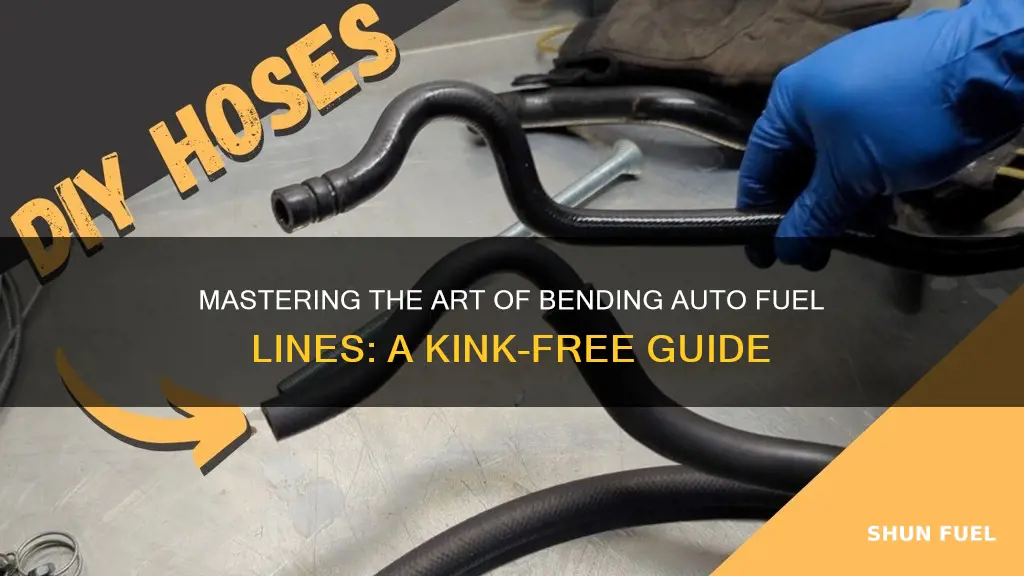

Bending fuel lines for your vehicle can be a delicate task, and one of the most common issues encountered is kinking, which can lead to fuel leaks and other problems. To avoid this, it's essential to follow the right techniques. This guide will provide you with a step-by-step process to bend auto fuel lines without kinking, ensuring a secure and reliable connection. By using the appropriate tools and following these instructions, you can achieve a smooth, kink-free bend that will stand the test of time.

What You'll Learn

- Materials: Choose flexible, durable materials like rubber or plastic for fuel lines

- Bending Tools: Use pliers or a fuel line bender for precise bends

- Angle and Radius: Aim for a 90-degree bend with a smooth, gradual radius

- Support: Secure the line with tape or clips to prevent kinking

- Testing: Inspect bends for kinks and ensure proper flow before installation

Materials: Choose flexible, durable materials like rubber or plastic for fuel lines

When it comes to bending auto fuel lines without causing kinks, the choice of materials is crucial. Opt for flexible and durable materials such as rubber or plastic to ensure a smooth and secure bend. These materials possess inherent flexibility, allowing for easy bending without compromising the structural integrity of the fuel line. Rubber, in particular, is renowned for its elasticity and ability to withstand various temperatures, making it an ideal choice for fuel lines. Its natural resilience reduces the likelihood of kinks, ensuring a consistent and reliable flow of fuel.

Plastic, another excellent option, offers a lightweight and flexible alternative. It is highly resistant to corrosion and chemical degradation, ensuring the longevity of the fuel line. Modern plastics, such as high-density polyethylene (HDPE), provide exceptional flexibility and durability, making them a popular choice for automotive applications. These materials are designed to mimic the natural flexibility of rubber, allowing for smooth bends without the risk of kinking.

The key advantage of using rubber or plastic is their ability to absorb and distribute stress evenly. When bending a fuel line, these materials can conform to the desired shape while maintaining their structural integrity. Unlike rigid materials, rubber and plastic can 'give' slightly, reducing the concentration of stress at any single point, which is essential to prevent kinks and potential fuel leaks.

Additionally, consider the thickness and wall gauge of the material. Thicker walls provide more structural support and can withstand higher pressure, making them suitable for high-performance vehicles. However, thinner walls might offer better flexibility, especially in tight spaces. The choice depends on the specific requirements of your vehicle and the desired level of flexibility.

In summary, selecting flexible and durable materials like rubber or plastic is a fundamental step in bending auto fuel lines without kinking. These materials offer the necessary flexibility, resilience, and resistance to stress, ensuring a secure and reliable fuel line installation. By understanding the properties of these materials, you can make an informed decision to optimize the performance and longevity of your vehicle's fuel system.

