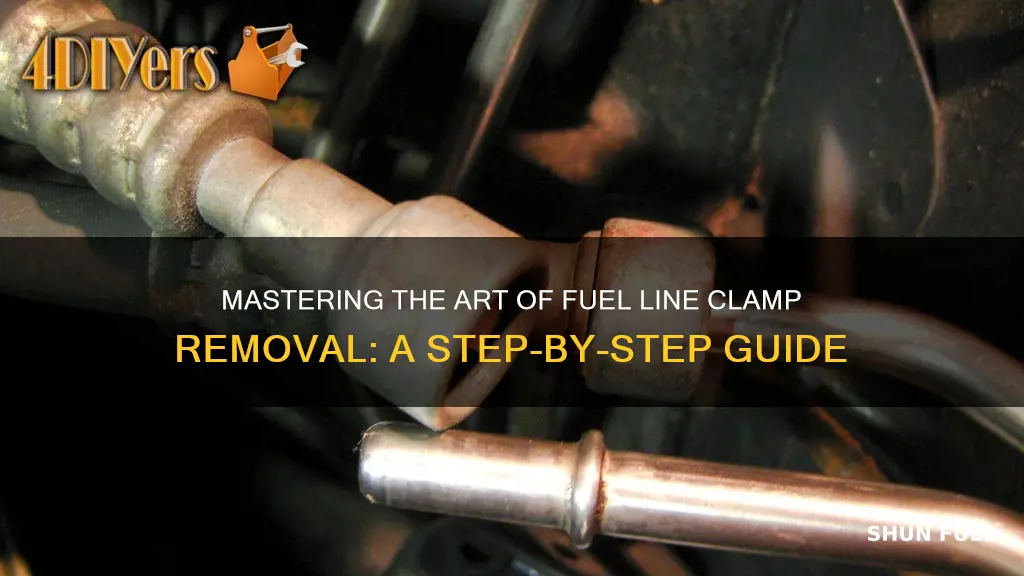

Removing fuel line clamps can be a straightforward process, but it requires careful attention to detail to avoid any potential hazards. Before beginning, ensure you have the necessary tools, such as a wrench or pliers, and a clean workspace. Start by identifying the specific clamp you need to remove, as different types of fuel lines may require varying techniques. Locate the clamp securely holding the fuel line and use the appropriate tool to loosen and remove it, being mindful of any fuel that may spill. Once the clamp is removed, carefully inspect the fuel line for any signs of damage or wear, and replace it if necessary. Always follow safety guidelines and consult a professional if you're unsure about any step.

What You'll Learn

- Identify Clamp Type: Determine the type of fuel line clamp (e.g., metal, plastic) to use the appropriate removal method

- Locate Clamp: Find the specific clamp you want to remove, often located near the fuel tank or engine

- Use Wrench or Pliers: Apply gentle force with a wrench or pliers to loosen and remove the clamp

- Slide or Cut: Slide the clamp off the fuel line or carefully cut it with a sharp tool

- Replace or Repair: After removal, decide if the clamp needs replacement or if the fuel line requires repair

Identify Clamp Type: Determine the type of fuel line clamp (e.g., metal, plastic) to use the appropriate removal method

Identifying the type of fuel line clamp is a crucial step before attempting to remove it, as different materials require specific removal techniques. The two primary types of fuel line clamps are metal and plastic. Each material has its own set of characteristics and challenges when it comes to removal.

Metal fuel line clamps are typically made from steel or aluminum and are known for their durability. These clamps often feature a sturdy construction with a robust design, making them more resistant to damage. When dealing with metal clamps, it's essential to use tools that won't compromise the material. A common approach is to use a pair of adjustable pliers or a fuel line clamp removal tool, which is specifically designed for this purpose. These tools provide a firm grip and allow you to apply controlled force to loosen and remove the clamp. It's important to be gentle yet firm to avoid damaging the fuel line or the clamp itself.

Plastic fuel line clamps, on the other hand, are lighter and more flexible than their metal counterparts. They are often used in applications where a more adaptable clamp is required. Plastic clamps can be more challenging to remove due to their tendency to become brittle over time. A gentle approach is recommended when dealing with plastic clamps to avoid cracking or breaking them. You can use a similar set of tools as for metal clamps, but be extra careful not to apply excessive force. Sometimes, a small amount of heat can be applied to the clamp to make it more pliable, but be cautious not to overheat the plastic.

