Installing a fuel line assembly can seem daunting, but with the right tools and instructions, it's a manageable task. The MTD753-04233 fuel line assembly is a specific component designed for certain lawn and garden equipment. This guide will provide a step-by-step process to ensure a successful installation, covering everything from preparing the necessary tools to the final adjustments. By following these instructions, you'll be able to safely and effectively connect the fuel line assembly to your equipment, ensuring optimal performance and longevity.

| Characteristics | Values |

|---|---|

| Product Type | Fuel Line Assembly |

| Application | For lawn and garden equipment |

| Compatibility | MTD753-04233 |

| Material | High-quality plastic and metal |

| Length | 10 feet (approx.) |

| Diameter | 0.75 inches (approx.) |

| Color | Black |

| Installation | Easy DIY installation |

| Package Includes | Fuel line, fittings, and installation guide |

| Brand | MTD (Maytag-Troy-Davenport) |

| Warranty | Limited manufacturer's warranty |

| Note | Ensure proper fuel line routing and secure connections to prevent fuel leaks. |

What You'll Learn

- Preparation: Gather tools and parts, ensure workspace is clean and organized

- Fuel Line Inspection: Check for damage, kinks, or leaks before installation

- Assembly Steps: Follow manufacturer's instructions for correct fuel line placement

- Clamping Techniques: Use appropriate tools to secure fuel line with tight, leak-free clamps

- Testing: Verify fuel line assembly is secure and functional, no leaks detected

Preparation: Gather tools and parts, ensure workspace is clean and organized

Before you begin the installation process of the MTD753-04233 fuel line assembly, it's crucial to prepare your workspace and gather the necessary tools and parts. This initial step ensures a smooth and efficient repair or replacement process.

Start by collecting all the required tools. You will need a set of wrenches, including both adjustable and standard types, to tighten and loosen various components. A socket set is also essential for accessing certain fasteners. Additionally, a fuel line cutter or a sharp knife will be necessary to carefully trim the fuel lines to the appropriate length. Don't forget to include a fuel line adapter or coupling if you need to connect different sizes of fuel lines. Other useful tools might include a rag or cloth for cleaning, a marker or pen for labeling parts, and a level to ensure proper alignment.

Next, ensure your workspace is clean and organized. Clear any clutter or debris from the area where you will be working. A well-lit, spacious workspace is ideal for this task. Cover the floor with a drop cloth or old newspapers to protect it from any potential spills or stains. It's also a good idea to have a flat surface, like a workbench or a large table, where you can lay out all the parts and tools you'll be using. This organized setup will make the installation process much more manageable and help you avoid any unnecessary complications.

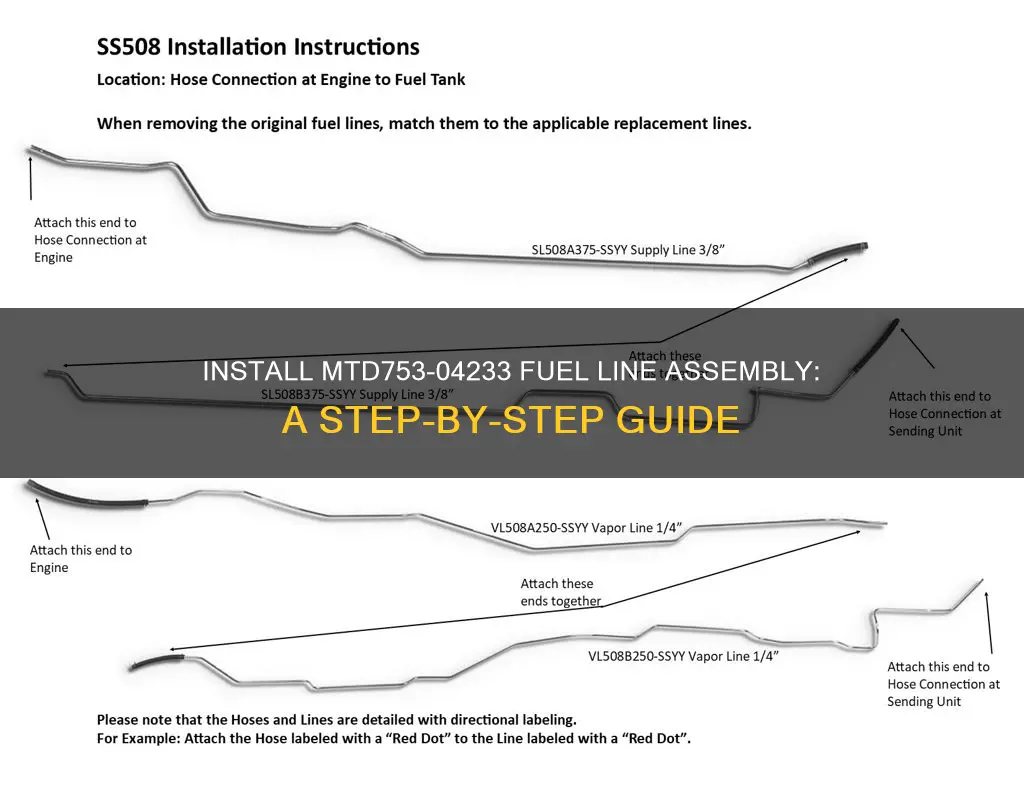

Furthermore, take the time to review the fuel line assembly diagram or instructions provided by the manufacturer. Understanding the layout and connections of the assembly will help you identify the correct placement of each component. This preparation step is vital to ensure you have all the parts in the right order and that you can quickly locate them when needed during the installation process.

