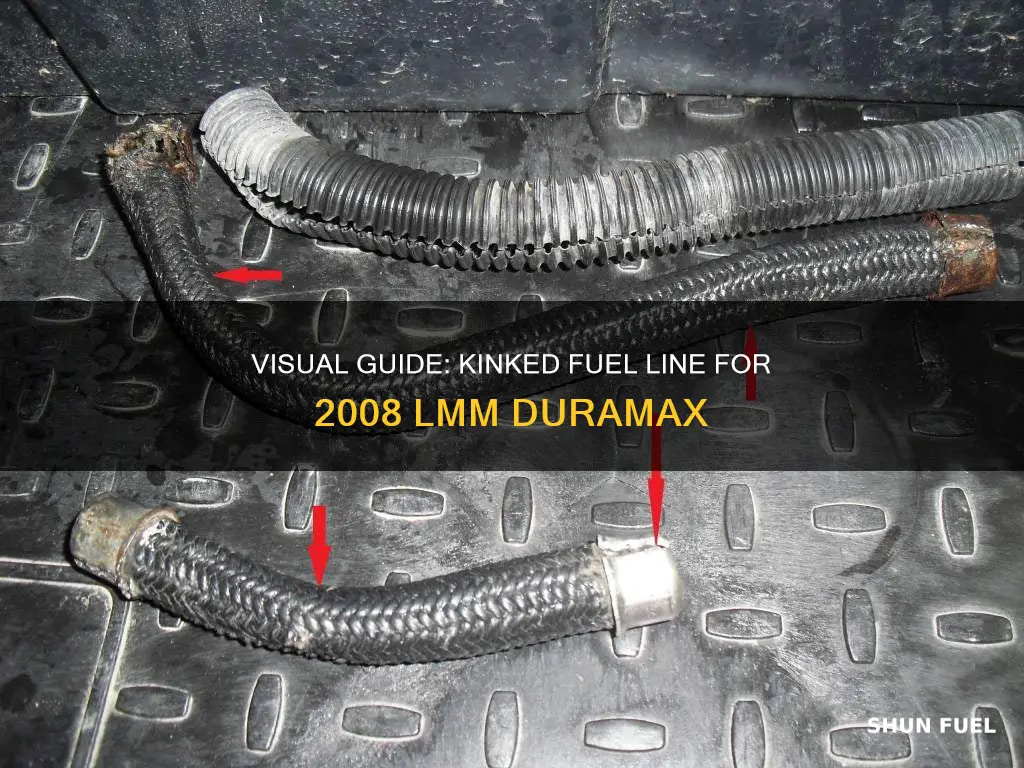

Understanding the appearance of a kinked fuel line on a 2008 LMM Duramax can be crucial for troubleshooting fuel system issues. This paragraph aims to provide an overview of what such a fuel line might look like and how it can be identified. A kinked fuel line on a 2008 LMM Duramax typically appears as a visible bend or kink in the fuel line itself. This kink can be caused by various factors, such as a sharp turn in the fuel line's path, a manufacturing defect, or damage from previous repairs. Identifying this kink is essential because it can lead to reduced fuel flow, engine performance issues, and potential long-term damage to the fuel system. Visual inspection is the primary method to detect a kink, but it may require removing parts of the fuel line to gain a clear view.

| Characteristics | Values |

|---|---|

| Kinked fuel line for 2008 LMM Duramax | The fuel line is designed with a series of kinks or bends to improve fuel flow and reduce pressure drop. |

| Appearance | It typically has a coiled or zigzag pattern, with multiple sharp turns along its length. |

| Material | Common materials include rubber, vinyl, or a flexible plastic compound, chosen for durability and resistance to fuel degradation. |

| Color | Often black or dark gray, matching the typical color of diesel fuel lines. |

| Diameter | Varies depending on the specific application, but is usually around 3/8" to 1/2" in diameter. |

| Length | Customizable, but often ranges from 10 to 20 feet for standard applications. |

| Compatibility | Specifically designed for 2008 Chevrolet Silverado/GMC Sierra trucks equipped with the LMM Duramax diesel engine. |

| Installation | Requires careful routing to avoid sharp bends or kinks that could restrict fuel flow. |