In some cases, you might encounter a hybrid clamp that combines metal and plastic components. These clamps can be a bit more complex to remove, as you'll need to consider the removal techniques for both materials. It's important to assess the specific design of the clamp to determine the best approach.

Remember, when removing fuel line clamps, it's crucial to take your time and use the appropriate tools for the clamp type. Rushing the process or using the wrong tools can lead to damage or injury. Always prioritize safety and follow the manufacturer's guidelines for your specific vehicle and fuel line system.

Understanding the Purpose of the Smaller Fuel Line on a Trimmer

You may want to see also

Locate Clamp: Find the specific clamp you want to remove, often located near the fuel tank or engine

To begin the process of removing a fuel line clamp, you must first locate the specific clamp you intend to remove. This clamp is typically found near the fuel tank or engine, as it is used to secure the fuel line to the tank or engine block. The exact location may vary depending on your vehicle's make and model, but it is generally an easily accessible spot.

Start by inspecting your vehicle's underbody or engine compartment. Look for any visible fuel lines that appear to be connected to the fuel tank or engine. These lines are often made of rubber or plastic and are usually black or dark in color. The clamp you want to remove will be attached to one of these fuel lines.

Once you've identified the fuel line, carefully inspect the area where it connects to the tank or engine. You should see a metal or plastic clamp with a screw or bolt on one end and a flat, smooth surface on the other. This clamp is designed to hold the fuel line in place and prevent any leaks.

If you're having trouble finding the clamp, you can refer to your vehicle's owner's manual. It will provide detailed diagrams and illustrations of the fuel system, making it easier to identify the correct clamp. Alternatively, you can search online for images or videos specific to your vehicle's fuel line layout.

Remember, when removing the clamp, be gentle to avoid damaging the fuel line or surrounding components. Use the appropriate tools, such as a screwdriver or wrench, to loosen and remove the screws or bolts holding the clamp in place. Take your time and ensure you have a clear understanding of the process to avoid any potential issues.

Unleash Your Engine's Potential: Understanding the 8AM Fuel Line

You may want to see also

Use Wrench or Pliers: Apply gentle force with a wrench or pliers to loosen and remove the clamp

When it comes to removing fuel line clamps, using the right tools and applying the correct technique is essential to ensure a safe and efficient process. One of the most common and effective methods is to use a wrench or pliers to carefully loosen and remove the clamp. Here's a step-by-step guide on how to do this:

Start by ensuring you have the appropriate tools. A standard adjustable wrench or a pair of channel lock pliers will suffice for most fuel line clamps. It's important to choose a tool that fits the clamp's size and shape to avoid slipping or damaging the clamp. Position the wrench or pliers around the clamp, ensuring it is securely gripped. Apply gentle and steady force to loosen the clamp. Start by turning the wrench or pliers in a counterclockwise direction, which will typically loosen the clamp. Be cautious not to apply excessive force, as this can damage the fuel line or the clamp itself. The goal is to loosen the clamp enough to allow for its removal without causing any harm.

As you turn the wrench or pliers, you should feel the clamp start to move. If it doesn't, it might be stuck due to corrosion or debris. In such cases, you can try to tap the tool with a light hammer or use a small brush to clean the clamp's surface. Once the clamp is loosened, you can carefully slide it off the fuel line. Remember to be gentle during this step to avoid any sudden movements that could lead to fuel leaks.

After removing the clamp, inspect it for any signs of damage or wear. If the clamp is severely damaged, it's best to replace it to ensure the safety and efficiency of your fuel system. Additionally, check the fuel line for any cracks or signs of deterioration, as these issues can also arise from the removal process.

Using a wrench or pliers to remove fuel line clamps is a straightforward process, but it requires patience and care. By applying gentle force and taking the necessary precautions, you can successfully remove the clamp without causing any damage to the fuel system. Always remember to prioritize safety and consult a professional if you're unsure about any step.

