Understanding the fuel lines on a Mantis tiller is crucial for proper maintenance and operation. The Mantis tiller, a popular garden tool, utilizes a fuel system to power its engine, and knowing the route of the fuel lines is essential for troubleshooting and ensuring optimal performance. This introduction aims to guide users through the process of identifying and understanding the placement of fuel lines on their Mantis tiller, providing a comprehensive overview to assist with any maintenance or repair tasks.

| Characteristics | Values |

|---|---|

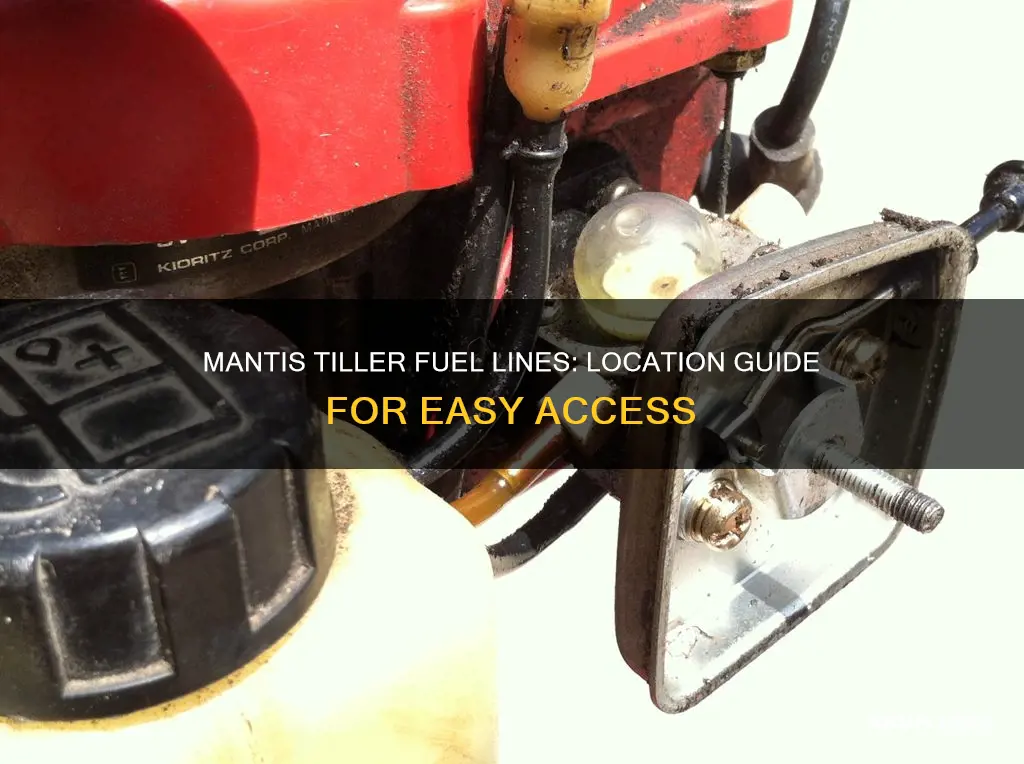

| Fuel Lines Location | The fuel lines on a Mantis tiller typically run from the fuel tank, located at the rear of the tiller, to the carburetor or fuel injection system. |

| Routing | They are usually routed along the frame or inside a protective sleeve to ensure they are not damaged by the tiller's moving parts. |

| Fuel Tank Capacity | The fuel tank on a Mantis tiller can vary, but it often holds around 2-3 gallons (7.5-11 liters) of gasoline. |

| Carburetor or Fuel Injection | Modern Mantis tillers may use a carburetor for fuel delivery, while some newer models incorporate electronic fuel injection systems. |

| Fuel Line Material | These lines are often made of rubber or plastic to withstand the fuel's chemicals and the tiller's operating conditions. |

| Fuel Filter | A fuel filter is commonly installed to prevent contaminants from entering the engine and ensure clean fuel delivery. |

| Fuel Pump | Some Mantis tillers may have a manual or electric fuel pump to deliver fuel from the tank to the carburetor or injection system. |

| Fuel Level Indicator | A fuel gauge or indicator is usually present to monitor the fuel level in the tank. |

| Fuel Line Diameter | The diameter of the fuel lines can vary depending on the tiller's engine size and power output. |

| Maintenance | Regular maintenance, including checking fuel lines for cracks or leaks, is essential to ensure optimal performance and prevent engine issues. |

What You'll Learn

- Fuel Tank Location: The fuel tank is typically located near the engine, often on the side or rear of the tiller

- Fuel Lines Routing: Fuel lines run from the tank to the engine, often following the frame or under the tiller

- Fuel Filter Access: The fuel filter is usually accessible from the side or rear of the tiller, near the fuel lines

- Fuel Pump Location: The fuel pump is often located near the fuel tank or integrated into the engine

- Fuel Level Indicator: The fuel level indicator is typically located near the fuel tank or on the tiller's dashboard

Fuel Tank Location: The fuel tank is typically located near the engine, often on the side or rear of the tiller

The fuel tank on a Mantis tiller is strategically positioned for easy access and efficient fuel management. It is commonly found near the engine, often on the side or rear of the tiller. This placement allows for convenient fueling and provides a clear view of the fuel level, ensuring you can monitor the remaining fuel without any complications. The proximity to the engine also facilitates the routing of fuel lines, which are crucial for delivering fuel from the tank to the engine.

