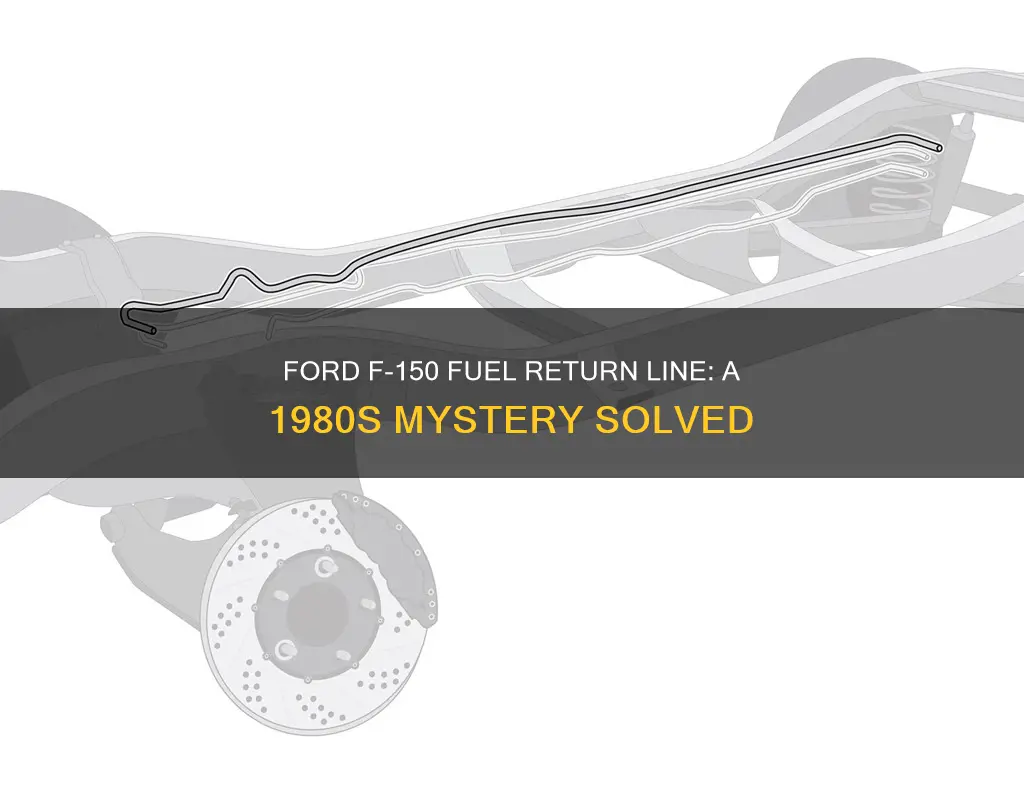

The 1980-1986 Ford F-150 pickup trucks were equipped with a fuel return line, which was a crucial component of the fuel system. This line directed excess fuel from the fuel tank back to the engine, ensuring that the fuel system remained properly pressurized and that the engine received the correct amount of fuel. Understanding the presence and function of the fuel return line is essential for any owner or mechanic working on these vehicles, as it can impact performance and fuel efficiency.

| Characteristics | Values |

|---|---|

| Fuel Return Line | The 1980-1986 Ford F150 models did not have a fuel return line. |

| Fuel System | These trucks used a conventional carburetor system without a return line. |

| Engine Type | V8 or inline-six gasoline engines. |

| Production Years | 1980-1986. |

| Model Variants | F150, F150 Regular Cab, F150 Extended Cab, F150 Crew Cab. |

| Fuel Capacity | Typically 24 gallons (98 liters) for the F150. |

| Fuel Injection | Not equipped with fuel injection during this period. |

| Return Line Purpose | A fuel return line is used to recycle fuel vapor from the carburetor to the fuel tank, which is not a feature in these models. |

What You'll Learn

- Engine Design: 1980-1986 Ford F150 engines had fuel return lines for efficient fuel management

- Performance: Fuel return lines improved engine performance and reduced emissions

- Reliability: These lines ensured reliable fuel supply, enhancing vehicle dependability

- Maintenance: Regular inspection of fuel return lines is crucial for vehicle maintenance

- Safety: Proper fuel return line function is essential for vehicle safety and preventing accidents

Engine Design: 1980-1986 Ford F150 engines had fuel return lines for efficient fuel management

The 1980-1986 Ford F150 engines were designed with a fuel return line, an essential component for efficient fuel management. This feature was a significant improvement over earlier models, addressing the issue of fuel wastage and optimizing engine performance. The fuel return line is a crucial part of the fuel injection system, allowing for better control and management of the fuel flow.

In these vehicles, the fuel return line connects the fuel tank to the engine, creating a loop that ensures any excess fuel is returned to the tank. When the engine is idling or during low-speed operation, the fuel pump may not be able to maintain a constant pressure, leading to potential fuel starvation. The return line prevents this by allowing the excess fuel to flow back, ensuring a steady supply when needed. This design feature was particularly important for the F150's powerful V8 engine, which required precise fuel management to deliver optimal performance.

