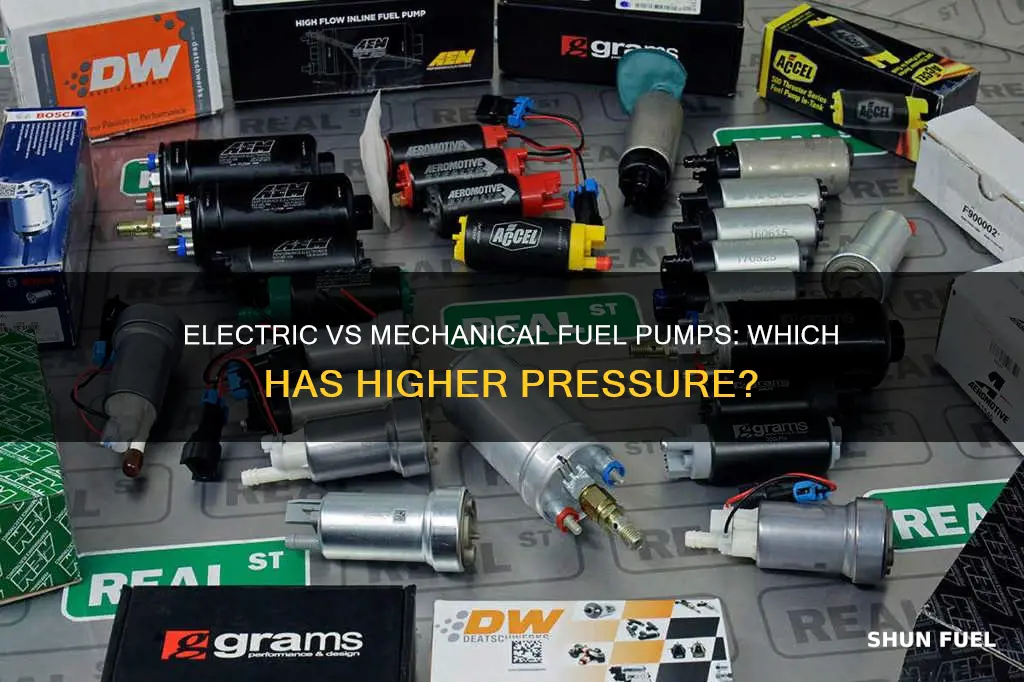

Fuel pumps are an integral part of a vehicle's fuel system, responsible for transferring fuel from the tank to the engine. There are two main types of fuel pumps: mechanical and electric. Mechanical fuel pumps are typically found in older vehicles and are powered by the crankshaft and driven by a motor. On the other hand, electric fuel pumps are more common in modern vehicles and use an electric motor to push fuel from the tank to the engine. One key difference between the two types of pumps is their pressure capabilities. Mechanical pumps are limited to a pressure of up to 6 psi, while electric pumps can operate at pressures of up to 40 psi. Electric pumps offer several advantages, including more efficient fuel delivery, easier installation, faster start times, and reduced maintenance costs. However, mechanical pumps have their own benefits, such as lower cost, ease of repair, and durability. Ultimately, the decision between a mechanical and electric fuel pump depends on various factors, including the vehicle's age, engine type, and specific requirements.

What You'll Learn

- Electric fuel pumps are more efficient, but mechanical pumps are more cost-effective

- Electric pumps can be located in the fuel tank, while mechanical pumps are engine-mounted

- Mechanical pumps are limited to a pressure of 6 psi, while electric pumps can manage 40 psi

- Mechanical pumps are more suitable for older vehicles with carburetors

- Electric pumps are better for newer vehicles with direct fuel injection systems

Electric fuel pumps are more efficient, but mechanical pumps are more cost-effective

When it comes to choosing a fuel pump, there are several factors to consider, including efficiency, cost, and durability. Electric and mechanical fuel pumps each have their advantages and disadvantages, and understanding these differences can help you make an informed decision.

Electric fuel pumps offer several benefits that make them a popular choice for modern vehicles. One of their key advantages is efficiency. Electric fuel pumps provide a consistent and steady flow of fuel to the engine, ensuring that your vehicle's performance remains unaffected by changes in temperature, altitude, or other environmental factors. This consistent fuel delivery results in better performance, improved power, and enhanced efficiency. Additionally, electric fuel pumps are generally easier to install, provide faster start times, and require less maintenance over time, reducing overall maintenance costs. Their reliability also stems from their longer lifespan and lower failure rate compared to mechanical pumps. Furthermore, electric fuel pumps contribute to reducing emissions by burning fuel more efficiently.

