Have you ever wondered if the fuel lines in your vehicle get hot during operation? It's a common question among car owners and enthusiasts. Fuel lines are an essential component of any engine, responsible for transporting gasoline or diesel from the tank to the engine. While they are designed to withstand high pressure, the question remains: do fuel lines get hot enough to cause damage or affect performance? In this article, we'll explore the factors that influence fuel line temperature and discuss the potential risks and benefits of heated fuel lines.

| Characteristics | Values |

|---|---|

| Fuel lines can get hot under certain conditions | Yes |

| Heat source | Engine operation, fuel pump, or nearby hot components |

| Temperature range | Typically up to 150-200°F (66-93°C) |

| Material impact | Different materials have varying heat resistance; metal lines may be more prone to overheating |

| Potential issues | Overheating can cause fuel line damage, reduced performance, or fuel leaks |

| Prevention | Use high-temperature-rated fuel lines, ensure proper insulation, and regular maintenance checks |

What You'll Learn

- Fuel Line Temperature: Understand how fuel lines heat up during engine operation

- Heat Transfer: Learn about the mechanisms of heat transfer in fuel lines

- Insulation: Discover the role of insulation in preventing fuel line overheating

- Engine Performance: Explore the impact of hot fuel lines on engine efficiency

- Safety Precautions: Identify measures to prevent fuel line damage from excessive heat

Fuel Line Temperature: Understand how fuel lines heat up during engine operation

Fuel lines play a crucial role in the operation of an internal combustion engine, and understanding their temperature behavior is essential for maintaining optimal engine performance and safety. When an engine is running, the fuel lines, which carry gasoline or diesel from the fuel tank to the engine, are subjected to high temperatures due to several factors.

One primary reason for fuel line heating is the combustion process itself. As the engine operates, it ignites the fuel-air mixture in the cylinders, generating a significant amount of heat. This heat is transferred through the engine components, including the fuel lines, which are in close proximity to the combustion chambers. The fuel lines act as a pathway for fuel delivery, and the intense heat from the engine's operation causes the fuel to expand and the lines to heat up.

Additionally, the engine's cooling system contributes to fuel line temperature. The cooling system, comprising the radiator, water pump, and coolant, helps regulate the engine's temperature. As the engine operates, the coolant circulates through the engine block, absorbing heat and preventing overheating. However, the fuel lines are not directly cooled by the coolant; instead, they rely on the engine's overall cooling mechanism. As the engine runs, the fuel lines absorb heat from the surrounding components, including the engine block and other hot surfaces, leading to an increase in temperature.

The material of the fuel lines also influences their temperature characteristics. Different types of materials have varying thermal properties, affecting how much heat they can conduct and retain. For example, steel fuel lines may heat up more rapidly than rubber or plastic lines due to their higher thermal conductivity. This is why it's important to choose the right material for fuel lines based on the engine's operating conditions and temperature requirements.

Understanding fuel line temperature is vital for several reasons. Firstly, excessive heat can lead to fuel degradation, affecting its quality and performance. Over time, high temperatures can cause fuel to break down, leading to reduced engine power and potential performance issues. Secondly, hot fuel lines can create safety concerns. If the temperature becomes too high, it may cause the fuel to vaporize, increasing the risk of fuel leaks and potential fires. Therefore, monitoring and managing fuel line temperature is essential to ensure the engine's longevity and safety.

Honda vs Mercury: Unraveling the Outboard Fuel Line Connector Mystery

You may want to see also

Heat Transfer: Learn about the mechanisms of heat transfer in fuel lines

Heat transfer is a critical concept to understand when dealing with fuel lines, especially in high-performance vehicles or those operating in extreme conditions. Fuel lines, which carry gasoline or diesel from the tank to the engine, are susceptible to heat transfer due to several factors. When fuel is burned, it undergoes a rapid chemical reaction, releasing a significant amount of heat energy. This heat can travel through the fuel line, potentially causing issues if not managed properly.

The primary mechanism of heat transfer in fuel lines is conduction. When the engine operates, the hot exhaust gases and the combustion process generate heat. This heat travels through the metal walls of the fuel line, especially if the line is made of a conductive material like steel. The fuel, being a liquid, also conducts heat, but to a lesser extent compared to the metal. As a result, the fuel line acts as a conduit for heat, transferring it from the engine to the surrounding environment or other components.

