Smoking the fuel line is a dangerous and potentially life-threatening act that can have severe consequences. It involves igniting the fuel in a vehicle's fuel line, which can lead to a fire or explosion. This practice is illegal and extremely risky, as it can cause significant damage to the vehicle and pose a serious threat to the safety of individuals and the environment. It is crucial to understand the potential hazards and legal implications associated with such actions to avoid any harmful outcomes.

What You'll Learn

- Fuel Line Location: Identify the fuel line's path and access points

- Fuel Line Inspection: Check for damage, leaks, and proper connections

- Fuel Pump Testing: Ensure the pump functions correctly to deliver fuel

- Fuel Filter Maintenance: Regularly clean or replace to prevent blockages

- Fuel Tank Inspection: Examine the tank for leaks and contamination

Fuel Line Location: Identify the fuel line's path and access points

The fuel lines in a vehicle are crucial components responsible for delivering fuel from the tank to the engine. Identifying their location and understanding their path is essential for any vehicle owner or mechanic. Here's a guide on how to locate and access the fuel lines:

Step 1: Familiarize Yourself with the Vehicle's Anatomy

Before you begin, it's helpful to have a basic understanding of your vehicle's layout. Refer to your vehicle's manual or a trusted online resource that provides a detailed diagram of the fuel system. This will give you an idea of where the fuel tank is located and the general direction of the fuel lines.

Step 2: Locate the Fuel Tank

The fuel tank is typically found in the front or rear of the vehicle, often in the lower part of the engine compartment or beneath the floor. It is usually a rectangular or oval-shaped container with a fuel filler neck. Once you've identified the fuel tank, you can start tracing the path of the fuel lines.

Step 3: Trace the Fuel Lines

Fuel lines are usually made of rubber or plastic and are color-coded for identification. Common colors include black, blue, or green. Start at the fuel tank and follow the lines as they run towards the engine. The lines may run along the frame, under the vehicle, or even inside the engine compartment. Look for any bends, clips, or brackets that secure the lines in place.

Step 4: Identify Access Points

Access points are areas where you can safely inspect or work on the fuel lines. These points are often located near the engine bay, under the vehicle, or along the frame. Common access points include:

- Engine Bay: The front or side of the engine compartment provides easy access to the upper part of the fuel lines.

- Under the Vehicle: The underbody of the vehicle is a common location for fuel lines, especially in older cars.

- Frame Rails: Fuel lines may run along the frame rails, providing access points for inspection or repairs.

- Fuel Pump Compartment: Some vehicles have a dedicated compartment for the fuel pump and related lines.

Step 5: Inspect and Test

Once you've identified the fuel lines and access points, it's essential to inspect them for any signs of damage, leaks, or contamination. Use a bright flashlight to examine the lines for cracks, brittleness, or signs of corrosion. You can also use a fuel line inspection mirror to check hard-to-reach areas. If you notice any issues, it's best to consult a professional mechanic for repairs or replacements.

Remember, working with fuel lines requires caution and proper safety equipment. Always ensure the vehicle is parked on a level surface, and never smoke or use open flames when working with fuel. If you're unsure about any aspect of the fuel line location or maintenance, consult a qualified mechanic to ensure the job is done safely and correctly.

Optimizing Fuel Flow: Choosing the Right Size Fuel Line for Your Holley 94 Carb

You may want to see also

Fuel Line Inspection: Check for damage, leaks, and proper connections

Fuel lines are critical components of a vehicle's fuel system, and ensuring their integrity is essential for optimal performance and safety. Inspecting the fuel lines regularly can help identify potential issues before they cause significant problems. Here's a comprehensive guide on how to inspect your fuel lines for damage, leaks, and proper connections:

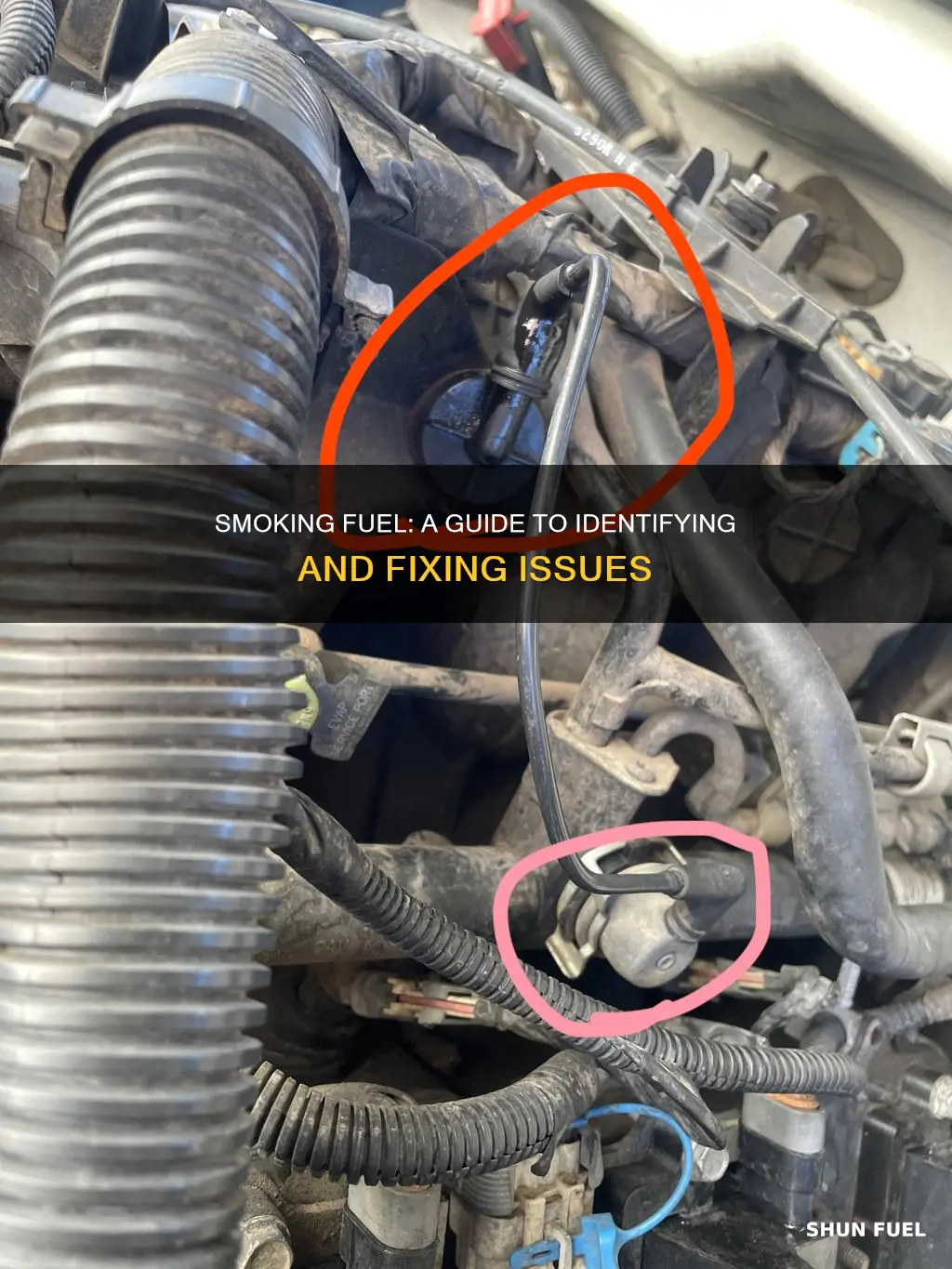

- Visual Inspection: Start by visually examining the fuel lines for any visible signs of damage. Look for cracks, punctures, or any discolored areas along the length of the line. Over time, fuel lines can degrade due to heat, chemicals, or physical damage from road debris. Inspect the lines where they connect to the fuel tank, the engine, and any other components. Even small tears or cuts can lead to fuel leaks, which can cause engine misfires, reduced performance, and potential safety hazards.

- Check for Leaks: Fuel line inspections should always include a leak check. Start by removing the fuel cap and ensuring there is no fuel vapor escaping. Then, use a fuel line dye or a soapy water solution to test for leaks. Apply the dye or soapy water to the fuel lines and observe if any bubbles appear or if the solution starts to foam. Bubbles indicate the presence of air, while foaming suggests a fuel leak. Leaks can lead to fuel wastage, engine performance issues, and potential fire risks if the fuel comes into contact with a hot surface.