What You'll Learn

- Kinked fuel line appearance: 2008 LMM Duramax fuel line with visible bends and twists

- Fuel line damage: Inspect for kinks, cracks, or leaks affecting fuel delivery

- Line flexibility: Ensure the line remains flexible and doesn't restrict fuel flow

- Line routing: Check if the line is properly routed and secured

- Visual inspection: Look for any signs of corrosion or deterioration

Kinked fuel line appearance: 2008 LMM Duramax fuel line with visible bends and twists

The appearance of a kinked fuel line on a 2008 LMM Duramax can be quite distinctive and should be visually inspected for any potential issues. When examining the fuel line, you'll notice several visible bends and twists along its length. These kinks are often the result of the fuel line being routed through tight spaces or around various engine components. The bends may appear as sharp, 90-degree turns or more gradual curves, depending on the specific design of the vehicle's fuel system.

In some cases, the kinks might be more pronounced, creating a series of sharp angles and twists that are easily visible to the naked eye. These visible bends can be a cause for concern as they may indicate potential pressure points or areas where the fuel line could be more susceptible to damage. Over time, the repeated bending and twisting can lead to wear and tear, potentially causing the fuel line to become brittle or even rupture.

A thorough inspection should reveal the extent of these kinks. Look for any signs of distortion, such as the fuel line appearing bent out of shape or deviating from a straight line. The twists might also cause the fuel line to appear shorter or longer than its actual length, especially if they are not symmetrical. It's important to note that the severity of the kinks can vary depending on the vehicle's usage, maintenance history, and the specific design of the fuel system.

If you notice any unusual wear or damage, it's crucial to address the issue promptly. A qualified mechanic can advise on the best course of action, which may include replacing the fuel line to ensure optimal performance and prevent potential fuel leaks or engine issues. Regular maintenance and inspections can help identify and rectify such problems before they escalate.

Remember, the appearance of a kinked fuel line is a visual indicator of potential underlying issues. While some level of bending is normal, excessive or visible kinks could be a sign of potential fuel system problems. Always consult with a professional for an accurate assessment and guidance on maintaining your vehicle's fuel system.

Understanding Fuel Lines: A1 vs. B1 Differences Explained

You may want to see also

Fuel line damage: Inspect for kinks, cracks, or leaks affecting fuel delivery

When inspecting the fuel lines of a 2008 LMM Duramax, it's crucial to look for any signs of damage that could impact fuel delivery. One of the most common issues is kinking, where the fuel line folds or bends sharply, creating a kink. These kinks can restrict fuel flow, leading to reduced engine performance or even a complete loss of power. To identify kinks, inspect the fuel lines for any sharp bends or folds. Gently straighten the lines if possible to assess the severity of the kink. If the kink is severe, it may be necessary to replace the affected section of the fuel line.

Cracks and leaks are another potential issue. Over time, fuel lines can develop small cracks or leaks due to wear and tear, exposure to heat, or chemical corrosion. These issues can lead to fuel spilling or leaking, which can be dangerous and cause engine misfires or performance issues. Inspect the fuel lines for any visible cracks, especially at connections, bends, and under the vehicle where they are more susceptible to damage. Look for signs of fuel leakage, such as a sweet odor or wet spots on the ground. If you notice any cracks or leaks, it's essential to replace the affected fuel line promptly to prevent further damage and ensure optimal engine performance.

In addition to kinks and cracks, check for any signs of corrosion or deterioration. Fuel lines can be susceptible to corrosion, especially if they are made of metal. Look for any rust or oxidation on the fuel lines, particularly in areas where they are exposed to the elements. Corroded fuel lines may need to be replaced to ensure proper fuel delivery. It's also a good idea to inspect the fuel lines for any signs of damage caused by previous repairs or modifications. If you notice any discrepancies or signs of previous work, it's best to have a professional mechanic inspect and address the issue.