Convection also plays a role in heat transfer within fuel lines. As the fuel flows through the line, it can carry heat with it due to the movement of the liquid. This is particularly noticeable in high-flow applications or when the fuel is under pressure. The convective heat transfer coefficient is higher in these cases, allowing for more efficient heat exchange. Additionally, the fuel's temperature can rise due to the friction and turbulence caused by the flow, further contributing to heat transfer.

Understanding these heat transfer mechanisms is essential for several reasons. Firstly, excessive heat in fuel lines can lead to fuel degradation, especially if the fuel contains volatile components. These components can evaporate at higher temperatures, reducing the overall fuel quality and potentially causing performance issues. Secondly, heat transfer can impact the fuel's properties, such as viscosity and density, which are crucial for efficient combustion.

To mitigate these issues, engineers often employ various strategies. One approach is to use insulated fuel lines, which can significantly reduce heat transfer by creating a thermal barrier between the fuel and the surrounding environment. Another method is to incorporate heat exchangers or cooling systems specifically designed to manage the heat generated during fuel delivery. By implementing these measures, it is possible to ensure that fuel lines operate within safe temperature limits, optimizing engine performance and longevity.

Boat Fuel Line Vent Hose: Size Guide for Optimal Performance

You may want to see also

Insulation: Discover the role of insulation in preventing fuel line overheating

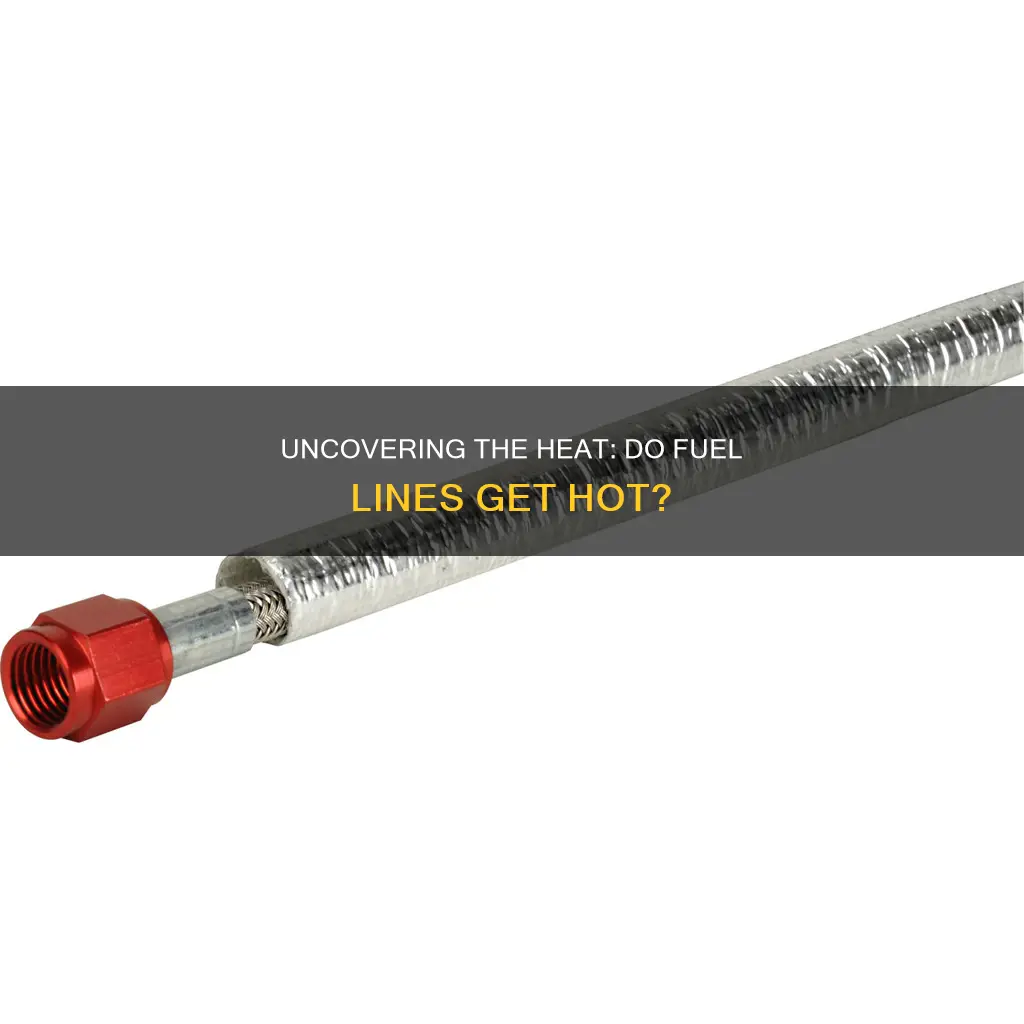

Insulation plays a critical role in maintaining the integrity and performance of fuel lines, especially in preventing overheating. When fuel lines are exposed to high temperatures, they can become brittle and prone to cracking, leading to potential fuel leaks and system failures. Insulation acts as a protective barrier, safeguarding the fuel lines from excessive heat and ensuring their longevity.

The primary function of insulation is to regulate temperature. It helps to absorb and dissipate heat, preventing the fuel lines from overheating. Insulation materials, such as rubber, plastic, or metal sleeves, are designed to withstand high temperatures and provide thermal resistance. By wrapping the fuel lines with insulation, you create a barrier that minimizes direct exposure to hot surfaces, engines, or exhaust systems. This is particularly important in high-performance vehicles or engines operating in demanding conditions.

In addition to temperature regulation, insulation also offers mechanical protection. Fuel lines are susceptible to damage from sharp edges, vibrations, and external impacts. Insulation sleeves or jackets provide a layer of cushioning, safeguarding the fuel lines from potential hazards. This protective layer ensures that the fuel lines remain intact and functional, even in challenging environments.

Proper insulation installation is crucial for its effectiveness. Insulation should be applied carefully, ensuring complete coverage of the fuel lines without any gaps or overlaps. The insulation material should be compatible with the fuel type and temperature range to guarantee optimal performance. Regular inspections and maintenance are also essential to identify any damaged or worn-out insulation, allowing for timely replacement.

