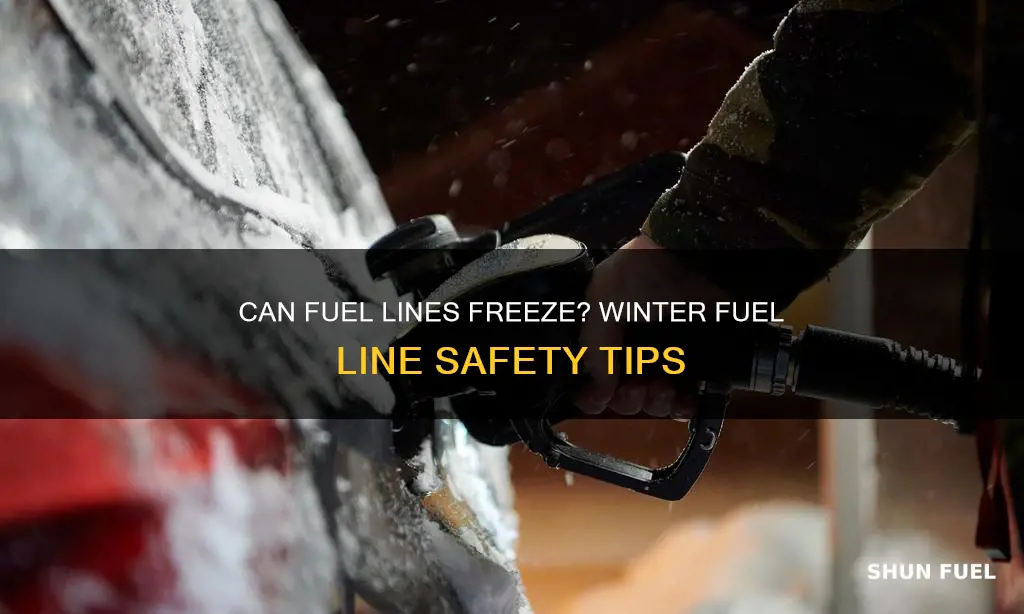

Fuel lines can indeed freeze, especially in colder climates or during winter months. This phenomenon is primarily due to the low temperatures causing the fuel to thicken and become more viscous, which can lead to blockages and reduced performance. The risk of freezing is particularly high in areas with extreme cold weather, as well as in vehicles that are not properly winterized. Understanding the potential for fuel lines to freeze is crucial for vehicle owners, as it can lead to costly repairs and inconvenience if not addressed proactively.

| Characteristics | Values |

|---|---|

| Common Issue | Yes, fuel lines can freeze, especially in cold climates. |

| Causes | Cold temperatures, lack of fuel, and poor insulation are common causes. |

| Symptoms | Engine difficulty starting, poor performance, and potential stalling. |

| Prevention | Using fuel line heaters, keeping the car in a heated garage, and using a fuel stabilizer. |

| Repair | Replacing the fuel line or using a fuel line repair kit. |

| Cost | Repair costs can vary, but replacing a fuel line can be expensive. |

| Maintenance | Regularly checking and maintaining the fuel system is recommended. |

| Safety | Frozen fuel lines can lead to engine damage and should be addressed promptly. |

What You'll Learn

- Fuel Line Material: Different materials have varying freezing points, affecting their susceptibility to freezing

- Fuel Type: Ethanol-blended fuels may freeze at lower temperatures than pure gasoline

- Fuel System Design: Proper insulation and design can prevent fuel lines from freezing

- Environmental Conditions: Cold climates and low humidity increase the risk of fuel line freezing

- Fuel System Maintenance: Regular checks and maintenance can identify and address potential freezing issues

Fuel Line Material: Different materials have varying freezing points, affecting their susceptibility to freezing

Fuel lines are an essential component of any vehicle's fuel system, and their material composition plays a critical role in determining their ability to withstand freezing temperatures. Different materials have varying freezing points, which directly impact their susceptibility to freezing and, consequently, their performance in cold climates. Understanding these material properties is crucial for ensuring the reliable operation of fuel systems in all weather conditions.

One of the most common materials used for fuel lines is rubber, which is known for its flexibility and durability. Rubber fuel lines are often made from synthetic compounds, such as neoprene or nitrile, which offer excellent resistance to fuel degradation and chemical corrosion. However, rubber has a relatively low freezing point, typically around -40°F (-40°C). When temperatures drop below this threshold, rubber fuel lines can become brittle and prone to cracking, leading to potential fuel leaks and system failures.

In contrast, fuel lines made from more robust materials, such as steel or stainless steel, have higher freezing points. These materials are less susceptible to freezing and can withstand much lower temperatures without losing their structural integrity. Steel fuel lines are often used in high-performance vehicles or in regions with extremely cold climates, where maintaining a reliable fuel supply is critical. The higher freezing point of steel ensures that the fuel lines remain flexible and functional even in sub-zero temperatures.

Another material commonly used for fuel lines is PVC (polyvinyl chloride). PVC is lightweight, cost-effective, and offers good chemical resistance, making it a popular choice for fuel lines. However, PVC has a relatively low freezing point, similar to rubber, and can become brittle in cold weather. This material is more commonly used in fuel systems that are not exposed to extreme cold, as it may not provide the necessary durability in such conditions.

