Installing fuel lines on an Earthquake MC43 tille can seem daunting, but with the right tools and a systematic approach, it's a manageable task. This guide will walk you through the process step-by-step, ensuring a secure and reliable fuel line installation. You'll learn about preparing the necessary materials, understanding the layout of the tille, and following a structured approach to connect the fuel lines safely. By the end of this guide, you'll have the knowledge to confidently install fuel lines on your Earthquake MC43 tille, enhancing its performance and reliability.

What You'll Learn

- Prepare Tools: Gather necessary tools like fuel line connectors, pliers, and a fuel line inspection kit

- Locate Fittings: Identify fuel line fittings and ensure they match the vehicle's specifications

- Cut and Prepare: Carefully cut fuel lines to the correct length and prepare fittings

- Connect Securely: Use the correct connectors and ensure a tight, leak-free connection

- Test and Inspect: Thoroughly test for leaks and ensure all connections are secure and functional

Prepare Tools: Gather necessary tools like fuel line connectors, pliers, and a fuel line inspection kit

Before you begin the process of installing fuel lines on your Earthquake MC43 tille, it's crucial to ensure you have all the necessary tools and equipment ready. This preparation will make the installation process smoother and more efficient. Here's a detailed guide on what you need to gather:

Fuel Line Connectors: These are essential components that allow you to join fuel lines together securely. Look for high-quality connectors that are compatible with the fuel line material you are using. Ensure they have the appropriate fittings for your specific application, such as male-to-male, male-to-female, or female-to-female connectors. Having a variety of sizes and types will be beneficial for different fuel line connections.

Pliers: A good pair of pliers is a versatile tool that will be useful for gripping and manipulating fuel lines during the installation process. Opt for pliers with adjustable jaws to accommodate various fuel line diameters. This tool will help you bend, shape, and secure the fuel lines in place. Make sure to choose pliers with a comfortable grip to ensure precision and control.

Fuel Line Inspection Kit: This kit is an invaluable asset for any fuel line installation or maintenance task. It typically includes a set of tools and accessories designed specifically for fuel line work. The inspection kit may contain a fuel line brush, which is used to clean and prepare the fuel lines, ensuring a proper connection. It might also include a fuel line cutter or a set of cutting tools to ensure precise and clean cuts. Additionally, look for a kit that provides various-sized fuel line clips or ties to secure the lines in place.

Having these tools ready will enable you to tackle the installation process with confidence. It's always a good practice to double-check your tool collection against a checklist or a tutorial video to ensure you haven't missed any essential items. Proper preparation will contribute to a successful and safe fuel line installation.

Thawing Frozen Fuel Lines: A Step-by-Step Guide to Repair

You may want to see also

Locate Fittings: Identify fuel line fittings and ensure they match the vehicle's specifications

When installing fuel lines on an Earthquake MC43 tiller, one of the crucial steps is locating the appropriate fittings that match the vehicle's specifications. This process ensures a secure and efficient fuel supply system. Here's a detailed guide on how to locate and identify the right fittings:

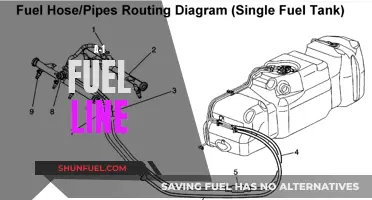

Start by referring to the vehicle's manual or manufacturer's guidelines. These resources provide valuable information about the specific fittings required for your Earthquake MC43 model. Look for diagrams or illustrations that show the fuel system layout, including the locations of various fittings and connectors. Understanding the vehicle's design will help you pinpoint the exact fittings needed.

Next, inspect the existing fuel lines and fittings (if any) on your tiller. This step is essential as it allows you to identify the types of fittings used and their corresponding sizes. Measure the diameters of the fuel lines and compare them with the standard sizes available in the market. Common sizes for fuel lines include 3/8", 1/2", and 5/8" diameters. Ensure that the fittings you choose match these measurements to ensure a proper fit.

Online resources and automotive forums can be valuable tools for finding the right fittings. Search for your specific vehicle model and the term "fuel line fittings" to access forums and discussions where enthusiasts and professionals share their experiences. These platforms often provide recommendations and suggestions for compatible fittings, ensuring you make an informed decision.