When it comes to the fuel lines, they are designed to be routed in a way that minimizes the risk of damage and ensures optimal performance. The lines are typically made of durable materials to withstand the rigors of outdoor use. They are carefully connected to the fuel tank and the engine, often using specialized fittings and clamps to ensure a secure and leak-free connection. The routing of these lines is critical, as they must be positioned to avoid any obstacles or interference with other components of the tiller.

The fuel lines on a Mantis tiller are usually routed in a straight line from the tank to the engine, ensuring a direct and efficient fuel supply. They may be protected by rubber or plastic sleeves to guard against potential impacts or damage during use. Proper routing also helps maintain a consistent fuel pressure, which is essential for the tiller's performance and longevity.

In some cases, the fuel lines might be slightly angled to accommodate the design of the tiller and its components. This angle ensures that the lines are not too tight or too loose, providing a smooth and continuous path from the tank to the engine. It's important to check the routing of the fuel lines to ensure they are not kinked or damaged, as this could lead to fuel leaks or reduced performance.

Understanding the location of the fuel tank and the routing of the fuel lines is essential for proper maintenance and troubleshooting. If you encounter any issues with fuel delivery or performance, it's crucial to inspect the fuel tank and lines to identify any potential problems. Regularly checking the fuel lines for damage or blockages can help ensure the tiller operates efficiently and reliably.

Fuel Rail Basics: Understanding the Line for Optimal Performance

You may want to see also

Fuel Lines Routing: Fuel lines run from the tank to the engine, often following the frame or under the tiller

Fuel lines play a crucial role in the operation of a Mantis tiller, ensuring a steady supply of fuel from the tank to the engine. Proper routing of these lines is essential to prevent leaks, maintain fuel pressure, and ensure the tiller's efficient performance. Here's a detailed guide on how to route the fuel lines on a Mantis tiller:

When you begin the installation, locate the fuel tank, which is typically mounted on the side or rear of the tiller. Identify the fuel lines that connect the tank to the engine. These lines are usually made of durable materials like rubber or plastic and are designed to withstand the rigors of outdoor use. The primary fuel line carries the fuel from the tank to the engine, while there may also be a return line to ensure proper fuel flow.

The routing of the fuel lines often follows a specific path to maintain stability and avoid potential hazards. One common approach is to run the lines along the frame of the tiller, ensuring they are securely attached to the frame using brackets or ties. This method provides structural support and protects the lines from potential damage caused by movement or impact. Alternatively, the fuel lines may be routed under the tiller, especially if there are no frame attachments available. In this case, ensure that the lines are well-insulated to prevent freezing in colder climates.

It is crucial to maintain a slight downward slope for the fuel lines to facilitate the flow of fuel from the tank to the engine. This slope helps prevent air bubbles and ensures that the fuel flows efficiently. Secure the lines using appropriate fasteners, such as clips, ties, or brackets, to keep them in place and prevent tangling or interference with other components.

Additionally, consider the engine's fuel intake and filter. The fuel lines should be directed to the engine's fuel inlet, ensuring a direct and efficient supply. The lines may need to be adjusted or extended to reach the correct position. Properly secure the connections to the fuel filter and the engine's fuel rail or injection system.

Remember, the specific routing and attachment methods may vary depending on the Mantis tiller model and its design. Always refer to the manufacturer's instructions or consult a professional if you are unsure about any aspect of the fuel line installation. Proper routing ensures the longevity of the fuel lines and contributes to the overall performance and reliability of your Mantis tiller.

Optimizing Performance: Choosing the Right Fuel Line for Your 326 LX

You may want to see also

Fuel Filter Access: The fuel filter is usually accessible from the side or rear of the tiller, near the fuel lines

The fuel filter on a Mantis tiller is a crucial component that ensures the engine receives clean and uninhibited fuel, promoting optimal performance and longevity. Understanding the location of the fuel filter is essential for maintenance and troubleshooting purposes.

When examining the fuel lines on your Mantis tiller, you'll notice that they are strategically routed to supply fuel from the tank to the engine. The fuel filter is typically positioned near these lines, often from the side or rear of the tiller. This placement allows for easy access during maintenance and inspection.

To locate the fuel filter, start by identifying the fuel lines. These lines are usually clear or slightly tinted, and they connect the fuel tank to the engine's fuel inlet. Once you've found the fuel lines, follow them to the point where they connect to the engine block. The fuel filter is often located just a short distance away, either on the side or rear of the tiller, close to the fuel lines.

Accessing the fuel filter is a straightforward process. You may need to remove a small cover or panel to expose the filter. This cover is often secured with a few screws or clips, which can be easily removed with the appropriate tools. Once the cover is off, you'll have clear access to the fuel filter, allowing you to inspect it for any signs of contamination or damage.

