Cutting metal fuel lines requires precision and care to ensure a safe and effective repair. This process involves using specialized tools and techniques to carefully sever the metal line, allowing for the installation of a replacement or repair of an existing line. It is crucial to follow safety protocols and use appropriate protective gear when handling metal fuel lines to prevent accidents and ensure the integrity of the fuel system. Understanding the specific requirements and challenges of cutting metal fuel lines is essential for any mechanic or DIY enthusiast looking to tackle this task.

What You'll Learn

- Safety Gear: Wear protective clothing and safety glasses to shield against sparks and debris

- Line Material: Choose the right metal fuel line material for the application, considering durability and flexibility

- Cutting Tools: Utilize a metal-cutting torch or a band saw for precise and clean cuts

- Safety Precautions: Ensure proper ventilation and follow safety protocols to avoid gas leaks

- Line Routing: Plan the route of the fuel line, considering accessibility and potential obstructions

Safety Gear: Wear protective clothing and safety glasses to shield against sparks and debris

When cutting metal fuel lines, prioritizing safety is paramount. One of the most critical aspects of this process is wearing the appropriate protective gear to safeguard against potential hazards. Here's a detailed guide on why and how to use safety gear:

Protective Clothing:

- Opt for heavy-duty leather gloves designed for heat and abrasion resistance. Metal fuel lines can generate sparks during the cutting process, and these gloves will provide essential protection for your hands.

- Wear long-sleeved shirts and pants made from fire-resistant materials. This clothing acts as a barrier, preventing sparks and hot metal fragments from coming into direct contact with your skin.

- Consider a full-body suit if the fuel line is in a particularly hazardous location or if there's a risk of flying debris.

Safety Glasses:

- Safety glasses are essential to protect your eyes from potential hazards. Metal cutting can produce sparks and small metal particles that may fly in various directions.

- Look for safety glasses with impact-resistant lenses and side shields to ensure comprehensive eye protection.

- Ensure the glasses fit comfortably over your prescription eyewear, if applicable, to maintain clear vision during the cutting process.

The primary purpose of wearing this safety gear is to minimize the risk of injury from sparks, flying debris, and hot metal. Metal fuel lines can become extremely hot during cutting, and the debris generated can cause severe cuts or burns. By donning the appropriate protective clothing and safety glasses, you create a safer working environment, reducing the likelihood of accidents and ensuring a more controlled cutting process. It is a simple yet crucial step in maintaining personal safety when working with metal fuel lines.

Air in Fuel Line: Causes, Effects, and Solutions

You may want to see also

Line Material: Choose the right metal fuel line material for the application, considering durability and flexibility

When it comes to choosing the right metal fuel line material, durability and flexibility are key considerations. Metal fuel lines are an essential component in any vehicle's fuel system, responsible for transporting fuel from the tank to the engine. The material used must be able to withstand the rigors of this role, including high temperatures, pressure, and exposure to corrosive substances.

One of the most common materials for metal fuel lines is stainless steel. This material is highly durable and resistant to corrosion, making it an excellent choice for fuel lines. Stainless steel can handle high temperatures and pressure without compromising its structural integrity. It is also flexible enough to navigate through tight spaces and bends in the vehicle's frame. The use of stainless steel ensures that the fuel lines remain reliable and long-lasting, even in harsh operating conditions.

Another option is aluminum, which offers a good balance of durability and flexibility. Aluminum fuel lines are lightweight, making them ideal for vehicles where weight reduction is a priority. They are also resistant to corrosion and can withstand high temperatures. However, aluminum may not be as flexible as stainless steel, so careful consideration of the vehicle's design is necessary to ensure proper installation.

For applications requiring even higher flexibility, brass or copper can be considered. These materials are more malleable, allowing for easier bending and installation. However, they may not be as durable as stainless steel or aluminum and can be more susceptible to corrosion over time. In such cases, a protective coating or lining might be necessary to ensure longevity.

In summary, when selecting the material for metal fuel lines, it is crucial to evaluate the specific requirements of the application. Stainless steel is often the go-to choice for its exceptional durability and resistance to corrosion. Aluminum provides a lightweight alternative with good temperature resistance. For maximum flexibility, brass or copper may be suitable, but additional considerations for corrosion protection should be made. The right choice will ensure the fuel lines perform reliably and efficiently, contributing to the overall performance and safety of the vehicle.

