The Yamaha Superjet is a high-performance aircraft renowned for its sleek design and powerful engine. Understanding the fuel lines' route is crucial for maintaining the jet's optimal performance. The fuel system is a complex network, and the lines play a vital role in delivering fuel from the tank to the engine. This paragraph will explore the intricate path of the fuel lines, highlighting their significance in ensuring the Superjet's efficient operation and overall safety.

What You'll Learn

- Fuel System Overview: The route of fuel lines from the tank to the engine in a Yamaha Superjet

- Fuel Pump Location: Where the fuel pump is positioned and how it delivers fuel

- Fuel Filters: The role of filters in ensuring clean fuel flow

- Fuel Injectors: How fuel injectors spray fuel into the engine's cylinders

- Return Lines: The path of used fuel back to the tank

Fuel System Overview: The route of fuel lines from the tank to the engine in a Yamaha Superjet

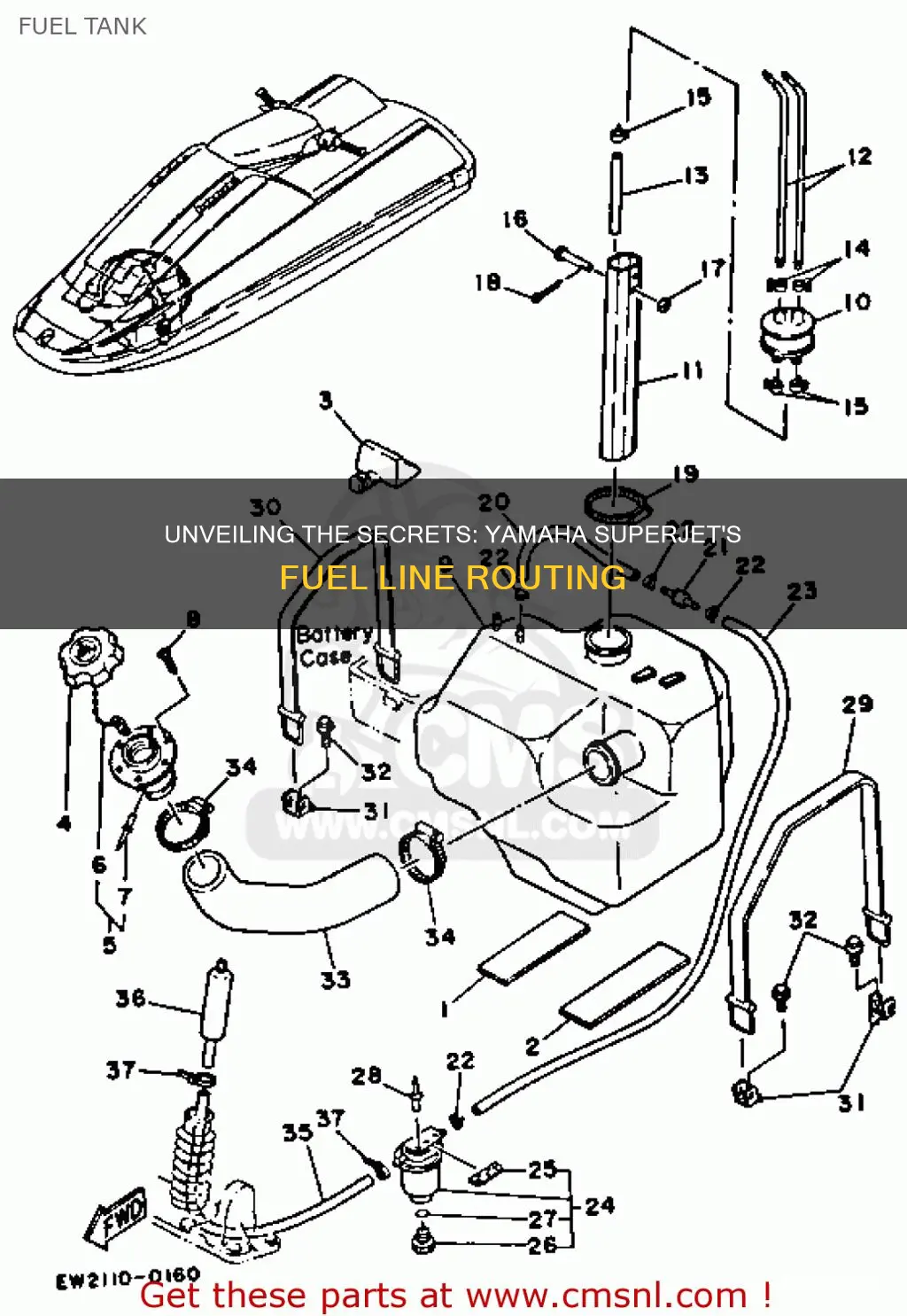

The fuel system in a Yamaha Superjet is a critical component that ensures a steady supply of fuel to the engine, allowing for efficient and reliable operation. The route of fuel lines from the tank to the engine is a carefully designed process, optimizing fuel flow while maintaining safety and performance. Here's an overview of this intricate system:

The journey begins at the fuel tank, a compact yet robust component typically located beneath the aircraft's seat or in a dedicated fuel cell. When the aircraft is stationary, the fuel pump, often an electric or mechanical device, activates to draw fuel from the tank. This pump is crucial as it provides the necessary pressure to move the fuel through the system. The fuel then travels through a network of lines, each serving a specific purpose.

The first section of the route is the fuel line, which connects the pump to the engine's fuel injection system. This line is designed to withstand high pressure and temperature, ensuring a continuous flow of fuel. From here, the fuel enters the engine's fuel injection system, a complex mechanism that precisely meters and injects the fuel into the combustion chamber. This process is highly regulated to maintain optimal engine performance and fuel efficiency.

In the Yamaha Superjet, the fuel injection system is often a multi-point injection setup, where multiple injectors are strategically placed to deliver fuel to different cylinders. This design ensures even fuel distribution and efficient combustion. The fuel lines continue from the injection system to the various cylinders, where the fuel is mixed with air and ignited, powering the aircraft's propulsion system.

