Understanding the intricacies of a dirt bike's engine can be a complex task, but one crucial aspect is the fuel system. The fuel lines play a vital role in delivering gasoline to the carburetor, where it mixes with air to create the fuel-air mixture for combustion. When it comes to dirt bikes, the question often arises: where exactly do the fuel lines attach to the carburetor? This paragraph aims to shed light on this specific attachment point, providing a clear understanding of the fuel line's connection to the carburetor on a dirt bike.

| Characteristics | Values |

|---|---|

| Attachment Point | Typically, the fuel lines attach to the carburetor's float bowl or the side of the carburetor body. |

| Fuel Line Routing | The fuel line should be routed away from the exhaust system to prevent heat damage. |

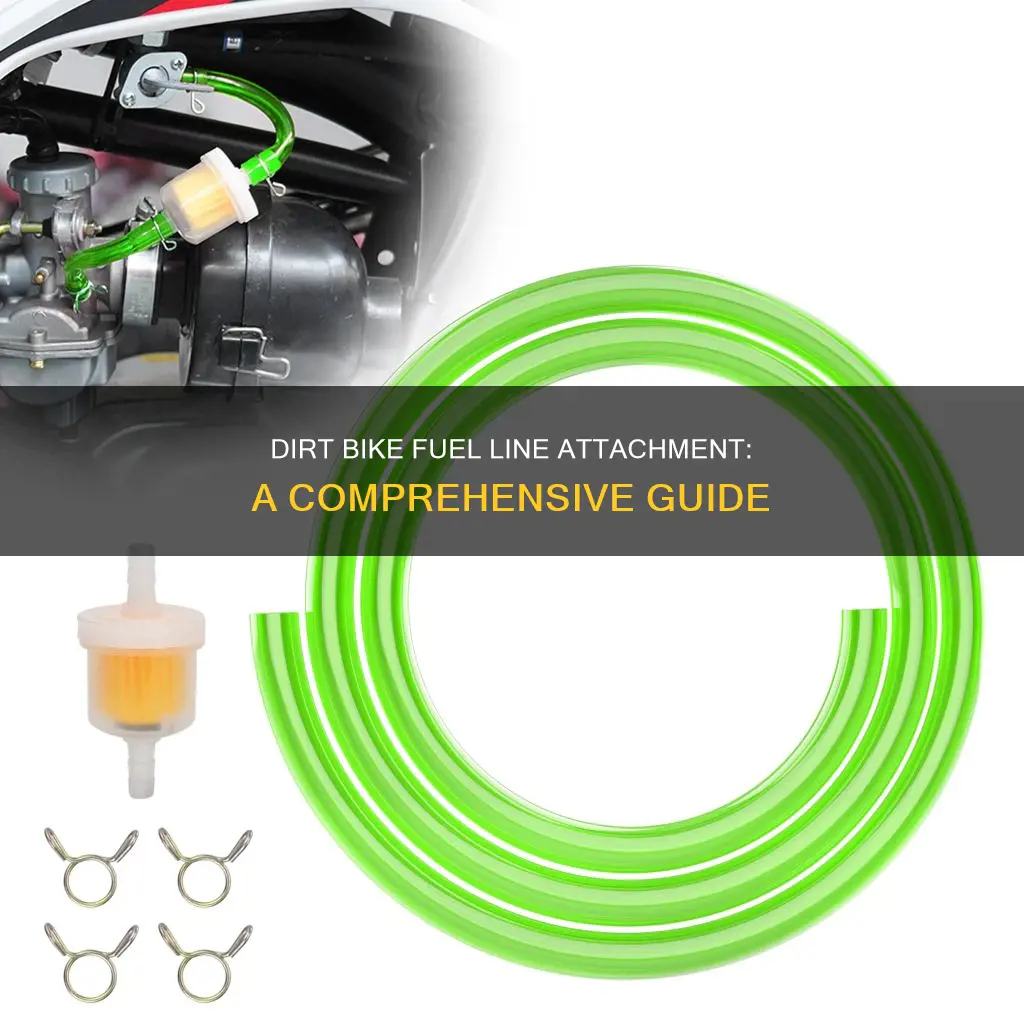

| Clamping | Use a fuel line clamp or a hose clamp to secure the fuel line in place. |

| Material | Common materials include rubber, vinyl, or braided steel for durability. |

| Length | Ensure the fuel line is long enough to reach the fuel tank but not too long to avoid unnecessary slack. |

| Compatibility | Check the specific model and year of your dirt bike to ensure the fuel line is compatible with the carburetor. |

| Maintenance | Regularly inspect the fuel lines for cracks, leaks, or damage, especially after intense riding conditions. |

