The fuel line on a carburetor is a crucial component of the fuel system in an internal combustion engine. It is responsible for delivering the correct amount of fuel to the carburetor, where it is mixed with air and ignited in the engine's cylinders. Understanding the path of the fuel line is essential for proper engine maintenance and troubleshooting. In this paragraph, we will explore the typical route of the fuel line, its connection points, and its role in ensuring optimal engine performance.

| Characteristics | Values |

|---|---|

| Location | The fuel line typically connects to the carburetor's float bowl or a dedicated fuel inlet port. |

| Purpose | It delivers fuel from the fuel tank to the carburetor for mixing with air and ignition in the engine. |

| Type | The fuel line can be made of various materials like rubber, vinyl, or metal, depending on the application and engine requirements. |

| Routing | It is usually routed along the side of the engine, sometimes with a protective covering or shield to prevent damage. |

| Connection | The line connects to the carburetor using a quick-connect fitting or a threaded adapter. |

| Length | The length of the fuel line varies depending on the engine design and can range from a few inches to several feet. |

| Compatibility | It must be compatible with the specific carburetor model and engine type to ensure proper fuel delivery. |

What You'll Learn

- Carburetor Fuel Line Routing: Path from fuel tank to carburetor

- Fuel Line Diameter: Standard size for optimal performance

- Carburetor Fuel Line Material: Common materials like rubber or plastic

- Fuel Line Connections: Methods for attaching to carburetor and tank

- Fuel Line Length: Optimal length for efficient fuel delivery

Carburetor Fuel Line Routing: Path from fuel tank to carburetor

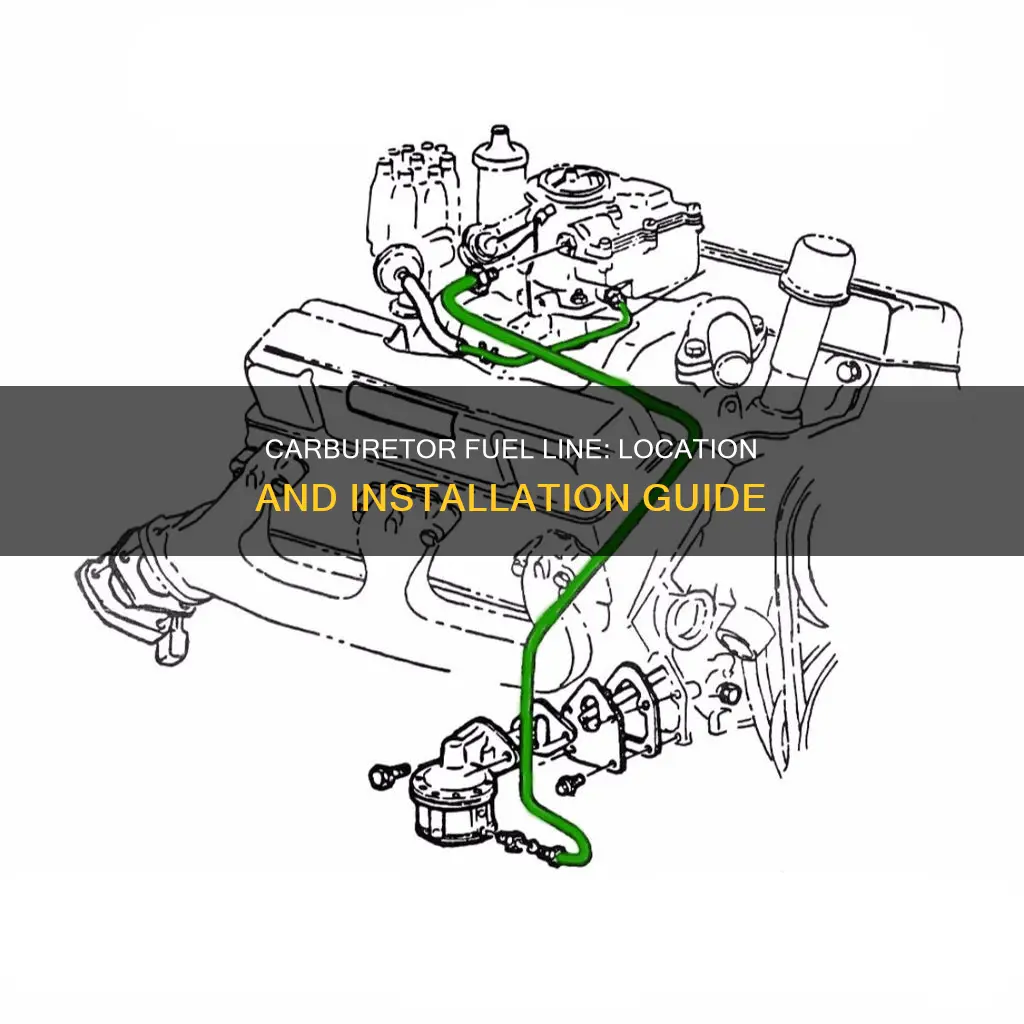

The fuel line on a carburetor is a critical component of the fuel system, responsible for delivering gasoline from the fuel tank to the carburetor, where it is mixed with air and ignited in the engine's cylinders. Proper routing of this line is essential to ensure efficient fuel flow and optimal engine performance. Here's a detailed guide on the typical path of the fuel line from the fuel tank to the carburetor:

Fuel Tank to Carburetor:

The fuel line begins its journey at the fuel tank, which is usually located beneath the vehicle's body or in the engine compartment. From the tank, the line typically runs along the frame or beneath the vehicle, depending on the vehicle's design. It is important to note that the fuel line should be routed away from hot engine components to prevent damage and potential fuel contamination.

As it exits the fuel tank, the line may pass through a fuel filter, which is designed to remove impurities and ensure clean fuel. This filter is crucial in maintaining the health of the engine and preventing blockages. After the filter, the fuel line continues its path, often following the contours of the vehicle's frame or body.

Routing Considerations:

The routing of the fuel line is a critical aspect of its design. It should be positioned to avoid sharp bends or kinks, as these can restrict fuel flow and potentially cause damage over time. A common practice is to route the line in a straight line as much as possible, ensuring it is not twisted or bent excessively. This straight routing helps maintain the integrity of the fuel flow and reduces the risk of fuel pressure loss.

In some vehicles, the fuel line may be protected by a rubber or plastic covering to shield it from potential impacts or damage. This protective covering is essential, especially in areas where the line might come into contact with moving parts or road debris.

Connection to Carburetor:

The fuel line terminates at the carburetor, where it connects to the carburetor's float bowl or fuel inlet. The carburetor's design varies across different vehicle models, but the fuel line typically attaches to a specific port or fitting on the carburetor body. This connection allows the fuel to enter the carburetor, where it is then mixed with air and distributed to the engine's cylinders.

Proper installation and securement of the fuel line at this point are vital to ensure a tight seal and prevent fuel leaks. Any issues with the connection can lead to fuel starvation, affecting engine performance and potentially causing starting difficulties or engine misfires.

In summary, the fuel line's path from the fuel tank to the carburetor is a carefully designed route that ensures efficient fuel delivery to the engine. Understanding this routing and paying attention to detail during installation or repair can help maintain optimal engine performance and reliability.

Understanding Aluminum Fuel Line Ratings: A Comprehensive Guide

You may want to see also

Fuel Line Diameter: Standard size for optimal performance

The fuel line is a critical component in the fuel delivery system of an engine, and its diameter plays a significant role in ensuring optimal performance. When it comes to the standard size for the fuel line, it is essential to consider the engine's specifications and the overall design of the carburetor. The diameter of the fuel line determines the flow rate of the fuel, which directly impacts the engine's power and efficiency.

In general, the standard fuel line diameter for most automotive applications is around 3/8 of an inch (9.5 mm). This size is chosen to provide a balance between fuel flow and pressure, allowing for efficient delivery without excessive restriction. A larger diameter would result in increased fuel flow, which might lead to over-fuelling and potential performance issues, especially in high-performance engines. On the other hand, a smaller diameter could restrict the fuel flow, causing the engine to run lean and potentially leading to performance losses.

The 3/8-inch diameter fuel line is often used because it offers a good compromise between performance and practicality. It ensures that the fuel can flow smoothly through the line, providing the engine with the necessary amount of fuel for optimal combustion. This standard size is widely used in various vehicle makes and models, making it easier for mechanics and enthusiasts to source replacement parts.

