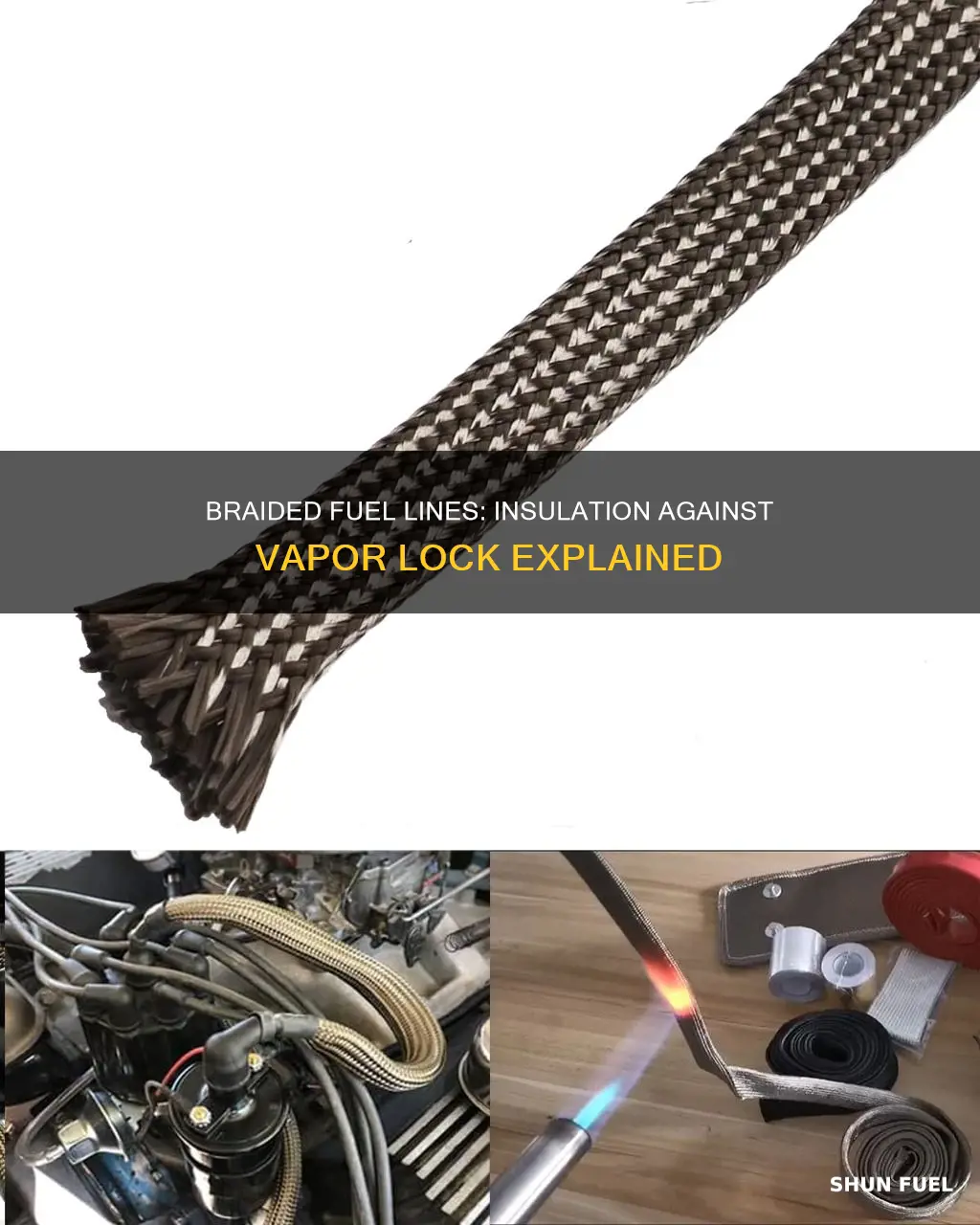

Braided fuel lines have become a popular choice for vehicle owners seeking to improve their engine's performance and reliability. One of the key benefits of braided fuel lines is their ability to help prevent vapor lock, a common issue that can occur when fuel turns to vapor due to high temperatures, causing the engine to stall. This is achieved through the use of a braided design that provides better insulation and flexibility compared to traditional rubber fuel lines. By reducing the risk of fuel vaporization, braided fuel lines can enhance engine performance and ensure a more stable driving experience, especially in hot climates or during extended periods of idling.

