Can fuel lines sit on exhaust? This question delves into the potential risks and implications of placing fuel lines in close proximity to exhaust systems. While it might seem like a simple design choice, the answer is more complex. Fuel lines, which carry gasoline or diesel from the tank to the engine, must be carefully positioned to avoid heat damage and potential leaks. Exhaust systems, on the other hand, generate significant heat, which can pose a threat to the integrity of fuel lines. This discussion aims to explore the safety considerations and best practices for positioning fuel lines in relation to exhaust systems.

| Characteristics | Values |

|---|---|

| Potential Risks | Fuel lines sitting on the exhaust can lead to fuel contamination and potential engine damage due to heat exposure. |

| Engine Performance | May result in reduced engine performance and fuel efficiency. |

| Safety Concerns | Increased risk of fire or explosion, especially in high-temperature environments. |

| Fuel Line Material | Different fuel line materials have varying tolerances to heat; some may degrade or become brittle over time. |

| Vehicle Make and Model | Certain vehicle designs might be more susceptible to issues with fuel lines on the exhaust. |

| Maintenance and Inspection | Regular inspection of fuel lines is crucial to ensure they are not damaged or positioned incorrectly. |

| Legal and Regulatory Compliance | Some regions may have specific regulations regarding fuel line placement to ensure safety. |

What You'll Learn

- Fuel Line Material: Different materials have varying heat resistance, affecting their suitability for exhaust environments

- Exhaust Temperature: High temperatures can cause fuel lines to degrade, leading to potential leaks and performance issues

- Fuel Line Routing: Proper placement away from hot components is crucial to prevent damage

- Fuel Line Length: Longer fuel lines may be more susceptible to heat-related issues and require insulation

- Fuel System Design: Efficient design minimizes fuel line exposure to exhaust heat, ensuring longevity

Fuel Line Material: Different materials have varying heat resistance, affecting their suitability for exhaust environments

When considering the placement of fuel lines in close proximity to exhaust systems, the choice of material becomes a critical factor. Different materials exhibit varying levels of heat resistance, which directly impacts their suitability for withstanding the harsh conditions present in exhaust environments. This is a crucial consideration to ensure the longevity and reliability of the fuel system.

One common material used for fuel lines is rubber. Rubber is known for its flexibility and resilience, making it a popular choice for various automotive applications. However, it is important to note that rubber has a relatively low heat resistance. When exposed to high temperatures, rubber can degrade, leading to potential fuel leaks and system failures. In exhaust environments, where temperatures can soar due to the combustion process, rubber fuel lines may not be the best option.

In contrast, synthetic materials like fluoropolymer or PTFE (polytetrafluoroethylene) offer superior heat resistance. These materials can withstand extremely high temperatures, making them ideal for fuel lines in close proximity to exhaust systems. Fluoropolymer, in particular, is known for its excellent chemical resistance and ability to maintain its structural integrity under intense heat. This ensures that the fuel lines remain intact and functional even in the harshest exhaust conditions.

Another material to consider is stainless steel. While it is not typically used for fuel lines due to its rigidity, it can be an excellent choice for high-temperature applications. Stainless steel has exceptional heat resistance and can withstand the extreme temperatures found in exhaust systems without any significant degradation. This makes it a viable option for fuel lines in certain specialized applications.

The choice of material for fuel lines is crucial to ensure the safe and efficient operation of the vehicle. By considering the heat resistance of different materials, engineers and mechanics can select the most appropriate fuel line material for the specific exhaust environment. This ensures that the fuel system remains reliable and performs optimally, even in the challenging conditions presented by exhaust systems.

Mastering Fuel Line Separation: A Step-by-Step Guide

You may want to see also

Exhaust Temperature: High temperatures can cause fuel lines to degrade, leading to potential leaks and performance issues

The proximity of fuel lines to exhaust systems in vehicles is a common design choice, but it also presents a unique challenge: the potential for excessive heat exposure. High exhaust temperatures can significantly impact the integrity and performance of fuel lines, which are crucial components in the fuel delivery system. These lines are responsible for transporting fuel from the tank to the engine, and their condition directly influences the engine's efficiency and reliability.

When fuel lines are positioned near the exhaust, they are exposed to the intense heat generated by the combustion process. Over time, this heat can cause the fuel lines to degrade, leading to several critical issues. One of the primary concerns is the development of cracks or splits in the fuel line material. The high temperatures can cause the rubber or plastic components of the fuel line to become brittle and lose their flexibility. As a result, the fuel lines may start to leak, allowing fuel to escape into the engine bay or even under the vehicle, creating a potential fire hazard.

Moreover, the degradation of fuel lines due to heat can lead to reduced fuel pressure and flow. As the lines age and become less flexible, they may restrict the fuel's path, causing performance problems. This can result in a noticeable decrease in engine power, fuel efficiency, and overall vehicle performance. In extreme cases, the engine may struggle to start or even stall due to insufficient fuel supply.

