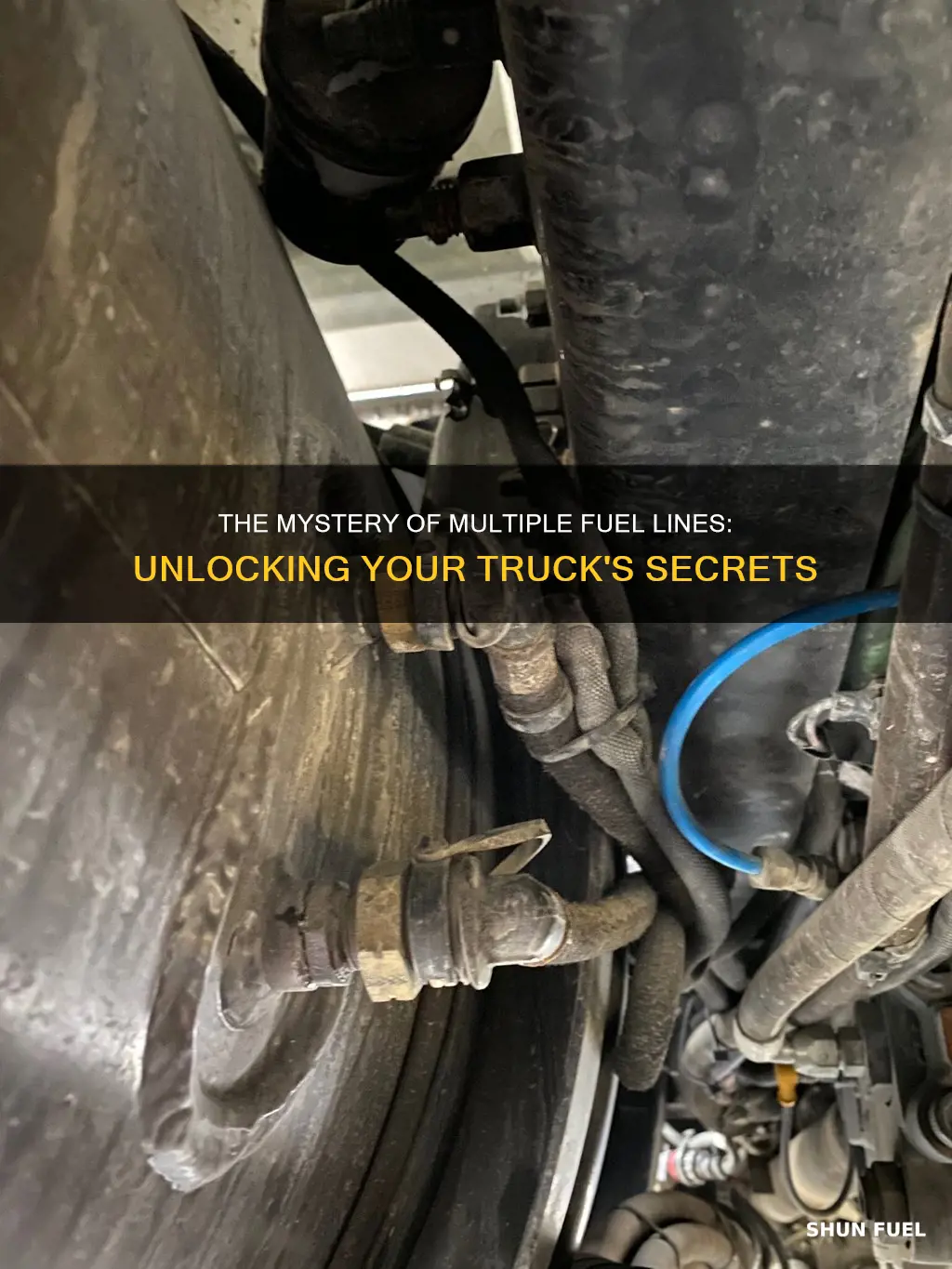

Have you ever wondered why your truck has three fuel lines? It's a common question among vehicle owners, and the answer lies in the intricate design of fuel systems. Each fuel line serves a specific purpose, ensuring optimal fuel delivery to the engine. The primary fuel line delivers the main supply of gasoline, while the secondary lines are often used for additional fuel sources or to provide a backup in case of a malfunction. Understanding the role of each fuel line can help you appreciate the complexity of your truck's fuel system and ensure its efficient operation.