For applications requiring the highest level of reliability in freezing temperatures, some manufacturers use a composite material called "fuel line compound." This material is a blend of rubber and other additives, specifically formulated to have a higher freezing point. Fuel line compound can withstand temperatures as low as -60°F (-51°C) or even lower, making it ideal for extreme cold climates. This specialized material ensures that fuel lines remain flexible and crack-free, even in the harshest winter conditions.

In summary, the material of a fuel line is a critical factor in determining its ability to withstand freezing temperatures. Rubber fuel lines are suitable for most vehicles but may fail in extremely cold climates. Steel and stainless steel offer higher freezing points and are more durable. PVC is a cost-effective option but may not be suitable for cold environments. Specialized composite materials provide the highest level of protection against freezing, ensuring the reliable operation of fuel systems in all weather conditions.

Fuel Line Fixes: Who's the Expert?

You may want to see also

Fuel Type: Ethanol-blended fuels may freeze at lower temperatures than pure gasoline

Ethanol-blended fuels, a common type of fuel used in many vehicles, especially in regions with colder climates, have a unique property that sets them apart from pure gasoline. One of the key characteristics of these blends is their tendency to freeze at lower temperatures compared to pure gasoline. This phenomenon is primarily due to the presence of ethanol, which is a polar solvent, in the fuel mixture.

When ethanol is added to gasoline, it lowers the freezing point of the resulting fuel. Pure gasoline, being a non-polar substance, has a higher freezing point, typically around -40°F (-40°C) or lower. However, when ethanol is introduced, the freezing point can drop significantly, sometimes as low as -25°F (-32°C) or even lower, depending on the ethanol content. This change in freezing point is crucial information for vehicle owners and operators, especially in colder regions.

The lower freezing point of ethanol-blended fuels can lead to several important considerations. Firstly, it means that these fuels can remain in a liquid state at temperatures where pure gasoline would already be solid. This is particularly relevant during the winter months when temperatures drop below the freezing point of pure gasoline. Secondly, it highlights the need for proper fuel management and storage, especially in regions with extreme cold weather.

For vehicle owners, this means ensuring that fuel lines and tanks are adequately insulated to prevent freezing. It also emphasizes the importance of using the correct type of fuel for the climate. In colder areas, using ethanol-free gasoline or blends with lower ethanol content can be necessary to avoid fuel system issues. Additionally, regular maintenance of fuel systems, such as fuel filters and lines, is crucial to prevent blockages and ensure optimal performance.

Understanding the freezing behavior of ethanol-blended fuels is essential for vehicle maintenance and operation, especially in regions with harsh winters. It allows for better preparation and the use of appropriate measures to ensure that fuel systems remain functional even in the coldest conditions. By being aware of these fuel properties, vehicle owners can take the necessary steps to protect their engines and ensure reliable performance throughout the year.

Fuel Line Placement: Carb Dirtbike Guide

You may want to see also

Fuel System Design: Proper insulation and design can prevent fuel lines from freezing

The prevention of fuel lines from freezing is a critical aspect of vehicle maintenance, especially in regions with cold climates. Fuel lines, which carry gasoline or diesel from the tank to the engine, can become susceptible to freezing temperatures, leading to potential engine issues and performance problems. Proper insulation and design of the fuel system are essential to mitigate this risk.

Insulation plays a vital role in maintaining the temperature of the fuel lines. When fuel lines are exposed to cold environments, they can lose heat to the surrounding air, causing the fuel to cool down rapidly. This is particularly problematic as fuel volume decreases with temperature, and the fuel's energy content can also be affected. Insulating the fuel lines with specialized materials, such as foam or rubber, helps retain heat and prevents the fuel from freezing. These insulating materials are designed to withstand low temperatures and provide a protective barrier around the fuel lines.

The design of the fuel system also contributes significantly to preventing freezing. Engineers can implement various strategies to ensure the system's reliability in cold conditions. One approach is to use a fuel pump with a built-in electric heater, which can maintain the fuel temperature and prevent ice formation. Additionally, incorporating a fuel filter with a heating element can further enhance the system's performance. These design choices ensure that the fuel remains in a liquid state, allowing for efficient combustion and optimal engine operation.

In regions with extremely low temperatures, a fuel tank heater can be a valuable addition. This device is designed to maintain the fuel temperature within the tank, preventing it from freezing. By keeping the fuel warm, the overall fuel system's efficiency is improved, and the risk of fuel line freezing is significantly reduced. Proper insulation and design also include the use of flexible hoses and connections, which can better withstand temperature fluctuations without cracking or leaking.

Furthermore, regular maintenance and inspections are crucial. Vehicle owners should check the fuel lines for any signs of damage or wear, especially after exposure to freezing temperatures. Ensuring that the fuel system is clean and free from debris is essential, as contaminants can affect the fuel's properties and increase the likelihood of freezing. By implementing these design considerations and maintenance practices, vehicle owners can effectively prevent fuel lines from freezing, ensuring reliable engine performance throughout the year.