What You'll Learn

- Carburetor Anatomy: Understanding the components and their functions

- Fuel Injection: How fuel lines connect to injectors for precise fuel delivery

- Throttle Body: Location and attachment points for fuel lines

- Air Filter: Impact on fuel line placement and maintenance

- Carburetor Cleaning: Proper techniques to ensure optimal fuel line function

Carburetor Anatomy: Understanding the components and their functions

The carburetor is a critical component of a dirt bike's engine, responsible for mixing air and fuel to create the combustion that powers the bike. It is a complex system with several key parts, each playing a specific role in the fuel delivery process. Understanding the anatomy of a carburetor is essential for anyone looking to maintain or modify their dirt bike's performance.

At its core, the carburetor consists of a series of passages and chambers designed to precisely control the fuel-air mixture. One of the primary components is the float bowl, a small reservoir that holds a measured amount of fuel. The float bowl is equipped with a float, a mechanism that rises and falls with the fuel level, ensuring the bowl is always filled to a specific height. This design prevents the carburetor from running dry and allows for accurate fuel measurement.

Connected to the float bowl is the main jet, a small orifice that regulates the flow of fuel into the carburetor. This jet is critical as it controls the overall fuel supply to the engine. The main jet's size and positioning determine the amount of fuel entering the system, which is then further adjusted by other components.

Another vital part is the carburetor jets, which are tiny passages that direct fuel into the air stream. These jets are carefully calibrated to ensure the correct fuel-air ratio is achieved. The air filter, often located near the carburetor, is responsible for cleaning the air before it enters the system, ensuring a consistent and clean supply of air-fuel mixture.

The fuel lines play a crucial role in this setup. They attach to the carburetor at specific points, typically near the float bowl and the main jet. The fuel lines carry the measured fuel from the float bowl to the carburetor jets, where it is mixed with air and directed into the engine's intake system. Proper attachment and routing of these lines are essential to ensure optimal performance and prevent fuel leaks.

Understanding CPE Fuel Line: A Comprehensive Guide

You may want to see also

Fuel Injection: How fuel lines connect to injectors for precise fuel delivery

Fuel injection systems have revolutionized the way engines operate, offering precise fuel delivery and improved performance. In the context of a dirt bike, understanding how fuel lines connect to injectors is crucial for optimizing the engine's power and efficiency. When it comes to older carbureted systems, the fuel lines typically attached to the carburetor, which is the component responsible for mixing air and fuel. However, with the advent of fuel injection, the process has evolved.

In a fuel-injected dirt bike engine, the fuel lines play a vital role in delivering the correct amount of fuel to the injectors. These lines are usually made of high-quality materials to ensure durability and flexibility. The fuel lines connect to the injectors, which are strategically positioned to spray fuel directly into the engine's intake manifold or cylinders. This direct injection method ensures that the fuel is atomized and mixed with air in the optimal ratio, resulting in efficient combustion.

The connection between the fuel lines and injectors is designed to be secure and reliable. Each fuel line is typically equipped with a quick-connect fitting or a similar coupling mechanism that allows for easy installation and removal. When attaching the fuel lines, it is essential to ensure a tight seal to prevent any fuel leaks. This is achieved by using O-rings or gaskets that create a secure connection between the fuel line and the injector body. Proper sealing is critical to maintain engine performance and prevent fuel wastage.

