Installing a tight fuel line is a crucial step in ensuring your vehicle's engine receives the necessary fuel for optimal performance. This process involves carefully routing the fuel line to maintain a secure and tight connection, preventing any potential leaks or fuel loss. By following a step-by-step guide, you can ensure a professional installation, enhancing the reliability and longevity of your vehicle's fuel system.

| Characteristics | Values |

|---|---|

| Step 1: Prepare the Tools and Materials | Gather the necessary tools and materials: fuel line, fuel line connectors, fuel pump, fuel filter, and a fuel line cleaner. Ensure you have the correct size and type of fuel line for your vehicle. |

| Step 2: Remove the Old Fuel Line | Locate the old fuel line and carefully cut it at the desired length. Disconnect the fuel line from the fuel pump, fuel filter, and any other components it is connected to. Clean the ends of the old fuel line to ensure a proper connection. |

| Step 3: Clean and Inspect the Fuel System | Use the fuel line cleaner to thoroughly clean the fuel system, including the fuel pump, filter, and any other components. Inspect for any signs of damage or corrosion and replace any faulty parts. |

| Step 4: Measure and Mark the New Fuel Line | Measure the length of the new fuel line required and mark the positions for the connectors. Ensure the line is straight and secure, allowing for easy installation. |

| Step 5: Connect the Fuel Line | Start by connecting one end of the new fuel line to the fuel pump. Secure it with the appropriate connector and ensure a tight fit. Repeat the process for the other end, connecting it to the fuel filter or the engine. |

| Step 6: Test the Fuel System | After connecting all the components, start the vehicle's engine and check for any leaks. Ensure the fuel system is functioning properly and that the fuel pressure is within the recommended range. |

| Step 7: Final Adjustments | Make any necessary adjustments to the fuel line routing to ensure it is secure and free from any sharp bends. Check for any loose connections and retighten as needed. |

| Safety Precaution: | Always work on a level surface and wear protective gear when handling fuel lines to avoid any accidents or exposure to fuel. |

What You'll Learn

- Prepare Tools: Gather necessary tools: wrench, fuel line, and cleaning supplies

- Locate Fittings: Identify engine's fuel fittings and mark for easy access

- Remove Old Line: Carefully disconnect and remove old fuel line, cleaning as needed

- Install New Line: Slide new fuel line into fittings, ensuring proper alignment and tightness

- Test and Inspect: Check for leaks, ensure proper connection, and verify functionality

Prepare Tools: Gather necessary tools: wrench, fuel line, and cleaning supplies

Before you begin the installation process, it's crucial to gather all the necessary tools and materials to ensure a smooth and efficient job. Here's a breakdown of the tools you'll need:

Wrench: A good-quality wrench is an essential tool for any fuel line installation. You'll need a wrench that fits the specific size and type of fuel line you're working with. Wrenches come in various sizes and types, such as adjustable wrenches, which can accommodate different pipe sizes. Ensure you have the appropriate size to comfortably grip and turn the fuel line without causing damage.

Fuel Line: This is the primary component you'll be installing. Obtain a fuel line that matches the specifications of your vehicle's fuel system. Consider the length and diameter required to connect the source (such as the fuel tank) to the destination (like the engine). It's important to choose a high-quality fuel line to ensure durability and prevent leaks.

Cleaning Supplies: Proper cleaning is essential to ensure a successful installation. Gather some cleaning supplies like a degreaser or fuel line cleaner, a brush or scrubber for removing debris, and a cloth or rag for wiping down surfaces. These supplies will help you prepare the fuel line and the surrounding areas, ensuring a clean and smooth installation process.

Having these tools and materials ready will set you up for success when it's time to install the tight fuel line. It's always a good practice to double-check the compatibility of the fuel line with your vehicle's make and model to avoid any potential issues during the installation.

