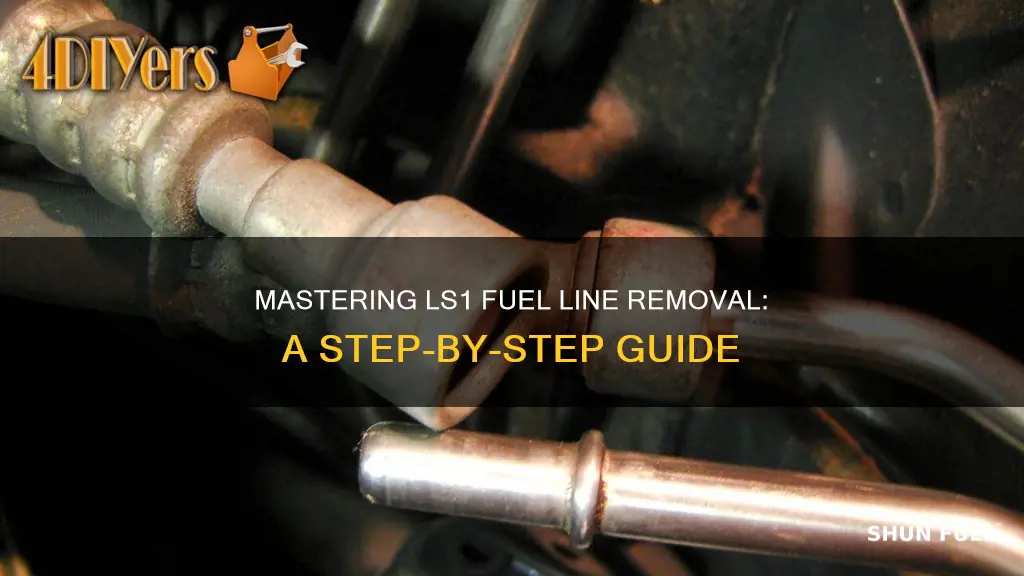

Removing fuel lines from an LS1 engine can be a delicate process, but with the right tools and knowledge, it is certainly achievable. This guide will provide a step-by-step approach to safely and effectively disconnect the fuel lines, ensuring you have the necessary information to tackle this task with confidence. Understanding the process is key to success, so let's begin by outlining the key steps involved.

What You'll Learn

Preparation: Gather tools: wrenches, fuel line cutter, safety gear

Before you begin the process of removing the fuel lines from an LS1 engine, it's crucial to ensure you have the right tools and safety gear ready. This preparation will make the job safer and more efficient. Here's a detailed guide on what you need:

Wrenches: You'll require a set of wrenches, preferably a combination of different sizes. The LS1 engine uses various types of fasteners, including bolts and nuts, so having a range of wrenches will allow you to access and loosen these components effectively. Look for a set that includes both standard and metric measurements to cover the engine's diverse fastening requirements.

Fuel Line Cutter: Removing fuel lines requires precise cutting tools. A fuel line cutter is essential for making clean, straight cuts without damaging the surrounding components. These cutters are designed to sever fuel lines without leaving sharp edges that could cause leaks or damage to other parts. Ensure you have a cutter that can accommodate the diameter of the fuel lines you'll be working with.

Safety Gear: Working on an engine involves potential hazards, so safety should always be a priority. Here's what you need:

- Gloves: Wear heat-resistant gloves to protect your hands from hot engine components and sharp tools.

- Safety Glasses: Eye protection is vital to shield your eyes from debris, sparks, or any potential fuel splashes.

- Breathing Mask: If there's a risk of inhaling fumes or dust, a respirator or dust mask can be beneficial.

- Earmuffs or Earplugs: Engine operation can produce loud noises, so consider ear protection to prevent hearing damage.

Having these tools and safety gear assembled beforehand will ensure you're well-prepared for the fuel line removal process, making the task more manageable and safer. It's always a good practice to double-check your equipment to avoid any last-minute surprises or delays during the project.

Fuel Line Hose: Who Uses Small Diameter?

You may want to see also

Locate Lines: Identify fuel lines under hood, near engine

When working on an LS1 engine, the first step to safely and effectively remove the fuel lines is to locate them. The LS1, a powerful V8 engine, utilizes a complex fuel injection system, and understanding its layout is crucial for any maintenance or repair tasks.

Under the hood, you'll find several fuel lines that supply gasoline to the engine. These lines are typically made of rubber or plastic and are color-coded for easy identification. The primary fuel lines are usually the largest in diameter and carry the main supply of fuel from the fuel pump to the engine. They are often green or black, depending on the vehicle's make and model. There may also be smaller lines, known as return lines, which carry excess fuel back to the fuel tank. These return lines are usually smaller in size and can be identified by their thinner diameter.