The fuel lines are usually routed through the engine's frame to reach the injectors. This routing should be carefully planned to avoid any obstructions or interference with other engine components. It is common to find rubber or plastic hoses with built-in reinforcement to withstand the engine's operating conditions. The fuel lines may also be equipped with filters to prevent contaminants from entering the system, ensuring clean fuel delivery to the injectors.

In summary, the fuel lines in a fuel-injected dirt bike engine are connected to the injectors, delivering precise fuel quantities for optimal combustion. The connection process requires attention to detail, ensuring secure attachments and proper sealing. Understanding the fuel injection system's intricacies allows riders and mechanics to maintain and tune the engine for maximum performance on the dirt track.

Optimizing Performance: Choosing the Right Fuel Line Size for Trans Lines

You may want to see also

Throttle Body: Location and attachment points for fuel lines

The throttle body is a crucial component in the fuel injection system of a dirt bike, and understanding its location and attachment points for fuel lines is essential for any rider or mechanic. This component is responsible for controlling the amount of fuel that enters the engine, and it is typically located near the intake manifold or directly in front of the air filter.

In a dirt bike, the throttle body is often a compact unit, designed to fit within the engine's limited space. It is usually mounted horizontally, with its intake port facing forward. The fuel lines from the fuel pump or the carburetor (if the bike still uses one) will attach to specific ports on the throttle body. These ports are strategically positioned to ensure an efficient and precise fuel supply to the engine.

The attachment points for fuel lines on the throttle body can vary depending on the make and model of the dirt bike. However, a common setup involves two primary fuel lines. One line connects to the low-pressure side of the throttle body, which is responsible for delivering fuel during low-speed or idle conditions. This line is typically shorter and thicker, ensuring a steady fuel supply at lower RPMs. The other fuel line connects to the high-pressure side, which provides fuel during high-speed or high-load situations. This line is usually longer and thinner, designed to handle higher fuel pressure.

When connecting the fuel lines, it is crucial to ensure a secure and tight fit. The lines should be routed away from any moving parts to prevent damage or interference. Properly secured fuel lines also help maintain a consistent fuel pressure, which is vital for optimal engine performance. It is recommended to use fuel line clips or ties to keep the lines in place and prevent any potential leaks or damage.

In some modern dirt bikes, the throttle body may be integrated with the carburetor, making the fuel line connections even more critical. In such cases, the fuel lines will attach directly to the throttle body's fuel rails or injectors. Understanding the specific layout of your bike's throttle body and fuel system is essential to ensure correct fuel line routing and attachment.

Chevy 49 Fuel Line: Size and Compatibility Guide

You may want to see also

Air Filter: Impact on fuel line placement and maintenance

The air filter plays a crucial role in the performance and longevity of a dirt bike's engine, and its impact on fuel line placement and maintenance is significant. When it comes to fuel lines on a dirt bike, the air filter's primary function is to ensure a clean and controlled airflow into the engine. This is especially important in the context of fuel line placement, as a well-maintained air filter can directly affect the fuel delivery system.

In the case of dirt bikes with carbureted engines, the air filter is typically located near the carburetor. It is designed to capture and filter out dust, dirt, and other particles from the incoming air, ensuring that only clean air reaches the carburetor. The carburetor then mixes the air with fuel, creating a precise fuel-air mixture that is essential for optimal engine performance. Proper air filtration is critical here because any contaminants in the air can lead to improper fuel-air ratios, resulting in reduced power, poor acceleration, and even engine damage.

The placement of fuel lines is closely tied to the air filter's position. Fuel lines carry the fuel from the tank to the carburetor, and their route should be as direct and unobstructed as possible. If the air filter is not maintained properly, it can restrict airflow, causing the engine to compensate by drawing more fuel to maintain the required air-fuel mixture. This can lead to over-fueling, which may result in fuel lines becoming more susceptible to damage or blockage. Therefore, keeping the air filter clean and well-maintained is essential to ensure the fuel lines remain in good condition.

Regular maintenance of the air filter is a straightforward task that can significantly impact the overall performance and longevity of a dirt bike. It involves replacing or cleaning the air filter element to remove accumulated dirt and debris. This process not only improves engine performance but also helps protect the fuel lines from potential damage caused by contaminated fuel. By ensuring a steady supply of clean air, the air filter contributes to the efficient operation of the fuel system, including the proper placement and protection of fuel lines.

