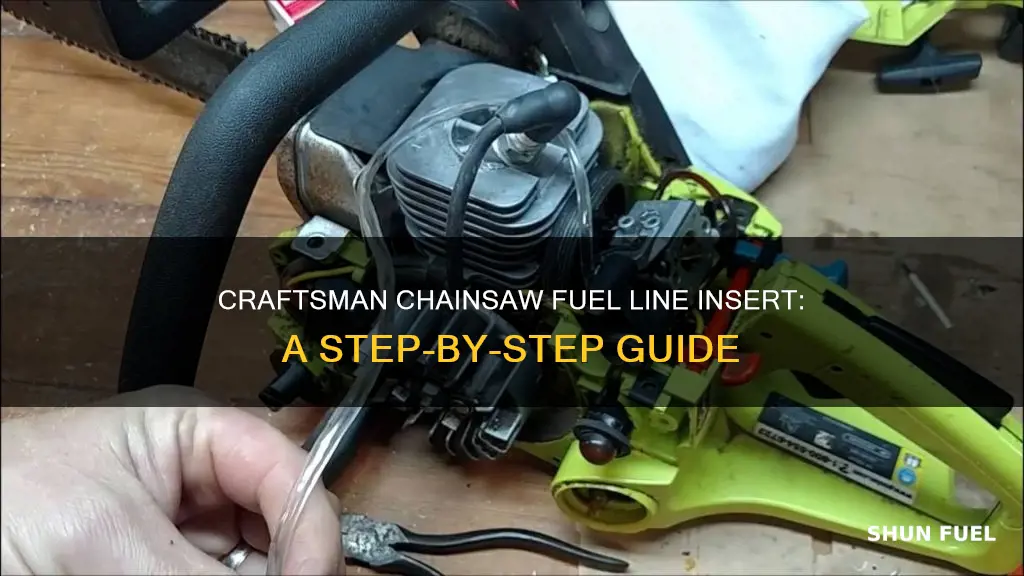

Inserting 2-cycle fuel lines into Craftsman chainsaws requires careful attention to detail and adherence to safety guidelines. This process involves connecting the fuel lines to the carburetor and ensuring proper fuel delivery to the engine. By following a step-by-step guide, you can efficiently install the fuel lines, ensuring optimal performance and longevity of your chainsaw. Understanding the specific model's requirements is essential to avoid any potential issues during the installation process.

| Characteristics | Values |

|---|---|

| Inserting 2-cycle fuel lines | Inserting fuel lines for a 2-cycle engine involves connecting the fuel tank to the carburetor, ensuring proper fuel flow and mixing. |

| Craftsman Chainsaw | Craftsman chainsaws typically use a 2-cycle engine, requiring fuel lines to deliver gasoline and oil mixture to the carburetor. |

| Fuel Line Installation | Start by disconnecting the old fuel line, if present. Then, locate the fuel tank and carburetor, and identify the appropriate fuel line ports. |

| Port Identification | The fuel line usually has a specific port for gasoline and another for oil. Ensure you connect the correct lines to the respective ports. |

| Clamps and Connections | Secure the fuel lines using clamps or fittings provided with the chainsaw. Tighten them securely but avoid over-tightening. |

| Fuel Mixture | When inserting the fuel lines, ensure the correct fuel-to-oil mixture ratio is maintained, typically 50:1 or 2-cycle engine specifications. |

| Testing | After installation, test the chainsaw to ensure the fuel lines are functioning correctly and there are no leaks. |

| Safety Precautions | Always disconnect the spark plug wire and drain the fuel tank before working on the fuel system to prevent accidental starting or fuel spills. |

What You'll Learn

- Fuel Line Material: Choose the right material for your 2-cycle fuel line, considering durability and compatibility with fuel

- Fuel Line Routing: Plan a safe and efficient route for the fuel line, avoiding tight spaces and potential damage

- Fuel Line Connections: Ensure secure connections using the appropriate fittings and seals to prevent fuel leaks