Mastering Harbor Freight Fuel Line Disconnect: A Comprehensive Guide

You may want to see also

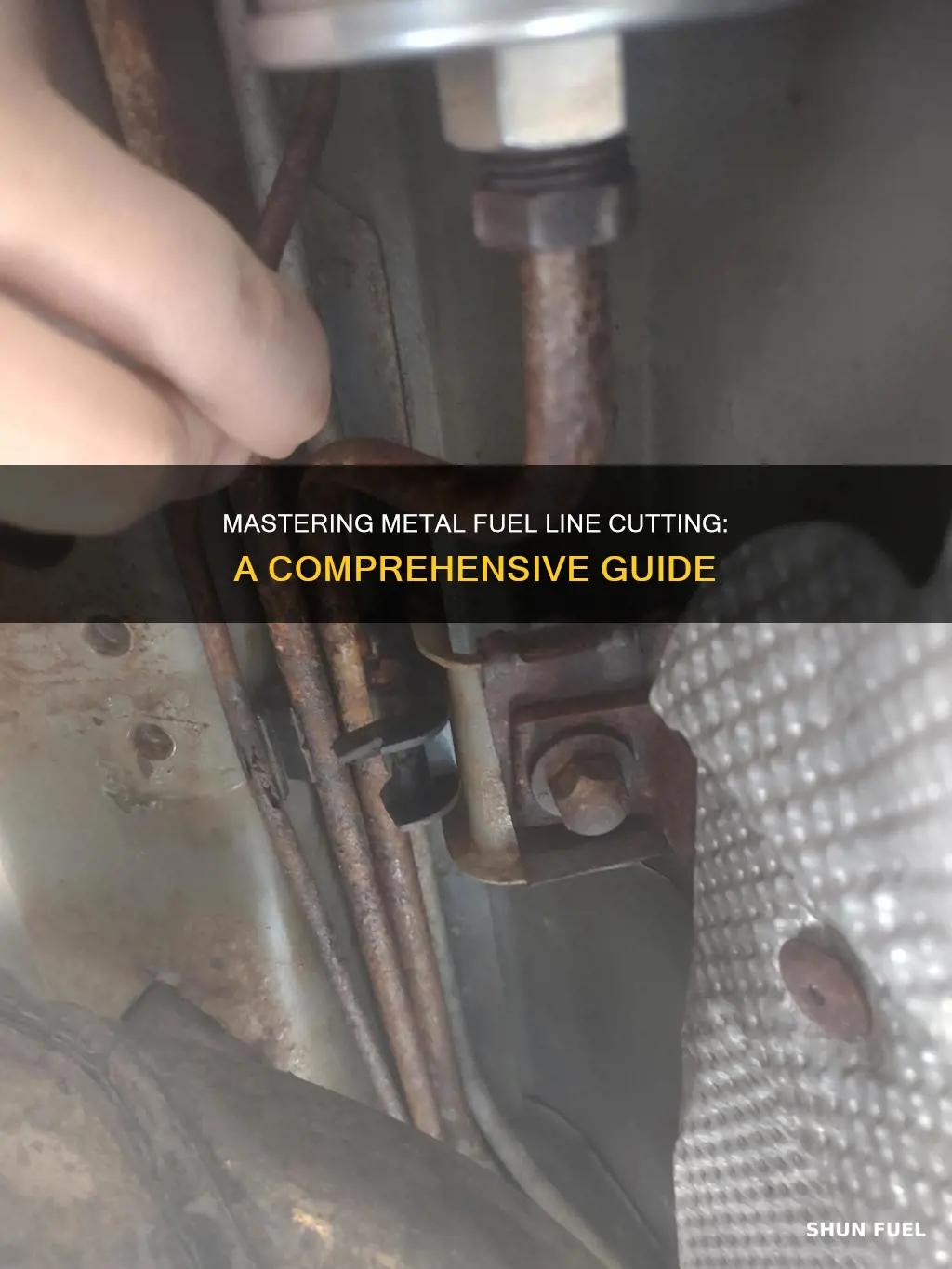

Cutting Tools: Utilize a metal-cutting torch or a band saw for precise and clean cuts

When it comes to cutting metal fuel lines, precision and safety are paramount. Utilizing the right tools and techniques can make the process efficient and minimize the risk of damage or injury. One of the most effective methods for cutting metal fuel lines is by using a metal-cutting torch or a band saw. These tools are specifically designed to handle the challenges of cutting through metal, ensuring clean and accurate results.