Engineers at Ford implemented this system to enhance the overall efficiency of the vehicle. By having a fuel return line, the engine could maintain a consistent fuel-air mixture, resulting in improved power output and better fuel economy. This design also contributed to a more stable engine operation, reducing the chances of engine knock and improving the overall driving experience.

The 1980-1986 F150's fuel return line was a well-thought-out addition, showcasing Ford's commitment to innovation in engine design. It demonstrated an understanding of the complexities of fuel injection systems and the need for efficient fuel management. This feature not only benefited the engine's performance but also contributed to a more environmentally friendly approach, as efficient fuel usage translates to reduced emissions.

For enthusiasts and owners of these classic trucks, understanding the presence and importance of the fuel return line is valuable knowledge. It highlights the advanced engineering of these vehicles and provides insight into why the 1980-1986 F150s are considered reliable and powerful machines. This feature, often overlooked, is a testament to Ford's attention to detail and their pursuit of excellence in automotive engineering.

Tribeca Fuel Line Removal: A Step-by-Step Guide for 2006 Models

You may want to see also

Performance: Fuel return lines improved engine performance and reduced emissions

The 1980-1986 Ford F-150, a classic pickup truck, utilized a fuel return line as a crucial component in its fuel system. This line played a significant role in enhancing engine performance and contributing to reduced emissions. By implementing this design, Ford engineers aimed to optimize fuel delivery and ensure efficient combustion.

The fuel return line's primary function was to facilitate the return of excess fuel from the injectors to the fuel tank. When the engine was running, the injectors would spray fuel into the intake manifold or directly into the cylinders. However, during certain operating conditions, such as when the engine was idling or during rapid acceleration, there could be a surplus of fuel. This excess fuel needed to be managed to prevent rich combustion, which could lead to decreased engine performance and increased emissions.

With the fuel return line, any excess fuel that was not injected into the cylinders was directed back to the fuel tank. This process ensured that the fuel system remained balanced and that the engine operated within the optimal fuel-air mixture range. By reducing the amount of unburned fuel in the system, the engine's performance improved, as it could maintain a more precise air-fuel ratio. This precision resulted in more efficient combustion, producing more power and better fuel economy.

Furthermore, the fuel return line contributed to reduced emissions. When excess fuel is left in the system, it can lead to the formation of harmful pollutants, such as carbon monoxide and unburned hydrocarbons. By returning this fuel to the tank, the engine's combustion process became cleaner, minimizing the release of these pollutants into the atmosphere. This not only improved the F-150's environmental performance but also ensured compliance with the emissions standards of the time.

In summary, the fuel return line in the 1980-1986 Ford F-150 was a critical component that enhanced engine performance and contributed to reduced emissions. Its design allowed for efficient fuel management, ensuring optimal combustion and a balanced fuel-air mixture. This feature was a testament to Ford's commitment to engineering innovative solutions that benefited both the vehicle's performance and environmental impact.

Transmission Oil vs. Fuel: Exploring the Feasibility of a Swap

You may want to see also

Reliability: These lines ensured reliable fuel supply, enhancing vehicle dependability

The 1980-1986 Ford F-150 pickup trucks, renowned for their durability and power, utilized a fuel return line as a crucial component in their fuel system design. This feature played a significant role in ensuring the vehicle's reliability and performance. By incorporating a fuel return line, Ford engineers aimed to optimize fuel efficiency and maintain a consistent fuel supply to the engine.

The fuel return line is an essential part of the fuel system's design, especially in older vehicles like the F-150. It acts as a safety net, preventing fuel from pooling in the tank and ensuring that any excess fuel is returned to the fuel tank instead of accumulating in the lines. This design feature is particularly important as it helps maintain a steady fuel pressure, which is critical for optimal engine performance. With a well-functioning fuel return line, the F-150 could deliver fuel efficiently, ensuring that the engine received the required amount of fuel without wastage.

In the context of reliability, this fuel return line design had a direct impact on the vehicle's dependability. By preventing fuel accumulation in the lines, it reduced the risk of fuel-related issues such as engine misfires, stalling, or reduced power output. This was especially crucial during long journeys or when the vehicle was subjected to varying driving conditions. The consistent fuel supply ensured that the engine could maintain its performance levels, providing drivers with a reliable and dependable vehicle.

Furthermore, the fuel return line's functionality contributed to the overall longevity of the F-150. By minimizing fuel-related problems, it reduced the chances of engine damage and the need for frequent repairs. This feature was particularly beneficial for professional drivers or those who relied on their vehicles for work, as it ensured minimal downtime and maximum productivity. The reliability of the fuel system, in turn, enhanced the overall reputation of the Ford F-150 as a robust and trustworthy vehicle.