| Characteristics | Values |

|---|---|

| Purpose | To provide multiple fuel supply paths, ensuring a reliable and consistent fuel flow to the engine. |

| Safety | Having three fuel lines can enhance safety by providing redundancy in case of a failure in one line. |

| Performance | It allows for better fuel management, optimizing performance and fuel efficiency. |

| Engine Type | Common in engines with multiple cylinders or those requiring precise fuel injection. |

| Design Consideration | Engineers design fuel systems with multiple lines to accommodate varying engine requirements and optimize power output. |

| Common Vehicles | Often found in trucks, SUVs, and some high-performance cars. |

| Maintenance | Regular inspection and maintenance of all fuel lines are crucial to prevent fuel leaks and ensure engine health. |

What You'll Learn

- Fuel Injection: Multiple lines for precise fuel delivery to the engine

- Safety: Redundancy to prevent fuel leaks and ensure engine operation

- Performance: Optimized fuel flow for better engine performance and efficiency

- Maintenance: Easier access for routine fuel system checks and repairs

- Design: Engineers design systems with multiple lines for specific functions

Fuel Injection: Multiple lines for precise fuel delivery to the engine

The presence of multiple fuel lines in a truck's fuel injection system is a design choice that ensures precise and efficient fuel delivery to the engine. This setup is a common feature in modern vehicles, especially those with fuel-injected engines, as it offers several advantages over a single fuel line system. The primary purpose of having multiple fuel lines is to provide a more controlled and accurate fuel supply, which is crucial for optimal engine performance and fuel economy.

In a typical fuel injection system, the engine requires a precise mixture of air and fuel for combustion. This is achieved through the use of injectors that spray fuel directly into the engine's cylinders. Multiple fuel lines are essential to ensure that each injector receives the correct amount of fuel at the right pressure and timing. By having separate lines for each injector, the system can maintain the required fuel pressure and flow rate, resulting in a more efficient and powerful engine.

The design of these fuel lines is critical to the overall performance. Each line is typically made of high-quality materials to withstand the pressure and temperature changes within the engine. The lines are often designed with specific diameters and lengths to optimize fuel flow, ensuring that the fuel reaches the injectors at the desired rate. This precision in fuel delivery is vital for maintaining the engine's performance, especially during acceleration and high-load conditions.

Furthermore, having multiple fuel lines allows for better fault tolerance. If one fuel line were to malfunction or become restricted, the other lines can compensate, ensuring that the engine still receives the necessary fuel. This redundancy is a key safety feature, as it prevents engine stall or performance degradation due to fuel system issues.

In summary, the multiple fuel lines in a truck's fuel injection system are a critical component that enables precise fuel delivery, optimizes engine performance, and provides a reliable fuel supply. This design choice showcases the engineering precision required to meet the demands of modern vehicles, ensuring that the engine operates efficiently and reliably under various driving conditions. Understanding the role of these fuel lines can help truck owners appreciate the complexity and sophistication of their vehicle's fuel injection system.

Optimal Fuel Line Size for Efficient Beckett Oil Furnace Performance

You may want to see also

Safety: Redundancy to prevent fuel leaks and ensure engine operation

The presence of multiple fuel lines in a truck is a safety feature designed to prevent fuel leaks and ensure the engine operates efficiently. This setup provides redundancy, which is crucial for maintaining the vehicle's performance and safety. Here's an explanation of why having three fuel lines is beneficial:

In a typical truck's fuel system, there are multiple fuel lines to ensure that the engine receives the required amount of fuel under various operating conditions. The primary purpose is to provide a backup in case of a failure in one of the lines. For instance, if one fuel line develops a crack or a leak, the other lines can compensate, ensuring the engine continues to receive fuel. This redundancy is essential because a single fuel line failure could result in a complete loss of fuel supply to the engine, potentially causing it to stall or fail to start. By having three lines, the system becomes more robust and reliable.

The fuel lines are strategically placed to optimize fuel delivery. The primary fuel line is usually the largest and carries the main supply of fuel from the tank to the engine. This line is designed to handle the majority of the fuel flow. The second and third lines are smaller and serve as backups. They are often positioned to supply fuel to specific areas of the engine or to ensure that the primary line's capacity is not exceeded, thus preventing potential pressure buildup. This distribution ensures that the engine receives a consistent fuel supply, promoting efficient combustion and optimal performance.