Mastering the Art of Soldering: Pinhole Repairs in Metal Fuel Lines

You may want to see also

Environmental Conditions: Cold climates and low humidity increase the risk of fuel line freezing

In regions with cold climates, the risk of fuel lines freezing is significantly heightened. This is primarily due to the low temperatures and the lack of moisture in the air, which is known as low humidity. When these two factors combine, they create an environment that is highly susceptible to fuel line freezing.

During winter, the temperature drops, and the air becomes drier. This dry air has a lower capacity to hold moisture, which means that any water present in the fuel can start to freeze. Fuel lines, being a closed system, often contain water due to condensation or other factors. When this water freezes, it can cause blockages, cracks, and even complete ruptures in the fuel lines. These issues can lead to a variety of problems, including engine misfires, reduced performance, and even complete engine failure.

The risk is especially high in areas with extremely low humidity, as this further reduces the air's ability to absorb moisture. In such conditions, any water in the fuel system is more likely to remain in a liquid state and then freeze when temperatures drop. This can be a critical issue for vehicles and equipment that are used in cold climates, as it can lead to unexpected breakdowns and costly repairs.

To mitigate this risk, it is essential to take preventive measures. One of the most effective ways is to use a fuel stabilizer, which can help prevent water from entering the fuel system and can also inhibit the formation of ice crystals. Additionally, keeping vehicles and equipment in a heated environment or using fuel heaters can help maintain the fuel system's temperature, reducing the chances of freezing. Regular maintenance, including fuel system inspections and the use of fuel system cleaners, can also help identify and address potential issues before they become major problems.

Understanding the environmental conditions that contribute to fuel line freezing is crucial for anyone operating vehicles or equipment in cold climates. By taking the necessary precautions, such as using stabilizers and maintaining a warm environment, the risk of fuel line freezing can be significantly reduced, ensuring reliable operation and minimizing potential downtime.

Fuel Line Removal: A Tool-Free Guide to Accessing the Fuel Rail

You may want to see also

Fuel System Maintenance: Regular checks and maintenance can identify and address potential freezing issues

The cold winter months can pose a unique challenge for vehicle owners: the potential for fuel lines to freeze. This issue is often overlooked, but it can lead to significant problems, leaving you stranded with a non-starting engine. Understanding the causes and implementing regular maintenance practices can help prevent this from happening.

One of the primary reasons fuel lines can freeze is the presence of water. Over time, water can enter the fuel system, especially if the fuel tank is not properly sealed or if there are issues with the fuel pump. When temperatures drop, this water can freeze, causing blockages and damage to the fuel lines. It's crucial to ensure that your fuel tank is in good condition and that all connections are secure to minimize the risk of water intrusion.

Regular maintenance is key to identifying and addressing potential freezing issues. Here are some steps you can take:

- Fuel Line Inspection: Periodically inspect the fuel lines for any signs of damage, cracks, or leaks. Look for any discolored or wet spots along the lines, as these could indicate water infiltration. If you notice any issues, have them repaired or replaced immediately.

- Fuel Filter Replacement: Changing the fuel filter regularly is essential. A clogged filter can restrict fuel flow and may trap water, which can then freeze. It's recommended to replace the filter every 30,000 to 50,000 miles or as per your vehicle's manufacturer guidelines.

- Engine Oil and Coolant Checks: Ensure that your engine oil and coolant levels are maintained as per the manufacturer's specifications. These fluids can absorb moisture, and proper levels will help prevent the formation of ice crystals in the engine and fuel system.

- Fuel System Flush: Consider flushing the fuel system with a fuel system cleaner to remove any contaminants, including water. This process can help ensure that the entire fuel system, including the lines, is free from potential freezing agents.

In addition to these maintenance practices, it's beneficial to park your vehicle in a garage or in a location that is protected from extreme cold. If you live in a particularly cold climate, consider using a fuel line heater, which can be installed in the fuel lines to prevent freezing.

By implementing these regular checks and maintenance routines, you can significantly reduce the chances of fuel line freezing and ensure that your vehicle's fuel system remains reliable, even during the harshest winter conditions. Remember, prevention is always better than cure when it comes to vehicle maintenance.

Chevy Silverado Fuel Line: 2008 Model Size Guide

You may want to see also

Frequently asked questions

Yes, fuel lines can freeze, especially in regions with extremely low temperatures. This is because the fuel in the lines can reach a freezing point, especially if it contains water or is not treated with an anti-freeze additive. When fuel freezes, it can block the flow, causing issues with starting the engine and potentially leading to engine damage.

To prevent freezing, it is recommended to use a fuel stabilizer or an anti-freeze additive in your fuel. These products can help lower the freezing point of the fuel, ensuring it remains liquid even in cold temperatures. Additionally, keeping your vehicle in a garage or using a block heater can provide additional warmth to the engine bay, reducing the chances of fuel line freezing.

If you notice any issues with starting your vehicle in cold weather, it is best to seek professional help. A mechanic can inspect the fuel lines for any signs of freezing, blockage, or damage. They may also recommend draining and replacing the fuel if necessary. It is important to address this issue promptly to avoid prolonged engine problems.