Installing fuel lines on a 1972 Monte Carlo can seem daunting, but with the right tools and a methodical approach, it's a manageable task. This guide will walk you through the process step-by-step, ensuring you understand the importance of proper installation and the materials needed. From preparing the fuel lines to securing them in place, you'll learn how to make the necessary connections and avoid common pitfalls. By the end, you'll have a better understanding of how to safely and effectively install fuel lines on your classic car.

What You'll Learn

- Preparation: Gather tools, safety gear, and fuel lines of correct size and length

- Engine Disassembly: Carefully remove necessary engine components to access the fuel system

- Line Routing: Route fuel lines through engine compartments, ensuring clearances and secure mounting

- Clamps and Connections: Secure fuel lines with appropriate clamps and ensure tight, leak-free connections

- Testing and Inspection: Test for leaks, ensure proper fuel flow, and inspect all connections

Preparation: Gather tools, safety gear, and fuel lines of correct size and length

Before you begin the process of installing fuel lines on your 1972 Monte Carlo, it's crucial to prepare the necessary tools, safety equipment, and components to ensure a smooth and safe installation. Here's a detailed breakdown of the preparation phase:

Tools and Equipment:

- Start by gathering a set of basic automotive tools that you'll need for the installation. This includes a fuel line cutter or a pair of sharp scissors or knives for precise cutting, a fuel line crimping tool or a pair of pliers for securing the lines, and a fuel line primer or adhesive to ensure a leak-free connection. Additionally, have a fuel line inspection mirror or a small camera to check for any blockages or damage inside the lines.

- Consider using a fuel line bracket or clamp to secure the lines in place, especially if your car has limited space or unique mounting requirements.

- Other essential tools might include a wrench set for any fuel-related fasteners, a torque wrench to ensure proper tightening, and a fuel filter to replace or clean if necessary.

Safety Gear:

- Safety should always be a top priority. Wear safety goggles to protect your eyes from any potential fuel splashes or debris. Gloves are also recommended to safeguard your hands and provide a better grip during the installation process.

- Ensure you have a well-ventilated workspace, preferably outdoors, to minimize the risk of inhaling fuel vapor.

- Keep a fire extinguisher nearby as a precaution, especially when working with fuel.

Fuel Lines:

- Obtain the correct size and length of fuel lines that are compatible with your 1972 Monte Carlo. Measure the existing lines (if any) or refer to the vehicle's manual for specifications. It's crucial to have the right dimensions to ensure a proper fit.

- Consider the material of the fuel lines. Common materials include rubber, vinyl, or braided steel. Choose a material that suits your car's fuel requirements and the overall installation process.

- If you're replacing old lines, inspect the new lines for any defects or damage before installation. Ensure they are free from cuts, tears, or any imperfections.

By gathering these tools, safety gear, and ensuring you have the correct fuel lines, you'll be well-prepared to tackle the installation process with confidence and efficiency. This preparation phase is essential to avoid any complications during the actual installation of the fuel lines on your classic Monte Carlo.

Kawasaki Bayou 185 Fuel Line Sizing Guide

You may want to see also

Engine Disassembly: Carefully remove necessary engine components to access the fuel system

To begin the engine disassembly process for your 1972 Monte Carlo, it's crucial to understand the specific components you'll need to remove to gain access to the fuel system. This step is essential to ensure you don't damage any other parts during the installation process. Start by consulting the vehicle's service manual or an online resource specific to your car's model, as the exact procedure may vary slightly depending on the engine configuration.

The first step is to locate the fuel pump, which is typically mounted on the engine block or near the fuel tank. You'll need to disconnect the electrical connections to the pump. Carefully inspect the wiring harness and identify the correct wires to disconnect, ensuring you don't accidentally unplug any critical sensors or ignition components. Once the electrical connections are severed, you can proceed to remove the fuel pump. This might involve unscrewing a mounting bracket or releasing a clip that secures the pump in place.

