The metal fuel line disconnect tool is a specialized device designed to safely and efficiently disconnect metal fuel lines, which is crucial for vehicle maintenance, repairs, or when replacing fuel tanks. This tool is essential for professionals and DIY enthusiasts alike, ensuring a secure and controlled process to avoid fuel spills and potential hazards. By following a few simple steps, you can effectively use this tool to disconnect metal fuel lines, making it a valuable asset for anyone working on fuel-related projects.

What You'll Learn

- Safety Precautions: Always wear protective gear and ensure the engine is off before using the tool

- Tool Familiarization: Understand the tool's components and functions for effective use

- Line Inspection: Check for damage, kinks, or leaks before disconnecting the fuel line

- Proper Technique: Use the tool's grip and release mechanism to safely disconnect the line

- Post-Disconnect Steps: Reattach the line securely, ensuring a tight fit and no leaks

Safety Precautions: Always wear protective gear and ensure the engine is off before using the tool

When working with a metal fuel line disconnect tool, it is crucial to prioritize safety to avoid any potential hazards. Always begin by wearing appropriate protective gear, such as gloves and safety goggles, to safeguard your hands and eyes from any sharp edges or debris that may be present during the process. This simple step can significantly reduce the risk of injury.

Before proceeding, ensure that the engine is completely off and has had sufficient time to cool down. Working on a hot or running engine can be extremely dangerous and may lead to severe burns or other accidents. Allow the engine to idle for a few minutes to ensure it is no longer under pressure and to prevent any sudden eruptions of fuel.

It is essential to exercise caution when disconnecting fuel lines. Fuel is highly flammable, and any spark or heat source could result in a dangerous fire. Always use the tool in a well-ventilated area, away from open flames or electrical sources. If possible, have an assistant present to help monitor the process and provide assistance if needed.

Additionally, be mindful of the fuel line's pressure. Some fuel lines may still retain pressure even after the engine is off, so it's crucial to release this pressure safely. Locate the fuel line's pressure relief valve and ensure it is properly engaged to prevent any sudden bursts of fuel.

Remember, taking these safety precautions is vital to ensure a secure and efficient working environment when using a metal fuel line disconnect tool. By being prepared and cautious, you can minimize the risks associated with fuel line disconnection and maintain a safe workspace.

Understanding Rubber Fuel Line Sizes for CJ7s

You may want to see also

Tool Familiarization: Understand the tool's components and functions for effective use