During the inspection, pay close attention to the connections and fittings. These areas are prone to developing leaks or becoming loose over time. Ensure that all connections are tight and secure. If you find any loose fittings, tighten them appropriately or consider replacing the fittings if they are damaged. Regularly checking and tightening these connections can prevent fuel leaks and ensure a reliable fuel supply to the engine.

Remember, proper maintenance and regular inspections are key to keeping your 2008 LMM Duramax in top condition. By carefully examining the fuel lines for kinks, cracks, leaks, and other signs of damage, you can identify potential issues early on and take the necessary steps to address them. This proactive approach will help ensure optimal engine performance and prevent unexpected breakdowns.

Clean Fuel: Tips for Removing Excess Carbon from Your Lines

You may want to see also

Line flexibility: Ensure the line remains flexible and doesn't restrict fuel flow

When it comes to the fuel lines in a 2008 LMM Duramax, ensuring line flexibility is crucial to maintaining optimal performance and preventing fuel flow restrictions. The fuel lines on this vehicle are designed to be flexible, allowing for easy movement and accommodating various engine positions during operation. This flexibility is essential to avoid any kinking or bending that could impede the flow of fuel, leading to potential performance issues.

One way to ensure line flexibility is to inspect the fuel lines regularly for any signs of wear and tear. Over time, fuel lines can develop cracks, brittleness, or damage from engine vibrations. These issues can cause the lines to become stiff and restrict fuel flow. It is recommended to check for any visible damage, such as cracks, punctures, or frayed ends, and replace any affected lines promptly. Additionally, paying attention to the routing of the fuel lines is vital. Properly securing and routing the lines to avoid sharp bends or kinks can help maintain their flexibility.

Another important aspect is the use of appropriate fuel line materials. The 2008 LMM Duramax likely utilizes fuel lines made from high-quality materials that offer flexibility without compromising durability. These materials should be able to withstand the high-pressure environment within the fuel system while remaining pliable. When replacing or upgrading fuel lines, ensure that you select compatible materials that meet the vehicle's specifications to guarantee optimal performance and longevity.

Furthermore, maintaining a clean and clutter-free engine bay is essential for line flexibility. Accumulated dirt, debris, or other contaminants can cause the fuel lines to become entangled or restricted. Regularly cleaning the engine bay and ensuring that the fuel lines are free from any obstructions will help maintain their flexibility and prevent potential fuel flow issues.

In summary, to ensure the fuel lines in a 2008 LMM Duramax remain flexible and do not restrict fuel flow, regular inspections for wear and tear, proper routing, the use of suitable materials, and maintaining a clean engine bay are essential practices. By following these guidelines, you can help optimize the performance of your Duramax and ensure a reliable fuel supply to the engine.

Fixing Fuel Lines: The Role of RTV

You may want to see also

Line routing: Check if the line is properly routed and secured

When inspecting the fuel line on a 2008 LMM Duramax, proper line routing is crucial for optimal performance and longevity. The fuel line should be routed in a way that avoids sharp bends or kinks, as these can restrict fuel flow and potentially cause damage over time. A common issue with older Duramax engines is the fuel line becoming kinked due to its position near the engine block or other components. Here's a step-by-step guide to ensure the fuel line is correctly routed and secured:

- Visual Inspection: Start by visually examining the fuel line. Look for any visible kinks, bends, or twists that might indicate improper routing. The line should appear smooth and straight, especially where it connects to the fuel pump and injectors. Check for any signs of wear or damage, such as cracks or leaks, as these could be caused or exacerbated by poor routing.

- Secure Mounting: Ensure the fuel line is securely mounted at various points along its length. It should be attached to the engine block, chassis, or other structural components using appropriate brackets or ties. These mounting points should be positioned to allow for slight movement, accommodating the engine's natural vibrations without causing stress on the line. Regularly inspect these mounting points to ensure they remain tight and secure over time.

- Clearance and Space: Verify that the fuel line has adequate clearance from moving parts and hot surfaces. It should not be in contact with engine components that could cause damage or restrict movement. Allow sufficient space for the line to move freely without any potential interference. This is particularly important near the engine's front and rear ends, where movement is more pronounced.