A metal-cutting torch, also known as a gas torch, is a versatile and powerful tool for this task. It operates using a fuel-air mixture, typically propane or natural gas, which is ignited to produce a high-temperature flame. The flame's heat is intense enough to melt and cut through metal, making it ideal for fuel line installations and repairs. To use a metal-cutting torch, you'll need to follow these steps: First, ensure you have the necessary safety gear, including heat-resistant gloves and a face shield. Then, position the torch at a comfortable angle and ignite it, adjusting the flame to the desired size and heat. Carefully guide the torch along the fuel line, applying consistent pressure to achieve a clean cut. Remember to work slowly and steadily to avoid overheating or damaging the surrounding area.

Alternatively, a band saw is another excellent option for cutting metal fuel lines, especially for more intricate or curved cuts. Band saws use a continuous band of toothed metal to make precise cuts, offering a clean and smooth finish. Here's a step-by-step guide: Begin by securing the fuel line firmly on a stable work surface. Set the band saw's speed and depth of cut according to the metal's thickness. Carefully guide the band saw along the fuel line, maintaining a steady pressure to ensure a straight and accurate cut. For curved or complex shapes, you can adjust the band's tension and angle to achieve the desired result. Always prioritize safety by wearing protective gear and ensuring proper ventilation when using a band saw.

Both metal-cutting torches and band saws require practice and skill to master. It's essential to understand the properties of the metal you're working with and the specific requirements of your project. For instance, thicker metal fuel lines may require more powerful tools and careful heat management to prevent warping or damage. Additionally, always ensure that the work area is well-ventilated and free from flammable materials to maintain a safe environment.

In summary, cutting metal fuel lines can be efficiently accomplished using metal-cutting torches or band saws. These tools provide the precision and control needed to make clean, accurate cuts. By following the outlined steps and prioritizing safety, you can successfully navigate this task, ensuring a professional-looking finish for your fuel line installation or repair. Remember, practice and experience will refine your skills, allowing you to tackle more complex metal-cutting projects with confidence.

Locate the Fuel Line: A Guide to Craftsman Chain Saw Maintenance

You may want to see also

Safety Precautions: Ensure proper ventilation and follow safety protocols to avoid gas leaks

When working with metal fuel lines, ensuring proper ventilation and adhering to safety protocols are crucial to prevent gas leaks and potential hazards. Here are some essential safety precautions to keep in mind:

Ventilation is key to maintaining a safe working environment. Before starting any cutting or modification of the fuel line, ensure that the area is well-ventilated. Open windows and doors to allow fresh air circulation. If working in a confined space, such as a garage or basement, use a powerful exhaust fan to remove any harmful fumes. Proper ventilation helps to disperse volatile organic compounds (VOCs) and other hazardous gases, reducing the risk of inhalation and potential health issues.

Always wear appropriate personal protective equipment (PPE) to minimize exposure to potential hazards. This includes heat-resistant gloves, safety goggles, and a respirator mask designed for gas protection. These items create a barrier between your body and any harmful substances that may be released during the cutting process. Ensure that the PPE is properly fitted and comfortable to encourage consistent use.

Before cutting the metal fuel line, inspect it for any signs of damage, corrosion, or wear. Look for cracks, holes, or any areas where the metal may be compromised. If you notice any issues, do not proceed with the cutting process. Instead, contact a professional mechanic or plumber to assess and repair the fuel line safely. Working with damaged lines can lead to gas leaks and potential fire hazards.

When cutting the fuel line, use a sharp, clean tool designed for metal cutting, such as a metal shear or a sharp pair of scissors. Avoid using rusty or dull tools that may cause uneven cuts and increase the risk of gas leakage. Take your time and make precise cuts to ensure a clean and safe connection. If you are unsure about the cutting technique, consult online tutorials or seek guidance from experienced professionals.