- Fuel Line Protection: Protect the fuel line from damage with sleeves or shields, especially in areas with debris or vibration

- Fuel Line Maintenance: Regularly inspect and maintain the fuel line to ensure optimal performance and prevent clogs or leaks

Fuel Line Material: Choose the right material for your 2-cycle fuel line, considering durability and compatibility with fuel

When it comes to choosing the right fuel line material for your 2-cycle Craftsman chainsaw, durability and compatibility with the fuel are key factors to consider. The fuel line is a critical component in the fuel delivery system, and using the appropriate material ensures optimal performance and longevity. Here's a detailed guide to help you make the right choice:

Durability: The fuel line should be able to withstand the harsh conditions it encounters during the operation of a chainsaw. It needs to be flexible yet robust to handle the constant movement and vibrations. Look for materials that offer excellent wear resistance and can resist the effects of fuel, including ethanol blends, which are commonly used in 2-cycle engines. Rubber and certain types of synthetic materials are often preferred for their durability and ability to withstand fuel exposure.

Compatibility with Fuel: Different types of fuel require specific fuel line materials to ensure compatibility and prevent fuel degradation. For 2-cycle engines, the fuel-oil mixture is typically a gasoline-based blend. Natural rubber is a common choice for fuel lines in this context as it can handle gasoline and is resistant to fuel-related chemicals. However, some modern chainsaws may use ethanol-blended fuel, so it's essential to check the manufacturer's recommendations. If your chainsaw operates on ethanol-blended fuel, consider using a fuel line made from materials like synthetic rubber or PVC, which offer better resistance to ethanol.

Consideration of Engine Type: Different 2-cycle engine designs may have specific requirements. For example, some engines might benefit from a fuel line with a slightly different durometer (hardness) to ensure proper fuel flow. Always refer to your Craftsman chainsaw's manual or the manufacturer's guidelines to determine the recommended fuel line material for your specific engine model.

Flexibility and Routing: The fuel line should be flexible enough to navigate the various angles and curves in the chainsaw's fuel system. When selecting a material, consider its flexibility at both room temperature and in cold conditions, as this can vary between different types of rubber or synthetic materials. Additionally, plan the fuel line routing carefully to avoid sharp bends or kinks that could restrict fuel flow.

By carefully considering the durability and compatibility of the fuel line material with the fuel type used in your Craftsman chainsaw, you can ensure a reliable and efficient fuel delivery system. This will contribute to the overall performance and longevity of your chainsaw.

Visual Guide: Kinked Fuel Line for 2008 LMM Duramax

You may want to see also

Fuel Line Routing: Plan a safe and efficient route for the fuel line, avoiding tight spaces and potential damage

When it comes to routing the fuel line for your Craftsman chainsaw, it's crucial to prioritize safety and efficiency. The goal is to ensure the fuel line is secure, well-protected, and free from any potential obstructions or damage. Here's a step-by-step guide to help you plan the optimal route:

Start by familiarizing yourself with the chainsaw's anatomy. Locate the fuel tank, which is typically positioned near the handle, and identify the fuel line, a flexible tube connecting the tank to the carburetor. Understanding the layout of the engine and its components will help you make informed decisions during the routing process. Consider the path the fuel line must take from the tank to the carburetor, ensuring it is not too complex or cramped.

Avoiding tight spaces is essential to prevent damage to the fuel line. Look for areas with ample room, such as the side of the engine or the frame, where the line can be securely routed without bending or kinking. Keep the fuel line away from moving parts like the chain guard, as it could lead to potential damage or interference. If the chainsaw has a protective cover or shield, utilize it to shield the fuel line from any sharp edges or protruding components.

The routing should also consider the fuel line's flexibility and durability. Avoid sharp bends or sharp turns that could cause stress on the line, potentially leading to cracks or leaks. Instead, opt for gentle curves and smooth transitions. If the fuel line needs to cross over other components, ensure it does so at a slight angle, reducing the risk of damage.