Additionally, consider the material of the fittings. Common materials include steel, brass, and aluminum. Each material has its advantages, such as durability, corrosion resistance, and flexibility. Choose a material that suits your vehicle's environment and operating conditions. For example, stainless steel is often preferred for its resistance to corrosion in harsh weather conditions.

By following these steps, you can accurately locate and identify the fittings required for your Earthquake MC43 tiller's fuel line installation. Remember, using the correct specifications and materials will ensure a reliable and safe fuel supply system for your vehicle.

Upgrading Your 2001 Silverado's Fuel Pump: A Step-by-Step Guide to Line Replacement

You may want to see also

Cut and Prepare: Carefully cut fuel lines to the correct length and prepare fittings

Before you begin the installation process, it's crucial to measure and cut the fuel lines to the precise length required for your specific Earthquake MC43 tille setup. This step ensures a proper fit and prevents any unnecessary strain or damage during the installation. Here's a detailed guide on how to cut and prepare the fuel lines:

Measuring and Marking: Start by referring to the manufacturer's instructions or online resources specific to your tille model. Obtain the recommended length of fuel lines, taking into account any bends or adjustments needed for your vehicle's layout. Use a tape measure to carefully measure the required length from the fuel tank to the engine's fuel inlet. Mark this length on the fuel line with a permanent marker or a piece of tape. Ensure that the mark is clear and easily visible to avoid any confusion during the cutting process.

Cutting the Fuel Lines: Using a sharp, clean pair of fuel line cutters or a utility knife, carefully cut along the marked line. Apply steady pressure to ensure a clean cut. It's essential to make precise cuts to avoid any burrs or sharp edges that could damage the fittings or cause leaks. If you're using a utility knife, hold the fuel line firmly and cut with a steady hand, taking care not to cut too deep or cause any damage to the surrounding components.

Preparing the Fittings: Once the fuel lines are cut to the correct length, it's time to prepare the fittings. Remove any excess material from the ends of the fuel lines, ensuring a smooth and clean surface. Use a file or sandpaper to gently smooth any rough edges, creating a precise and clean connection point. This preparation step is vital to ensure a secure and leak-free connection when attaching the fittings.

Safety Precautions: When cutting and preparing fuel lines, always exercise caution. Wear protective gear, such as gloves and safety goggles, to prevent any potential injuries from sharp tools or fuel line material. Ensure you are working in a well-ventilated area, and consider using a fuel line cutting tool that provides a controlled and safe cutting action to minimize the risk of fuel spills or fires.

By following these steps, you'll be able to carefully cut and prepare the fuel lines, ensuring a professional and secure installation on your Earthquake MC43 tille. Remember, precision and attention to detail are key during this process to guarantee a successful outcome.

Unveiling Stihl Fuel Line Material: A Comprehensive Guide

You may want to see also

Connect Securely: Use the correct connectors and ensure a tight, leak-free connection

When installing fuel lines on an Earthquake MC43 tiller, ensuring a secure and leak-free connection is crucial for safe and efficient operation. The process involves several key steps to guarantee a tight fit and prevent any potential fuel leaks.

Firstly, it's essential to use the correct connectors designed for the specific fuel lines and tiller model. These connectors are typically made of durable materials like brass or stainless steel to withstand the pressure and temperature variations associated with fuel systems. Check the manufacturer's specifications or consult the installation manual to identify the appropriate connector type. Using the right connectors ensures compatibility and a reliable seal, preventing fuel from leaking out.

Next, prepare the fuel lines by cleaning them thoroughly. Remove any dirt, debris, or old fuel residue that might be present. This step is critical as contaminants can affect the seal and lead to leaks. Use a suitable cleaner and ensure the lines are completely dry before proceeding.

Now, it's time to connect the fuel lines to the tiller. Start by aligning the connectors with the fuel line ports, ensuring they match up correctly. Apply thread seal tape or pipe compound to the male threads of the connectors to create a secure and leak-resistant connection. Tighten the connectors firmly, but be careful not to over-tighten, as this can damage the threads or the fuel lines. A snug fit is essential, so use a wrench or a tool designed for this purpose to ensure the connectors are properly secured.