The fuel system's design also includes safety measures. For instance, fuel lines are often equipped with filters to prevent contaminants from entering the system, ensuring the fuel's quality. Additionally, the system may feature pressure relief valves to prevent overpressure, which could lead to potential hazards. This intricate network of fuel lines and components showcases Yamaha's commitment to creating a robust and reliable fuel system for their Superjet aircraft.

Transmission Oil vs. Fuel: Exploring the Feasibility of a Swap

You may want to see also

Fuel Pump Location: Where the fuel pump is positioned and how it delivers fuel

The Yamaha Superjet, a high-performance watercraft, relies on a precise and efficient fuel system to deliver power to its engine. The fuel pump is a critical component in this setup, and its location and function are key to understanding the overall fuel lines route.

In the Yamaha Superjet, the fuel pump is typically positioned near the engine, often integrated into the fuel tank or located close to it. This proximity to the engine ensures a quick and direct supply of fuel, allowing for rapid response and efficient power delivery. The pump's design is such that it creates a vacuum or low-pressure environment, which draws fuel from the tank and sends it through the fuel lines. This process is a fundamental aspect of the engine's operation, ensuring a steady and controlled fuel supply.

The fuel pump's role is to maintain a consistent pressure and flow rate, which is crucial for optimal engine performance. It operates by using an electric motor or a diaphragm to create a pumping action. When the engine is running, the pump continuously delivers fuel, ensuring a steady supply to the carburetor or fuel injection system. This real-time fuel delivery is essential for maintaining the engine's power and responsiveness.

The fuel lines route from the pump to the engine is carefully designed to minimize resistance and ensure efficient fuel transfer. These lines are typically made of durable materials like steel or aluminum and are routed in a way that avoids sharp bends or kinks, which could restrict flow. The route often includes filters and strainers to prevent contaminants from entering the system, ensuring clean fuel delivery.