Additionally, plan the route to allow for easy access during maintenance or repairs. Keep the fuel line away from areas where it might be difficult to reach, such as under the seat or in hard-to-access compartments. By providing clear access, you'll make it simpler to inspect, clean, or replace the fuel line when necessary.

Remember, the key to successful fuel line routing is a well-thought-out plan. Take the time to measure and mark the desired path, ensuring it aligns with the engine's design. This meticulous approach will result in a safe and efficient fuel line setup, contributing to the overall performance and longevity of your Craftsman chainsaw.

Finding the Perfect Fit: Husqvarna 240 Fuel Line Dimensions

You may want to see also

Fuel Line Connections: Ensure secure connections using the appropriate fittings and seals to prevent fuel leaks

When working with two-stroke fuel lines on Craftsman chainsaws, ensuring secure and leak-free connections is crucial for optimal performance and safety. Here's a step-by-step guide to achieving this:

Understanding the Components: Familiarize yourself with the fuel line, carburetor, and fuel tank assembly. The fuel line connects the fuel tank to the carburetor, delivering the two-stroke mixture to the engine. It's essential to use the correct fittings and seals designed for your specific model.

Preparation: Before connecting the fuel line, ensure you have the necessary tools, including fuel line connectors, seals, and a fuel line adapter kit. Clean the fuel line and remove any old seals or fittings that may be present. This step ensures a fresh and secure connection.

Connection Process: Start by attaching the fuel line to the fuel tank outlet. Use the appropriate fitting and ensure it is tightened securely. Then, connect the other end of the fuel line to the carburetor inlet. Again, use the correct fitting and tighten it firmly. Pay attention to the orientation of the fuel line to avoid kinks or twists that could restrict fuel flow.

Sealing and Protection: To prevent fuel leaks, it's crucial to use the right seals. Insert the provided seals into the fuel line connections and ensure they are snugly fitted. Over-tightening can damage the fuel line, so use the appropriate torque settings for the fittings. Additionally, consider using fuel line protectors or sleeves to safeguard against damage during installation and operation.

Testing and Maintenance: After connecting the fuel line, start the chainsaw and let it run for a few minutes. Check for any signs of fuel leaks around the connections. If no leaks are found, test the chainsaw's performance to ensure it runs smoothly. Regularly inspect the fuel line connections and replace any worn-out seals or fittings to maintain a reliable fuel supply. Proper maintenance will contribute to the longevity of your Craftsman chainsaw.

Wire-Lined Fuel Lines: Essential or Overkill?

You may want to see also

Fuel Line Protection: Protect the fuel line from damage with sleeves or shields, especially in areas with debris or vibration

When working on your Craftsman chainsaw, it's crucial to prioritize the protection of the fuel line to ensure optimal performance and longevity. The fuel line is a critical component that delivers gasoline to the engine, and any damage to it can lead to costly repairs or even render the chainsaw inoperable. Here's a comprehensive guide on how to safeguard your fuel line:

Understanding the Fuel Line's Vulnerability: The fuel line is a delicate component that can be susceptible to various forms of damage. Common issues include kinking, crushing, or puncturing, which can occur during the installation process or due to external factors. In areas with dense foliage, debris, or underbrush, the risk of damage is significantly higher. Additionally, vibration from the chainsaw's engine can also take a toll on the fuel line over time.

Implementing Fuel Line Sleeves: One effective method to protect the fuel line is by using sleeves or protective covers. These sleeves are typically made of durable materials such as rubber or plastic and are designed to slide over the fuel line, providing a barrier against potential hazards. When inserting the fuel line, ensure that the sleeve is securely in place, covering the entire length of the line. This simple yet effective measure can prevent damage from sharp objects, branches, or even accidental impacts.

Shielding the Fuel Line: Consider using shields or protective caps at key points along the fuel line. These shields can be made of metal or sturdy plastic and are designed to fit specific sections of the line. For instance, you can attach a shield near the fuel tank to protect the line from potential impacts during refuelling. Additionally, shields can be installed at the point where the fuel line connects to the carburetor, safeguarding it from debris and vibrations.