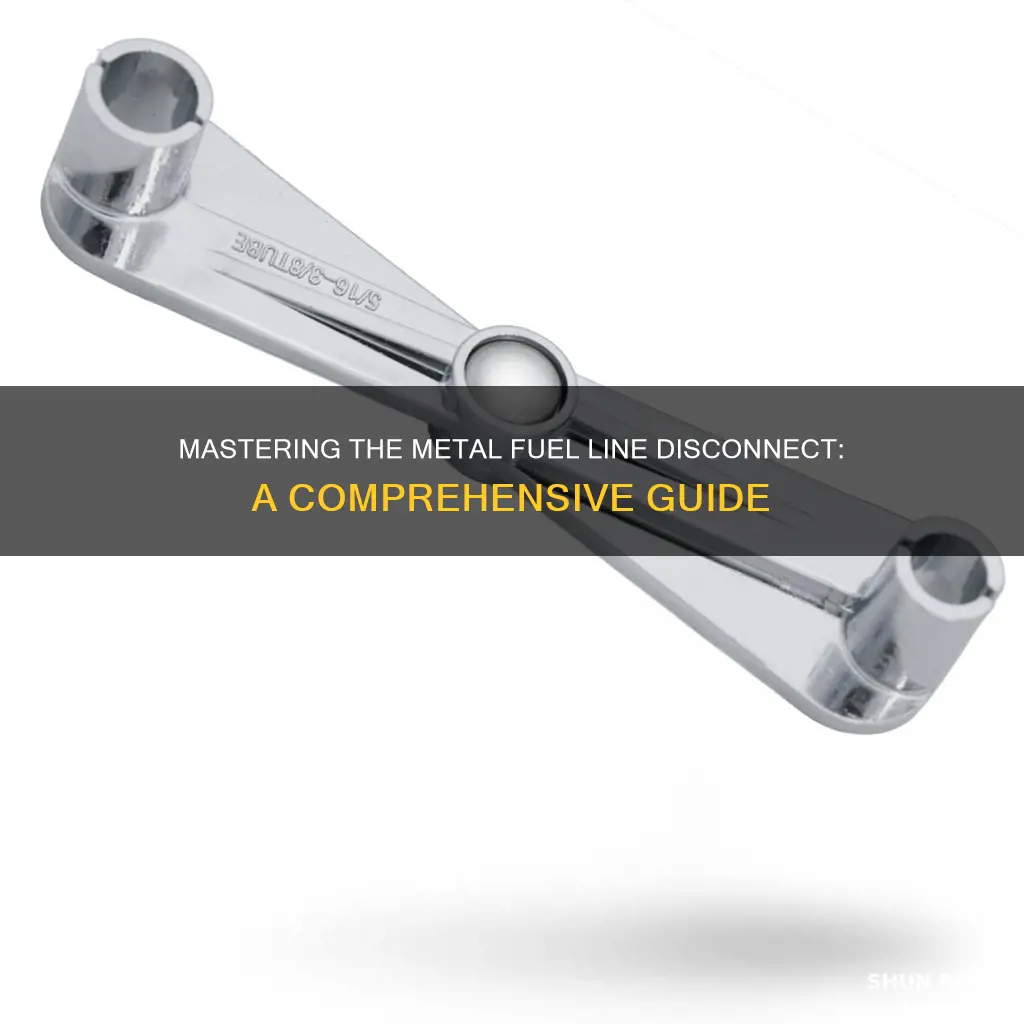

To effectively utilize a metal fuel line disconnect tool, it's crucial to first familiarize yourself with its components and functions. This tool is specifically designed to safely and efficiently disconnect metal fuel lines, ensuring a secure and controlled process. Here's a detailed breakdown to guide you through the process:

Understanding the Tool's Components:

The metal fuel line disconnect tool typically consists of a few key elements. Firstly, there's the main body, often made of durable materials like steel or aluminum, providing structural integrity. This body houses the disconnect mechanism, which is the heart of the tool. This mechanism is designed to grip and release the metal fuel line securely. It usually features a set of jaws or a clamp-like structure that can be adjusted to fit different fuel line diameters. Additionally, you'll find a handle or grip, often ergonomic, to provide comfort and control during use. Some tools may also include a safety catch or release mechanism to prevent accidental disconnections.

Identifying Functions:

- Grip and Hold: The primary function of this tool is to firmly grip the metal fuel line. The disconnect mechanism is designed to apply pressure evenly, ensuring a secure hold without damaging the fuel line.

- Controlled Release: After securing the grip, the tool allows for a controlled release. This is achieved through a lever or button mechanism that activates the disconnect function. It ensures that the fuel line is released safely, minimizing the risk of spills or damage.

- Adjustability: Many disconnect tools offer adjustable features. This might include a sliding mechanism to accommodate different fuel line sizes or a customizable grip to fit various diameters. This adjustability is crucial for versatility and ensures compatibility with a wide range of fuel lines.

- Safety Features: As mentioned, safety is a priority. Some tools incorporate a safety lock to prevent accidental activation, ensuring that the fuel line remains secure until intended use.

Pre-Use Inspection:

Before employing the tool, inspect it for any signs of damage or wear. Check the condition of the grip, the integrity of the disconnect mechanism, and the overall functionality of the tool. Any visible defects or malfunctions should be addressed before use to ensure safety and effectiveness.

By thoroughly understanding the tool's components and functions, you can ensure a smooth and safe disconnect process for metal fuel lines. This familiarity is essential for professionals and DIY enthusiasts alike, providing confidence and precision in their work.

Fuel Line Liter Valve: Location and Function

You may want to see also

Line Inspection: Check for damage, kinks, or leaks before disconnecting the fuel line

Before attempting to disconnect a metal fuel line, it is crucial to perform a thorough inspection to ensure safety and prevent any potential accidents. This initial step is often overlooked but is essential for a successful and safe process. Here's a detailed guide on how to inspect the fuel line:

Visual Inspection: Begin by visually examining the fuel line for any visible signs of damage, cracks, or corrosion. Look for any discolored areas, especially around the connection points where the fuel line is attached to the fuel tank and the engine. Over time, fuel lines can deteriorate due to exposure to fuel, heat, and vibration, leading to cracks or corrosion. These issues can cause fuel leaks, which are extremely dangerous. Inspect the entire length of the line, paying close attention to bends and kinks. Even a small kink can restrict fuel flow and cause pressure buildup, making the line more susceptible to damage when disconnected.

Leak Test: A simple yet effective method to check for leaks is to spray a small amount of soapy water or a suitable leak detection fluid along the length of the fuel line. If there are any leaks, you will notice bubbles forming where the liquid comes into contact with the fuel. This test is crucial as it indicates potential weak spots or damage that could lead to fuel escaping during the disconnection process. Ensure the engine is off and the fuel system is cool before performing this test to avoid any accidents.

Pressure Check: Fuel lines often operate under pressure, so it's essential to check for any signs of pressure-related damage. Look for any bulging or swelling along the line, which could indicate internal damage or a potential explosion hazard. If you notice any pressure-related issues, it is best to seek professional assistance to avoid further complications.