Fuel Line Sizing Guide: Perfect Fit for Your SSR Pit Bike

You may want to see also

Bending Tools: Use pliers or a fuel line bender for precise bends

When working with auto fuel lines, it's crucial to avoid kinks and sharp bends to ensure a smooth flow of fuel and prevent potential issues. One effective method to achieve this is by utilizing specific bending tools, such as pliers or a fuel line bender. These tools provide the necessary precision and control to create clean, kink-free bends.

Pliers are a versatile option for bending fuel lines. They offer a simple yet effective approach. Start by positioning the pliers around the desired bend point, ensuring a firm grip on the fuel line. Apply gentle pressure and twist the pliers to create a smooth bend. It's important to work slowly and steadily to avoid putting excessive force on the line, which could lead to kinking. Practice and patience are key when using pliers for bending.

For more intricate and precise bends, a fuel line bender is a specialized tool that can be highly beneficial. These benders are designed to create consistent and controlled bends without causing damage to the fuel line. To use a fuel line bender, position the tool around the bend point, ensuring it fits snugly around the line. Apply pressure and rotate the bender to create the desired bend. The bender's design often includes markings or guides to help you achieve the correct angle and curvature.

When using either pliers or a fuel line bender, it's essential to consider the material of the fuel line. Different materials may require varying levels of force and techniques. For example, some fuel lines might be more flexible and can be bent by hand with gentle pressure, while others may require the use of tools to avoid damage. Always refer to the manufacturer's guidelines for the specific fuel line you are working with.

In summary, employing the right bending tools is crucial for successfully navigating auto fuel lines without causing kinks. Pliers provide a simple and accessible method, while fuel line benders offer precision and control for more complex bends. By utilizing these tools and understanding the material properties of the fuel line, you can ensure a smooth and efficient fuel system in your vehicle.

Nylon Fuel Line Lifespan: Unveiling the Ultimate Durability

You may want to see also

Angle and Radius: Aim for a 90-degree bend with a smooth, gradual radius

When bending an auto fuel line, achieving the right angle and radius is crucial to prevent kinking and ensure a smooth flow of fuel. The ideal goal is to create a 90-degree bend with a gradual and smooth radius, avoiding sharp turns that could lead to kinks and potential fuel flow issues.

To achieve this, start by identifying the desired bend point on the fuel line. Mark this point with a pen or a small piece of tape to guide your bending process. Then, using a pair of adjustable pliers or a fuel line bending tool, begin to apply pressure and gradually bend the line. The key is to move the bending process slowly and steadily, ensuring that the radius of the bend increases gradually as you approach the 90-degree mark. This gradual increase in radius prevents the formation of sharp corners that could lead to kinking.

As you near the 90-degree angle, maintain a consistent pressure and continue to increase the radius smoothly. Avoid applying excessive force, as this can cause the fuel line to crimp or fold over itself, leading to potential damage or kinking. Instead, focus on using controlled pressure and a steady hand to create the desired bend.

Once you've reached the 90-degree angle, ensure that the bend is consistent and uniform. Check that there are no sharp creases or folds in the fuel line, as these could restrict fuel flow or cause damage over time. Smooth out any uneven bends by carefully adjusting the pliers or tool and re-bending the line.

Remember, the goal is to create a seamless transition from the straight section of the fuel line to the bend, with a smooth and gradual radius. This technique will help prevent kinking and ensure the longevity of the fuel line while maintaining optimal fuel flow to the engine.

Signs of a Clogged Fuel Line: What to Look For

You may want to see also

Support: Secure the line with tape or clips to prevent kinking

When working with auto fuel lines, ensuring they are bent without kinking is crucial for the system's functionality and safety. One effective method to achieve this is by securing the fuel line with tape or clips. This simple yet essential step can significantly reduce the likelihood of kinking, especially when the line is bent around sharp corners or through tight spaces.

Start by identifying the section of the fuel line that needs bending. It's important to choose a point where the line is relatively straight and free from any existing bends. This initial straight section will serve as the anchor for the bend. Once identified, use a sharp, flat tool, such as a screwdriver or a utility knife, to carefully score the line along the desired bend path. This scoring will help guide the bending process and ensure a more precise bend.

Next, apply a small amount of fuel line compound or a similar lubricant to the scored area. This step is crucial as it reduces friction and makes it easier to bend the line without causing damage or kinking. Take your time with this process, ensuring the lubricant is evenly distributed along the scored length.

Now, it's time to bend the line. Use your hands or a pair of pliers to apply gentle pressure and start bending the line along the scored path. Maintain a consistent and controlled force to avoid putting too much pressure on any one spot, which could lead to kinking. As you bend the line, it's essential to keep it as straight as possible to minimize the risk of kinking.