| Characteristics | Values |

|---|---|

| Insulation Effectiveness | Braided fuel lines can provide some insulation from extreme temperatures, which may indirectly help prevent vapor lock by maintaining a more consistent fuel temperature. |

| Flexibility | Braided fuel lines are known for their flexibility, allowing them to bend and move with the vehicle's components, reducing the risk of fuel line damage and potential vapor lock issues caused by restricted fuel flow. |

| Corrosion Resistance | Braided fuel lines often have a protective layer that prevents corrosion, ensuring the fuel remains clean and free-flowing, which is crucial for engine performance and preventing fuel-related issues. |

| Durability | The braided design makes these fuel lines durable and less prone to damage from road debris or vibrations, contributing to long-term reliability. |

| Visual Inspection | Regular visual inspection of braided fuel lines can help identify any signs of damage or wear, allowing for timely maintenance and potentially preventing vapor lock. |

| Cost | Braided fuel lines might be more expensive than standard fuel lines, but their durability and potential long-term savings on fuel-related repairs make them a worthwhile investment. |

| Compatibility | These fuel lines are designed to be compatible with various vehicle models and fuel systems, ensuring a proper fit and potential performance benefits. |

What You'll Learn

Braided Fuel Lines: Enhanced Insulation for Engine Performance

Braided fuel lines are an essential component of any vehicle's fuel system, offering a range of benefits that contribute to improved engine performance and reliability. One of the key advantages of braided fuel lines is their ability to provide enhanced insulation, which plays a crucial role in preventing vapor lock, a common issue in fuel systems.

Vapor lock occurs when the fuel in the system turns into a vapor due to high temperatures, causing the fuel to become less dense and potentially blocking the flow of fuel to the engine. This can lead to engine stalling, reduced performance, and even damage to the fuel pump. Braided fuel lines are designed to address this problem by offering superior insulation properties. The braided construction, typically made from materials like steel or stainless steel, creates a flexible yet robust structure that can withstand the extreme temperatures and pressure fluctuations within the fuel system.

The insulation provided by braided fuel lines helps to maintain the temperature of the fuel, preventing it from overheating and turning into vapor. This is particularly important in high-performance engines or vehicles operating in hot climates, where fuel temperatures can rise significantly. By keeping the fuel in a liquid state, braided fuel lines ensure a consistent and reliable fuel supply to the engine, optimizing performance and reducing the risk of fuel-related issues.

In addition to insulation, braided fuel lines offer other advantages. Their flexibility allows for easy routing around the engine bay, providing better protection against sharp bends and potential damage from engine movement. The braided design also reduces the risk of fuel contamination, as the lines are less susceptible to absorbing moisture or other impurities from the air. This ensures that the fuel remains clean and of high quality, promoting efficient combustion and engine health.

When considering an upgrade to braided fuel lines, it is essential to choose the right size and material for your specific vehicle. Proper installation is also critical to ensure the insulation benefits are fully realized. With the right setup, braided fuel lines can significantly improve engine performance, reduce the chances of vapor lock, and contribute to a more reliable and efficient driving experience.

Unveiling the Tvr Tasmin's Fuel Line Mystery: Size Matters!

You may want to see also

Fuel Line Braiding: Preventing Vapor Lock in Hot Weather

Braiding fuel lines is a clever technique to combat a common issue in hot weather: vapor lock. This problem occurs when the fuel in your engine turns to vapor due to high temperatures, causing the engine to stall or lose power. By braiding the fuel lines, you can effectively insulate the fuel and prevent this unwanted phenomenon.

The process of braiding involves twisting and intertwining the fuel line material, creating a protective layer around the fuel. This braiding technique has several advantages. Firstly, it helps to maintain a consistent temperature around the fuel, reducing the likelihood of vaporization. The braided structure also provides a physical barrier, preventing the fuel from direct exposure to hot engine components, which can accelerate the vaporization process.

In regions with extreme summer heat, this method becomes even more crucial. As temperatures soar, the risk of vapor lock increases significantly. Braiding the fuel lines acts as a simple yet effective solution, ensuring that the fuel remains in a liquid state and continues to flow efficiently to the engine. This is particularly important for vehicles or equipment that operate in outdoor environments or during extended periods of high-temperature exposure.

Additionally, braided fuel lines offer another benefit: flexibility. The twisting and braiding process allows the fuel lines to maintain their shape and flexibility, even under pressure and varying temperatures. This flexibility is essential for the fuel lines to navigate the engine's complex layout without restricting flow or causing damage.