- Inspect Connections: Fuel lines are connected to various components of the fuel system, including the fuel pump, injectors, and the engine. Check all these connections for tightness and corrosion. Over time, connections can loosen due to vibration or corrosion, leading to fuel leaks. Ensure that all fittings and clamps are secure and in good condition. If you notice any corrosion or damage, it may indicate a need for replacement or repair.

- Look for Contamination: Contaminated fuel can cause engine problems and should be addressed during fuel line inspections. Check for any signs of water or debris in the fuel lines, especially if the vehicle has been stationary for an extended period. Moisture in the fuel can lead to corrosion and engine issues. If you suspect contamination, have the fuel system flushed and the fuel lines inspected by a professional.

- Use Specialized Tools: For a thorough inspection, consider using specialized tools like a fuel line brush. This tool can help remove any debris or contaminants from the interior of the fuel lines. Additionally, a fuel pressure gauge can be used to check for proper fuel pressure and identify any potential pump issues.

Regular fuel line inspections are a proactive approach to vehicle maintenance. By checking for damage, leaks, and proper connections, you can ensure that your fuel system operates efficiently and safely. Remember, if you notice any issues during the inspection, it's best to consult a professional mechanic to prevent further complications.

Choosing the Right Fuel Line for Your 2005 650 V2

You may want to see also

Fuel Pump Testing: Ensure the pump functions correctly to deliver fuel

Fuel pump testing is a critical procedure to ensure the proper functioning of the fuel delivery system in an engine. It is an essential step to maintain the engine's performance and prevent potential issues related to fuel supply. Here's a comprehensive guide on how to test and verify the fuel pump's functionality:

Preparation and Safety: Before beginning the test, ensure you have the necessary tools, including a fuel pressure gauge, a fuel pump tester, and a fuel line cleaner. It is crucial to work on a level surface and wear appropriate safety gear, such as gloves and eye protection, to avoid any potential hazards. Additionally, locate the fuel pump access points, which are typically found beneath the vehicle or in the engine compartment, and mark them for easy reference.

Fuel Pump Tester Setup: Connect the fuel pump tester to the fuel line, ensuring a secure and leak-free connection. The tester will allow you to control the fuel pump's operation and measure the pressure. Set the tester to the appropriate settings, usually a specific voltage or current, to simulate the engine's electrical system. This setup will enable you to assess the pump's performance under various conditions.

Testing the Fuel Pump: Start the testing process by activating the fuel pump using the tester. Listen for the pump's operation and feel for any vibrations or pulsations in the fuel line. A properly functioning pump should produce a steady flow of fuel, indicated by a consistent pressure reading on the gauge. If the pump is weak or faulty, you may notice a decrease in pressure or an irregular flow, which could lead to engine performance issues.

Pressure and Flow Measurement: Measure the fuel pressure at different operating conditions. Start with the engine off and then start it, allowing it to idle. Record the pressure readings and compare them to the expected values for your specific engine. A healthy fuel pump should maintain a stable pressure within the recommended range. Additionally, check the fuel flow rate by measuring the time it takes to fill a known volume of fuel, ensuring it aligns with the pump's specifications.

Troubleshooting and Maintenance: If the fuel pump test reveals any abnormalities, further investigation may be required. Check for clogs or restrictions in the fuel line using the cleaner and ensure all connections are secure. Inspect the pump for any signs of damage or wear, as these issues can impact performance. Regular maintenance, including fuel line cleaning and pump inspections, is essential to prevent fuel-related problems and ensure optimal engine operation.

Jeep Grand Cherokee Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Fuel Filter Maintenance: Regularly clean or replace to prevent blockages

Fuel filter maintenance is a crucial aspect of vehicle care that often gets overlooked. Over time, fuel filters can become clogged with contaminants, leading to reduced engine performance and potential damage. Regular cleaning or replacement of the fuel filter is essential to ensure optimal fuel flow and maintain the longevity of your vehicle's engine.

The primary function of a fuel filter is to remove impurities from the fuel before it reaches the engine. These impurities can include dirt, rust, water, and other contaminants that may have accumulated in the fuel tank or entered the system during fuel storage or transportation. When these impurities are left unchecked, they can cause blockages in the fuel lines, leading to restricted fuel flow and potential engine misfires.