On the other hand, mechanical fuel pumps have their strengths as well. One of their most significant advantages is cost-effectiveness. Mechanical fuel pumps are typically less expensive than electric fuel pumps, making them a budget-friendly option. They are also easier to repair due to their simpler design and fewer parts. When it comes to durability, mechanical fuel pumps excel in extreme conditions and are more resilient in harsh environments.

While electric fuel pumps offer superior efficiency and performance, mechanical fuel pumps provide a cost-effective and durable alternative. Electric fuel pumps tend to be more expensive, complex, and prone to overheating due to higher operating temperatures. In contrast, mechanical fuel pumps may struggle with lower efficiency, higher failure rates, and more complicated installation processes.

In summary, electric fuel pumps are more efficient and provide better performance, but mechanical fuel pumps offer cost savings and enhanced durability in extreme conditions. The decision between the two ultimately depends on specific requirements, such as budget, vehicle type, and performance needs. Consulting with professionals can help determine the most suitable option for your vehicle, ensuring optimal efficiency and reliability.

Fuel Pressure Requirements for the MK3 Supra Explained

You may want to see also

Electric pumps can be located in the fuel tank, while mechanical pumps are engine-mounted

The placement of fuel pumps in vehicles depends on whether they are electric or mechanical. Electric pumps can be located in the fuel tank, while mechanical pumps are engine-mounted.

Electric Pumps

Electric fuel pumps are usually located inside the fuel tank or very close to it. They are connected to the fuel tank by a fuel line. When the engine is started, the computer turns on the pump, which creates a vacuum in the fuel line, drawing the fuel into the pump. The pump then pushes the fuel into the engine. When the engine is stopped, the computer turns off the pump.

Mechanical Pumps

Mechanical fuel pumps, on the other hand, are mounted on the side of the engine block. They are connected to the engine with a belt or, in the case of older cars, powered by a crankshaft and driven by a motor. Mechanical pumps use a piston or a diaphragm to pull the fuel from the tank and deliver it to the carburetor.

Factors Influencing Pump Placement

The placement of the fuel pump is influenced by several factors, including the type of engine, the fuel delivery system, and the vehicle's age. Modern vehicles with fuel injection systems typically use electric pumps located in the fuel tank, while older vehicles with carbureted engines often use mechanical pumps mounted on the engine.

Advantages of Electric Pumps in the Fuel Tank

Placing the electric pump inside the fuel tank offers several advantages. It eliminates the possibility of vapor lock, a common issue with mechanical pumps, as the pump is always immersed in fuel, keeping it cool and lubricated. Additionally, electric pumps provide a more consistent and steady flow of fuel, resulting in improved vehicle performance and reduced emissions.

Finding the Fuel Pressure Regulator in 2005 Silverado Models

You may want to see also

Mechanical pumps are limited to a pressure of 6 psi, while electric pumps can manage 40 psi

The pressure generated by a fuel pump is a key consideration when choosing between a mechanical and an electric pump. Mechanical pumps are limited to a pressure of 6 psi, while electric pumps can manage 40 psi. This makes a huge difference in their applications.

Mechanical pumps, which are driven by a crankshaft and a motor, have been around since the early days of automobiles. They use an internal spring-loaded diaphragm to pump fuel from the tank to the engine. Mechanical pumps are generally mounted on the engine and are perfect for older engines with carburetors. They are known for being reliable, quiet, and easy to repair. However, they may not be suitable for fuel injection conversions as they cannot provide enough pressure and volume. Additionally, mechanical pumps can be prone to vapor lock, which occurs when the fuel turns into vapour before reaching the pump due to excessive heat from the engine or exhaust system.

On the other hand, electric pumps offer higher pressure, making them ideal for newer vehicles with direct fuel injection systems. They use an electric motor to push fuel from the tank to the engine and can be located inside the fuel tank or very close to it. Electric pumps provide a consistent, steady flow of fuel, resulting in better performance and improved fuel efficiency. They are also easier to install and require less maintenance than mechanical pumps. However, they tend to be more expensive and can be more complex, with a higher number of moving parts.