In summary, braiding fuel lines is a practical and efficient way to prevent vapor lock, especially in hot weather conditions. It provides insulation, maintains fuel temperature, and ensures a consistent fuel supply to the engine. By implementing this technique, vehicle owners and operators can avoid the inconvenience and potential damage caused by vapor lock, ensuring reliable performance even in the hottest of climates.

Heat Shield for Fuel Line: Top Sources Revealed

You may want to see also

Insulation Benefits: Braided Lines Keep Fuel Cool

Braided fuel lines, often overlooked, offer a significant advantage in vehicle maintenance: they act as an effective insulator, preventing fuel vaporization and the associated issue of vapor lock. This is particularly crucial for vehicles operating in extreme temperatures or those with fuel systems that are more susceptible to overheating. By understanding the role of insulation in fuel lines, you can ensure your vehicle's engine runs smoothly and efficiently, even in challenging environmental conditions.

The primary benefit of using braided fuel lines is their ability to insulate the fuel system. Traditional rubber fuel lines can absorb and retain heat, leading to fuel vaporization, especially when the engine is idling or during prolonged periods of high temperature. This vaporization can cause the fuel to turn into a gas, which, when mixed with air, can lead to engine misfires, reduced performance, and even stalling. Braided lines, however, are constructed with a high-temperature-resistant material that prevents the fuel from overheating and vaporizing.

Braided fuel lines are designed with a unique, flexible weave that allows them to conform to the contours of the vehicle's engine bay. This design not only ensures a secure fit but also helps in distributing heat more evenly. The insulation provided by the braided structure helps to maintain the fuel's temperature, ensuring that it remains in a liquid state and is delivered efficiently to the engine. This is particularly important in high-performance vehicles or those with modified engines, where the fuel system's efficiency and reliability are critical.

In addition to preventing vapor lock, braided fuel lines offer other advantages. They are more resistant to abrasion and less likely to develop cracks or leaks over time. This durability is especially beneficial in harsh environments or for vehicles that undergo frequent temperature fluctuations. The braided construction also provides a more flexible and durable solution compared to traditional rubber lines, which can become brittle and prone to failure over time.

By investing in braided fuel lines, vehicle owners can ensure that their fuel system operates optimally, regardless of the environmental conditions. This not only improves engine performance but also extends the lifespan of the fuel system, saving both time and money on maintenance and repairs. The insulation benefits of braided lines are a valuable feature that should not be overlooked, especially for those looking to optimize their vehicle's performance and reliability.

6AN 3/8 Stainless Braided Fuel Line: Ultimate Upgrade for Your Engine

You may want to see also

Vapor Lock Mitigation: Braiding Fuel Lines for Engine Protection

Vapor lock is a common issue that can occur in fuel systems, especially in high-performance or modified vehicles. It happens when the fuel in the system turns to vapor due to heat, causing the fuel to expand and potentially block the flow, leading to engine stalling or reduced performance. One method to mitigate this problem is by using braided fuel lines, which offer several advantages over traditional rubber hoses.

Braided fuel lines are constructed with multiple layers of durable materials, such as steel, nylon, or Kevlar, braided together to form a strong and flexible structure. This design provides several benefits for vapor lock prevention. Firstly, the braided construction allows for better heat dissipation, as the materials can absorb and distribute heat more effectively than rubber. This is crucial because fuel lines are often exposed to high temperatures, especially in the engine bay, which can accelerate the vaporization process. By conducting heat more efficiently, braided lines help maintain the fuel's liquid state, reducing the chances of vapor lock.

The flexibility of braided fuel lines is another advantage. They can accommodate engine movement and vibrations without kinking or cracking, which is essential for long-term reliability. Traditional rubber hoses may become brittle over time due to heat and engine movement, leading to potential fuel leaks and performance issues. Braided lines, with their reinforced structure, are more resistant to wear and tear, ensuring a consistent and secure fuel supply.

Additionally, braided fuel lines often feature a higher pressure rating compared to rubber hoses. This is particularly important in high-performance applications where fuel pressure can be significantly higher. The braided design can withstand increased pressure without compromising flexibility, ensuring a reliable and consistent fuel delivery system. This feature is especially beneficial for engines that require precise fuel management for optimal performance.

