When it comes to vehicle maintenance, ensuring the integrity of fuel lines is crucial for optimal performance and safety. One common question that arises is whether thread tape can be used on fuel lines. Thread tape, also known as thread sealing tape, is a versatile tool used for sealing threads and preventing leaks. However, its application on fuel lines requires careful consideration due to the specific requirements and risks associated with fuel systems. This paragraph will explore the suitability of thread tape for fuel lines, considering factors such as material compatibility, durability, and the potential risks of using alternative sealing methods.

| Characteristics | Values |

|---|---|

| Material Compatibility | Thread tape is generally not recommended for fuel lines as it may not adhere well to the material, potentially leading to leaks. |

| Temperature Resistance | It can withstand moderate temperatures, but prolonged exposure to high temperatures (over 200°F) may cause it to degrade. |

| Flexibility | Thread tape is flexible, allowing it to conform to the shape of the fuel line, but it may not provide the same level of flexibility as specialized fuel line tape. |

| Adhesion | The adhesion of thread tape can vary depending on the surface it is applied to. It may not adhere strongly to fuel lines, especially if they are made of certain materials. |

| Leak Prevention | Using thread tape on fuel lines is not an effective method for preventing leaks. It is not designed for this purpose and may not create a secure seal. |

| Durability | Over time, thread tape may become brittle and crack, especially in harsh environments, which can lead to fuel leaks. |

| Alternatives | For fuel line repairs, consider using specialized fuel line tape or rubber fuel line repair kits, which are designed to provide a secure and long-lasting solution. |

What You'll Learn

- Tape Compatibility: Is thread tape suitable for all fuel line materials

- Leak Prevention: Can thread tape effectively prevent fuel line leaks

- Durability: How long does thread tape last on fuel lines

- Installation: What's the best way to apply thread tape to fuel lines

- Safety: Are there any safety concerns using thread tape on fuel lines

Tape Compatibility: Is thread tape suitable for all fuel line materials?

When it comes to working on fuel lines, ensuring the right materials are used is crucial for safety and performance. One common question that arises is whether thread tape, also known as electrical tape or insulation tape, is suitable for all fuel line materials. The answer is not a simple yes or no, as it depends on the specific characteristics of the fuel line and the tape itself.

Thread tape is typically made from materials like vinyl, rubber, or a combination of both. These materials are chosen for their flexibility, durability, and ability to provide a secure bond. However, not all fuel lines are created equal. Different types of fuel lines can be made from various materials, such as rubber, plastic, or metal. For example, older fuel lines might be made from natural rubber, while newer ones could be constructed from synthetic materials like EPDM (ethylene propylene diene monomer) rubber or PVC (polyvinyl chloride).

The compatibility of thread tape with fuel line materials is essential to consider. If the tape is not compatible with the fuel line material, it may not adhere properly, leading to potential issues. Incompatible tape can cause the fuel line to become loose over time, resulting in fuel leaks or reduced performance. On the other hand, if the tape is too aggressive and damages the fuel line during installation, it can create a safety hazard. Therefore, it is crucial to understand the specific requirements of the fuel line and choose the appropriate thread tape accordingly.

To ensure compatibility, it is recommended to consult the manufacturer's guidelines or specifications for both the fuel line and the thread tape. Some manufacturers provide detailed instructions on their websites or product packaging, specifying the types of materials their products are designed for. Additionally, automotive repair manuals or fuel system maintenance guides might offer valuable insights into the compatibility of different materials.

In summary, while thread tape can be a useful tool for securing and protecting fuel lines, its suitability depends on the specific fuel line material. It is essential to consider the composition of the fuel line and select thread tape that is compatible to ensure a secure and safe installation. Always refer to the manufacturer's recommendations and guidelines to make informed decisions when working with fuel systems.

Fuel Line Placement: Expert Tips for Optimal Performance

You may want to see also

Leak Prevention: Can thread tape effectively prevent fuel line leaks?

Thread tape, also known as thread sealing tape or thread locking tape, is a type of adhesive tape designed to create a secure and leak-resistant seal on threaded connections. It is commonly used in plumbing and automotive applications to reinforce and protect threads, ensuring a tight and reliable bond. When it comes to fuel lines, the question arises: Can thread tape effectively prevent leaks?