To maintain a healthy fuel system, it is recommended to inspect and clean the fuel filter regularly. This can be done by removing the filter and using a fuel filter cleaner to dissolve any built-up contaminants. Alternatively, if the filter is easily accessible, you can simply rinse it with clean water to remove any visible dirt or debris. However, it's important to note that cleaning a fuel filter multiple times may not be necessary, as replacement is often more effective in preventing blockages.

Replacing the fuel filter is a more permanent solution and is typically recommended every 30,000 to 50,000 miles or as advised by the vehicle manufacturer. Over time, the filter's mesh becomes less effective at trapping contaminants, and its structure may degrade, leading to reduced filtration capacity. By replacing the filter regularly, you ensure that the fuel system remains clean and free-flowing, promoting better engine performance and fuel efficiency.

In addition to regular maintenance, it is crucial to monitor the condition of the fuel filter and address any issues promptly. If you notice any signs of contamination, such as engine hesitation, reduced power, or unusual noises, it may indicate a clogged or failing fuel filter. In such cases, it is advisable to have the filter inspected and replaced by a qualified mechanic to prevent further complications.

1979 Sportster Fuel Line: Size Guide for Optimal Performance

You may want to see also

Fuel Tank Inspection: Examine the tank for leaks and contamination

When inspecting a fuel tank, it is crucial to check for any signs of leaks and contamination to ensure the safety and efficiency of the vehicle's fuel system. Here's a step-by-step guide on how to examine the tank for these issues:

- Visual Inspection: Begin by visually assessing the fuel tank. Look for any visible signs of damage, such as cracks, corrosion, or rust. Inspect the tank's surface for any unusual stains or discolouration, which could indicate fuel leaks or contamination. Pay close attention to the tank's seams, especially if it's an older model, as these areas are prone to developing leaks over time.

- Leak Detection: One of the most critical aspects of the inspection is identifying leaks. Start by removing the fuel tank's cap and checking for any fuel odour or moisture around the opening. If you notice a strong fuel smell, it might indicate a leak. Additionally, you can use a simple leak detection method by placing a small amount of detergent in the fuel tank and then checking for bubbles in the fuel line. Bubbles indicate the presence of air, which could be a sign of a leak or contamination.

- Contamination Testing: To ensure the fuel's quality, perform a contamination test. You can use a fuel contamination tester, which is a small device that measures the water content and acid levels in the fuel. Insert the tester into the fuel tank and follow the manufacturer's instructions. If the test indicates high water content or excessive acid, it suggests contamination, which can lead to engine problems.

- Pressure Testing: For a more comprehensive inspection, consider pressure testing the fuel system. This method involves using a fuel pressure gauge to measure the pressure inside the tank. Low pressure might indicate a leak, while excessive pressure could be a sign of contamination or a malfunctioning fuel pump. It is recommended to consult a professional mechanic for this test, as it requires specialized equipment and knowledge.

- Professional Assistance: If you're unsure about any aspect of the inspection or notice any potential issues, it's best to consult a professional mechanic. They have the expertise and tools to perform a thorough fuel tank inspection, including advanced diagnostic techniques. A qualified mechanic can provide a detailed report on the tank's condition and suggest necessary repairs or replacements.

Remember, regular fuel tank inspections are essential to maintain the overall health of your vehicle's engine. By following these steps, you can identify and address potential issues related to leaks and contamination, ensuring a reliable and efficient fuel system.

Understanding 6AN Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Frequently asked questions

Smoking the fuel line, which is a serious issue, can lead to a complete loss of fuel supply to the engine. This can cause the engine to stall or fail to start, and in some cases, it may result in engine damage due to the lack of proper lubrication and cooling.

Smoking from the fuel line is often a clear sign of a fuel leak or a damaged fuel system. You may notice a cloud of smoke near the fuel tank or under the car, especially when the engine is running or during acceleration. It's important to address this issue promptly to prevent further damage.

Smoking can occur due to various reasons, including a cracked or damaged fuel line, a loose connection, a faulty fuel pump, or a problem with the fuel injectors. Over time, fuel lines can deteriorate due to age, heat, or chemical corrosion from the fuel itself.

Immediate action is required to fix a smoking fuel line. If you notice smoke, park the vehicle in a safe area and turn off the engine. Inspect the fuel line for any visible damage or leaks. If it's a minor issue, you might be able to repair it by tightening connections or replacing small sections. However, for major damage or if you're unsure, it's best to consult a professional mechanic who can diagnose and fix the problem safely and effectively.