After cutting the fuel line, it is essential to properly manage the ends to prevent gas leaks. Use a suitable primer or sealant designed for fuel lines to coat the exposed metal surfaces. This step helps to create a barrier and prevent the metal from oxidizing, which could lead to corrosion and potential leaks. Additionally, ensure that all connections are tightened securely and checked for tightness to maintain a safe and leak-free system.

Remember, safety should always be the top priority when working with fuel lines. By following these precautions and staying vigilant, you can minimize the risks associated with gas leaks and ensure a secure and efficient fuel system.

Safe and Effective Methods to Thaw Frozen Car Fuel Lines

You may want to see also

Line Routing: Plan the route of the fuel line, considering accessibility and potential obstructions

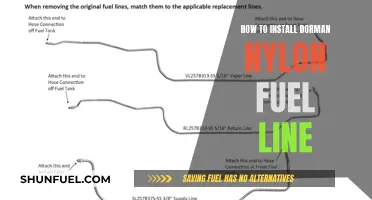

When planning the route for a metal fuel line, it's crucial to prioritize accessibility and safety. The goal is to ensure that the line is easily accessible for maintenance and repairs while also avoiding potential hazards. Here's a step-by-step guide to help you plan the optimal route:

- Assess the Vehicle's Layout: Begin by thoroughly examining the vehicle's interior and engine compartment. Identify the current positions of various components, such as the fuel tank, engine, and any existing fuel lines. Understanding the layout will help you determine the most logical path for the new fuel line. Look for areas with minimal obstructions and easy access points.

- Consider Accessibility: Aim for a route that provides easy access for future maintenance. Avoid running the fuel line through tight spaces or areas that might become difficult to reach over time. For example, consider placing the line in a location where you can easily inspect and service the connections without removing other components.

- Avoid Obstructions and Hazards: Carefully plan the route to steer clear of potential obstacles. This includes engine components, suspension parts, and any other moving parts that could interfere with the fuel line's movement. Additionally, ensure the line doesn't run parallel to areas where heat or vibration might cause damage. For instance, avoid routing the line near exhaust pipes or under the engine's hot surfaces.

- Use Appropriate Support: To maintain the integrity of the metal fuel line, consider using appropriate support structures. This could include metal brackets or clips that secure the line in place, preventing it from sagging or coming loose over time. Proper support will also help maintain the line's flexibility and reduce the risk of damage.

- Document and Verify: Once you've planned the route, create detailed documentation of your decisions. Include measurements, diagrams, and notes on the chosen path. This documentation will be invaluable during the cutting and installation process, ensuring that you stay on track and maintain the desired accessibility and safety standards.

By following these steps, you can create a well-planned fuel line route that is both functional and easy to maintain, ensuring the long-term reliability of your vehicle's fuel system. Remember, proper planning will make the cutting and installation process smoother and safer.

Fuel Line Conversion: 5 mm to Inches Explained

You may want to see also

Frequently asked questions

Cutting a metal fuel line requires caution and the right tools. Always wear protective gear, including gloves and safety goggles. Use a sharp, clean pair of metal shears or a fuel line cutter to make a precise cut. Ensure the line is disconnected from the fuel source and the engine is off before cutting.

For cutting metal fuel lines, it's recommended to use a heavy-duty metal shear with a sharp blade. Look for shears designed for metal fuel line work, often made with high-carbon steel for durability. Ensure the shear has a comfortable grip and a locking mechanism to control the cutting force.

No, standard scissors are not suitable for cutting metal fuel lines. Metal fuel lines are thick and rigid, and regular scissors may not provide enough leverage or precision. Using the wrong tool can lead to uneven cuts or damage to the line, potentially causing fuel leaks.

If the metal fuel line is damaged and cannot be repaired, it should be replaced immediately. Start by disconnecting the line from the fuel tank and the engine. Measure the length of the damaged section and purchase a replacement line with the same specifications. Ensure a proper fit by using fuel line connectors and following the manufacturer's instructions for a secure connection.