Understanding the fuel pump's location and function provides insight into the Yamaha Superjet's fuel system design. This knowledge is valuable for maintenance, troubleshooting, and optimizing the watercraft's performance, ensuring that the fuel pump continues to deliver fuel efficiently and reliably.

Is Fuel Line Safe for Coolant? Uncover the Truth

You may want to see also

Fuel Filters: The role of filters in ensuring clean fuel flow

Fuel filters are an essential component in the fuel system of any vehicle, including the Yamaha Superjet. These filters play a critical role in ensuring that the fuel flowing to the engine is clean and free from contaminants, which is crucial for optimal performance and longevity of the engine. The primary function of a fuel filter is to remove impurities and debris from the fuel, ensuring that only clean fuel reaches the engine. This is particularly important in high-performance vehicles like the Superjet, where the engine operates at its peak efficiency and requires a precise and clean fuel supply.

In the context of the Yamaha Superjet's fuel lines, the fuel filter is strategically positioned to capture contaminants as the fuel flows from the fuel tank to the engine. Over time, fuel can accumulate various impurities, including water, dirt, rust, and other debris, which can lead to engine performance issues. The filter acts as a barrier, trapping these contaminants and preventing them from entering the engine. This is especially vital as the Superjet's engine is designed to operate with a precise fuel-air mixture, and any impurities can disrupt this balance, leading to reduced power, poor acceleration, and even engine damage.

The design of the fuel filter is tailored to handle the specific requirements of the Superjet's fuel system. It is typically made of high-quality materials that can withstand the pressure and temperature variations within the fuel lines. The filter media, often a series of fine mesh screens or pleated paper, is designed to capture small particles and ensure that the fuel remains clean. Regular maintenance and replacement of the fuel filter are recommended to ensure its effectiveness. Over time, the filter can become clogged with contaminants, reducing its ability to filter the fuel. Therefore, it is essential to check and replace the filter at regular intervals as per the manufacturer's guidelines.

In addition to the primary function of filtering, some fuel filters also incorporate additional features to enhance their performance. For instance, some filters may include a water separator, which helps to remove any moisture from the fuel, further ensuring its cleanliness. This is particularly important in marine environments where water contamination is a common issue. Moreover, advanced fuel filters might have a bypass mechanism, allowing fuel to bypass the filter when it is clean, thus optimizing fuel flow and engine performance.

In summary, fuel filters are a vital component in the Yamaha Superjet's fuel system, serving as the first line of defense against contaminants. By ensuring a constant supply of clean fuel, these filters contribute to the engine's performance, reliability, and longevity. Regular maintenance and attention to the fuel filter are essential practices for any Superjet owner to keep the vehicle running smoothly and efficiently. Understanding the role and importance of fuel filters can help owners make informed decisions regarding their vehicle's maintenance.

Air in Fuel Line: Symptoms and Solutions

You may want to see also

Fuel Injectors: How fuel injectors spray fuel into the engine's cylinders

Fuel injectors are a crucial component in modern engines, responsible for delivering fuel to the engine's cylinders in a precise and controlled manner. This process is essential for efficient combustion and optimal engine performance. Here's a detailed explanation of how fuel injectors work and their role in the engine's cylinder operation:

Fuel Injection Process:

Fuel injectors are designed to spray a fine mist of fuel into the engine's cylinders, ensuring a thorough mixture of air and fuel. This process begins with the fuel pump, which draws fuel from the tank and pressurizes it. The pressurized fuel is then directed to the fuel injectors via a network of fuel lines. Each cylinder in the engine has its own dedicated fuel injector, ensuring precise control over the fuel supply. When the engine's computer (ECU) detects the need for fuel, it activates the injector.

Spraying Mechanism:

The fuel injector operates using a solenoid valve, which is an electromagnetic actuator. When energized, the solenoid valve opens, allowing high-pressure fuel to pass through. The fuel is then sprayed through a narrow nozzle, creating a fine mist. This mist is designed to have a specific droplet size, ensuring optimal atomization. Atomization is crucial as it increases the surface area of the fuel droplets, allowing for better mixing with air and subsequent combustion.

