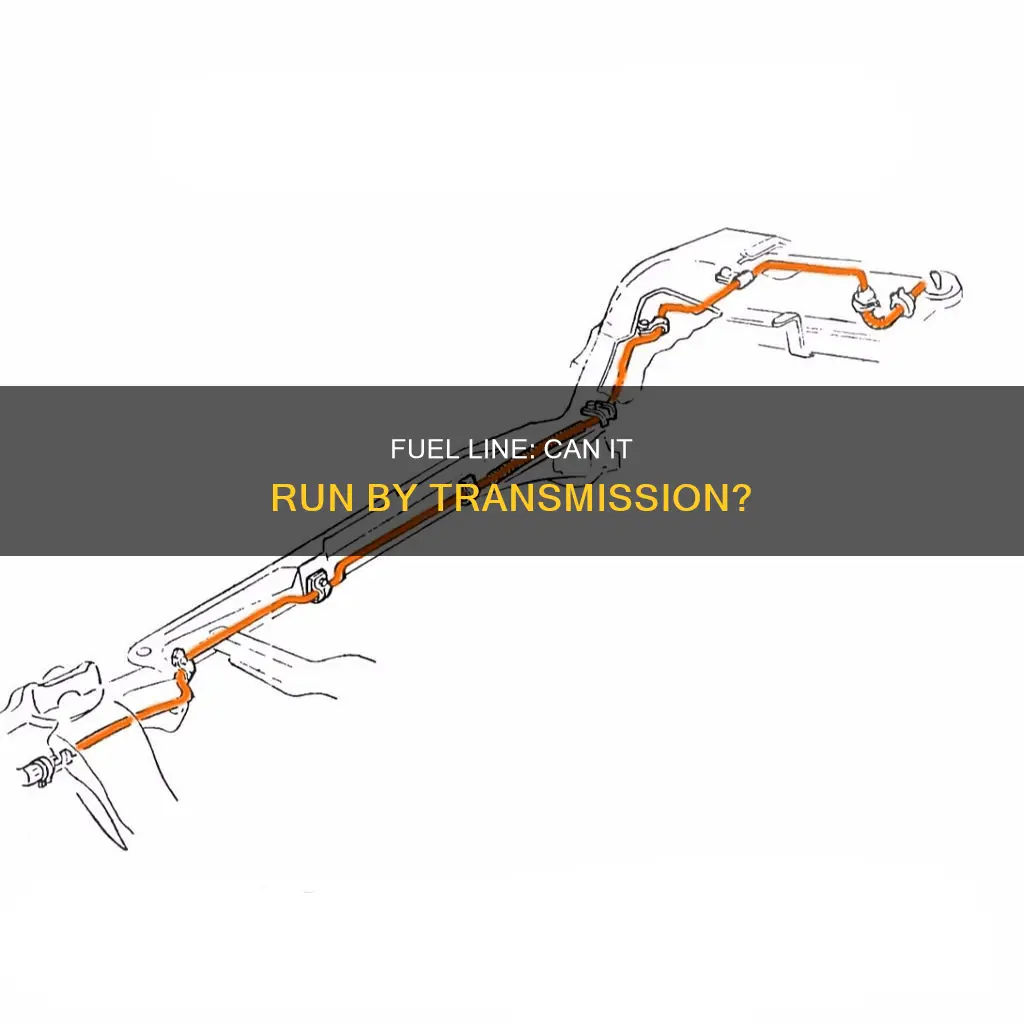

Can fuel lines be run by the transmission? This question often arises in vehicle maintenance and repair discussions. The answer is not a simple yes or no, as it depends on the specific vehicle and its design. In some cases, fuel lines can be routed through the transmission, especially in older vehicles or those with unique engine layouts. However, this arrangement can lead to potential issues, such as increased pressure on the fuel lines and the risk of damage from transmission components. Understanding the vehicle's design and the specific routing of the fuel lines is crucial to ensure proper functionality and safety.