In summary, the inclusion of a fuel return line in the 1980-1986 Ford F-150 was a strategic design choice that significantly contributed to the vehicle's reliability. It ensured a consistent and efficient fuel supply, reducing the likelihood of performance issues and engine damage. This feature is a testament to Ford's commitment to building durable and dependable vehicles, making the F-150 a trusted choice for drivers seeking a reliable workhorse.

Understanding Aluminum Fuel Line Ratings: A Comprehensive Guide

You may want to see also

Maintenance: Regular inspection of fuel return lines is crucial for vehicle maintenance

The fuel return line is an essential component of a vehicle's fuel system, and its proper functioning is critical to the overall performance and longevity of the engine. For Ford F150 models from 1980 to 1986, understanding the maintenance requirements of this line is vital, especially for those who own and operate these vehicles regularly.

Regular inspections of the fuel return line are a fundamental aspect of vehicle maintenance. This line is responsible for directing excess fuel from the injectors back to the fuel tank, ensuring that the engine operates efficiently and preventing fuel accumulation in the system. Over time, this line can develop issues such as clogs, leaks, or damage, which may lead to reduced engine performance, increased fuel consumption, and potential safety hazards.

During an inspection, owners should look for any signs of deterioration, such as cracks, corrosion, or kinks in the line. These issues can be caused by various factors, including age, exposure to harsh weather conditions, and the presence of contaminants in the fuel. It is recommended to use a bright flashlight to examine the line for any blockages or damage, especially in hard-to-reach areas. If any problems are identified, immediate attention is necessary to prevent further complications.

In addition to visual inspections, it is beneficial to listen for any unusual noises during the engine's operation. A whistling or hissing sound could indicate a potential issue with the fuel return line, such as a leak or a partially blocked line. Regularly checking for these signs and addressing them promptly can save vehicle owners from more extensive and costly repairs in the future.

To ensure optimal vehicle performance, it is advised to consult the manufacturer's guidelines or seek professional advice for specific maintenance procedures. Regular maintenance and inspections of the fuel return line will contribute to a well-maintained vehicle, providing peace of mind and potentially extending the life of the Ford F150.

Unraveling the Mystery: Why Fuel Lines Break

You may want to see also

Safety: Proper fuel return line function is essential for vehicle safety and preventing accidents

The fuel return line is a critical component in a vehicle's fuel system, especially for older models like the 1980-1986 Ford F150. Its primary function is to ensure that any excess fuel that cannot be burned in the engine is safely returned to the fuel tank, preventing potential hazards. When this line malfunctions or is absent, it can lead to dangerous situations on the road.

One of the key safety concerns is the risk of fuel accumulation and potential fire hazards. In older vehicles, the fuel return line might not have been as robust as modern systems, making it more susceptible to damage or clogs. If the line is blocked or damaged, fuel can accumulate in the system, creating a flammable mixture that could ignite under certain conditions. This is a serious safety issue, especially during high-temperature situations or when the vehicle is stationary.

Furthermore, a malfunctioning fuel return line can lead to engine performance issues. When the line is not functioning correctly, fuel may not be properly recycled, resulting in a buildup of fuel in the system. This can cause the engine to run rich, leading to reduced performance, increased emissions, and potential engine damage over time. In extreme cases, it might even cause the engine to stall or fail to start.

To ensure vehicle safety, it is crucial to regularly inspect and maintain the fuel return line. Drivers should look out for any signs of damage, such as cracks, leaks, or blockages. If any issues are detected, immediate professional attention is required to prevent further complications. Proper maintenance can also include using the correct type of fuel and ensuring the fuel tank is kept clean to minimize the risk of contamination and potential line blockages.

In summary, the fuel return line plays a vital role in vehicle safety, especially for older models like the 1980-1986 Ford F150. Its proper function is essential to prevent fuel accumulation, potential fire hazards, and engine performance issues. Regular maintenance and inspections are key to ensuring the line remains in good condition, ultimately contributing to a safer driving experience.

Grease's Fuel Line Fitting: A Comprehensive Guide

You may want to see also

Frequently asked questions

Yes, these models were equipped with a fuel return line, which is a crucial component in the fuel system. The return line allows excess fuel to flow back to the fuel tank, ensuring proper fuel management and preventing fuel accumulation in the lines.

The primary function of the fuel return line is to maintain a consistent fuel pressure and ensure efficient fuel delivery to the engine. It helps in preventing fuel wastage and allows for better engine performance by providing a continuous supply of fuel.

Over time, the fuel return line can develop issues such as clogs, leaks, or damage due to age and wear. Clogged lines can lead to reduced fuel flow, while leaks may result in fuel wastage and potential engine performance problems. Regular inspection and maintenance are recommended to ensure optimal performance.

Signs of potential fuel return line issues include engine misfires, reduced power, or unusual fuel odors. If you notice any changes in engine behavior or fuel efficiency, it is advisable to inspect the fuel system, including the return line, for any signs of damage or blockages.