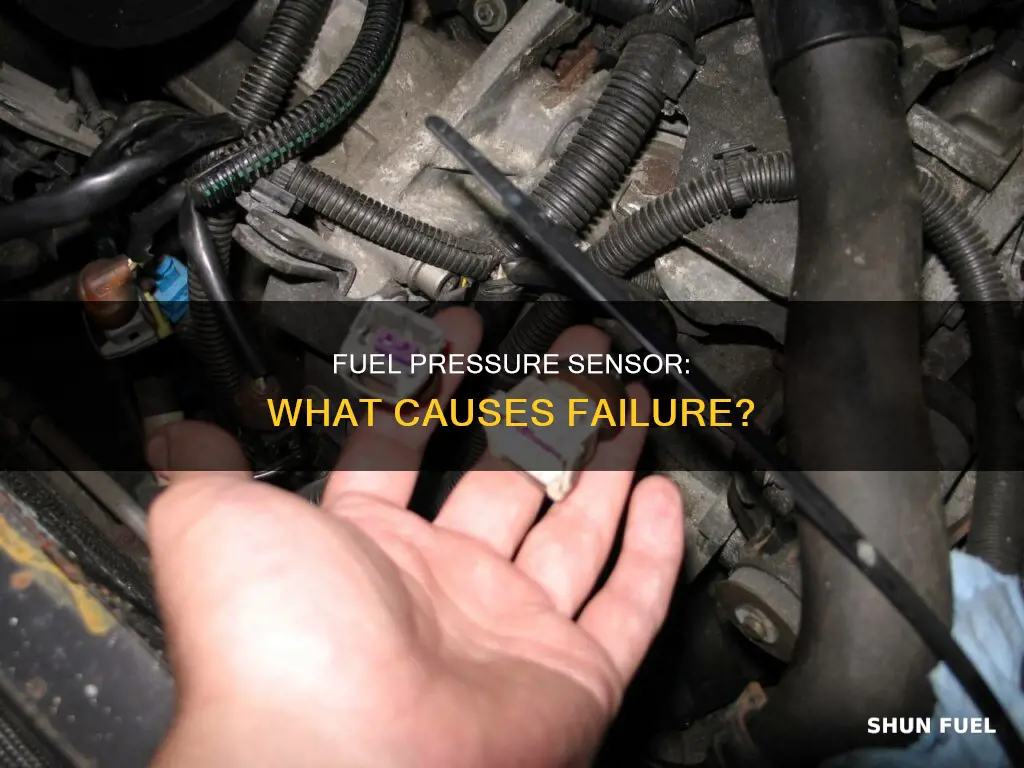

A fuel rail pressure sensor is an electronic device that monitors the pressure inside the fuel rail, the metal tube that connects the fuel delivery system to the engine. When the sensor fails, the engine's performance suffers, and warning lights may illuminate. Several factors can cause a fuel pressure sensor to fail, including wear and tear, contaminated fuel, excessive heat or vibration, electrical issues, and fuel system problems. A faulty sensor can cause various issues, such as difficulty starting the engine, weak acceleration, reduced fuel efficiency, and engine misfires. To fix a bad fuel pressure sensor, it must be replaced, and the total replacement cost, including parts and labour, can range from $150 to $350 or more.

| Characteristics | Values |

|---|---|

| Engine performance | Poor |

| Idling | Rough |

| Fuel efficiency | Reduced |

| Check Engine Light (CEL) | On |

| Engine start | Difficult |

| Exhaust emissions | Excessive |

| Engine misfires | Occurs |

| Engine stalling | Occurs |

| Power loss | Sudden |

| Fuel consumption | Increased |

| Fuel system problems | Occurs |

| Fuel quality | Low |

| Electrical issues | Occurs |

What You'll Learn

Wear and tear

The sensing element, for instance, may become less sensitive to pressure changes over time, resulting in incorrect pressure measurements. Similarly, the electronic circuitry can deteriorate, affecting the sensor's ability to transmit data accurately.

In addition, the fuel pressure sensor is subject to the extreme conditions of the engine bay. Prolonged exposure to high temperatures, continuous vibrations, and in some cases, corrosive substances or contaminants in the fuel, can accelerate the deterioration of the sensor's construction and reliability.

Furthermore, the pressurised fuel system itself contributes to the wear and tear of the sensor. As the sensor ages, it may not be able to perform adjustments to the fuel pressure as effectively, leading to engine performance issues and potential sensor failure.

To mitigate the effects of wear and tear, regular maintenance of the vehicle's fuel system is crucial. This includes using high-quality fuel, changing the fuel filter at recommended intervals, and promptly addressing any warning signs or issues.

Testing Fuel Pressure: Lincoln Navigator Guide

You may want to see also

Contaminated fuel

The fuel pressure sensor plays a critical role in monitoring and regulating fuel pressure in the vehicle's fuel system. It detects the pressure within the fuel rail and sends this information to the engine control module (ECM), allowing it to adjust the fuel delivery accordingly. Contaminated fuel can affect the accuracy of these readings, leading to improper fuel pressure and, subsequently, engine performance issues.