By implementing insulation, vehicle owners and mechanics can significantly reduce the risk of fuel line failures and ensure a reliable fuel supply. Insulation's ability to manage temperature and provide mechanical protection makes it an indispensable component in fuel line maintenance, especially in high-performance applications where overheating is a concern.

Mini Cooper Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Engine Performance: Explore the impact of hot fuel lines on engine efficiency

The performance of an engine is significantly influenced by the temperature of its fuel lines, and understanding this relationship is crucial for optimizing engine efficiency. When fuel lines get hot, it can have both positive and negative effects on the engine's overall performance.

One of the primary impacts of hot fuel lines is the potential for increased engine power output. As fuel lines heat up, the fuel within them undergoes a process known as thermal expansion. This expansion leads to a slight increase in fuel volume, which can result in a more efficient atomization process when the fuel enters the engine's intake system. Fine fuel droplets are essential for optimal combustion, as they allow for better mixing with air, leading to more complete burning and increased power. However, this effect is often minimal and may not significantly boost performance in most everyday driving conditions.

On the other hand, excessively hot fuel lines can lead to engine performance degradation. High temperatures can cause the fuel to vaporize more readily, leading to a condition known as fuel vaporization. This can result in poor fuel-air mixture quality, as the excess vapor may not be properly atomized, leading to incomplete combustion. Incomplete combustion can cause a decrease in engine power, increased fuel consumption, and even the release of harmful pollutants. Additionally, hot fuel lines can contribute to engine knock or pinging, especially in engines with higher compression ratios, as the hot fuel can ignite prematurely, causing engine damage over time.

The design and material of the fuel lines play a critical role in managing temperature-related issues. Modern fuel lines are often made of materials that offer good thermal insulation, such as rubber or synthetic compounds with low thermal conductivity. These materials help to dissipate heat more slowly, allowing the fuel to remain at a more stable temperature. However, in high-performance applications or environments with extreme temperatures, specialized fuel line designs, such as those with heat shields or cooling jackets, might be necessary to maintain optimal engine operation.

To mitigate the negative effects of hot fuel lines, engine manufacturers often employ various strategies. One common approach is to use a fuel cooler, which is typically located near the fuel pump or in the fuel rail. The cooler helps to reduce the temperature of the fuel before it enters the engine, ensuring a more consistent and controlled fuel-air mixture. Additionally, engine management systems can be programmed to adjust fuel injection timing and other parameters in response to temperature changes, optimizing performance and fuel efficiency.