By gathering the necessary tools and parts, and organizing your workspace, you'll be well-prepared to tackle the installation of the MTD753-04233 fuel line assembly with confidence and efficiency. This organized approach will make the task less daunting and help you complete it successfully.

Understanding In-Line Fuel Filters: Benefits and Maintenance Tips

You may want to see also

Fuel Line Inspection: Check for damage, kinks, or leaks before installation

Before you begin the installation of the MTD753-04233 fuel line assembly, it is crucial to conduct a thorough inspection of the fuel lines to ensure optimal performance and prevent potential issues. This inspection process is a critical step to guarantee the safety and efficiency of your equipment. Here's a step-by-step guide to inspecting the fuel lines:

- Visual Inspection: Start by examining the fuel lines for any visible signs of damage, wear, or deterioration. Look for cracks, punctures, or any discolored areas along the length of the lines. Check for any signs of corrosion or rust, especially if the lines have been exposed to harsh weather conditions. Pay close attention to the connections and fittings, ensuring they are intact and securely attached.

- Flexibility and Movement: Fuel lines should be flexible and allow for movement without restricting the engine's operation. Check for any kinks or bends that might have occurred during transportation or storage. Gently manipulate the lines to ensure they can move freely without causing any strain on the engine or other components. This step is essential to prevent damage during the installation process.

- Leak Detection: One of the most critical aspects of the inspection is identifying potential leaks. Start by applying a small amount of diesel fuel or a suitable leak detection fluid along the length of the fuel lines. Observe the lines carefully for any signs of fuel seepage or dripping. Check all connections and fittings, as these areas are prone to leaks. Ensure that the fuel lines are properly sealed and that there are no gaps or damaged seals that could lead to fuel loss.

- Pressure Test (Optional): For added assurance, you can perform a pressure test to check the integrity of the fuel lines. This test involves connecting a pressure gauge to the fuel line and applying a controlled amount of pressure. Observe the gauge for any drops in pressure, which could indicate a leak. This method is particularly useful for identifying hidden leaks that might not be visible during a visual inspection.

By following these inspection steps, you can ensure that the MTD753-04233 fuel line assembly is in excellent condition before installation. This process helps to prevent potential issues, such as engine damage or fuel leaks, and ensures the longevity of your equipment. Remember, proper inspection and maintenance are key to keeping your machinery running smoothly and efficiently.

Choosing the Right Fuel Line for Your 25 HP Mercury Outboard

You may want to see also

Assembly Steps: Follow manufacturer's instructions for correct fuel line placement

When it comes to installing the MTD753-04233 fuel line assembly, it's crucial to follow the manufacturer's instructions meticulously to ensure a proper and safe setup. This fuel line assembly is designed to connect the fuel tank to the engine, and getting it right is essential for optimal performance and safety. Here's a step-by-step guide to help you through the assembly process:

- Preparation: Before you begin, ensure you have all the necessary tools and components required for the installation. This includes the fuel line assembly kit, which typically includes the fuel line, fittings, and any necessary clamps or ties. Also, locate the fuel tank and the engine, identifying the specific points where the fuel line will be connected.

- Locate the Fuel Line Routing: Refer to the manufacturer's diagram or instructions provided with the assembly. This diagram will show you the correct path the fuel line should take from the fuel tank to the engine. Mark these points on the diagram to ensure accurate placement.

- Remove Old Fuel Lines (if applicable): If you're replacing an existing fuel line, carefully remove the old one. Take note of how it was connected and the order of removal to make the new installation process smoother. Clean the areas where the old fuel line was attached to ensure no debris or contaminants interfere with the new assembly.

- Connect the Fuel Line Assembly: Start by attaching the fuel line to the fuel tank according to the manufacturer's instructions. Use the provided fittings and ensure a secure connection. Then, carefully route the fuel line along the marked path, ensuring it is not pinched or damaged. Secure the fuel line in place using the recommended clamps or ties to prevent movement.

- Final Connections: Once the fuel line is routed correctly, make the final connections to the engine. This may involve attaching the fuel line to the fuel injectors or the carburetor, depending on your equipment. Again, follow the manufacturer's instructions for precise placement. Double-check all connections to ensure they are tight and secure.