To mitigate these issues, it is essential to consider the placement of fuel lines during the vehicle's design phase. Engineers can implement various strategies, such as using heat-resistant materials for the fuel lines or installing insulation to protect them from the high temperatures. Regular maintenance and inspections are also crucial, especially for older vehicles, to identify and replace any damaged fuel lines before they cause significant performance issues.

In summary, while placing fuel lines near the exhaust can be a practical design choice, it requires careful consideration of the potential heat-related risks. By understanding the impact of high exhaust temperatures, vehicle manufacturers and owners can take proactive measures to ensure the longevity and reliability of the fuel system, ultimately contributing to a safer and more efficient driving experience.

Fuel Line Fixes: A Step-by-Step Guide to Getting Your Car Back on the Road

You may want to see also

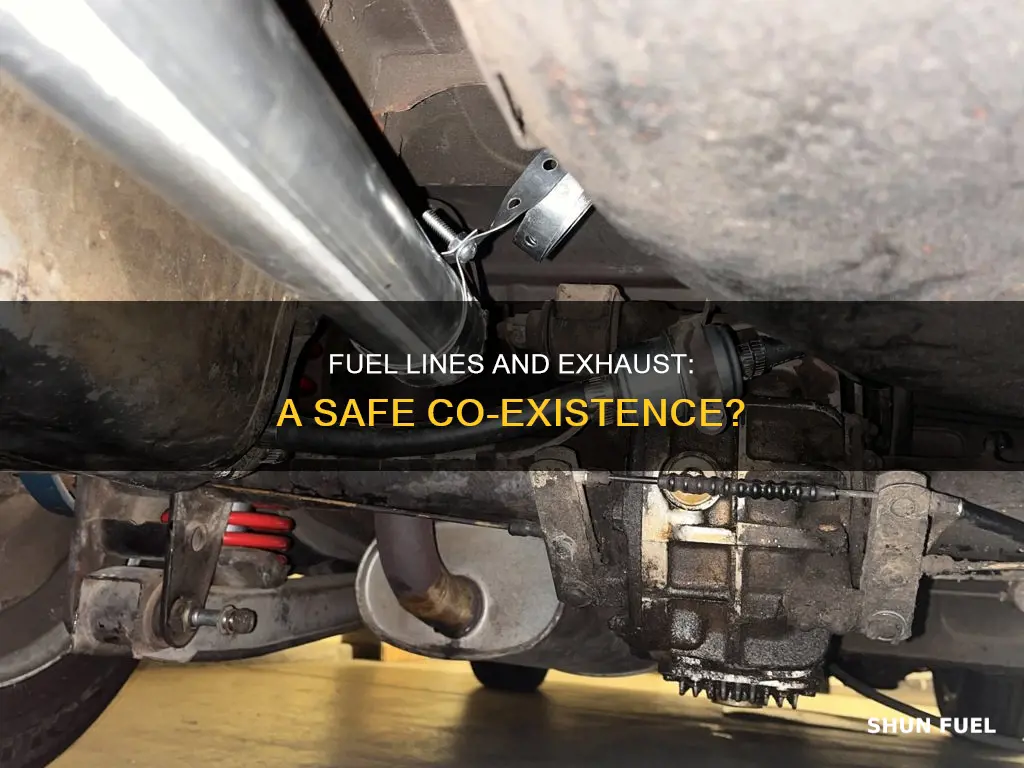

Fuel Line Routing: Proper placement away from hot components is crucial to prevent damage

When it comes to fuel line routing, proper placement is essential to ensure the longevity and reliability of your vehicle's fuel system. One critical aspect often overlooked is the positioning of fuel lines relative to hot components, such as the exhaust system. While it might seem convenient to route fuel lines along the exhaust, this practice can lead to significant issues and potential damage over time.

The primary concern with placing fuel lines near hot exhaust components is the risk of heat damage. Exhaust systems, particularly those with high-performance catalysts or mufflers, generate substantial heat. Prolonged exposure to these elevated temperatures can cause fuel lines to degrade, leading to cracks, leaks, and potential fuel contamination. This is especially critical in high-performance vehicles or those operating in demanding conditions.

To prevent such damage, it is recommended to route fuel lines as far away from hot exhaust components as possible. This can be achieved by carefully planning the path of the fuel lines during the vehicle's assembly. A common practice is to run the fuel lines through the engine compartment, away from the exhaust system, and towards the fuel tank or fuel pump. This approach ensures that the fuel lines are insulated from the high temperatures generated by the exhaust, reducing the risk of premature wear and tear.

Additionally, when working on fuel line installation or repairs, it is crucial to double-check the placement. Ensure that the fuel lines are not inadvertently routed close to hot surfaces. This might involve using heat shields or protective insulation to safeguard the fuel lines from direct contact with hot components. Proper insulation can significantly extend the life of the fuel lines and maintain the overall efficiency of the fuel system.

In summary, while convenience might tempt one to route fuel lines along the exhaust, it is essential to prioritize the long-term health of the fuel system. Proper placement, away from hot exhaust components, is a critical aspect of fuel line routing that can prevent costly repairs and ensure the vehicle's performance and reliability. Always consult the vehicle's manual or seek professional advice to ensure the correct routing of fuel lines.