In the context of fuel lines, thread tape can be a valuable tool for leak prevention. Fuel lines are crucial components in a vehicle's engine system, responsible for transporting fuel from the tank to the engine. Over time, these lines can develop leaks due to various factors such as corrosion, damage, or improper installation. Thread tape offers a practical solution to address this issue. By applying thread tape to the threads of the fuel line connectors, you create a robust and flexible barrier that seals the connection. This tape is typically made of a strong adhesive material that adheres to the threads, providing a reliable seal. The tape's adhesive properties create a tight bond, preventing any gaps or spaces that could lead to fuel leakage.

The effectiveness of thread tape lies in its ability to provide a secure and durable seal. When applied correctly, it forms a continuous barrier around the threads, ensuring that no fuel can seep through. This is particularly important in fuel lines, as leaks can lead to engine misfires, reduced performance, and potential safety hazards. Thread tape is designed to withstand the pressure and temperature changes associated with fuel systems, making it a reliable choice for leak prevention. Additionally, its flexibility allows it to accommodate slight movements and vibrations, ensuring a long-lasting seal without compromising the functionality of the fuel line.

However, it is essential to follow proper installation techniques when using thread tape on fuel lines. The tape should be applied in a clean and dry environment, ensuring that the threads are free from dirt and debris. Over-tightening or under-tightening the connections can also affect the tape's performance. It is recommended to consult the vehicle's manual or seek professional guidance for specific instructions on using thread tape for fuel line repairs or maintenance.

In summary, thread tape can be an effective method for preventing fuel line leaks. Its ability to create a secure and flexible seal makes it a valuable tool for maintaining the integrity of fuel lines. By providing a reliable barrier around the threads, thread tape ensures that fuel lines remain leak-free, contributing to the overall performance and safety of the vehicle's engine system. Proper installation techniques and regular inspections are key to maximizing the benefits of using thread tape for leak prevention in fuel lines.

Understanding In-Line Fuel Filters: Benefits and Maintenance Tips

You may want to see also

Durability: How long does thread tape last on fuel lines?

The durability of thread tape on fuel lines is an important consideration for any vehicle owner or mechanic. Thread tape, also known as thread sealing tape or thread locking tape, is a type of adhesive tape designed to secure and seal threads on various components, including fuel lines. It is commonly used to repair or reinforce connections in automotive applications.

When it comes to fuel lines, thread tape can be a reliable solution for temporary repairs or as a preventative measure to avoid leaks. The tape is typically made from a strong, flexible material that adheres well to the threads of the fuel line, creating a tight seal. This can be particularly useful in situations where a more permanent fix is not feasible or when quick access to the vehicle is required.

The longevity of thread tape on fuel lines depends on several factors. Firstly, the quality of the tape itself plays a significant role. High-quality thread tape, often made from durable materials like polyester or nylon, can provide excellent resistance to fuel chemicals and environmental factors. These tapes are designed to withstand the harsh conditions of fuel systems, including exposure to fuel vapors, temperature fluctuations, and mechanical stress.

Secondly, the installation process is crucial for long-term durability. Proper application ensures a strong bond between the tape and the fuel line threads. This involves cleaning the threads to remove any debris, applying a thin layer of tape, and using a tight-fitting ferrule or connector to compress the tape, creating a secure seal. If the installation is not done correctly, the tape may come loose or fail over time.

Additionally, the environment in which the thread tape is used can impact its durability. Fuel lines exposed to extreme temperatures, vibrations, or corrosive substances may require more robust tape solutions. In such cases, specialized thread tape designed for high-performance applications might be necessary. These tapes often feature enhanced adhesive properties and additional protective layers to ensure longevity.

In summary, thread tape can be a viable option for securing fuel lines, especially in temporary or low-stress applications. However, for long-term reliability, it is essential to choose high-quality tape, ensure proper installation, and consider the specific environmental demands of the fuel system. Regular inspections and maintenance can also help identify and address any potential issues with thread tape on fuel lines.

