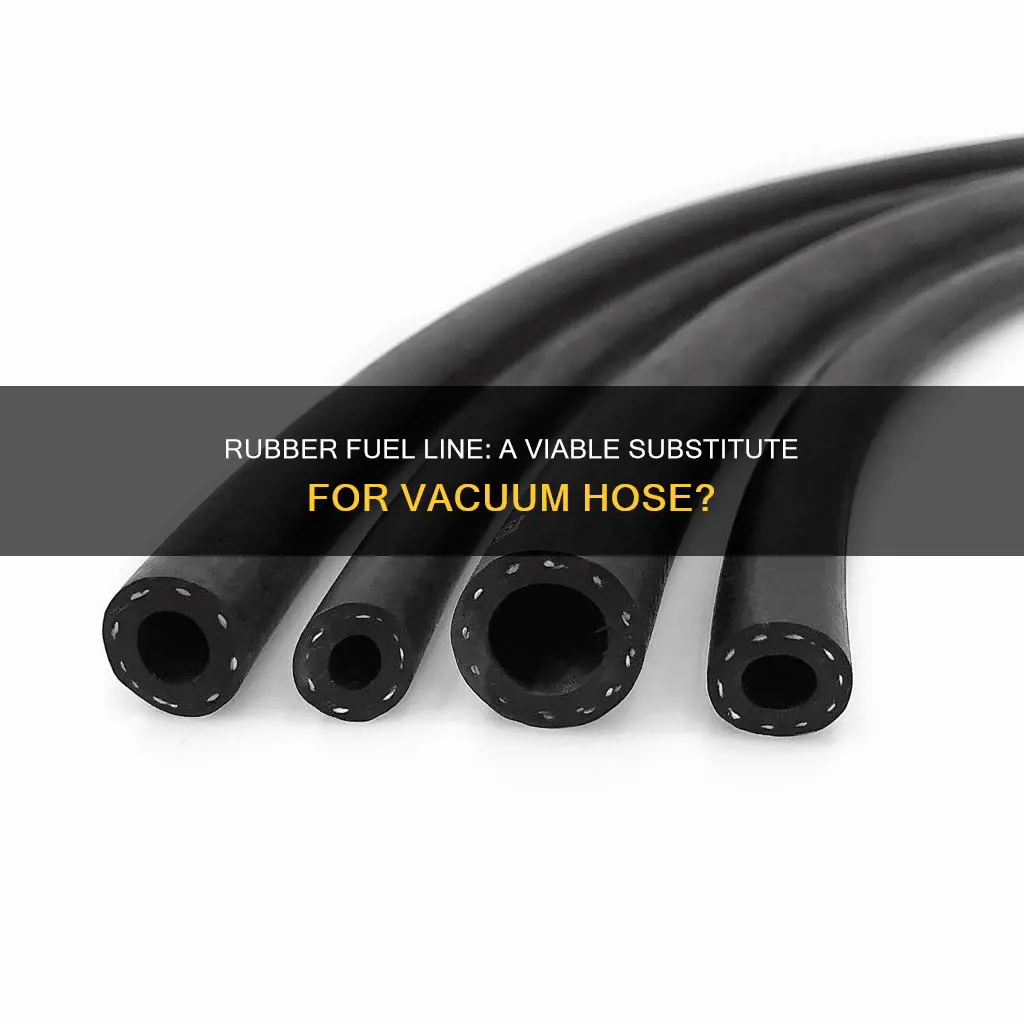

When it comes to vehicle maintenance, understanding the compatibility of different materials is crucial. One common question that arises is whether rubber fuel lines can be used as vacuum hoses. This inquiry is particularly relevant for car enthusiasts and DIY mechanics who often seek cost-effective solutions for their projects. The answer to this question is not straightforward, as it depends on various factors, including the specific application, the type of rubber used, and the environmental conditions it will endure. Rubber fuel lines and vacuum hoses serve distinct purposes, and their materials and construction methods differ, which can impact their performance and longevity.

What You'll Learn

- Material Compatibility: Rubber fuel lines can be used for vacuum hoses if they are compatible with the fuel type

- Flexibility: Rubber's flexibility makes it suitable for tight spaces and bends in vacuum systems

- Temperature Resistance: Rubber can withstand temperature changes, ensuring vacuum hose durability

- Chemical Resistance: Rubber is resistant to chemicals, making it safe for various fuel types

- Cost-Effectiveness: Rubber fuel lines are often more affordable than other materials for vacuum hoses

Material Compatibility: Rubber fuel lines can be used for vacuum hoses if they are compatible with the fuel type

When considering the use of rubber fuel lines for vacuum hoses, material compatibility is a critical factor to ensure the system's reliability and performance. Rubber fuel lines are commonly used in automotive applications due to their flexibility and durability. However, it is essential to understand that not all rubber fuel lines are suitable for vacuum hoses, especially when it comes to the type of fuel being used.

The compatibility of rubber with the fuel type is a key consideration. Different fuels have varying chemical compositions and properties, and some can be detrimental to rubber over time. For example, gasoline-based fuels may contain additives that can cause rubber to degrade, leading to potential leaks and system failures. On the other hand, ethanol-blended fuels or diesel fuel may have different chemical properties that could affect the rubber's performance. It is crucial to choose rubber fuel lines that are specifically designed and formulated to withstand the specific fuel type being used.