Next, you'll need to access the fuel lines. These are often secured with clips or brackets, and you'll need to carefully remove them without causing any damage. Start by identifying the primary fuel lines, which typically run from the fuel tank to the engine. Locate the clips or brackets holding these lines in place and use a flathead screwdriver or a specialized tool to release them gently. Be cautious not to force anything, as you want to avoid bending or breaking the fuel lines.

As you work on the fuel lines, you might also need to remove other engine components to gain better access. This could include the air filter housing, intake manifold, or even parts of the engine block, depending on the specific design of your 1972 Monte Carlo. Each component will have its own set of fasteners, such as bolts or screws, which you'll need to remove in the correct sequence to avoid any potential issues during reassembly.

Remember, the key to successful engine disassembly is patience and a systematic approach. Take your time to carefully remove each component, documenting the process with photographs if possible, to ensure you can reassemble everything correctly. This meticulous approach will help you avoid costly mistakes and ensure a successful fuel line installation on your classic Monte Carlo.

Tygon Fuel Line: The Ultimate Choice for Performance Enthusiasts?

You may want to see also

Line Routing: Route fuel lines through engine compartments, ensuring clearances and secure mounting

When installing fuel lines on a 1972 Monte Carlo, proper line routing is crucial for both performance and safety. The engine compartment of this classic car can be tight and crowded, so careful planning and execution are essential. Here's a detailed guide on how to route the fuel lines effectively:

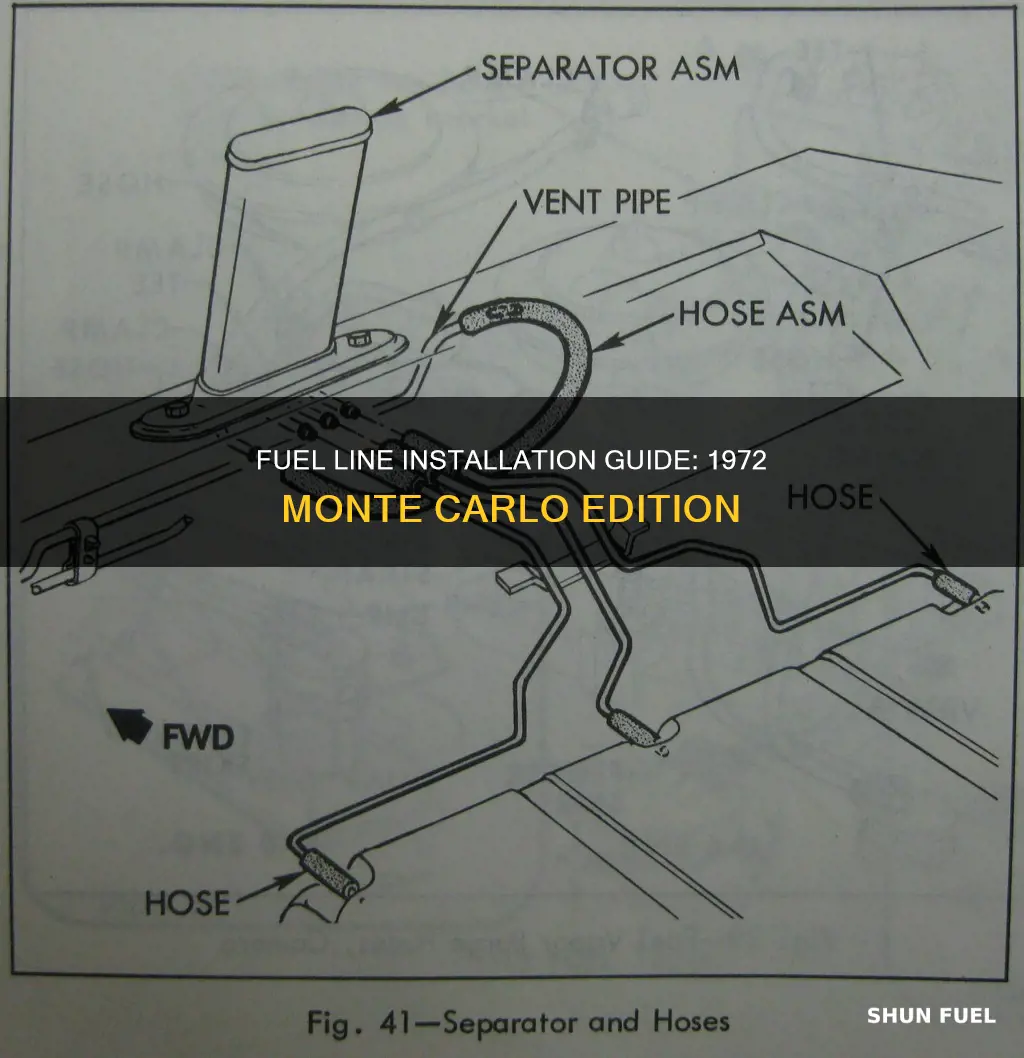

Start by familiarizing yourself with the factory routing, as the original design provides optimal clearances and protection. Typically, the fuel lines on this model are routed from the fuel tank, usually located behind the driver's side front seat, to the engine bay. The lines often follow the firewall, providing a clear path through the engine compartment. Identify the factory mounting points and brackets, as these will be used to secure the new lines. Reinforcing the importance of maintaining the original routing is the fact that deviating from it may result in clearance issues with other engine components.

Once you've identified the optimal path, it's time to route the lines. Begin by carefully feeding the fuel lines through the firewall, ensuring they are not kinked or pinched. Use the appropriate fuel line clips or ties to secure the lines at regular intervals, maintaining tension to prevent sagging. In the engine bay, take advantage of the existing mounting points and brackets to secure the lines. Ensure that the lines are routed away from moving parts, such as the camshaft and valve train, to avoid potential damage. Consider using fuel line protective sleeves or heat shields in areas where the lines may come into contact with hot surfaces.

Pay close attention to clearance when routing the lines. The fuel lines should have sufficient clearance from the engine block, headers, and other components to prevent damage during engine operation. Check for any potential interference with the suspension or steering components, especially if the car has been modified. Proper clearance ensures that the lines will not rub or be pinched, which could lead to fuel leaks or reduced performance.

Finally, secure the fuel lines in a way that ensures they remain in place during various driving conditions. Use the factory mounting points or additional brackets to attach the lines firmly. Consider using fuel line supports or harnesses to keep the lines organized and prevent tangling. A well-secured fuel line system will not only improve the overall appearance of the engine bay but also ensure the reliability and safety of your classic Monte Carlo.

Marine Fuel Line Valves: When and Why to Replace

You may want to see also

Clamps and Connections: Secure fuel lines with appropriate clamps and ensure tight, leak-free connections

When working on fuel line installation for a classic car like the 1972 Monte Carlo, one of the most critical aspects is ensuring secure and leak-free connections. The fuel lines must be properly clamped and connected to maintain the vehicle's performance and safety. Here's a step-by-step guide to achieving this:

Choosing the Right Clamps: Select fuel line clamps that are compatible with the specific fuel lines you are using. Different types of fuel lines may require various clamp styles, such as metal or plastic clamps, each with unique features. For example, metal clamps offer excellent durability and are ideal for high-pressure fuel lines, while plastic clamps are more flexible and suitable for softer lines. Ensure the clamps are the correct size to provide a snug fit around the fuel lines without causing damage or restricting flow.

Installation Process: Begin by laying out the fuel lines according to the vehicle's original design or your chosen layout. This step is crucial for maintaining the correct positioning and routing of the lines. Once the layout is finalized, start installing the clamps. Secure each clamp firmly around the fuel line, ensuring it is tight enough to prevent any movement but not so tight that it causes crimping or damage to the line. Leave a small gap between the clamp and the fuel line to allow for slight movement during operation.