Duramax Fuel Line Diameter: 2003 Specs Revealed

You may want to see also

Installation: What's the best way to apply thread tape to fuel lines?

When it comes to working with fuel lines, it's important to ensure that any modifications or repairs are done safely and effectively. Thread tape, also known as electrical tape or insulating tape, can be a useful tool for sealing and reinforcing fuel lines. Here's a step-by-step guide on how to apply thread tape to fuel lines for optimal performance and longevity:

Step 1: Prepare the Fuel Line

Before applying thread tape, ensure that the fuel line is clean and free of any debris or contaminants. Use a cloth or a soft brush to wipe down the surface, removing any dirt or old tape residue. This step is crucial to ensure proper adhesion and prevent any potential leaks.

Step 2: Measure and Cut the Thread Tape

Thread tape typically comes in rolls, and you'll need to measure the length of the fuel line that requires reinforcement. Cut the tape to the appropriate length, ensuring it is slightly longer than the fuel line section you want to cover. This extra length will allow for proper overlap and secure bonding.

Step 3: Apply the Tape

Start by wrapping the thread tape around the fuel line, overlapping the edges by about 1/2 inch. Press the tape firmly against the fuel line to create a tight seal. Ensure that the tape is wrapped in a clockwise direction, following the natural flow of the fuel line. Apply enough pressure to make the tape adhere to the line, but be careful not to overtighten, as it may restrict fuel flow.

Step 4: Secure with Clamps (Optional)

For added security, especially on longer fuel lines, consider using clamps to hold the tape in place. Place the clamp around the fuel line and tape, ensuring it is tight and secure. This extra step can provide additional protection against fuel leaks and ensure the tape remains in place over time.

Step 5: Test and Inspect

After applying the thread tape, it's essential to test the fuel system for any leaks. Start the engine and check for any signs of fuel escaping at the taped area. If no leaks are detected, inspect the tape to ensure it is intact and securely bonded. Regularly check the tape's condition, especially in areas with high vibration or temperature fluctuations, and reapply or replace it as necessary.

Remember, when working with fuel lines, it's always better to be cautious and thorough. Properly applying thread tape can help prevent fuel leaks, improve fuel efficiency, and ensure the overall reliability of your vehicle's fuel system.

Amplifying Safety: The Fuel Line Clip Lock Advantage

You may want to see also

Safety: Are there any safety concerns using thread tape on fuel lines?