To ensure compatibility, it is recommended to consult the fuel supplier or manufacturer's guidelines. They can provide information on the recommended materials and components for the particular fuel being utilized. Using the right type of rubber fuel line that is compatible with the fuel will help prevent issues such as fuel leakage, cracking, or deterioration of the vacuum hose system.

Additionally, it is important to consider the temperature range and operating conditions of the application. Rubber fuel lines should be able to withstand the temperature fluctuations and environmental factors present in the vacuum hose system. Some rubber compounds may be more suitable for high-temperature environments, while others might offer better resistance to cold temperatures. Selecting the appropriate rubber material based on these factors will ensure the longevity and functionality of the vacuum hose assembly.

In summary, while rubber fuel lines can be used for vacuum hoses, careful consideration of material compatibility with the fuel type is essential. By choosing the right rubber material and following manufacturer recommendations, you can ensure a reliable and efficient vacuum hose system, even when using rubber fuel lines. This approach helps to prevent potential issues and ensures the overall performance and safety of the vehicle's fuel system.

Can Rubber Fuel Lines Handle EGR Systems?

You may want to see also

Flexibility: Rubber's flexibility makes it suitable for tight spaces and bends in vacuum systems

The flexibility of rubber is a key advantage when considering its use as a vacuum hose material. Rubber's inherent pliability allows it to conform to various shapes and sizes, making it ideal for navigating the intricate pathways of a vacuum system. This is particularly important in applications where space is limited, such as in automotive or industrial settings.

In vacuum systems, hoses need to be able to bend and twist without kinking or becoming damaged. Rubber's flexibility ensures that the hose can accommodate these movements, reducing the risk of blockages or damage to the system. This is especially crucial in high-pressure environments where rigid hoses might fail, leading to potential system failures or safety hazards.

The ability of rubber to flex also contributes to its durability. When a vacuum hose is subjected to repeated bending, the rubber material can absorb and distribute the stress, preventing premature wear and tear. This is essential for the long-term reliability of the vacuum system, as it ensures consistent performance without the need for frequent replacements.

Furthermore, the flexibility of rubber allows for easier installation and maintenance. Technicians can manipulate the hose to fit into tight spaces, ensuring a secure and efficient connection. This is particularly beneficial during the initial setup of a vacuum system, where the hose needs to be routed around various components without causing damage.

In summary, the flexibility of rubber is a critical factor in its suitability for vacuum hose applications. It enables the hose to navigate tight spaces, bend without kinking, and maintain durability over time. This makes rubber an excellent choice for vacuum systems, providing a reliable and flexible solution for various industrial and automotive needs.

Honda XR50 Fuel Line: Size and Compatibility Guide

You may want to see also

Temperature Resistance: Rubber can withstand temperature changes, ensuring vacuum hose durability

The temperature resistance of rubber is a critical factor when considering its use as a vacuum hose material. Rubber's ability to maintain its structural integrity across a wide range of temperatures is essential for ensuring the long-term durability and reliability of vacuum systems. This property makes rubber an ideal choice for vacuum hoses, especially in applications where temperature fluctuations are common.

In many industrial and automotive settings, vacuum hoses are exposed to varying temperatures, from extreme cold to high heat. Rubber's inherent flexibility and resilience allow it to accommodate these temperature changes without compromising its performance. It can withstand rapid temperature shifts, making it suitable for environments where temperatures may fluctuate rapidly, such as in outdoor settings or during seasonal changes.

The temperature resistance of rubber is attributed to its molecular structure. Rubber molecules are highly cross-linked, forming a robust and elastic network. This network enables rubber to resist deformation and maintain its shape even when subjected to extreme temperatures. When temperatures drop, the rubber material remains flexible, preventing brittleness and cracking, which could lead to hose failure. Conversely, in high-temperature environments, rubber's ability to retain its elasticity prevents hardening and maintains its ability to transmit vacuum effectively.

Furthermore, the temperature resistance of rubber is enhanced by its ability to resist aging and degradation. Over time, many materials can break down when exposed to repeated temperature changes, leading to reduced performance and potential failure. Rubber, however, ages gracefully, maintaining its integrity and functionality even after prolonged exposure to varying temperatures. This makes rubber vacuum hoses ideal for long-term use in demanding environments.

In summary, the temperature resistance of rubber is a key advantage when using it as a vacuum hose material. Its ability to withstand temperature changes, resist aging, and maintain structural integrity ensures the durability and reliability of vacuum systems. This property makes rubber an excellent choice for applications requiring hoses that can perform consistently across a wide range of temperatures.

Understanding Fuel Pickup Lines for Outboard Motors: A Comprehensive Guide

You may want to see also

Chemical Resistance: Rubber is resistant to chemicals, making it safe for various fuel types

When it comes to choosing the right material for fuel lines and vacuum hoses, chemical resistance is a critical factor to consider. Rubber is an excellent choice for this purpose due to its inherent chemical properties. This natural material is known for its ability to withstand a wide range of chemicals, making it a safe and reliable option for various fuel types.