Fuel Line Routing: LS Swap Guide for 1984 C10

You may want to see also

Locate Fittings: Identify engine's fuel fittings and mark for easy access

When preparing to install a tight fuel line, the first crucial step is to locate the engine's fuel fittings. These fittings are typically located along the fuel lines, often near the fuel tank and the engine block. They serve as the connection points for the fuel lines, allowing for the transfer of fuel from the tank to the engine. Identifying these fittings is essential to ensure a successful and secure installation.

Start by examining the engine bay and locating the fuel tank. The fuel tank will have a visible fuel line running from it towards the engine. Follow this line to identify the first fitting, which is usually a quick-connect coupling or a threaded fitting. Mark this point with a piece of tape or a small piece of chalk to indicate the starting point of the fuel line.

Next, trace the fuel line further to locate the other fittings. These fittings can vary in type, including quick-connect couplings, threaded fittings, or even fuel injectors. Each fitting will have a specific purpose, such as connecting to the fuel pump, the engine's fuel rail, or individual fuel injectors. Take note of the positions of these fittings and mark them accordingly. You can use a permanent marker or a small piece of electrical tape to create a visual indicator.

It is important to ensure that the markings are clear and easily accessible. This will make the installation process more efficient and less time-consuming. You can also consider taking reference photos of the engine bay with the markings to have a visual guide during the installation.

By carefully locating and marking the engine's fuel fittings, you set the foundation for a precise and secure fuel line installation. This step ensures that you have a clear understanding of the fuel line's path and the specific fittings involved, making the subsequent installation process more manageable and less prone to errors.

Unraveling the Secrets: Why Boat Fuel Lines Go Wrong

You may want to see also

Remove Old Line: Carefully disconnect and remove old fuel line, cleaning as needed

When replacing a fuel line, the first crucial step is to remove the old one. This process requires careful attention to detail and a systematic approach to ensure a clean and safe installation. Here's a step-by-step guide to help you through this phase:

- Prepare the Work Area: Begin by ensuring you have a well-lit and spacious work area. Lay down a clean, flat surface, preferably a workbench or a sturdy table, to provide a stable platform for your tasks. Gather all the necessary tools and materials, including the new fuel line, a fuel line cutter or a suitable cutting tool, and cleaning supplies.

- Locate the Old Line: Identify the old fuel line you intend to replace. This line typically runs from the fuel tank to the engine, delivering fuel for combustion. Carefully inspect the line for any signs of damage, corrosion, or deterioration. Take note of any bends, kinks, or areas where the line may be worn out, as these will need to be addressed during removal.

- Disconnect the Line: Carefully disconnect the old fuel line from the fuel tank and the engine. Locate the fittings or clamps that secure the line to these components. Use the appropriate tools to loosen and remove these fasteners. Be gentle to avoid damaging the surrounding areas. Once disconnected, carefully pull the old fuel line away from the fittings, ensuring you don't twist or kink the line further.

- Remove and Clean: With the line disconnected, carefully lift and remove the old fuel line from the work area. Inspect the line for any debris, rust, or contaminants that may have accumulated over time. Clean the interior of the line using a suitable solvent or cleaner to remove any built-up material. This step is crucial to ensure the new line is installed in a pristine condition.

- Dispose of Old Line: After cleaning, dispose of the old fuel line responsibly. Check with local regulations regarding the disposal of fuel lines to ensure you follow the appropriate guidelines. Proper disposal helps prevent environmental contamination and ensures a safe working environment.

By following these steps, you'll carefully remove the old fuel line, ensuring a clean slate for the new installation. This process requires patience and attention to detail to guarantee a successful and safe fuel line replacement.