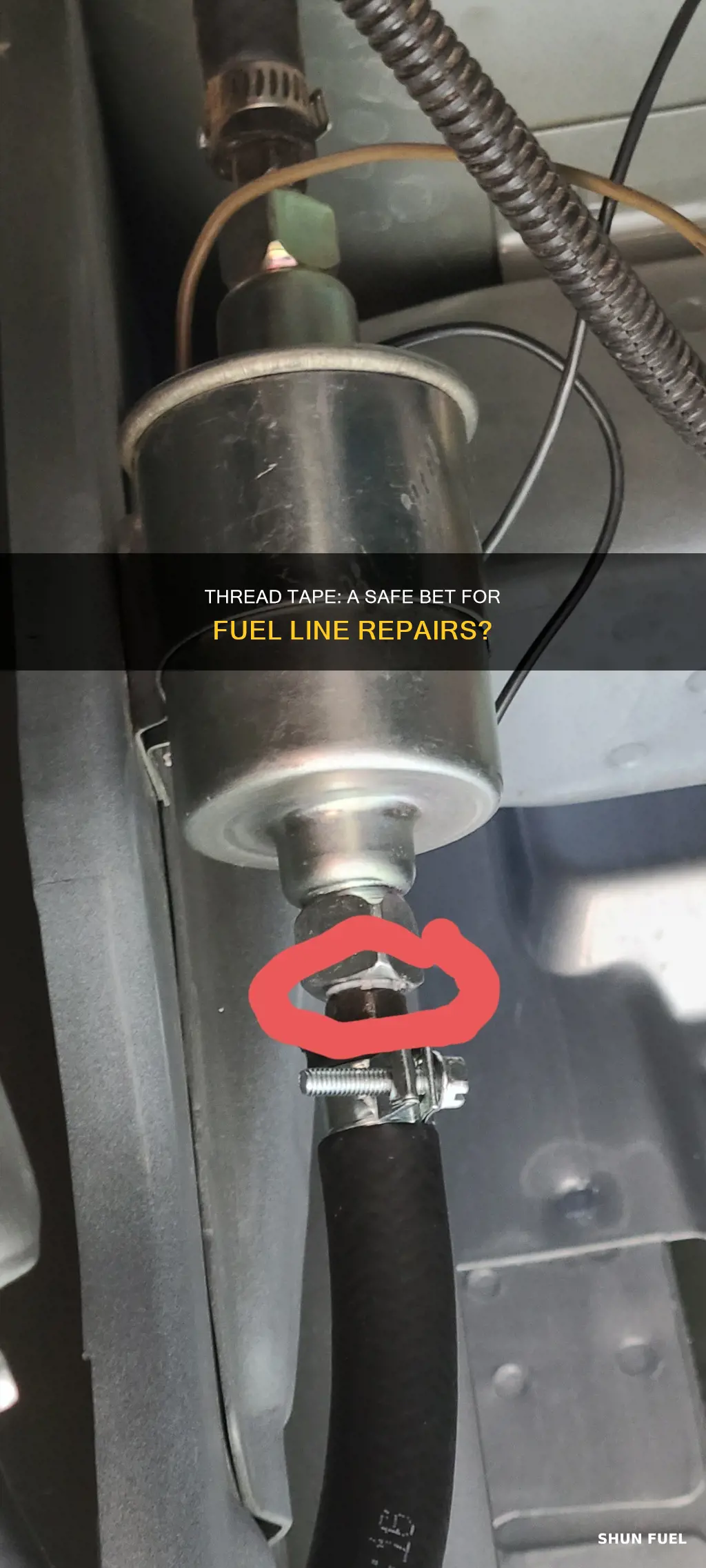

When considering the use of thread tape on fuel lines, it's crucial to prioritize safety as the primary concern. While thread tape can be a temporary solution for sealing small leaks or temporarily fixing fuel lines, it is not a recommended or safe method for long-term use. The primary safety issue lies in the potential for the tape to compromise the integrity of the fuel system.

Thread tape, also known as electrical tape or insulating tape, is designed for electrical insulation and is not intended for use in fuel systems. Fuel lines are subject to high pressure and temperature variations, and the tape may not withstand these conditions over time. If the tape fails, it can lead to fuel leaks, which pose significant safety risks. Leaking fuel can ignite, causing fires or explosions, especially in the presence of ignition sources like sparks from the engine or static electricity.

Furthermore, the tape may not provide a secure and permanent seal, leading to potential fuel loss and reduced engine performance. Over time, the tape can become brittle and crack, allowing fuel to seep through, which can contaminate the engine and lead to costly repairs. In some cases, the tape might not adhere properly to the fuel line material, creating a weak joint that could fail under pressure.

To ensure safety, it is advisable to use proper fuel line repair methods, such as replacing damaged sections with new fuel lines or using specialized fuel line repair kits. These kits often include materials designed to withstand the harsh conditions of fuel systems, ensuring a secure and long-lasting repair. Regular maintenance and inspections of fuel lines are also essential to identify and address any issues promptly, preventing potential hazards.

Mastering Carb Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Thread tape, also known as electrical tape or insulating tape, is not suitable for use on fuel lines. It is designed for electrical insulation and can be flammable, which is a major concern when dealing with fuel lines. Instead, specialized fuel line tape or fuel line repair kits are recommended, which are made from materials that are resistant to fuel and can withstand the high temperatures associated with fuel systems.

Regular thread tape is not designed for the specific requirements of fuel lines. Fuel lines operate in harsh environments, and regular thread tape may not provide the necessary durability and heat resistance. It can also be prone to melting or becoming brittle over time, which could lead to fuel leaks or system failures.

For fuel line repairs, it is best to use products specifically designed for this purpose. These include fuel line repair tape, which is typically made from a flexible, fuel-resistant material that can adhere to the fuel line and provide a secure seal. Additionally, fuel line repair kits often include a variety of tools and materials to ensure a proper and long-lasting repair.