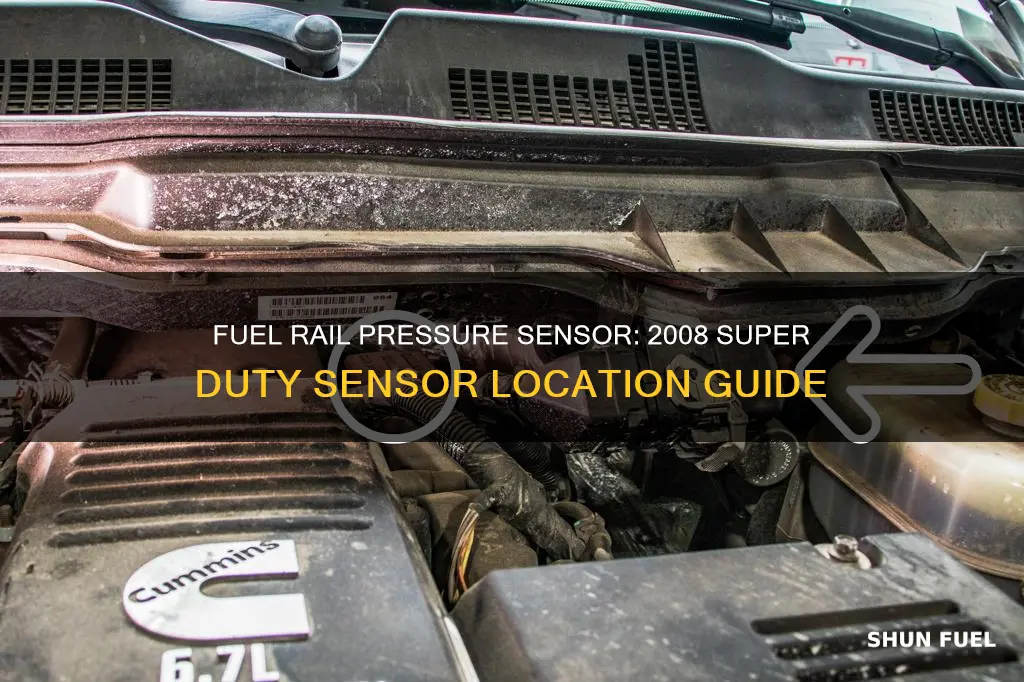

The fuel rail pressure sensor is an important part of the engine management system. It helps ensure that the engine is running at optimal performance. The sensor is usually located somewhere along the engine's fuel rail, which is responsible for distributing fuel to the fuel injectors. This could be tucked in on the side or right on top. The fuel rail pressure sensor monitors the pressure of the fuel in the injector and sends a signal to the engine control unit (ECU). If the pressure is too low, the ECU will increase the amount of fuel injected. If it's too high, the ECU will decrease the amount.

| Characteristics | Values |

|---|---|

| Location | Near the middle of the fuel rail |

| Function | Monitors the pressure of the fuel in the injector |

| Function | Sends a signal to the engine control unit (ECU) |

What You'll Learn

- The sensor is located near the middle of the fuel rail

- It measures the pressure of the fuel in the injectors

- It sends a signal to the engine control unit (ECU)

- If the pressure is too low, the ECU increases the amount of fuel injected

- If the pressure is too high, the ECU decreases the amount of fuel injected

The sensor is located near the middle of the fuel rail

The fuel rail pressure sensor is located near the middle of the fuel rail. This sensor is an important part of the engine management system, ensuring the engine runs at optimal performance.

The sensor measures the pressure of the fuel in the injectors and sends a signal to the engine control unit (ECU). The ECU then uses this information to control the amount of fuel injected into the engine. If the pressure is too low, the ECU increases the amount of fuel injected, and if the pressure is too high, the ECU decreases the amount. This is a vital process in a vehicle's fuel system.

The fuel rail pressure sensor is usually found on the outside of the engine, either tucked in on the side or on top. It can be difficult to access, and you may need to disconnect several wires to remove the engine's intake manifold to reach it.

The sensor is an electronic device that monitors the fuel pressure going to the injectors. It detects the pressure of the fuel feeding the injectors and sends a signal to the computer so that it can make adjustments for optimum performance and efficiency.

A faulty sensor can cause performance issues and engine problems, so it is important to keep an eye on it and ensure it is working correctly.

Arctic Cat 600: Understanding Fuel Pressure Performance

You may want to see also

It measures the pressure of the fuel in the injectors

The fuel rail pressure sensor is an important part of the engine management system. It is responsible for monitoring the pressure of the fuel being delivered to the engine. The sensor is located near the middle of the fuel rail, which is the metal pipe that delivers fuel to the injectors.

The fuel rail pressure sensor measures the pressure of the fuel in the injectors. It does so by sensing the mechanical strain applied by the fuel passing through it. This results in a change in the electrical resistivity of the material, which is then converted into a digital signal for the PCM or ECU. The PCM or ECU uses this information to control the amount of fuel injected into the engine. If the pressure is too low, the PCM or ECU will increase the fuel supply. Conversely, if the pressure is too high, the PCM or ECU will decrease the fuel supply.