The presence of contaminants can also cause physical damage to the sensor's components. For example, corrosive substances can eat away at the sensor's circuitry, while debris can clog or damage the sensing element. Over time, this can lead to inaccurate readings or even complete sensor failure.

Additionally, contaminated fuel can affect the fuel injectors, which rely on precise fuel pressure to function correctly. If the injectors become clogged or damaged due to contaminated fuel, they may not be able to deliver the right amount of fuel at the right time, further exacerbating the problem.

To prevent issues with the fuel pressure sensor and other fuel system components, it is essential to use high-quality fuel and maintain the vehicle's fuel system regularly. This includes using recommended fuel types, changing the fuel filter at the recommended intervals, and addressing any signs of fuel system problems promptly. By taking these proactive measures, you can help ensure the longevity and optimal performance of your vehicle's fuel pressure sensor.

Checking Fuel Pressure in an Oldsmobile Silhouette

You may want to see also

Excessive heat or vibration

The location of the fuel pressure sensor within the engine bay exposes it to high temperatures and vibrations. Excessive heat or continuous vibrations can cause the sensor to fail in several ways.

Firstly, prolonged exposure to extreme heat can weaken the sensor's construction, affecting its reliability over time. The heat can cause the sensor's housing to warp or melt, leading to a loss of structural integrity. Additionally, the heat can damage the internal components of the sensor, such as the sensing element and electronic circuitry, resulting in inaccurate readings or complete sensor failure.

Secondly, continuous vibrations can also take their toll on the sensor. Vibrations can cause mechanical stress on the sensor's housing and internal components, leading to cracks or damage. This can affect the sensor's ability to accurately measure fuel pressure and transmit data.

Furthermore, excessive heat and vibrations can cause the sensor's electrical connections to become loose or damaged. This can lead to disruptions in the sensor's ability to transmit data accurately, resulting in incorrect fuel pressure readings and potential engine issues.

To mitigate the effects of excessive heat and vibrations, it is essential to ensure that the sensor is properly secured and insulated within the engine bay. Regular maintenance and inspections can also help identify any signs of damage or wear caused by these factors, allowing for timely interventions to prevent sensor failure.

Testing Fuel Pressure in a 1996 Toyota Corolla

You may want to see also

Electrical issues

The fuel pressure sensor plays a critical role in monitoring and regulating fuel pressure. It detects the pressure within the fuel rail and sends this data to the ECM or PCM. The sensor consists of a semiconductor and an electric circuit, and it measures the force applied by the fuel passing through it. Therefore, electrical problems can have a significant impact on the sensor's functionality and the overall performance of the engine.

In addition to electrical issues, there are other factors that can contribute to the failure of a fuel pressure sensor. These include wear and tear, contaminated fuel, excessive heat or vibration, fuel system problems, and manufacturing defects. Regular maintenance of the vehicle's fuel system, including the use of high-quality fuel and timely addressing of any warning signs, can help prevent premature failure of the fuel pressure sensor.

Testing Fuel Pressure Regulator in '99 Camry: A Step-by-Step Guide

You may want to see also

Fuel system problems

For example, if the fuel pressure regulator malfunctions, it can cause excessive fuel pressure, putting undue stress on the sensor and leading to its failure. Similarly, a clogged fuel filter or a failing fuel pump can affect the performance of the sensor by disrupting the flow of fuel and causing fluctuations in fuel pressure.

In older vehicles with neglected fuel systems, the fuel rail where the sensor is located may become clogged or contaminated with debris, impacting the sensor's performance. This contamination can affect the accuracy of the sensor's readings, leading to improper fuel pressure adjustments and potential damage to the sensor.

It is important to note that regular maintenance of the vehicle's fuel system, including using high-quality fuel and changing the fuel filter at recommended intervals, can help prevent premature failure of the fuel pressure sensor. By addressing any warning signs and following the manufacturer's recommended service schedule, you can maintain the health and longevity of this crucial sensor.

Checking Fuel Pressure: '07 Fusion Maintenance Guide

You may want to see also

Frequently asked questions

A bad fuel pressure sensor can cause a range of issues, including poor engine performance, rough idling, reduced fuel efficiency, difficulty starting the engine, and stalling. The check engine light may also illuminate, indicating a problem with the fuel system.

There are several factors that can contribute to the failure of a fuel pressure sensor:

- Wear and tear over time due to normal usage, exposure to elements, and degradation of internal components.

- Contaminated fuel, which can introduce debris, water, or corrosive substances that damage the sensor's delicate components.

- Excessive heat or vibration from the engine bay, which can weaken the sensor's construction.

- Electrical issues such as corroded wires, loose connections, or short circuits that disrupt data transmission.

- Fuel system problems like a clogged fuel filter, failing fuel pump, or fuel pressure regulator malfunction, placing additional strain on the sensor.

A bad fuel pressure sensor typically needs to be replaced rather than repaired. It is recommended to consult a qualified mechanic or a professional repair shop to ensure safe and proper installation.