While mechanical pumps are limited to 6 psi, this pressure is suitable for most carburetors, which typically operate at 2-4 psi. This makes mechanical pumps a good choice for older vehicles with carbureted engines.

In contrast, electric pumps can provide up to 40 psi, which is necessary for fuel injection systems. This higher pressure ensures that the fuel injectors receive the required volume and pressure of fuel for efficient combustion. Therefore, electric pumps are the preferred choice for newer vehicles with fuel injection systems.

In summary, the pressure capabilities of mechanical and electric fuel pumps make them suited for different applications. Mechanical pumps, with their lower pressure output, are ideal for older vehicles with carbureted engines, while electric pumps, with their higher pressure capacity, are better suited for newer vehicles with fuel injection systems.

Finding the Fuel Pump Port in Your 2002 VW Beetle

You may want to see also

Mechanical pumps are more suitable for older vehicles with carburetors

Mechanical fuel pumps are more suitable for older vehicles with carburetors. Carburetors rely on mechanical fuel pumps, while EFI engines require high-pressure electric pumps. Mechanical fuel pumps are typically mounted on the engine and are actuated by a lever that rides on a fuel pump cam lobe, creating a suction that pulls fuel from the tank and delivers it to the carburetor. They are quiet in operation and generally cannot be heard when pumping.

Mechanical pumps have a pre-set fuel pressure that works with typical two and four-barrel carburetors, and they do not require a fuel return line to the tank. They are also less expensive and easier to repair than electric fuel pumps, making them a cost-effective option for older vehicles.

Additionally, mechanical fuel pumps are more durable, especially in extreme conditions, and their simpler design makes them easier to install in older vehicles. They were standard in many vehicles for many years before being overtaken by electric fuel pumps in the 1930s and 1940s due to the latter's improved efficiency and lower cost.

While electric fuel pumps offer benefits such as improved efficiency, faster start times, and reduced maintenance, mechanical fuel pumps remain a practical choice for older vehicles with carburetors due to their ease of use, durability, and cost-effectiveness.

Fuel Rail Pressure Sensor: 2008 Super Duty Sensor Location Guide

You may want to see also

Electric pumps are better for newer vehicles with direct fuel injection systems

Electric fuel pumps are a better choice for newer vehicles with direct fuel injection systems. These pumps are more efficient at delivering fuel, providing a consistent and steady flow that isn't affected by environmental factors like temperature and altitude. This results in improved vehicle performance and lower emissions. Electric pumps are also easier to install and require less maintenance, saving time and money over the vehicle's lifespan.

Newer vehicles with direct fuel injection systems require higher fuel pressure, and electric fuel pumps can deliver this. Electric pumps can operate at pressures of up to 40 psi, compared to mechanical pumps, which are limited to 6 psi. This makes electric pumps ideal for modern fuel injection systems.

The location of electric pumps within the fuel tank also eliminates the possibility of vapor lock, a significant advantage. Vapor lock occurs when fuel turns into vapour before reaching the pump due to excessive heat from the engine or exhaust system, causing the car to stall.

Additionally, electric pumps are more flexible in terms of placement. They can be located inside the fuel tank or very close to it, which is not possible with mechanical pumps, which need to be near the engine. This flexibility allows for more efficient fuel delivery and can help prevent issues such as fuel starvation.

While electric pumps may be more expensive and complex, their benefits for newer vehicles with direct fuel injection systems are significant. They offer improved performance, efficiency, and reliability, making them a better choice for modern vehicles with higher fuel pressure requirements.

Fuel Pressure and RPM: Understanding the Relationship

You may want to see also

Frequently asked questions

A fuel pump moves fuel from the gas tank to the engine and regulates the pressure.

Mechanical fuel pumps are reliable, quiet, easy to install and repair, and perfect for older engines with carburetors. They are also generally cheaper than electric fuel pumps.

Mechanical fuel pumps are limited to a pressure of up to 6 psi and may not be able to keep up with the demands of a high-performance engine. They are also more prone to failure due to having more moving parts, and require more maintenance.

Electric fuel pumps are faster, more efficient, and more accurate. They can be located in the fuel tank, which is much more flexible than a mechanical fuel pump, and eliminates the possibility of a vapor lock.

Electric fuel pumps are generally more expensive, more complex, and can be difficult to replace. They also generate more heat and require more power.