What You'll Learn

- Fuel Line Material: Choose appropriate materials for fuel lines to withstand transmission pressure and temperature

- Clamping and Routing: Secure fuel lines with proper clamps and route them away from transmission components

- Pressure Testing: Conduct thorough pressure testing to ensure fuel lines can handle transmission output

- Compatibility: Verify compatibility between fuel lines and transmission fluids to prevent contamination

- Maintenance and Inspection: Regularly inspect and maintain fuel lines to prevent leaks and ensure optimal performance

Fuel Line Material: Choose appropriate materials for fuel lines to withstand transmission pressure and temperature

When it comes to fuel lines, choosing the right material is crucial to ensure they can withstand the pressure and temperature variations that occur within a transmission system. The fuel lines are responsible for transporting fuel from the tank to the engine, and they must be able to handle the dynamic environment of a vehicle's transmission. Here's a detailed guide on selecting appropriate materials for this critical component:

Material Selection: The primary challenge with fuel lines is the potential for fuel to contain volatile compounds, which can lead to pressure buildup and temperature fluctuations. To combat this, engineers often opt for materials that offer excellent resistance to these factors. One popular choice is high-temperature synthetic rubber compounds, specifically designed to handle the extreme conditions within a transmission. These rubbers are known for their flexibility, durability, and ability to withstand heat without compromising structural integrity. Another option is braided steel or stainless steel fuel lines, which provide superior strength and pressure resistance. These materials are less flexible but offer exceptional longevity, making them ideal for high-performance vehicles or those with demanding transmission systems.

Consideration of Transmission Environment: The transmission's environment is harsh, with varying temperatures and pressure changes during acceleration and deceleration. Materials must be chosen to endure these conditions without degradation. For instance, fuel lines should be able to withstand the high temperatures generated during rapid acceleration, as well as the cold temperatures experienced during engine start-up. Additionally, the fuel lines should be resistant to fuel-related chemicals, such as ethanol, which can cause degradation in some materials over time.

Flexibility and Routing: Fuel lines need to be flexible enough to accommodate the various angles and routes they must take within a vehicle's engine compartment. Rigid materials like steel may not be suitable for all applications, as they can restrict movement and potentially damage other components. Therefore, a balance between flexibility and strength is essential. Modern fuel lines often incorporate a flexible outer covering, ensuring they can navigate through tight spaces without kinking or bending excessively.

Testing and Standards: To ensure the chosen materials meet the required standards, rigorous testing is essential. This includes subjecting the fuel lines to extreme temperatures, pressure tests, and even vibration simulations to mimic real-world driving conditions. Many manufacturers adhere to industry standards, such as those set by the Society of Automotive Engineers (SAE), to guarantee the performance and reliability of their fuel line systems.

In summary, selecting the right material for fuel lines is a critical aspect of vehicle engineering. By considering the transmission's harsh environment and choosing materials that offer flexibility, durability, and resistance to temperature and pressure, engineers can ensure the fuel lines perform reliably, providing efficient fuel delivery to the engine. This attention to detail contributes to the overall performance and longevity of the vehicle.

Ferrell An6 Fuel Line Placement: Expert Guide

You may want to see also

Clamping and Routing: Secure fuel lines with proper clamps and route them away from transmission components

When dealing with fuel lines, proper clamping and routing are essential to ensure the system's reliability and longevity. The fuel lines should be securely fastened to the vehicle's frame or body using appropriate clamps, and they should be routed away from any potential sources of damage, including the transmission. This practice is crucial to prevent fuel line damage, leaks, and potential safety hazards.

Clamping is a critical step in securing fuel lines. The clamps used should be designed specifically for fuel line applications and made from materials that can withstand the internal fuel pressure and environmental conditions. Common types of fuel line clamps include spring-loaded and screw-type clamps. Spring-loaded clamps offer a tight grip and are easy to install, while screw-type clamps provide a more secure hold and are often used for longer-term installations. It is important to choose the correct clamp size to ensure a proper fit and to avoid excessive pressure on the fuel line.

Routing the fuel lines is another vital aspect of the installation process. Fuel lines should be routed in a way that minimizes the risk of damage from vibration, heat, or impact. A common practice is to run the lines along the vehicle's frame or body, using rubber or plastic hosing to protect them from sharp edges and potential chafing. It is essential to avoid routing the fuel lines directly over or near the transmission, as this can lead to potential issues. The transmission's moving parts can cause the fuel lines to rub or become damaged over time, resulting in fuel leaks or system failures.