Once the desired bend is achieved, secure the line in place using tape or clips. Electrical tape or duct tape is a common choice for this purpose. Wrap the tape around the bent section, ensuring it is tightly secured and covers the entire bend. Alternatively, small clips or ties specifically designed for fuel lines can be used. These clips are often more convenient and provide a more permanent solution. When using clips, ensure they are positioned to avoid any potential interference with other components.

By following these steps and securing the fuel line with tape or clips, you can effectively prevent kinking and ensure a smooth, functional bend. This method is particularly useful when dealing with older vehicles or custom fuel line installations, where precision and attention to detail are essential. Remember, taking the time to secure the line properly will pay off in the long run, as it will help maintain the integrity of your vehicle's fuel system.

Fuel Return Line: Essential or Overrated?

You may want to see also

Testing: Inspect bends for kinks and ensure proper flow before installation

When working with auto fuel lines, it's crucial to ensure that the bends are not only aesthetically pleasing but also functional and safe. One of the primary concerns during the bending process is avoiding kinks, as these can restrict fuel flow and potentially lead to engine performance issues. Here's a detailed guide on how to inspect and test the bends for kinks and ensure proper flow before installation:

Visual Inspection: Begin by carefully examining the bent fuel line. Look for any visible signs of kinking, such as sharp bends, sharp corners, or any part of the line that appears compressed or folded. Kinks can occur at the point of bending or along the length of the line due to improper handling. Use a bright light or a flashlight to illuminate the area and ensure you can see any potential issues clearly. Pay attention to the entire length of the line, especially where it connects to fuel tanks, pumps, and injectors.

Flexibility Test: Assess the flexibility of the bent fuel line. Kinks can make the line stiff and less flexible, which may lead to issues during installation and operation. Gently try to bend the line at various points along its length to check for any resistance or rigidity. A kinked section should feel different from the rest of the line, often being stiffer and less pliable. If you encounter any kinks, carefully straighten them out and re-bend the line using a proper bending technique to avoid further kinking.

Flow Test: Proper fuel flow is essential for engine performance. Conduct a flow test to ensure that the bent fuel line allows for smooth and unrestricted fuel movement. You can use a fuel pressure gauge to measure the pressure at different points along the line. Start at the fuel source and work your way towards the engine, checking for consistent pressure. Any significant drops in pressure could indicate a kink or restriction in the line. Additionally, you can use a transparent section of the line to visually inspect the flow, ensuring that there are no blockages or obstructions.

Pressure Test: Perform a pressure test to further validate the integrity of the bent fuel line. Connect a pressure gauge to the line and apply a measured amount of pressure. Observe the gauge for any drops or fluctuations in pressure, which could indicate a weak point or kink. This test is especially important if the fuel line will be subjected to varying pressures during engine operation. Ensure that the line can withstand the expected pressure without any signs of distress or kinking.

Documentation and Record-Keeping: Maintain detailed records of the bending and testing process. Note the techniques used, the locations of bends, and any issues encountered during inspection and testing. This documentation will be valuable for future reference, especially when troubleshooting or replacing fuel lines. It also ensures that you can consistently achieve the desired results and maintain the integrity of the fuel system.

By following these testing procedures, you can ensure that the auto fuel line is free from kinks and ready for a smooth installation, contributing to optimal engine performance and reliability.

Polaris Fuel Line Connections: A Comprehensive Guide

You may want to see also

Frequently asked questions

Bending a fuel line requires careful consideration to avoid kinks, which can restrict fuel flow and potentially cause engine issues. Start by ensuring the line is not under tension and is supported at regular intervals. Use a fuel line bender or a flexible metal tube to guide the bend, applying gentle pressure to create a smooth curve. Avoid sharp bends and always follow the manufacturer's guidelines for your specific fuel line type.

Before bending, ensure the fuel line is clean and free of any debris or contaminants. Use a fuel line cleaner or a mild detergent to remove any built-up residue. This step is crucial to prevent any blockages or contamination of the fuel system. Additionally, inspect the line for any existing damage and mark the points where you plan to bend it to maintain consistency.

Using the right tools is essential for a successful bend without kinking. Consider investing in a fuel line bender, which is designed to create smooth bends without causing damage. You can also use a flexible metal tube or a pair of pliers, but ensure they are the appropriate size for the fuel line diameter. Always choose tools that provide a controlled and gradual bending process to minimize the risk of kinks.

Reusing a kinked fuel line is not recommended as it can lead to long-term issues. Kinks can cause fuel restrictions, leading to reduced engine performance or even starting difficulties. If a fuel line kinks, it's best to replace it to ensure optimal engine operation and prevent potential safety hazards. Regularly inspect your fuel lines and address any bends or kinks promptly to maintain a reliable fuel system.