The chemical resistance of rubber is a result of its molecular structure. Rubber is composed of long chains of carbon and hydrogen atoms, which form a flexible and resilient material. These chains are resistant to breakdown when exposed to most chemicals, ensuring that the rubber fuel line or vacuum hose will not degrade or become compromised over time. This is particularly important in fuel systems, where the presence of various chemicals and additives is common.

In the context of fuel lines, rubber's chemical resistance is crucial for several reasons. Firstly, it ensures that the fuel remains pure and uncontaminated. Different fuels contain various additives and impurities, and using a material that is not chemically resistant could lead to leaching and potential contamination. Rubber's resistance to chemicals prevents the migration of fuel components into the hose, maintaining the integrity of the fuel.

Additionally, rubber's chemical properties make it suitable for use with a wide range of fuel types. Whether it's gasoline, diesel, aviation fuel, or biofuels, rubber fuel lines can safely transmit these substances without breaking down or releasing harmful substances. This versatility is essential for automotive, aviation, and industrial applications where different fuel types are commonly used.

Furthermore, the chemical resistance of rubber contributes to the overall durability and longevity of the fuel lines and vacuum hoses. By withstanding the chemical challenges posed by various fuels, rubber ensures that the hoses remain intact and functional over extended periods. This reliability is vital for maintaining efficient and safe fuel systems in vehicles, machinery, and other equipment.

Where to Find 1/4 Clear Fuel Lines: A Comprehensive Guide

You may want to see also

Cost-Effectiveness: Rubber fuel lines are often more affordable than other materials for vacuum hoses

When considering the use of rubber fuel lines for vacuum hoses, one of the most compelling advantages is the cost-effectiveness of this material. Rubber is generally an affordable and readily available option, making it an attractive choice for various applications. Compared to other materials like stainless steel or aluminum, rubber fuel lines offer a more budget-friendly alternative without compromising on performance. This is particularly beneficial for projects or repairs where a tight budget is a concern, as rubber lines provide a cost-efficient solution without sacrificing durability.

The affordability of rubber fuel lines is a result of several factors. Firstly, the production process of rubber is relatively simple and cost-efficient, allowing manufacturers to offer these products at competitive prices. Additionally, rubber's versatility enables it to be easily molded and shaped, reducing the complexity of manufacturing and further contributing to its cost-effectiveness. This makes rubber an excellent choice for applications where a balance between price and performance is required.

In the context of vacuum hoses, rubber fuel lines can be an ideal solution, especially for temporary or low-pressure applications. Rubber's flexibility and resilience make it well-suited for creating a tight seal and maintaining vacuum integrity. Despite its cost-effectiveness, rubber can still provide the necessary durability to withstand the demands of vacuum systems, ensuring a reliable and long-lasting solution. This combination of affordability and performance makes rubber fuel lines a practical and economical choice for many vacuum hose applications.

Furthermore, the ease of installation and maintenance of rubber fuel lines adds to their cost-effectiveness. Rubber hoses are typically lightweight and flexible, allowing for straightforward installation without the need for specialized tools or extensive training. This simplicity in installation can save time and labor costs, making rubber an even more attractive option for DIY projects or small-scale repairs. Additionally, rubber's resistance to wear and tear means that these hoses can often outlast other materials, reducing the frequency of replacements and further enhancing their cost-effectiveness over time.

In summary, the affordability of rubber fuel lines is a significant advantage, especially when compared to other materials for vacuum hoses. Its cost-efficient production, versatility, and ease of installation contribute to its popularity in various industries. While other materials may offer specific benefits, rubber provides a well-rounded solution that balances performance and price, making it a practical and economical choice for vacuum hose applications. This cost-effectiveness, coupled with its durability, ensures that rubber fuel lines remain a preferred option for those seeking an affordable yet reliable vacuum hose solution.

Toyota Corolla Fuel Line Location: A Comprehensive Guide

You may want to see also

Frequently asked questions

Yes, rubber fuel line can be used as a vacuum hose in certain applications. It is a suitable replacement for traditional vacuum hoses due to its flexibility and ability to withstand high temperatures. However, it's important to note that rubber fuel line is designed for fuel-carrying purposes and may not be as flexible or durable as dedicated vacuum hoses. Always ensure you choose the appropriate size and thickness of rubber fuel line for your specific vacuum system.

Rubber fuel line offers several benefits when used as a vacuum hose. It is relatively easy to install and can provide a secure connection due to its ability to conform to various shapes. The material is also resistant to heat and chemicals, making it suitable for high-temperature environments and exposure to engine fluids. Additionally, rubber is flexible, allowing for some movement and vibration dampening, which can be advantageous in automotive applications.

While rubber fuel line can be a viable option, there are a few considerations. Rubber may not be as durable as specialized vacuum hoses, especially in high-pressure applications. Over time, it can become brittle and crack, leading to potential leaks. It's crucial to inspect the rubber fuel line regularly for any signs of damage or wear. Additionally, ensure that the fuel line is compatible with the vacuum system's requirements, as using the wrong size or type can lead to performance issues.