By regulating fuel pressure, the fuel rail pressure sensor helps to ensure that the engine receives the right amount of fuel at the right time and at optimum pressure. This is crucial for maintaining engine performance and efficiency, as well as reducing emissions and unburnt fuel.

A faulty fuel rail pressure sensor can cause various issues, including decreased fuel economy, poor engine performance, engine misfires, and a check engine light. Therefore, it is important to keep an eye on this sensor and ensure that it is functioning properly.

Ideal Fuel Pressure for 93 Camaro 350: What You Need to Know

You may want to see also

It sends a signal to the engine control unit (ECU)

The fuel rail pressure sensor is an important part of the engine management system. It helps to ensure that the engine is running optimally. The sensor sends a signal to the engine control unit (ECU), which then uses this information to control the amount of fuel injected into the engine.

The ECU relies on the fuel rail pressure sensor to relay the correct amount of fuel during the intake stroke. The sensor constantly monitors the fuel pressure in the fuel rail and sends this data to the ECU, which adjusts the fuel pressure and injection timing as required. This improves performance and efficiency, and also reduces emissions and the amount of unburnt fuel.

The fuel rail pressure sensor is made up of a semiconductor and an integrated electric circuit. When fuel passes through the sensor, it applies a mechanical strain on the semiconductor. This results in a change in the material's electrical resistivity. The integrated circuit then converts this change in electrical resistivity into a digital signal for the ECU.

A faulty fuel rail pressure sensor can cause a range of issues, including a decrease in fuel economy, acceleration, and engine performance. It may also cause the engine to run rough and stall. In some cases, the check engine light will come on. If you experience any of these symptoms, it is important to have the vehicle inspected by a professional technician, who can diagnose the problem and replace the sensor if necessary.

Fuel Pressure Sweet Spot for Motorcycle Performance

You may want to see also

If the pressure is too low, the ECU increases the amount of fuel injected

The fuel rail pressure sensor is an important part of the engine management system. It helps ensure that the engine is running optimally. The sensor is located near the middle of the fuel rail. It monitors the pressure of the fuel in the injector and sends a signal to the engine control unit (ECU).

If the pressure is too low, the ECU will increase the amount of fuel injected. This is because the ECU controls the injection of fuel and, in petrol engines, the timing of the spark to ignite it. It determines the position of the engine's internals using a Crankshaft Position Sensor so that the injectors and ignition system are activated at the correct time.

The amount of mixture is important, but the ratio of that mixture also has to be correct. Too much fuel and too little oxygen will result in dirty and wasteful combustion. Too little fuel and too much oxygen will make the combustion slow and weak. The ECU has to deal with many variables when deciding on the correct mixture ratio.

An increase in engine demand, such as accelerating, will require an increase in the overall quantity of the mixture. The combustion characteristics of the fuels in use also require a change in the ratio of this mixture. When you press the accelerator pedal, your throttle flap will open to allow more air into the engine. The increase in airflow to the engine is measured by the Mass Air Flow sensor (MAF) so the ECU can change the amount of fuel that's injected, keeping the mixture ratio within limits.

If the pressure is too low, it will decrease the amount of fuel that is injected into the cylinders. This can cause engine performance issues and may even damage the engine. Therefore, it is important to keep an eye on this sensor and make sure that it is working properly.

Locating the Fuel Pressure Sensor in a 2010 Chevy Colorado

You may want to see also

If the pressure is too high, the ECU decreases the amount of fuel injected

The fuel rail pressure sensor is an important part of the engine management system. It helps ensure that the engine is running at optimal performance. The sensor is located near the middle of the fuel rail, which is a pipe that supplies pressurized fuel to all of the injectors.

The fuel rail pressure sensor measures the pressure of the fuel in the injectors and sends a signal to the engine control unit (ECU). The ECU uses this information to control the amount of fuel that is injected into the engine. If the pressure is too high, the ECU will decrease the amount of fuel that is injected. This is because too much fuel in the engine can lead to decreased fuel efficiency, increased emissions, and even engine damage.

The ECU is responsible for controlling the fuel injection, ignition timing, and other engine functions. It uses digitally stored equations and numeric tables to make precise calculations and adjustments to the engine's performance. By monitoring the pressure of the fuel in the injectors, the ECU can adjust the amount of fuel injected to maintain the ideal air-to-fuel ratio, also known as the "stoichiometric" or "Lambda" ratio.

Maintaining the correct fuel pressure is crucial for optimal engine performance. If the pressure is too high, it can lead to excessive fuel delivery, causing issues such as decreased fuel efficiency and increased emissions. Therefore, the ECU responds by decreasing the amount of fuel injected to maintain the proper balance.

It's important to note that a faulty fuel rail pressure sensor can cause problems with engine performance and fuel efficiency. If you suspect any issues with the sensor, it's recommended to have your vehicle inspected by a professional technician for diagnosis and repair.

Fuel Injector Pressure: 89 Ford 351 Specifications

You may want to see also

Frequently asked questions

The fuel rail pressure sensor is located near the middle of the fuel rail.

A fuel rail pressure sensor is an engine management component that is commonly found on diesel and is part of the fuel injection system.

The sensor sends a signal to the engine control unit (ECU), which uses it to regulate the amount of fuel injected into the engine.