Locate the Fuel Line: 2001 Monte Carlo Guide

You may want to see also

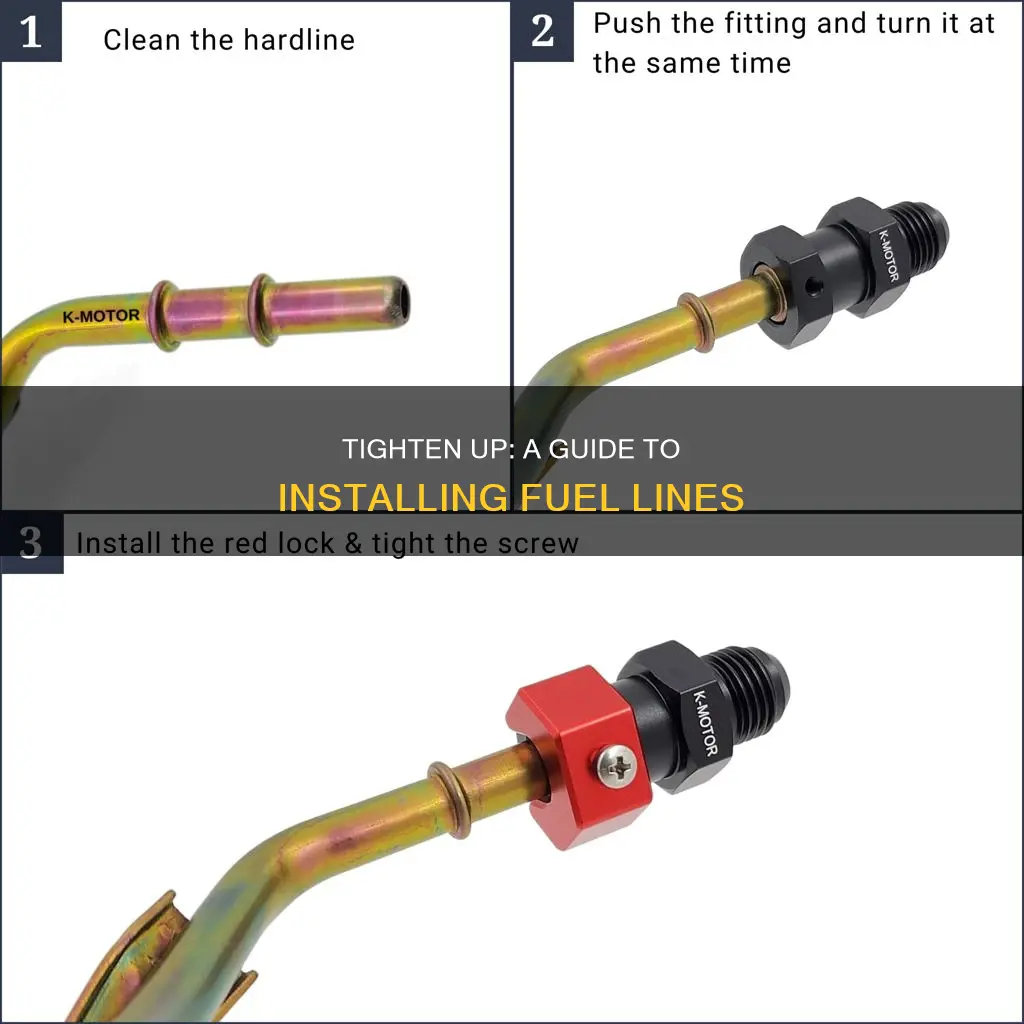

Install New Line: Slide new fuel line into fittings, ensuring proper alignment and tightness

Installing a new fuel line requires careful attention to detail to ensure a secure and tight connection. Here's a step-by-step guide to help you through the process:

Start by gathering the necessary tools and materials. You'll need the new fuel line, appropriate fittings (such as compression or quick-connect fittings), and a fuel line tool or a similar device to assist with the installation. Ensure that the new fuel line is the correct size and length for your application.

Next, locate the existing fuel line and identify the fittings it is connected to. Carefully remove the old fuel line, being cautious not to damage any surrounding components. Clean the fittings and the surrounding areas to ensure a proper seal.