However, it's important to note that the optimal fuel line diameter can vary depending on several factors. For instance, high-performance engines or those with modified carburetors might require a larger diameter to accommodate increased fuel flow. In such cases, a 1/2-inch (12.7 mm) fuel line could be used to ensure the engine receives the required amount of fuel for optimal power output. Conversely, smaller engines or those with less demanding performance requirements might benefit from a smaller diameter, such as 1/4-inch (6.35 mm), to maintain efficiency without unnecessary fuel consumption.

In summary, the standard fuel line diameter for optimal performance is typically 3/8 of an inch, but adjustments may be necessary based on specific engine requirements. Understanding the relationship between fuel line diameter and engine performance is crucial for anyone working on carburetor-equipped vehicles, ensuring that the fuel delivery system operates efficiently and effectively.

Can Braided Fuel Lines Be Used for Brakes?

You may want to see also

Carburetor Fuel Line Material: Common materials like rubber or plastic

The carburetor fuel line is a critical component in an engine's fuel system, responsible for delivering the correct amount of fuel to the engine's cylinders. The material used for this line is crucial as it directly impacts the performance and longevity of the engine. Common materials for the fuel line include rubber and plastic, each offering unique advantages and considerations.

Rubber is a popular choice for carburetor fuel lines due to its flexibility and durability. It can withstand the high pressure and temperature variations encountered in an engine environment. Rubber fuel lines are known for their ability to absorb vibrations, ensuring a smooth and consistent fuel flow. This material is also resistant to fuel degradation, which can cause the line to crack or become brittle over time. Rubber fuel lines are often used in high-performance applications where flexibility and resistance to heat are essential.

Plastic, on the other hand, offers a lightweight and cost-effective alternative. It is less flexible than rubber but can still provide adequate performance in many applications. Plastic fuel lines are known for their resistance to corrosion and chemical degradation, making them suitable for engines with specific fuel requirements. However, plastic lines may not be as flexible as rubber, which can be a consideration in certain engine designs.

When choosing the material for the carburetor fuel line, it is essential to consider the specific requirements of the engine. Factors such as engine power, operating conditions, and fuel type play a significant role in determining the most suitable material. For high-performance engines, rubber may be the preferred choice due to its superior flexibility and heat resistance. In contrast, plastic could be more appropriate for lighter-duty applications or engines with specific fuel requirements.

In summary, the carburetor fuel line's material is a critical aspect of engine performance and longevity. Rubber and plastic are the most common materials, each offering unique advantages. Rubber provides flexibility and durability, making it ideal for high-performance engines, while plastic offers lightweight and corrosion-resistant properties. The choice of material should be based on the engine's specific needs to ensure optimal fuel delivery and engine operation.

Bronco Fuel Pump: Easy Gas Line Removal Guide

You may want to see also

Fuel Line Connections: Methods for attaching to carburetor and tank

The fuel line is a critical component in any internal combustion engine, and its proper connection to the carburetor and fuel tank is essential for optimal performance. When attaching the fuel line, it's important to understand the different methods and techniques to ensure a secure and leak-free connection. Here's a detailed guide on how to connect the fuel line to the carburetor and tank:

Connecting to the Carburetor:

The carburetor is a crucial component that mixes air and fuel for combustion. The fuel line connects to the carburetor at a specific port, often referred to as the 'fuel inlet' or 'jet' port. Here's how to make this connection:

- Locate the carburetor on your engine. It is typically a cylindrical component attached to the intake manifold.

- Identify the fuel inlet or jet port, which is usually a small opening or hole on the carburetor body. This is where the fuel line will connect.

- Ensure the carburetor is properly secured and aligned. The fuel line should be connected to the correct port to deliver fuel to the carburetor's float bowl.

- Use a fuel line adapter or a carburetor-specific fitting to attach the line. These adapters often have a male thread on one end and a female thread on the other, allowing for a secure connection. Tighten the fitting securely but be careful not to overtighten, as it may damage the carburetor.

- Check for any leaks by starting the engine and monitoring for any fuel escaping around the connection. If there are leaks, tighten the fitting further or consider using a fuel-resistant sealant to ensure a tight seal.