In summary, braided fuel lines are an effective solution for mitigating vapor lock issues. Their ability to dissipate heat, flexibility, and high-pressure resistance make them a reliable choice for fuel systems, especially in demanding environments. By investing in braided fuel lines, vehicle owners can ensure better engine performance and longevity, even in the face of challenging driving conditions. This simple upgrade can provide peace of mind and improve the overall reliability of the fuel system.

Mastering the Art of Fuel Line Clamp Removal: A Step-by-Step Guide

You may want to see also

Fuel Line Design: Braiding for Improved Insulation and Efficiency

Braiding fuel lines is a technique that has gained popularity in the automotive industry, particularly for its potential to enhance insulation and prevent vapor lock. This method involves twisting multiple strands of fuel line material together, creating a braided pattern. The primary goal is to improve the insulation properties of the fuel lines, especially in high-temperature environments where traditional fuel lines might fail.

Vapor lock is a common issue in fuel systems, especially in older vehicles or those with inefficient fuel management. It occurs when the fuel in the system turns into vapor due to heat, causing the fuel to stop flowing properly. This can lead to engine stalling, reduced performance, and potential damage to the fuel system. Braided fuel lines aim to mitigate this problem by providing better insulation and heat resistance.

The design of braided fuel lines is meticulous. It starts with selecting the right materials, often a combination of rubber and plastic compounds, which offer flexibility and durability. These materials are then braided in a specific pattern, ensuring that the fuel line maintains its shape and structure even under pressure. The braiding process creates a compact, flexible, and lightweight fuel line that can withstand the rigors of the engine environment.

One of the key advantages of braided fuel lines is their ability to provide superior insulation. The braided pattern traps air between the strands, creating a layer of insulation that helps regulate fuel temperature. This is crucial in preventing vaporization, especially during prolonged periods of high-temperature operation. By maintaining a more consistent fuel temperature, braided fuel lines can significantly reduce the likelihood of vapor lock.

Additionally, the efficiency of braided fuel lines is notable. The braided design allows for better fuel flow, ensuring that the engine receives a steady supply of fuel. This improved flow can lead to better engine performance, faster response times, and a more responsive driving experience. The braiding technique also helps to reduce fuel pressure drop, ensuring that the fuel system operates optimally under various driving conditions.

In summary, braided fuel lines offer a practical solution to the challenges posed by vapor lock and fuel system inefficiencies. Their design, combining careful material selection and a precise braiding process, results in fuel lines that provide excellent insulation, prevent vaporization, and improve overall fuel system efficiency. As a result, braided fuel lines are becoming an increasingly popular choice for vehicle manufacturers and enthusiasts seeking to optimize their fuel systems.

Choosing the Right Fuel Line for Your Lawn Mower: A Guide

You may want to see also

Frequently asked questions

Braided fuel lines are designed to provide a more flexible and durable alternative to traditional fuel lines. They are made with a braided pattern of fibers, typically steel or stainless steel, which offers several advantages. Firstly, the braided construction provides excellent flexibility, allowing the fuel line to move and bend without kinking or cracking, even under extreme conditions. This flexibility is crucial in preventing vapor lock, as it ensures that the fuel line can accommodate the engine's movement without restricting fuel flow. Additionally, the braided material offers superior insulation properties, helping to maintain the fuel's temperature and reduce the risk of vaporization, especially in hot environments.

Yes, braided fuel lines can be an excellent replacement for traditional rubber fuel lines. Braided lines offer several benefits over rubber, including increased durability, flexibility, and resistance to heat and chemicals. They are less prone to cracking and can withstand higher pressure, making them ideal for high-performance applications. However, it's important to ensure that the braided fuel line is compatible with your vehicle's fuel system and that the correct size and length are chosen to fit the existing mounting points. Proper installation and regular maintenance will further enhance the performance and longevity of the braided fuel line.

Proper maintenance is essential to ensure the longevity of braided fuel lines. Here are some tips:

- Regularly inspect the fuel lines for any signs of damage, such as cracks, leaks, or corrosion.

- Keep the fuel lines clean and free from debris and contaminants that could affect performance.

- Check for any clogs or blockages in the fuel system that might impact fuel flow.

- Use a fuel stabilizer in the tank to prevent fuel degradation and maintain its quality.

- Avoid using high-octane fuels that could potentially damage the braided material over time.

- Ensure that the fuel lines are securely mounted and protected from physical damage, especially during extreme weather conditions.