Cylinder Operation:

As the fuel mist is injected into the cylinder, it mixes with the air-fuel mixture already present. This mixture is then ignited by the spark plug, creating a controlled explosion (combustion). The timing and amount of fuel injected are precisely controlled by the ECU, ensuring that the engine operates efficiently and produces the desired power output. The fuel injectors' ability to deliver fuel in the correct ratio with air is vital for meeting emissions standards and optimizing engine performance.

Advantages of Fuel Injectors:

Fuel injectors offer several advantages over traditional carburetor systems. They provide better fuel-air mixture control, resulting in improved engine performance and fuel efficiency. Injectors can deliver fuel at higher pressures, allowing for more precise atomization and combustion. This leads to reduced emissions of harmful pollutants. Additionally, fuel injectors can adapt to varying engine loads and speeds, ensuring optimal performance across different driving conditions.

In summary, fuel injectors play a critical role in modern engines by precisely spraying fuel into the cylinders. This process ensures efficient combustion, optimal power output, and reduced emissions. The use of fuel injectors has revolutionized engine technology, providing better performance and reliability compared to older carburetor systems. Understanding the inner workings of fuel injectors highlights their importance in the overall engine management system.

Mastering the Metal Fuel Line Disconnect: A Comprehensive Guide

You may want to see also

Return Lines: The path of used fuel back to the tank

The return lines on a Yamaha Superjet are a crucial component of the fuel system, ensuring that used fuel is efficiently directed back to the tank after it has been burned in the engine. These lines are an essential part of the fuel loop, completing the cycle by providing a safe and controlled path for the fuel to travel.

When the engine operates, the fuel is injected into the combustion chamber and burned, producing power. However, this process also results in the creation of exhaust gases, which are then expelled from the engine. The return lines play a vital role in managing the flow of used fuel, which is now in a highly pressurized state due to the combustion process.

The path of the return lines begins at the engine's fuel injectors. After the fuel has been injected and burned, the exhaust gases and unburned fuel vapor are directed through the exhaust manifold and into the engine's lower parts. Here, the used fuel is separated from the exhaust gases, and the fuel vapor is condensed and directed back towards the fuel tank. This process is facilitated by the return lines, which are typically made of durable materials like steel or aluminum to withstand the high pressure and temperature.

These lines are designed with specific diameters and lengths to ensure optimal flow characteristics. The fuel is pushed through these lines using the engine's vacuum and pressure differentials. The return lines are often connected to a fuel pump, which helps maintain the required pressure and ensures a consistent fuel supply to the injectors. This pump is crucial in the overall fuel management system, as it provides the necessary force to move the fuel against gravity and back to the tank.

In summary, the return lines are a critical component of the Yamaha Superjet's fuel system, facilitating the safe and efficient transport of used fuel from the engine back to the tank. They work in conjunction with the fuel pump and other system components to ensure that the engine always has the required amount of fuel, even during high-performance maneuvers. Understanding the design and function of these return lines is essential for maintaining the overall health and performance of the Yamaha Superjet.

Mastering Harbor Freight Fuel Line Disconnect: A Comprehensive Guide

You may want to see also

Frequently asked questions

The fuel lines in a Yamaha Superjet are an essential component of the fuel system, responsible for delivering fuel from the tank to the engine. They ensure a steady and efficient supply of fuel, allowing the aircraft to operate optimally.

Compared to conventional aircraft, the Yamaha Superjet's fuel lines have a unique routing system. It incorporates a design that minimizes fuel sloshing and improves stability during flight. The lines are strategically placed to maintain a consistent fuel level, enhancing the aircraft's performance and handling characteristics.

Yes, proper maintenance of the fuel lines is crucial. Regular inspections should be conducted to ensure there are no leaks, blockages, or damage. Due to their location, the lines may be susceptible to impact damage during takeoff and landing, so careful inspection and potential replacement may be required to maintain the aircraft's safety and performance.