Regular maintenance of the fuel filter is essential to ensure the tiller's engine operates efficiently. Over time, the filter can accumulate debris and contaminants, which can restrict fuel flow and potentially cause engine issues. Cleaning or replacing the fuel filter at recommended intervals will help maintain the tiller's performance and reliability.

Finding the Perfect Fuel Line for Your NX250

You may want to see also

Fuel Pump Location: The fuel pump is often located near the fuel tank or integrated into the engine

The fuel pump is a critical component of any engine system, and its location can vary depending on the specific design of the vehicle or equipment. In the case of a Mantis tiller, understanding the fuel pump's position is essential for proper maintenance and troubleshooting.

As you delve into the specifics of the Mantis tiller, you'll find that the fuel pump is strategically placed to ensure efficient fuel delivery to the engine. One common design is to locate the fuel pump near the fuel tank. This placement allows for a direct and secure connection between the pump and the tank, minimizing the risk of fuel leakage or contamination. By being close to the fuel source, the pump can quickly draw fuel and deliver it to the engine when needed.

In some Mantis tillers, the fuel pump might be integrated directly into the engine itself. This design choice offers several advantages. Firstly, it simplifies the overall system by combining the pump and engine into a single unit, reducing the number of components and potential points of failure. Secondly, integrating the pump into the engine ensures a more compact and streamlined design, which can be beneficial for space-constrained applications. This integration also allows for better heat management, as the pump is in close proximity to the engine, facilitating efficient cooling.

When working on a Mantis tiller, it's crucial to identify the fuel pump's location to ensure proper fuel line routing. The fuel lines should be carefully connected to the pump and then extended to the engine, following the manufacturer's guidelines. Proper routing minimizes the risk of damage from vibrations or impacts, ensuring a reliable fuel supply to the engine.

Understanding the fuel pump's location on a Mantis tiller is fundamental for maintenance and repairs. Whether the pump is near the fuel tank or integrated into the engine, its position influences the overall design and functionality of the tiller. By knowing the specific layout, technicians can efficiently access and service the fuel pump, ensuring optimal performance and longevity of the equipment.

Snowmobile Fuel Line Sizing: A Comprehensive Guide

You may want to see also

Fuel Level Indicator: The fuel level indicator is typically located near the fuel tank or on the tiller's dashboard

The fuel level indicator is a crucial component of any tiller, including the Mantis tiller, as it provides essential information about the fuel levels in the tank. This indicator is designed to ensure that the operator is aware of the remaining fuel, allowing for better fuel management and preventing unexpected shutdowns during operation.

In the case of the Mantis tiller, the fuel level indicator is strategically placed for easy access and visibility. It is typically located near the fuel tank, often on the side of the tank or on the dashboard of the tiller. This placement ensures that the operator can quickly glance at the indicator without having to move their focus from the tiller's controls. The proximity to the fuel tank also allows for a more accurate reading of the fuel level, as the indicator is in direct communication with the fuel system.

The design of the fuel level indicator varies, but it often consists of a gauge or a digital display. The gauge might be a simple analog pointer that moves as the fuel level changes, providing a quick visual representation. Alternatively, modern tillers may feature a digital display that shows the exact percentage or volume of fuel remaining. This type of indicator offers more precise information and can be easily read at a glance.

When checking the fuel level, it is essential to ensure that the tiller is turned off and properly grounded to prevent any accidents. The indicator will typically show a full tank when the tiller is new and unused. As the tiller operates and fuel is consumed, the indicator will gradually decrease, providing a clear visual cue to the operator. It is recommended to monitor the fuel level regularly, especially during extended use, to avoid running out of fuel unexpectedly.

In summary, the fuel level indicator on a Mantis tiller is an essential safety feature that provides real-time information about the fuel status. Its location near the fuel tank or on the dashboard ensures easy access and visibility, allowing operators to manage their fuel efficiently and safely. Understanding the placement and functionality of this indicator is vital for maintaining the tiller's performance and preventing fuel-related issues.

Fuel Line MRI: Locating the Right Source

You may want to see also

Frequently asked questions

The fuel lines on a Mantis Tiller are typically located along the handle and near the tiller's base. They run from the fuel tank, usually located at the rear of the tiller, to the engine or the carburetor, ensuring a steady supply of fuel for the tiller's operation.

To inspect the fuel lines, start by ensuring the tiller is turned off and properly secured. Visually examine the lines for any signs of cracks, punctures, or damage. Check for leaks by applying a small amount of diesel fuel or soapy water along the lines and observing for any bubbles or seepage. If any issues are found, it's recommended to replace the fuel lines to prevent fuel leaks and potential engine damage.

Yes, you can modify the fuel line routing to improve accessibility and maintenance. Consider moving the lines to a more convenient location, such as along the side of the tiller or under the seat (if applicable). Ensure that the new routing doesn't interfere with other components and provides easy access for refuelling and maintenance. Always refer to the manufacturer's guidelines for any modifications to ensure the tiller's optimal performance and safety.