- Bending Radius: Maintain a consistent bending radius throughout the fuel line's length. Avoid sharp bends that could lead to kinking or damage. The line should be bent gradually, ensuring that the radius of curvature is sufficient to prevent any potential issues. This is especially critical where the line connects to the fuel pump and injectors, as sharp bends here can restrict fuel flow and impact engine performance.

- Regular Maintenance: Implement a regular maintenance routine to inspect and adjust the fuel line's routing as needed. Over time, the line may shift or loosen due to engine movement or other factors. Periodically check for any changes in the line's position or condition, making adjustments to ensure it remains properly routed and secured. This proactive approach can help prevent issues related to kinking and ensure the engine's long-term reliability.

Finding the Perfect Fuel Line Hose for Your 500HP Engine

You may want to see also

Visual inspection: Look for any signs of corrosion or deterioration

When performing a visual inspection of the fuel line on your 2008 LMM Duramax, it's crucial to look for any signs of corrosion or deterioration. These signs can often indicate potential issues with the fuel system and should be addressed promptly to prevent further damage. Here's a detailed guide on what to look for:

Start by examining the fuel line for any visible corrosion or rust. Over time, fuel lines can develop a layer of corrosion, especially if they are exposed to moisture or have been damaged. Look for discolored or flaky areas along the length of the line. The corrosion might appear as a white, orange, or brown powder-like substance or as a rough, textured surface. If you notice any of these signs, it's essential to replace the fuel line immediately.

Check for any cracks or splits in the fuel line's outer casing. These defects can allow fuel to leak out, leading to potential safety hazards and engine performance issues. Inspect the line for any visible breaks, especially at bends or points where the line is secured. Cracks might be more challenging to spot, so a magnifying glass can be useful for a thorough examination.

Look for any signs of deterioration at the connections and fittings. These areas are prone to wear and tear, and damage here can lead to fuel leaks. Inspect the fittings for any signs of corrosion or damage, and ensure that they are tight and secure. If you notice any loose connections or corrosion around the fittings, it's recommended to replace the fuel line to prevent potential fuel loss.

Pay attention to the overall condition of the fuel line. If the line appears brittle, cracked, or discolored, it may be beyond repair and should be replaced. The fuel line should be flexible but not brittle, and it should not show any signs of cracking or splitting. If you notice any of these issues, it's best to consult a professional mechanic for advice.

Remember, regular visual inspections are essential for maintaining your vehicle's performance and safety. By keeping an eye out for corrosion, cracks, and other signs of deterioration, you can ensure that your 2008 LMM Duramax's fuel system remains reliable and efficient.

The Ultimate Guide to Propane Fuel Line Manufacturers

You may want to see also

Frequently asked questions

A kinked fuel line on a 2008 LMM Duramax typically appears as a visible bend or kink in the fuel line itself. This kink can be a result of various factors such as improper installation, damage during transportation, or even normal wear and tear over time. It may be noticeable as a sharp change in the line's direction, often causing a visible bulge or twist in the fuel line's path.

Identifying a kinked fuel line can be done through visual inspection. Look for any visible bends, twists, or kinks along the length of the fuel line. It might be more apparent when the engine is running, as the fuel line may expand or contract, making the kink more noticeable. Additionally, check for any signs of fuel leakage or reduced fuel flow, as these could be indicators of a kinked fuel line.

A kinked fuel line can lead to several issues. It may restrict fuel flow, causing reduced engine performance, rough idling, or even stalling. Over time, the kink can cause fuel to accumulate in the line, leading to potential fuel-related problems. In some cases, a kinked fuel line can also cause fuel to leak, which can be a safety hazard and may require immediate attention.

Fixing a kinked fuel line involves carefully straightening the line to remove the kink. Ensure you do this gently to avoid further damage. If the fuel line is severely damaged or kinked multiple times, it is best to replace it with a new one. Consult a professional mechanic or refer to the vehicle's manual for specific instructions on replacing the fuel line to ensure proper installation and avoid any further complications.