- Testing: After completing the assembly, it's crucial to test the system. Start the engine and monitor for any leaks. Check all connections and fittings to ensure they are secure. If any leaks are detected, tighten connections or replace fittings as necessary.

Remember, the key to a successful installation is attention to detail and adherence to the manufacturer's guidelines. Each step should be carefully executed to guarantee a safe and efficient fuel system.

Fuel Line Removal: A Step-by-Step Guide for Your Jeep TJ

You may want to see also

Clamping Techniques: Use appropriate tools to secure fuel line with tight, leak-free clamps

When it comes to installing the MTD753-04233 fuel line assembly, ensuring a tight and leak-free connection is crucial for the proper functioning of your equipment. Clamping techniques play a vital role in achieving this, and using the right tools can make the process efficient and effective. Here's a detailed guide on how to secure the fuel line with appropriate clamps:

Start by gathering the necessary tools, which typically include adjustable wrenches, pliers, and fuel line clamps. The key to a successful installation lies in the precision of your clamping. Begin by identifying the fuel line's specific diameter and selecting a clamp that matches this dimension. Ensure that the clamp is made from a durable material, such as stainless steel, to withstand the fuel's pressure and temperature variations.

Now, locate the fuel line assembly and identify the areas where clamping is required. These points are usually marked with small notches or indentations. Carefully slide the clamp onto the fuel line, ensuring it covers the entire length of the line at the clamping point. Use your adjustable wrench or pliers to tighten the clamp securely. The goal is to create a firm grip without causing any damage to the fuel line. Apply steady pressure and check for any signs of movement or looseness.

For optimal results, aim for a tight fit that is neither too tight nor too loose. Over-tightening can lead to fuel line damage, while under-tightening may result in leaks. Take your time and use the tools to apply the correct amount of force. Remember, the clamp should hold the fuel line in place without restricting its flexibility, which is essential for the assembly's overall functionality.

After tightening the clamp, inspect the connection thoroughly. Ensure there are no visible gaps or spaces between the clamp and the fuel line. A leak-free connection is critical to prevent fuel loss and potential engine issues. If you notice any discrepancies, carefully adjust the clamp and re-tighten it until the connection is secure.

By employing these clamping techniques and utilizing the appropriate tools, you can effectively secure the MTD753-04233 fuel line assembly, ensuring a reliable and safe operation of your equipment. Always remember to follow manufacturer guidelines for specific instructions tailored to your model.

Unclogging Toro 500 Series Fuel Lines: A Step-by-Step Guide

You may want to see also

Testing: Verify fuel line assembly is secure and functional, no leaks detected

Before you begin testing, ensure you have the necessary tools and equipment, including a fuel pressure gauge, a leak detection kit, and a clean workspace. The MTD753-04233 fuel line assembly is designed to be a precise fit for your equipment, so it's crucial to follow the manufacturer's guidelines for testing.

Start by visually inspecting the fuel line assembly. Check for any signs of damage, such as tears, punctures, or kinks. Ensure all connections are intact and securely fastened. Look for any visible signs of corrosion or contamination that could affect the assembly's performance. If any issues are found, address them before proceeding with the test.

Next, perform a pressure test to ensure the fuel lines are functioning correctly. Attach the fuel pressure gauge to the fuel line assembly and check the pressure reading. The pressure should be within the specified range as per the manufacturer's data. If the pressure is too high or too low, it may indicate a problem with the fuel pump or the assembly itself.

To detect any potential leaks, use the leak detection kit. Apply a small amount of the leak detection fluid to the fuel line connections and observe for any signs of leakage. Even a small amount of fluid escaping from a connection could indicate a potential issue. If any leaks are detected, tighten the connections or replace the affected parts to ensure a secure assembly.

Finally, run the equipment and monitor its performance. Check for any unusual noises or vibrations that could be related to the fuel line assembly. Ensure that the fuel is flowing smoothly and that there are no disruptions in the fuel supply. If everything functions as expected, your MTD753-04233 fuel line assembly is ready for use, ensuring optimal performance and reliability.

Boat Fuel Line Direction: What You Need to Know

You may want to see also

Frequently asked questions

The MTD753-04233 fuel line assembly is a component designed for lawn mowers and outdoor power equipment. It is a replacement part that connects the fuel tank to the engine, ensuring a steady supply of fuel for operation.

Compatibility can vary depending on the make and model of your lawn mower. It's essential to check the manufacturer's specifications or consult the user manual to ensure the MTD753-04233 assembly fits your specific model. You can also contact the manufacturer's customer support for assistance.

Many fuel line assembly installations are designed for DIY enthusiasts and can be done with basic tools and mechanical knowledge. However, if you are unsure or uncomfortable with the process, it is recommended to seek the help of a professional technician to ensure a safe and proper installation.

The tools and materials needed may vary depending on the make and model of your equipment. Generally, you will require basic hand tools such as wrenches, pliers, and screwdrivers. It is also advisable to have fuel line connectors, fuel filter, and any other specific parts recommended by the manufacturer for a complete and successful installation.