Tight, Leak-Free Connections: The key to a successful installation is creating tight, leak-free connections. Start by inserting the fuel line into the appropriate fittings or connectors. Ensure a snug fit by using the correct tools to tighten the connections. Over-tightening can damage the fuel line, so use a torque wrench if available to achieve the recommended tightening force. Check for any signs of leakage by applying a small amount of diesel fuel or a suitable sealant to the connection and observing if any seepage occurs. If leaks are detected, tighten the connection further or consider using a different type of sealant.

Testing and Inspection: After completing the installation, it is essential to test the system for any leaks. Start the engine and listen for any unusual noises, especially hissing sounds, which could indicate a fuel line leak. Check under the vehicle for any signs of fuel residue, as this may suggest a leak. If no issues are found, ensure that the fuel lines are securely fastened and that all clamps are in place. Regularly inspect the fuel lines during the vehicle's operation to identify any potential problems early on.

By following these steps and paying close attention to the clamps and connections, you can ensure a successful fuel line installation on your 1972 Monte Carlo, maintaining the vehicle's performance and reliability.

Fuel Line for PCV: A Viable Option?

You may want to see also

Testing and Inspection: Test for leaks, ensure proper fuel flow, and inspect all connections

Before you can drive your 1972 Monte Carlo with confidence, it's crucial to ensure that the fuel lines are installed correctly and function flawlessly. Testing and inspection are vital steps in this process, as they help identify potential issues and ensure the safety and performance of your vehicle. Here's a detailed guide on how to approach these critical tasks:

Leak Testing: Start by thoroughly inspecting the fuel lines for any signs of damage or leaks. Use a soapy water solution as a simple yet effective leak detection method. Apply the solution to all connections, bends, and fittings of the fuel lines. If you notice any bubbles forming, it indicates a potential leak. Bubbles are caused by the soap breaking down the surface tension of the fuel, allowing it to escape. Address any leaks immediately by tightening connections or replacing damaged sections. This step is crucial to prevent fuel spills and potential fire hazards.

Fuel Flow Verification: After ensuring the lines are leak-free, it's time to check the fuel flow. Start the engine and monitor the fuel gauge. A properly functioning system should maintain a steady fuel level as the engine operates. If the gauge drops significantly or fluctuates erratically, it suggests a restriction or blockage in the lines. You might need to adjust the fuel pressure regulator or clean the fuel filter to restore proper flow. Remember, a consistent fuel supply is essential for optimal engine performance.

Connection Inspection: Carefully examine all connections and fittings for any signs of corrosion, damage, or improper installation. Tighten any loose connections and ensure that all components are securely in place. Over time, fuel lines can develop cracks or become brittle, especially in older vehicles like the 1972 Monte Carlo. If you notice any cracks or signs of deterioration, it's best to replace the affected sections to avoid potential fuel leaks during operation.

Additionally, check for any signs of rust or corrosion around the fuel tank and lines, as these can lead to contamination and performance issues. Keep the fuel system clean and well-maintained to ensure long-term reliability. By following these testing and inspection procedures, you'll have peace of mind knowing that your fuel lines are installed correctly and ready to deliver fuel efficiently to your engine.

Fuel Line Flush: Essential Maintenance for Optimal Engine Performance

You may want to see also

Frequently asked questions

You will need a fuel line kit specific to your 1972 Monte Carlo, including the correct size and type of fuel lines, fittings, and any necessary adapters. Basic hand tools such as wrenches, pliers, and a fuel line cutter are essential. Additionally, have a fuel pump and a fuel tank to ensure a complete system.

Start by cleaning the fuel lines and removing any old or damaged lines. Use a fuel line cleaner to ensure a proper bond and remove any contaminants. Cut the new fuel lines to the appropriate length, allowing for some extra length to facilitate routing. Then, use the appropriate fittings to connect the lines to the fuel pump, tank, and any other components.

Yes, proper routing is crucial for a 1972 Monte Carlo. The fuel lines should be routed away from heat sources and sharp bends to prevent damage and ensure optimal fuel flow. Typically, the lines are run along the frame rails, behind the firewall, and under the dashboard. Consider the vehicle's layout and ensure the lines are secure and protected from potential road hazards.