Connecting to the Fuel Tank:

The fuel tank is the primary reservoir for fuel in your vehicle. The fuel line must be connected to the tank to draw fuel and supply it to the carburetor. Here's the process:

- Locate the fuel tank, which is usually a large, cylindrical container under the vehicle's hood or in the trunk.

- Identify the fuel outlet or sending unit, which is a small port or opening on the tank. This is where the fuel line will connect.

- Ensure the fuel tank is properly secured and that there are no obstructions blocking the fuel line's path.

- Use a fuel line fitting specifically designed for the tank. These fittings often have a quick-connect style or a threaded adapter to secure the line.

- Slide the fuel line into the fuel outlet and attach the fitting. Tighten it securely, ensuring a tight seal to prevent fuel leakage.

- Test the connection by starting the engine and checking for any fuel odors or leaks around the tank and line connections.

Remember, when working with fuel lines, it's crucial to use the correct fittings and adapters for your specific engine and vehicle. Always refer to your vehicle's manual or consult a mechanic if you're unsure about any connections. Proper fuel line connections ensure efficient fuel delivery, optimal engine performance, and prevent potential issues related to fuel leaks.

Unraveling the Mystery: Why Fuel Lines Break

You may want to see also

Fuel Line Length: Optimal length for efficient fuel delivery

The length of the fuel line is a critical factor in ensuring efficient fuel delivery to the carburetor, especially in older vehicles that rely on this mechanical system. The fuel line's primary purpose is to transport fuel from the fuel tank to the carburetor, where it is mixed with air and ignited in the engine's cylinders. While it might seem counterintuitive, the length of the fuel line is not just about the distance it covers but also about maintaining a consistent fuel pressure throughout the system.

Optimal fuel line length is crucial for several reasons. Firstly, it ensures that the fuel reaches the carburetor at the right pressure. If the line is too short, the fuel may not have enough time to accelerate and reach the carburetor at the desired pressure, leading to poor engine performance. Conversely, if the line is too long, the fuel may lose pressure due to the increased distance, resulting in an inefficient mixture and potential engine misfires.

The ideal fuel line length is typically around 2 to 3 feet (approximately 60 to 90 cm) for most vehicles. This length allows for a smooth flow of fuel while maintaining adequate pressure. Longer lines can introduce unnecessary restrictions and pressure drops, especially if they are not properly secured and supported. It's essential to route the fuel line in a way that avoids sharp bends or kinks, as these can restrict flow and cause fuel pressure issues.

When installing or replacing a fuel line, it's recommended to measure the distance from the fuel tank to the carburetor and ensure the new line matches this length. Some vehicles may have specific requirements due to their unique engine configurations. For instance, high-performance engines or those with modified fuel systems might demand slightly different line lengths to optimize performance.

In summary, the fuel line's length is a critical consideration for efficient fuel delivery to the carburetor. A well-maintained, appropriately long fuel line ensures that the engine receives the correct fuel pressure, resulting in optimal performance. Regular inspection and replacement of the fuel line when necessary can help maintain the overall health and efficiency of the vehicle's fuel system.

Volvo VNL Fuel Line Sizing: Expert Guide

You may want to see also

Frequently asked questions

The fuel line is typically connected to the carburetor's float bowl or the main jet. It is usually a small diameter hose or tube that delivers fuel from the fuel tank to the carburetor, where it is mixed with air and injected into the engine's cylinders.

The fuel line can often be found running from the fuel tank, along the side or bottom of the engine, and connecting to the carburetor. It may be visible as a black or blue hose, and its path can vary depending on the vehicle's make and model. Referring to the vehicle's manual or a visual guide specific to your engine can provide precise details.

If the fuel line is disconnected, the engine will not receive the necessary fuel for combustion. This will result in the engine stalling or failing to start. It is essential to ensure that the fuel line is securely connected to both the carburetor and the fuel tank to maintain proper engine operation.

Adjusting the fuel line's position is generally not recommended unless it is for maintenance or repair purposes. The optimal position of the fuel line is crucial for efficient fuel delivery. Any significant changes might affect the engine's performance and could lead to fuel-related issues. It is best to consult a mechanic or refer to the vehicle's documentation for guidance on any necessary adjustments.