Now, it's time to install the new fuel line. Slide the new line into the fittings, ensuring that it is properly aligned. The key to a tight installation is precision. Make sure the fuel line is centered and seated correctly within the fittings. Use the fuel line tool to push the line into the fittings, applying firm pressure to create a secure connection. Take your time with this step to ensure the line is snug and won't come loose over time.

Check the tightness of the connection by gently wiggling the fuel line. It should feel firm and secure, with no play or movement. If you notice any movement, tighten the fittings further using the appropriate tools. Be careful not to overtighten, as this can damage the fuel line or fittings.

Finally, inspect your work. Ensure that all connections are tight and secure. Look for any signs of leakage around the fittings. If everything is in order, you've successfully installed a new fuel line that will provide a reliable and tight connection for your fuel system.

Nitro RC Car Fuel Lines: Where to Buy

You may want to see also

Test and Inspect: Check for leaks, ensure proper connection, and verify functionality

After completing the installation of the tight fuel line, it is crucial to thoroughly test and inspect the system to ensure its reliability and safety. This step is often overlooked, but it is essential to verify that the fuel line is secure and functioning correctly. Here's a detailed guide on how to test and inspect the fuel line:

Checking for Leaks:

Start by inspecting the fuel line for any signs of leaks. Turn on the fuel pump and listen carefully for any hissing or dripping sounds. Walk around the vehicle and check for any fuel stains or wet spots under the car, especially in areas where the line connects to the fuel tank, engine, and other components. Even a small leak can lead to serious issues, including engine damage and potential fire hazards. If you notice any leaks, immediately shut off the fuel pump and address the issue by tightening connections or replacing damaged parts.

Ensuring Proper Connection:

Verify that all connections are secure and tight. Check the fuel line's fittings and clamps to ensure they are properly installed and tightened according to the manufacturer's specifications. Wiggle the fuel line at the connections to ensure there is no play or looseness. Proper connections prevent fuel leaks and ensure optimal fuel flow to the engine. If you find any loose connections, re-tighten them using the appropriate tools and torque specifications.

Verifying Functionality:

With the engine off, start the fuel pump and listen for any unusual noises. Check for steady fuel flow, ensuring that the pump is delivering fuel to the engine as expected. You can use a fuel pressure gauge to measure the pressure and confirm that it meets the recommended specifications. If the fuel pressure is too low, it may indicate a restricted fuel line or a problem with the fuel pump. Additionally, check the engine's performance during startup. A properly installed fuel line should allow for smooth and quick engine ignition.

Visual Inspection:

Conduct a visual inspection of the entire fuel line system. Look for any signs of damage, such as cracks, punctures, or corrosion. Inspect the line for any kinks or twists that might restrict fuel flow. Ensure that the fuel line is not rubbing against any sharp edges or protruding components that could cause damage over time. A thorough visual check will help identify potential issues before they become major problems.

Remember, proper testing and inspection are critical to maintaining a safe and efficient fuel system. By following these steps, you can ensure that the tight fuel line installation is secure, leak-free, and ready for optimal engine performance. Regular maintenance and inspections will also contribute to the longevity of your vehicle's fuel system.

Poulan Chainsaw Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Frequently asked questions

Before you begin, ensure you have the necessary tools and materials, including the fuel line itself, a fuel line cutter, a fuel line crimper, and a fuel line primer. Also, make sure the engine is cool to avoid any burns.

Measure the length of the fuel line required, typically from the fuel tank to the engine's fuel rail or injectors. Use the fuel line cutter to make a clean, precise cut. It's important to cut the line at a slight angle to create a better seal when crimping.

Crimping the connectors ensures a tight and secure connection. Place the connector over the fuel line, ensuring it is centered. Use the crimper to apply firm pressure, following the manufacturer's instructions for the correct crimping force. Repeat this process for each connector, and consider using a fuel line primer to ensure a good seal and prevent leaks.