To ensure optimal performance and safety, fuel lines should be positioned to maintain a slight downward slope, allowing any accumulated fuel to drain back into the tank. This practice helps prevent fuel line corrosion and ensures that the system operates efficiently. Additionally, it is recommended to use fuel line shields or protective covers in areas where the lines are particularly vulnerable, such as under the vehicle or in close proximity to exhaust components.

In summary, clamping and routing fuel lines correctly is a critical step in maintaining a reliable fuel system. By using the right clamps and carefully routing the lines away from transmission components, you can minimize the risk of damage and ensure the long-term performance and safety of your vehicle's fuel system. Proper installation practices contribute to the overall reliability and longevity of the vehicle's mechanical components.

Understanding the Fuel Tank Return Line: A Comprehensive Guide

You may want to see also

Pressure Testing: Conduct thorough pressure testing to ensure fuel lines can handle transmission output

Pressure testing is a critical step in ensuring the integrity and reliability of fuel lines when they are integrated with a transmission system. This process involves subjecting the fuel lines to specific pressure conditions to verify their ability to withstand the output of the transmission. By conducting thorough pressure testing, you can identify potential weaknesses or vulnerabilities in the fuel lines before they are put into operation, thus preventing costly repairs or system failures.

The testing process typically begins with the identification of the fuel lines' specifications, including their diameter, material, and design. This information is crucial in determining the appropriate pressure range for the test. Engineers or technicians will then use specialized equipment to apply pressure to the fuel lines, gradually increasing it to match or exceed the expected transmission output. The goal is to simulate real-world conditions and assess the fuel lines' performance under various loadings.

During the pressure test, several parameters are monitored to ensure the fuel lines' integrity. These include pressure readings at different points along the line, fluid temperature, and any signs of leakage or distortion. Advanced testing equipment, such as pressure gauges, temperature sensors, and visual inspection tools, are employed to gather accurate data. Any deviations from the expected behavior or performance indicators should be carefully noted, as they may indicate potential issues with the fuel lines.

To ensure accuracy, pressure testing should be conducted in a controlled environment, simulating the conditions the fuel lines will encounter in the vehicle. This includes considering factors like temperature variations, fluid viscosity, and the specific characteristics of the transmission system. By replicating these conditions, technicians can make informed decisions about the fuel lines' suitability and make any necessary adjustments or modifications.

In summary, pressure testing is an essential procedure to validate the compatibility of fuel lines with transmission systems. It provides a comprehensive assessment of the fuel lines' ability to handle transmission output, ensuring optimal performance and safety. By following standardized testing procedures and closely monitoring the results, engineers can make informed decisions, leading to the successful integration of fuel lines with transmission systems in various automotive applications.

Mastering Fuel Cell Efficiency: The Art of Running Return Lines

You may want to see also

Compatibility: Verify compatibility between fuel lines and transmission fluids to prevent contamination

When considering the use of fuel lines in a transmission system, it is crucial to prioritize compatibility to avoid potential issues. The primary concern is preventing contamination, as fuel lines are designed to carry gasoline or diesel, while transmission fluids are formulated specifically for the hydraulic system. Mixing these fluids can lead to severe consequences.

To ensure compatibility, it is essential to understand the properties of both fuel lines and transmission fluids. Fuel lines are typically made of materials that can withstand the corrosive effects of gasoline or diesel, such as rubber or specific types of plastic. These materials are chosen to resist degradation over time. On the other hand, transmission fluids are engineered to lubricate and cool the transmission components, and they often contain additives that make them incompatible with fuel.

Verifying compatibility involves checking the manufacturer's specifications for both the fuel lines and the transmission fluid. Each component should be compatible with the specific type of fluid it will come into contact with. For instance, some transmission fluids may require specific types of seals and gaskets to prevent leaks and contamination. It is also important to consider the temperature range and operating conditions to ensure the materials can handle the expected environment.

In some cases, if the fuel lines are to be used in a transmission, an adapter or a specialized fitting might be necessary to ensure a proper connection. This is especially true for older vehicles or those with unique transmission designs. The goal is to create a sealed system that prevents any mixing of fluids, which could lead to performance issues, corrosion, or even system failure.