In summary, the air filter's role in maintaining a clean airflow is vital for the proper functioning of a dirt bike's fuel system. Its placement near the carburetor influences the positioning of fuel lines, and regular maintenance ensures optimal engine performance and fuel line health. By understanding the relationship between the air filter and fuel lines, dirt bike enthusiasts can take proactive measures to keep their engines running smoothly and efficiently.

Optimizing Performance: Choosing the Right Fuel Line for Your Atomic 4 Engine

You may want to see also

Carburetor Cleaning: Proper techniques to ensure optimal fuel line function

Carburetor cleaning is an essential maintenance task for any dirt bike owner to ensure optimal performance and longevity of the fuel system. Over time, dirt, debris, and varnish can accumulate in the carburetor, leading to reduced power, poor fuel efficiency, and even engine misfires. Proper cleaning techniques will help restore the carburetor's functionality and maintain the bike's overall performance.

When cleaning the carburetor, it is crucial to understand the different components and their functions. The carburetor is responsible for mixing air and fuel in the correct ratio for combustion. It consists of a series of passages, jets, and needles that regulate the fuel flow. The fuel lines attach to the carburetor at a specific point, typically a small opening or port, allowing fuel to enter the carburetor's float bowl. This attachment point is usually located near the top of the carburetor, where the float bowl is accessible.

To begin the cleaning process, start by disconnecting the fuel line from the carburetor. This step is essential to prevent any spills or mess during the cleaning procedure. Use a fuel line disconnect tool or a pair of pliers to carefully remove the line. Once disconnected, you can access the float bowl, which is a critical component for holding and regulating the fuel level. Pour a suitable carburetor cleaner into the float bowl, ensuring it covers the entire surface. Allow the cleaner to sit for a few minutes to loosen any built-up deposits.

Next, use a small brush or a specialized carburetor cleaning tool to gently scrub the inside of the float bowl and the surrounding areas. Pay attention to the jets and passages, as these are prone to clogging. Ensure you remove any debris or varnish buildup. After cleaning, rinse the float bowl and carburetor passages with a clean solvent to remove any remaining cleaner. This step is crucial to prevent any residue from affecting the fuel mixture.

Finally, reattach the fuel line securely, ensuring a tight connection. Test the carburetor by starting the engine and observing its performance. Proper cleaning should result in improved throttle response, smoother power delivery, and enhanced overall engine operation. Regular maintenance and cleaning of the carburetor will contribute to the long-term reliability and performance of your dirt bike.

Understanding the U.S. Coast Guard's Latest Fuel Line Standard

You may want to see also

Frequently asked questions

The fuel lines typically attach to the carburetor's float bowl or the throttle body. The float bowl is a small container inside the carburetor that holds fuel, and the fuel lines are connected to this bowl to deliver the fuel to the engine. Alternatively, in some modern dirt bikes, the fuel lines may connect to the throttle body, which is the component that controls the air-fuel mixture entering the engine.

To ensure a proper connection, you should use fuel line connectors or clamps that are designed for the specific fuel line material. Tighten the connectors or clamps securely, but be careful not to overtighten, as it can damage the fuel line. It's also a good practice to inspect the connections regularly for any signs of wear or damage, especially after intense riding sessions.

No, it's crucial to use the correct type of fuel line for your dirt bike's carburetor system. Different carburetor designs may require specific fuel line materials, such as rubber or vinyl. Using the wrong type of fuel line can lead to fuel leaks, engine performance issues, or even damage to the carburetor. Always refer to your dirt bike's manual or consult a mechanic to determine the appropriate fuel line specifications.

If you notice any signs of a fuel line leak, such as fuel odor, stains, or engine misfires, it's essential to address the issue promptly. Start by inspecting the fuel lines for any visible damage or cracks. If you find a leak, you may need to replace the affected fuel line section. It's recommended to have a professional mechanic inspect and repair the fuel system to ensure safe and efficient operation.