Routing the Fuel Line Safely: Proper routing is essential to prevent unnecessary strain and damage. Avoid sharp bends or kinks in the fuel line, as these can restrict flow and potentially cause damage over time. Instead, route the line in a smooth, gentle curve, allowing it to move freely with the engine's vibrations. Use fuel line clips or ties to secure the line in place, ensuring it remains taut and free from any obstructions.

Regular Inspection and Maintenance: Regular maintenance is key to ensuring the fuel line's longevity. Inspect the line periodically for any signs of wear, damage, or debris accumulation. Check for cracks, leaks, or any unusual behavior during operation. By staying proactive and addressing issues early on, you can prevent more significant problems and ensure your Craftsman chainsaw operates efficiently.

Fuel Line Routing: A Guide for 2-Stroke Engine Enthusiasts

You may want to see also

Fuel Line Maintenance: Regularly inspect and maintain the fuel line to ensure optimal performance and prevent clogs or leaks

Maintaining the fuel line on your Craftsman chainsaw is an essential part of regular care to ensure it runs smoothly and efficiently. Over time, fuel lines can become susceptible to wear and tear, leading to potential issues such as clogs, leaks, or even fuel contamination. Here's a step-by-step guide to help you with fuel line maintenance:

Start by locating the fuel line, which is typically a flexible tube that connects the fuel tank to the carburetor. It is often black or dark in color and may have a slight bend or kink to it. Inspect the fuel line for any visible signs of damage, such as cracks, punctures, or excessive wear. Look for any signs of fuel leakage around the connections or where the line passes through tight spaces or under the engine. Even small leaks can lead to significant issues over time.

Regularly cleaning the fuel line is crucial to prevent the buildup of dirt, debris, and varnish. Over time, these substances can accumulate and restrict fuel flow, leading to poor performance or even engine stall. You can use a fuel line cleaner, available at most hardware or garden stores, to flush out any contaminants. Connect the cleaner's hose to the fuel line and run it through the system, following the instructions on the cleaner's packaging. This process helps to dissolve and remove any deposits.

After cleaning, it's essential to inspect the fuel line for any signs of damage or wear. Check for any cracks, splits, or areas where the line has become brittle. If you notice any issues, it's best to replace the fuel line to avoid potential leaks or performance problems. You can find replacement fuel lines at your local hardware store or online, ensuring you get the correct size and type for your specific model.

Additionally, pay attention to the condition of the fuel filter, as it works in conjunction with the fuel line to ensure clean fuel reaches the carburetor. Regularly replace the fuel filter according to the manufacturer's recommendations to maintain optimal performance. By following these maintenance steps, you can ensure that your Craftsman chainsaw's fuel system remains in good condition, providing reliable and efficient operation.

Stihl Trimmer Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Frequently asked questions

Inserting the fuel lines into your Craftsman chainsaw is a straightforward process. First, ensure the engine is cool to avoid any burns. Locate the fuel line connection point, usually near the carburetor. Slide the fuel line into the connection, ensuring it is aligned correctly. Secure the line with the provided clamp, tightening it gently to create a snug fit. Test the connection by starting the saw and checking for any leaks.

For optimal performance, it's crucial to use the correct fuel mixture in your Craftsman chainsaw. The standard ratio is 2.6 ounces of gasoline to 1 ounce of oil. Measure the gasoline carefully and add the specified oil volume. Stir the mixture gently to ensure even distribution. Using the correct fuel ratio will enhance engine performance, reduce emissions, and extend the life of your chainsaw.

If your Craftsman chainsaw fails to start, there are a few common troubleshooting steps. Check the fuel lines for any blockages or leaks, ensuring they are properly connected. Inspect the spark plug for wear or damage and replace it if necessary. Verify that the air filter is clean and free of debris. If the saw still doesn't start, check the fuel tank for sufficient fuel and ensure the carburetor is adjusted correctly. Consider consulting the user manual or seeking professional assistance for further guidance.