By carefully selecting compatible components and ensuring proper installation, you can safely and effectively utilize fuel lines in a transmission system without the risk of contamination or other adverse effects. This attention to detail is vital for maintaining the integrity and longevity of both the fuel system and the transmission.

Mantis Tiller Fuel Lines: Location Guide for Easy Access

You may want to see also

Maintenance and Inspection: Regularly inspect and maintain fuel lines to prevent leaks and ensure optimal performance

Regular maintenance and inspection of fuel lines are crucial to ensure the safe and efficient operation of your vehicle. Over time, fuel lines can develop cracks, become brittle, or develop leaks, which can lead to engine performance issues and potential safety hazards. Here's a comprehensive guide on how to maintain and inspect your fuel lines to prevent these problems:

Visual Inspections: Start by regularly examining the fuel lines for any visible signs of damage. Look for cracks, brittleness, or any discolored areas along the lines. These issues are often more noticeable under the hood, where the fuel lines are more exposed. Check for any signs of corrosion or deterioration, especially if your vehicle is older or has been exposed to harsh weather conditions. Even small cracks or punctures can lead to fuel leaks, so any visible damage should be addressed immediately.

Pressure Testing: Conducting pressure tests is an effective way to identify potential fuel line issues. This test involves attaching a pressure gauge to the fuel line and measuring the pressure. If the fuel system is functioning correctly, the pressure should remain stable. Any drops in pressure or unusual fluctuations could indicate a leak or a problem with the fuel pump or lines. It is recommended to have a professional mechanic perform this test to ensure accurate results.

Fuel Line Condition: Inspect the overall condition of the fuel lines. Check for any signs of swelling, hardening, or softening, as these can affect the flexibility and integrity of the lines. Fuel lines should be flexible enough to move with the engine components without kinking or bending excessively. If you notice any unusual wear or damage, it may be necessary to replace the affected sections or the entire line.

Fuel Pump and Filter Maintenance: Proper maintenance of the fuel pump and filter is essential, as they work in conjunction with the fuel lines. Regularly check the fuel pump for any unusual noises or vibrations, which could indicate a failing pump. Additionally, keep the fuel filter clean and replace it at the recommended intervals to prevent contaminants from entering the fuel system and potentially causing damage to the fuel lines.

Addressing Leaks: If you identify any leaks during your inspections, it is crucial to take immediate action. Leaks can lead to fuel wastage, engine misfires, and even fire hazards. Start by identifying the source of the leak, which may require removing and inspecting the fuel lines. Depending on the severity, you might need to replace the affected section or the entire fuel line. Always refer to your vehicle's manual for specific instructions and safety guidelines when working on fuel-related components.

By implementing a regular maintenance and inspection routine, you can significantly reduce the risk of fuel line failures and ensure your vehicle's engine operates at its best. Remember, early detection and addressing any issues promptly can save you from potential breakdowns and costly repairs.

Optimizing Fuel Delivery: Choosing the Right Line for Your 500HP EFI Engine

You may want to see also

Frequently asked questions

Yes, it is possible to route the fuel line alongside the transmission, but it is not recommended due to the potential risks. The transmission system operates at high pressure and temperature, and any damage to the fuel line could lead to fuel leaks, which can be dangerous and cause engine issues.

Running the fuel line near the transmission can result in several problems. Firstly, the high heat generated by the transmission can cause the fuel line to degrade over time, leading to cracks or leaks. Secondly, if the transmission fluid leaks, it can contaminate the fuel, causing engine performance issues. Additionally, any impact or vibration from the transmission's movement could damage the fuel line, creating a potential safety hazard.

When installing or routing a fuel line, it is crucial to follow manufacturer guidelines and best practices. The fuel line should be positioned away from hot surfaces, sharp edges, and areas prone to vibration. It is recommended to use protective sleeves or insulation to safeguard the fuel line from potential damage. Properly securing the fuel line to prevent movement and ensuring it is not pinched or compressed is also essential.

Modifying an existing fuel line to accommodate a new route alongside the transmission should be done with caution. If the original routing was not ideal, it might be better to replace the fuel line entirely to ensure optimal performance and safety. Consulting a professional mechanic or referring to the vehicle's manual is advisable to ensure the modifications are made correctly and safely.