Finally, inspect the connections thoroughly. Check for any signs of leakage by gently pressing around the connectors and looking for any fuel seepage. If everything is tight and secure, you should have a leak-free connection. This step is crucial to ensure the safety and performance of your tiller, as fuel leaks can lead to dangerous situations. Always take the time to double-check your work and verify the integrity of the connections.

Fixing the 2005 Chevy Blazer's Fuel Line: A Step-by-Step Guide

You may want to see also

Test and Inspect: Thoroughly test for leaks and ensure all connections are secure and functional

Before you can finalize the installation of fuel lines on your Earthquake MC43 tiller, it is crucial to conduct a comprehensive test and inspection process. This step ensures the safety and reliability of your equipment, preventing any potential hazards associated with fuel leaks. Here's a detailed guide on how to thoroughly test and inspect the fuel lines:

Leak Testing: Start by applying a small amount of diesel fuel or a suitable leak detection fluid along the entire length of the fuel lines. Use a spray bottle or a syringe to carefully inject the fluid into the lines. Pay close attention to all connections, bends, and fittings. After applying the fuel, observe the lines for any signs of leakage. Leaks can occur at connections, where the lines attach to the tiller, or at any damaged areas. If you notice any drips or puddles forming, it indicates a potential issue that requires further investigation and repair.

Pressure Testing: To ensure the integrity of the fuel lines, perform a pressure test. Connect a pressure gauge to the fuel line and attach the other end to a fuel source. Gradually increase the pressure and monitor the gauge reading. The pressure should remain stable without any drops or spikes. If the pressure drops, it suggests a possible leak or a compromised connection. This test is essential to identify hidden leaks that might not be visible during the visual inspection.

Connection Inspection: Carefully examine all connections and fittings to ensure they are secure and tight. Check for any signs of corrosion, damage, or excessive wear. Tighten any loose connections and replace any damaged components. It is crucial to have all connections properly sealed to prevent fuel leaks and potential engine damage. Consider using thread seal tape or pipe dope on threads to enhance the seal.

Functional Testing: After addressing any potential issues, it's time to test the fuel lines' functionality. Start the tiller's engine and monitor it closely. Listen for any unusual noises, such as hissing or roaring, which could indicate a fuel leak. Check for any fuel odor around the engine and tiller, as this could also be a sign of a leak. Ensure that the engine runs smoothly and that there are no fuel-related performance issues.

Documentation and Record-Keeping: Document the entire testing and inspection process, including any issues found and the corresponding repairs. Keep a record of the fuel line installation, including the materials used, connections made, and any adjustments or modifications. This documentation will be valuable for future reference, maintenance, and troubleshooting.

By following these steps, you can ensure that the fuel lines on your Earthquake MC43 tiller are installed correctly, leak-free, and ready for safe operation. Thorough testing and inspection are essential to prevent accidents and maintain the longevity of your equipment.

Fuel Line Mystery: FL20C's Dual Fuel Lines Explained

You may want to see also

Frequently asked questions

Installing fuel lines on an Earthquake MC43 tille involves several steps. First, ensure you have the necessary tools and materials, including the appropriate fuel lines, fittings, and tools for cutting and bending. Then, locate the fuel tank and identify the fuel lines that need to be connected. Clean the ends of the fuel lines and ensure a tight seal. Use fuel line connectors or fittings to join the lines securely. Test the installation by checking for any leaks and ensuring the fuel flow is adequate.

Yes, you'll need a few specialized tools for this task. A fuel line cutting tool or a sharp knife with a guard is essential for precise cuts. A fuel line bender will help you create the necessary angles and bends. Additionally, have a fuel line inspection tool or a similar device to check for leaks after installation. It's also recommended to have a wrench or pliers for any additional tightening or adjustments.

While it is possible to install fuel lines yourself, especially if you have experience with automotive repairs, it is generally recommended to seek professional assistance. Fuel line installation requires precision and knowledge of vehicle systems to ensure a safe and proper connection. Professionals have the expertise to identify potential issues and ensure the fuel lines are installed correctly, minimizing the risk of leaks or other problems.

One common mistake is using the wrong type or size of fuel line, which can lead to improper fit and potential leaks. Always double-check the specifications and ensure compatibility. Another error is not cleaning the fuel lines properly before installation, which may result in contamination and reduced performance. Additionally, avoid overtightening fittings, as it can damage the fuel lines. Regularly inspect the installed fuel lines for any signs of damage or wear.