In summary, while hot fuel lines can have some positive effects on engine power, they also present challenges that can impact overall engine efficiency. Understanding and managing fuel line temperatures are essential for engine manufacturers and enthusiasts to ensure optimal performance and longevity. Proper fuel line design, insulation, and the use of cooling systems can help strike a balance between the benefits and drawbacks of hot fuel lines, ultimately contributing to a more efficient and reliable engine.

Can Fuel Lines Freeze? Winter Fuel Line Safety Tips

You may want to see also

Safety Precautions: Identify measures to prevent fuel line damage from excessive heat

When it comes to vehicle maintenance, it's crucial to understand the potential risks associated with fuel lines, especially regarding excessive heat. Fuel lines play a vital role in delivering fuel from the tank to the engine, and they can indeed get hot, especially during high-performance driving or in certain weather conditions. This heat can lead to several issues, including fuel line damage, which may result in costly repairs and potential safety hazards. Here are some essential safety precautions to prevent fuel line damage from excessive heat:

- Regular Inspections: One of the most effective ways to ensure the safety of your fuel lines is to perform regular inspections. Check the fuel lines for any signs of wear, cracks, or damage, especially in areas where they are exposed or close to hot components. Look for any leaks or disconnections, as these can be early indicators of potential problems. It is recommended to inspect the fuel lines during routine maintenance checks or before and after long drives, especially in extreme weather conditions.

- Insulation and Protection: Proper insulation is critical to safeguarding fuel lines from excessive heat. Ensure that all fuel lines are adequately insulated, particularly those running near the engine or exhaust system. You can use specialized heat shields or protective sleeves to cover the fuel lines, especially in high-temperature areas. Additionally, consider using a fuel line protector, which is a flexible, heat-resistant material that can be wrapped around the fuel lines to provide an extra layer of defense against heat-related damage.

- Engine Bay Organization: Maintaining a well-organized engine bay is essential for heat management. Keep the engine bay clean and free from debris, as this can reduce the risk of fuel line damage. Ensure that no hot components or exhaust parts are in direct contact with the fuel lines. Properly secure all electrical connections and components to prevent any potential interference with the fuel lines. Regularly check and adjust the engine's cooling system to guarantee optimal performance and prevent overheating.

- Fuel System Maintenance: Regular maintenance of the entire fuel system is vital. This includes checking the fuel filter regularly and replacing it as recommended by the manufacturer. A clogged or dirty fuel filter can restrict fuel flow, causing the engine to overheat and potentially damaging the fuel lines. Additionally, ensure that the fuel pump is functioning correctly, as a faulty pump can lead to uneven fuel distribution and potential heat-related issues.

- Driving Habits: Driver awareness and responsible driving habits can significantly contribute to preventing fuel line damage. Avoid rapid acceleration and frequent hard braking, as these actions can cause sudden temperature spikes in the engine and fuel lines. Maintain a steady driving speed and avoid prolonged idling, especially in stop-and-go traffic. When driving in extreme weather, be mindful of the engine's temperature and consider using the air conditioning or defrosters to reduce heat buildup inside the vehicle.

By implementing these safety precautions, you can effectively minimize the risk of fuel line damage caused by excessive heat. Regular maintenance, proper insulation, and cautious driving habits are key to ensuring the longevity and reliability of your vehicle's fuel system. Remember, prevention is always better than cure, and taking these simple measures can save you from potential headaches and costly repairs.

Duramax Fuel Line Pressure: Testing and Troubleshooting Guide

You may want to see also

Frequently asked questions

Yes, fuel lines can get hot, especially in high-performance engines or when the vehicle is running for extended periods. The heat is primarily generated by the combustion process and the friction between the moving parts of the engine.

Fuel lines heat up due to the proximity to hot engine components, such as the fuel pump, injectors, and exhaust system. The fuel itself can also contribute to the heat, as it absorbs heat from the engine during the combustion process.

Absolutely. Excessive heat in fuel lines can lead to several problems. It can cause fuel to vaporize, reducing its energy content and potentially leading to poor engine performance. Hot fuel lines may also experience increased pressure, which can result in fuel leaks or even fuel line failures.

There are a few measures to consider. Using high-quality, heat-resistant fuel lines can help. Ensuring proper insulation and maintaining a clean engine environment are also crucial. Regularly checking for any signs of damage or wear on the fuel lines and addressing them promptly can prevent overheating and potential engine issues.