Kink Detection: Feel the fuel line along its length to check for kinks or bends that might restrict flow. A kinked line can cause fuel pressure issues and make disconnection more challenging. Ensure the line is straight and free-flowing before proceeding.

By following these inspection steps, you can identify potential issues that might otherwise lead to dangerous situations during the disconnection process. It is always better to be cautious and ensure the fuel line is in optimal condition before attempting any maintenance or repair work.

Effective Fuel Line Cleaning: Methods and Solutions

You may want to see also

Proper Technique: Use the tool's grip and release mechanism to safely disconnect the line

To safely disconnect a metal fuel line using the appropriate tool, it's crucial to follow a methodical approach. Begin by ensuring you have the right tool for the job; these tools are specifically designed to grip and release metal fuel lines without causing damage or injury. The key feature of this tool is its grip and release mechanism, which allows for a secure hold and controlled disconnection.

Position yourself comfortably, ensuring you have a stable base. Locate the fuel line you intend to disconnect, typically found under the vehicle's hood. Use the tool's grip to firmly hold the fuel line, ensuring a secure hold. The grip should be firm but not overly tight to avoid putting excessive pressure on the line.

Now, activate the tool's release mechanism. This action will allow you to carefully pull the fuel line away from its connection point. The mechanism is designed to provide a smooth and controlled release, reducing the risk of sudden movements that could lead to accidents. As you disconnect the line, maintain a steady grip to prevent any potential slippage.

Once the line is disconnected, carefully guide it away from the connection point, ensuring it remains intact and undamaged. Inspect the line for any signs of damage or wear, especially if it will be reattached. Properly disposing of or storing the disconnected line is essential to maintain a clean and safe work environment.

Remember, the key to successful and safe disconnection lies in the tool's grip and release mechanism. Practice and familiarity with the tool will enhance your efficiency and safety. Always prioritize safety when working with fuel lines, and ensure you have the necessary knowledge and equipment before beginning any maintenance or repair tasks.

Fuel Line Fabrication: Cost Breakdown for Custom Solutions

You may want to see also

Post-Disconnect Steps: Reattach the line securely, ensuring a tight fit and no leaks

After successfully disconnecting the metal fuel line, it's crucial to reattach it securely to prevent any potential leaks and ensure the system's safety. Here's a step-by-step guide to achieving a tight and reliable connection:

- Prepare the Components: Before reattachment, inspect the fuel line, fittings, and the disconnect tool. Ensure all parts are clean, free from debris, and in good condition. Check for any signs of damage or wear, especially on the threads and sealing surfaces. Having a clean and undamaged setup is essential for a secure connection.

- Thread Alignment: When reattaching the fuel line, align the threads carefully. Ensure the male and female threads are properly aligned and engaged. Start by inserting the fuel line into the fitting, rotating it clockwise until it is firmly in place. The threads should interlock smoothly without any binding or cross-threading.

- Tighten Securely: Use a wrench or a suitable tool to tighten the connection. Apply firm pressure in a clockwise direction, ensuring that the fuel line is snugly fitted. The goal is to achieve a tight seal without over-tightening, as this can lead to damage or distortion of the fittings. Use your hands to feel for resistance and ensure the connection is secure.

- Leaks Check: After tightening, it's vital to verify that there are no leaks. Turn the fuel line by hand to ensure it is free to rotate. Then, apply a small amount of fuel or a suitable sealant to the connection and observe for any signs of leakage. If no leaks are detected, the reattachment is successful.

- Final Inspection: As a final step, inspect the entire system. Check for any visible signs of damage, corrosion, or improper installation. Ensure that all connections are tight and secure. This thorough inspection will help identify any potential issues before the system is put back into operation.

By following these post-disconnect steps, you can guarantee a secure and leak-free reattachment of the metal fuel line. Proper technique and attention to detail are key to maintaining a safe and efficient fuel system.

Fuel Line Plug: Location on 2002 Elantra Injector Rail

You may want to see also

Frequently asked questions

A metal fuel line disconnect tool is a specialized device designed to safely and efficiently disconnect metal fuel lines, allowing for easy access to fuel tanks, pumps, or other fuel system components during maintenance, repairs, or fuel system replacements.

Begin by ensuring the engine is off and the vehicle is in a stable position. Locate the metal fuel line you wish to disconnect and position the tool's clamp around it. Apply firm pressure and twist the tool to loosen the connection. Once disconnected, carefully remove the line and secure the ends to prevent fuel spillage.

Yes, it is crucial to exercise caution when working with fuel lines. Always wear protective gear, such as gloves and safety goggles, to guard against potential fuel splashes. Ensure you are in a well-ventilated area, and consider using a fuel containment system to catch any spilled fuel.

Absolutely! This tool is designed to be versatile and can be reused for various fuel line sizes and types. However, it is essential to inspect the tool for any signs of wear or damage before each use to ensure optimal performance and safety.