Furthermore, the arrangement of these fuel lines is carefully planned to minimize the risk of damage and leaks. They are typically made of durable materials like steel or high-quality rubber to withstand the rigors of the road and engine vibrations. The lines are also routed to avoid sharp bends or kinks, which could lead to cracks or punctures over time. Proper installation and regular maintenance are essential to ensure the lines remain intact and functional.

In summary, the use of three fuel lines in a truck is a safety measure that enhances the vehicle's reliability and performance. It provides redundancy to prevent fuel-related issues and ensures the engine operates smoothly even under challenging conditions. This design consideration is a testament to the importance of safety in automotive engineering, where every precaution is taken to protect the driver and the vehicle.

Choosing the Right Rubber for Your Fuel Line: A Guide

You may want to see also

Performance: Optimized fuel flow for better engine performance and efficiency

The presence of multiple fuel lines in a truck's fuel system is often a strategic design choice to optimize performance and efficiency. The primary reason for having three fuel lines is to ensure a precise and controlled fuel supply to the engine, which directly impacts power output and overall engine health. Each fuel line serves a specific purpose, allowing for a more efficient and effective fuel delivery system.

The first fuel line is typically the primary fuel supply line, which delivers the main volume of fuel to the engine. This line is usually the thickest and is designed to handle the majority of the fuel flow required for the engine's operation. It ensures that the engine receives the necessary amount of fuel to meet its performance demands. By having a dedicated primary fuel line, the system can maintain a consistent and reliable fuel supply, which is crucial for optimal engine performance.

The second fuel line is often a return line, which serves a critical function in the fuel system's efficiency. This line recirculates excess fuel back to the fuel tank or a reservoir, preventing fuel wastage and maintaining a steady pressure within the system. By recirculating the fuel, the engine can ensure that the correct amount of fuel is always available, reducing the risk of fuel starvation and promoting better overall performance. This return line also helps to maintain a consistent fuel level, which is essential for accurate fuel management and engine control.

The third fuel line, in some cases, can be an additional supply line or a secondary return line, depending on the truck's design. This additional line provides redundancy and ensures that the engine always has access to fuel, even in the event of a failure in the primary fuel line. By having a backup fuel supply, the truck can maintain its performance and prevent sudden power loss, which is especially important during high-demand driving conditions. This extra line also allows for more precise fuel management, as it can be used to control fuel pressure and ensure the engine receives the optimal fuel-air mixture.

In summary, the use of three fuel lines in a truck's fuel system is a strategic approach to enhance performance and efficiency. Each line serves a specific purpose, from the primary fuel supply to recirculating excess fuel and providing redundancy. This setup ensures a consistent and controlled fuel flow, allowing the engine to operate at its peak performance while maintaining efficiency and reliability. Understanding the role of these fuel lines can help truck owners appreciate the intricate design choices that contribute to their vehicle's overall performance.

Fuel Line Size for 1977 Suzuki KZ650: Essential Guide

You may want to see also

Maintenance: Easier access for routine fuel system checks and repairs

Having multiple fuel lines in a truck is a common feature that can be both a benefit and a potential source of confusion for vehicle owners. The presence of three fuel lines is often a result of the vehicle's design and the need to supply fuel efficiently to various parts of the engine. Each line serves a specific purpose, and understanding their roles is crucial for proper maintenance.

One of the primary reasons for having three fuel lines is to ensure that the engine receives the required fuel at the right pressure and temperature. The main fuel line, often the largest, carries the primary supply of fuel from the tank to the engine. This line is typically designed to handle the highest volume of fuel and is crucial for the engine's performance. Additionally, there might be a secondary fuel line, which can be used to supply additional fuel or to provide a backup in case of any issues with the primary line. This setup ensures that the engine always has the necessary fuel, even if one line encounters a problem.

In terms of maintenance, easier access to these fuel lines is essential for routine checks and repairs. The truck's fuel system requires regular maintenance to ensure optimal performance and longevity. Here's how easier access can simplify the process:

- Routine Checks: Regular inspections of the fuel lines are vital to identify any signs of wear, corrosion, or damage. With multiple fuel lines, it is essential to check each one for any leaks, blockages, or signs of deterioration. Easier access allows mechanics and vehicle owners to inspect each line thoroughly, ensuring that potential issues are caught early. This routine maintenance can prevent costly repairs and ensure the truck's fuel system operates efficiently.