Fuel Line Fixes: Who's the Expert?

You may want to see also

Fuel Line Length: Longer fuel lines may be more susceptible to heat-related issues and require insulation

When it comes to fuel line placement, the length of the fuel lines is a critical factor that can significantly impact their performance and longevity. Longer fuel lines may seem convenient, but they can present unique challenges, especially in terms of heat management.

In automotive applications, fuel lines are responsible for transporting fuel from the tank to the engine. While shorter lines are often preferred for their simplicity and reduced weight, longer fuel lines can be more susceptible to heat-related problems. The primary concern arises from the increased distance the fuel must travel, which can lead to several issues. Firstly, longer lines may experience higher temperatures due to the fuel's natural tendency to heat up during operation. This is particularly problematic as excessive heat can cause the fuel to degrade faster, leading to reduced performance and potential engine issues.

To mitigate these heat-related problems, proper insulation becomes essential. Insulation materials, such as rubber or specialized thermal coatings, can be applied to the fuel lines to protect them from high temperatures. This insulation acts as a barrier, preventing the heat from the exhaust system or engine components from directly affecting the fuel lines. By maintaining a stable temperature, the fuel's quality is preserved, ensuring optimal combustion and engine efficiency.

Additionally, the placement of longer fuel lines should be carefully considered. Positioning them away from hot engine components, such as the exhaust manifold or catalytic converter, can help reduce the risk of heat damage. This strategic placement ensures that the fuel lines are not exposed to excessive heat sources, further minimizing the chances of heat-related issues.

In summary, while longer fuel lines may offer certain advantages, their increased length can make them more prone to heat-related problems. Proper insulation and careful line placement are crucial to maintaining the integrity of the fuel system and ensuring the engine operates at its best. By addressing these considerations, vehicle owners can optimize their fuel line setup and avoid potential performance and reliability concerns.

Step-by-Step Guide: Removing Fuel Lines from a Crown Vic

You may want to see also

Fuel System Design: Efficient design minimizes fuel line exposure to exhaust heat, ensuring longevity

The placement of fuel lines in a vehicle's engine bay is a critical aspect of fuel system design, especially when considering the potential for fuel lines to be exposed to exhaust heat. While it might seem convenient to route fuel lines alongside the exhaust system, this practice can lead to significant performance and longevity issues. The high temperatures generated by the exhaust can cause fuel lines to degrade over time, leading to potential fuel leaks and reduced engine performance.

To address this, engineers must prioritize efficient fuel system design that minimizes the exposure of fuel lines to exhaust heat. One effective strategy is to route fuel lines away from the exhaust system as much as possible. This can be achieved by carefully planning the layout of the engine bay and using appropriate insulation materials to protect the fuel lines. Insulation materials should be chosen based on their ability to withstand high temperatures without compromising their structural integrity.

In addition to insulation, the use of flexible fuel lines with built-in heat shielding can further protect against exhaust heat. These specialized fuel lines are designed to maintain their flexibility even when exposed to high temperatures, ensuring that they can withstand the rigors of the engine environment. By incorporating these heat-resistant materials, fuel lines can be effectively shielded from the intense heat generated by the exhaust system.

Another design consideration is the use of fuel line brackets and supports that are strategically placed to maintain the correct positioning of the fuel lines while also providing some level of insulation. These brackets should be made from materials that can withstand the heat and should be securely fastened to prevent any movement that could lead to excessive wear and tear on the fuel lines. Proper support and insulation can help maintain the integrity of the fuel lines and reduce the risk of damage from heat-related expansion and contraction.

Furthermore, regular maintenance and inspections are essential to ensure the longevity of the fuel system. Over time, fuel lines can develop cracks or other forms of damage due to heat exposure, especially in areas where the lines are most susceptible to heat transfer. Regular checks can help identify these issues early on, allowing for prompt repairs or replacements to prevent potential fuel leaks and engine performance degradation.

Air in Fuel Line: Causes, Effects, and Solutions

You may want to see also

Frequently asked questions

No, it is not recommended to place fuel lines on or near the exhaust system. Exhaust components, such as pipes and mufflers, can reach extremely high temperatures, which can cause fuel lines to degrade, crack, or even melt over time. This can lead to fuel leaks, which pose a fire hazard and can damage the vehicle's engine.

Fuel lines should be insulated and routed away from hot surfaces to prevent damage. The exhaust system, being one of the hottest areas in a vehicle, can accelerate the deterioration of fuel lines, leading to potential fuel system failures.

Risks include fuel line damage, fuel leaks, and potential fires. High temperatures can cause fuel to vaporize, increasing the risk of leaks and the possibility of a fire. Additionally, exhaust gases can corrode fuel lines over time, further compromising their integrity.

Yes, it is crucial to use heat-resistant materials for fuel lines when they are near the exhaust system. Materials like stainless steel or high-temperature rubber can better withstand the extreme conditions, ensuring the fuel lines remain intact and functional.

Proper insulation and routing are essential. Use heat shields or protective sleeves to cover the fuel lines where they come into contact with the exhaust. Regular inspections and maintenance can also help identify any potential issues before they become major problems.