Perfect Fuel Line Clamp for Honda XR50: Size Guide

You may want to see also

Slide or Cut: Slide the clamp off the fuel line or carefully cut it with a sharp tool

When it comes to removing fuel line clamps, there are a few methods you can employ, but sliding or cutting the clamp is a common and effective approach. This method requires a bit of patience and precision to ensure you don't damage the fuel line or cause any leaks. Here's a step-by-step guide on how to do it:

Sliding the Clamp Off: Start by identifying the clamp and its position on the fuel line. Clamps are typically made of metal or plastic and are designed to be slid over the fuel line. Locate the clamp's release mechanism, which might be a small tab or a slot. Gently insert a thin, sharp tool, such as a flathead screwdriver or a specialized fuel line removal tool, into the release mechanism. Carefully apply pressure to slide the clamp off the fuel line. Take your time to ensure you don't force it, as this could lead to damage. Once the clamp is loose, you can carefully pull it off the fuel line.

Cutting the Clamp: If sliding doesn't work or the clamp is too tight, you may need to cut it off. This method should be used as a last resort and with extreme caution. First, ensure you have the right cutting tool, such as a sharp pair of diagonal pliers or a fuel line cutter. Position the tool at the point where the clamp meets the fuel line. Apply steady pressure and cut through the clamp, being careful not to cut into the fuel line. Once the clamp is severed, carefully remove any remaining parts that are still attached to the fuel line.

Remember, when working with fuel lines, it's crucial to exercise caution to avoid any fuel leaks, which can be dangerous and cause environmental harm. Always wear protective gear, such as gloves and safety goggles, and ensure you are in a well-ventilated area. If you're unsure or uncomfortable with the process, it's best to consult a professional mechanic who can safely and efficiently remove the fuel line clamps.

Fuel Line or Coolant: Which Works Better for Your Engine?

You may want to see also

Replace or Repair: After removal, decide if the clamp needs replacement or if the fuel line requires repair

When you've successfully removed the fuel line clamp, it's crucial to assess the condition of both the clamp and the fuel line to determine the necessary course of action. Here's a step-by-step guide to help you decide whether to replace or repair:

Inspect the Clamp: Start by examining the removed clamp closely. Look for any signs of wear, damage, or corrosion. Check if the clamp's metal or plastic components are intact and free from cracks. If the clamp shows visible signs of deterioration or if the surface is corroded, it's likely that the clamp has reached the end of its useful life and needs to be replaced. Additionally, consider the age of the clamp; older clamps may be more prone to degradation over time.

Examine the Fuel Line: After inspecting the clamp, turn your attention to the fuel line itself. Carefully examine the fuel line for any cuts, punctures, or signs of damage. Even a small tear or crack can lead to fuel leaks, which are a serious safety hazard. If you notice any damage to the fuel line, it's essential to repair or replace it immediately. Look for any kinks or bends in the line, as these can also cause issues during operation.

Decide on Replacement: If the clamp shows significant wear or damage, or if the fuel line has any visible issues, it's best to replace both the clamp and the fuel line. New clamps and fuel lines will ensure a secure and safe connection, reducing the risk of fuel leaks and potential engine damage. Make sure to choose high-quality replacement parts that are compatible with your vehicle's make and model.

Consider Repair: In some cases, the fuel line might be salvageable. If the damage is minor and limited to a small section, you can attempt to repair it. Clean the affected area, apply a suitable adhesive or sealant, and ensure a proper bond. However, if the damage is extensive or the fuel line is severely compromised, replacement is the safer option.

Remember, proper maintenance and timely replacements are essential to ensure the longevity and reliability of your vehicle's fuel system. Always refer to your vehicle's manual for specific instructions and recommendations regarding fuel line maintenance and replacement.

Dirt Bike Fuel Line: Top Stores for Your Ride

You may want to see also

Frequently asked questions

When removing fuel line clamps, it's important to prioritize safety. Start by ensuring the engine is cool to avoid any burns. Use a fuel line clamp removal tool or a pair of adjustable pliers to carefully grip the clamp and loosen it. If the clamp is stubborn, apply gentle force and avoid twisting to prevent damage to the fuel line.

While a hammer might seem like a quick fix, it is not recommended for removing fuel line clamps. Hitting the clamp with a hammer can lead to fuel line damage or even personal injury. Instead, employ the proper tools and techniques mentioned above to safely and effectively release the clamp.

Corrosion on fuel line clamps can make removal challenging. In such cases, start by soaking the clamp in a suitable solvent or using a wire brush to remove the corrosion. If the clamp remains stubborn, consider replacing it with a new one to ensure a secure and reliable fuel line connection.