- Quick Repairs: In the event of a fuel line issue, having multiple lines provides redundancy and easier access for repairs. If one fuel line develops a leak or becomes damaged, the presence of a secondary line can prevent the engine from running out of fuel. Mechanics can quickly identify the affected line and perform the necessary repairs or replacements, minimizing downtime. This accessibility also applies to routine tasks like replacing fuel filters or cleaning the fuel injectors, which are essential for maintaining the engine's performance.

- Preventive Measures: Easier access to the fuel lines enables vehicle owners and mechanics to take preventive measures. This includes regular cleaning of the fuel system to remove contaminants and ensuring that all connections are secure. By keeping the fuel lines in good condition, the risk of fuel-related issues, such as engine misfires or reduced power, can be significantly reduced.

In summary, the presence of three fuel lines in a truck is a design feature that ensures efficient fuel supply and engine performance. However, it also requires vehicle owners and mechanics to be vigilant about maintenance. Easier access to these fuel lines simplifies routine checks and repairs, allowing for prompt identification and resolution of potential issues. Regular maintenance of the fuel system is essential to keep the truck running smoothly and avoid unexpected breakdowns.

Perfect Fuel Line Fit: 2001 VL800 Guide

You may want to see also

Design: Engineers design systems with multiple lines for specific functions

The presence of multiple fuel lines in a truck's fuel system is a design choice made by engineers to optimize performance and ensure efficient operation. This design approach is not unique to trucks; many vehicles, including cars and motorcycles, utilize multiple fuel lines for various reasons. The primary goal is to deliver fuel to the engine in a precise and controlled manner, catering to the specific demands of different engine configurations.

Engineers have determined that having multiple fuel lines can provide several advantages. Firstly, it allows for the separation of fuel flow to different parts of the engine, ensuring that each component receives the required amount of fuel. For instance, in a multi-cylinder engine, each cylinder may have its own dedicated fuel line, ensuring that the fuel is delivered directly to the respective injectors. This design minimizes the risk of fuel starvation in any particular cylinder, promoting even combustion and optimal engine performance.

Additionally, the use of multiple fuel lines can enhance the overall fuel system's reliability. By dividing the fuel supply, engineers can reduce the pressure on individual lines, preventing potential issues like fuel pump wear or line rupture. This design approach also enables the implementation of different fuel pressure regulators for each line, allowing for precise control over the fuel-air mixture in various engine operating conditions.

In some cases, the third fuel line is often associated with a return line, which serves a critical function in the fuel system's design. This return line recirculates excess fuel back to the fuel tank or a reservoir, ensuring that the system maintains the correct fuel level and pressure. This design feature is particularly useful in preventing fuel accumulation and potential engine issues caused by excessive fuel pressure.

Engineers' design choices with multiple fuel lines demonstrate a thoughtful approach to vehicle engineering. By optimizing fuel delivery, they aim to improve engine performance, efficiency, and longevity. This design consideration is a testament to the intricate and precise nature of modern automotive systems, where every component plays a vital role in ensuring the vehicle's overall functionality and reliability.

Outboard Fuel Line Clogs: Causes and Solutions

You may want to see also

Frequently asked questions

Having multiple fuel lines is a common design choice in vehicles, especially trucks, due to the need for efficient and reliable fuel delivery. The three lines are typically a primary fuel line, a return line, and a vapor line. The primary line delivers fuel from the tank to the engine, the return line recirculates excess fuel back to the tank, and the vapor line manages the fuel vapor emissions.

The return fuel line is essential for maintaining proper fuel pressure and ensuring efficient combustion. It allows excess fuel that is not used by the engine to be recycled back into the fuel tank, preventing wastage and ensuring a steady supply of fuel.

It is not recommended to drive with a damaged fuel line as it can lead to fuel leaks, poor engine performance, and potential safety hazards. If you suspect any issues with the fuel lines, it's best to have them inspected and repaired by a qualified mechanic to ensure your truck's optimal performance and safety.

Regular maintenance and inspections are crucial for vehicle health. It is advisable to check the fuel lines during routine oil changes or when performing other under-the-hood inspections. Look for any signs of damage, leaks, or corrosion, and address any issues promptly.

Extreme temperatures, both hot and cold, can impact the fuel lines. In cold weather, fuel can become thicker and harder to pump, while hot temperatures might cause fuel expansion. These conditions can affect the fuel lines' flexibility and performance. Proper fuel management and regular maintenance can help mitigate these issues.