To locate the fuel lines, start by inspecting the engine bay. Look for the fuel pump, which is typically located near the front of the engine compartment. The fuel pump sends gasoline through the lines to the engine, so it's a good starting point. Follow the main fuel line from the pump, as it will lead you to the engine's fuel injectors or carburetor, depending on the vehicle's setup. The lines may be bundled together, so carefully separate them to identify the correct ones.

Near the engine, you might find additional fuel lines connected to the intake manifold or the engine block. These lines are crucial for delivering fuel to the combustion chambers. Take note of their positions and any connections they make, as this information will be essential when removing them.

Identifying the fuel lines is a critical step to ensure you don't accidentally remove the wrong lines, which could lead to engine damage or poor performance. Take your time to inspect the engine bay thoroughly, and if you're unsure, consult the vehicle's manual or seek guidance from an experienced mechanic.

Fuel Lines: Powering Your Body's Vital Functions

You may want to see also

Disconnection: Use appropriate tools to disconnect lines carefully

When it comes to removing fuel lines from an LS1 engine, a powerful and high-performance V8, a careful and methodical approach is essential. The LS1's intricate fuel system requires precise handling to avoid damage or spills. Here's a step-by-step guide to safely disconnecting the fuel lines:

Gather the Right Tools: Before you begin, ensure you have the necessary tools. You'll need a fuel line disconnect tool, often referred to as a fuel line cutter or fuel line removal tool. These tools are designed to grip and cut the fuel lines without causing damage. Additionally, have a set of wrenches or pliers for any remaining connections.

Locate the Fuel Lines: Identify the fuel lines you need to disconnect. The LS1 engine typically has multiple fuel lines, including the high-pressure fuel line, return line, and various injectors' lines. Locate these lines, noting their positions and any unique identifiers or markings.

Apply Pressure and Disconnect: Carefully apply pressure to the fuel line disconnect tool, positioning it around the fuel line. The tool's design will allow you to grip the line firmly. Then, with a steady hand, twist and pull the tool to disconnect the line from the engine. Take your time to avoid forcing the tool, as this can lead to damage. For any remaining connections, use the appropriate wrench or pliers to carefully loosen and remove them.

Be Mindful of Fuel Spills: As you work, be cautious of any potential fuel spills. Fuel lines can be delicate, and disconnecting them may release fuel. Have a suitable container nearby to catch any spills, and ensure you are working in a well-ventilated area to minimize the risk of inhalation of fuel vapors.

Test for Leaks: After disconnecting the fuel lines, it's crucial to test for any leaks. Inspect the disconnected areas for any signs of fuel seepage. If you notice any leaks, tighten the connections or replace the affected lines to ensure a secure fit.

Honda Motorcycle Fuel Line: Size Guide for Optimal Performance

You may want to see also

Fuel Drain: Bleed fuel system to prevent spills

When working on an LS1 engine, it's crucial to handle fuel lines with care to prevent spills and ensure a clean operation. One essential step in this process is draining the fuel system to eliminate any potential leaks. Here's a step-by-step guide on how to bleed the fuel system to prevent spills:

Step 1: Preparation

Before you begin, ensure you have the necessary tools and safety equipment. You'll need a fuel pump primer bulb, a large container to catch any spilled fuel, and protective gear like gloves and goggles. Locate the fuel lines connected to the engine, typically found near the fuel pump and injectors. Identify the drain plugs or bleeder screws, which are usually located at the bottom of the fuel tank or along the fuel lines.

Step 2: Draining the Fuel

Start by removing the drain plugs or bleeder screws to allow the fuel to drain. Place the container beneath the drain points to catch any fuel that flows out. As you remove the plugs, you might notice some fuel escaping, which is normal. Use the primer bulb to prime the fuel pump, ensuring it is fully engaged. This step helps to clear any air bubbles and ensures a smooth flow of fuel.

Step 3: Bleeding the System

Now, carefully bleed the fuel lines by applying pressure to the primer bulb. Squeeze the bulb and release it slowly, allowing the fuel to flow through the lines. This process helps to remove any air pockets and ensures that the fuel system is filled with clean, pressurized fuel. Continue this process until you observe a steady flow of fuel from the drain points, indicating that the system is bled properly.

Step 4: Reassembly and Testing

Once you've bled the system, carefully reassemble the drain plugs or bleeder screws, ensuring they are tightened securely. Check for any signs of fuel leaks around the connections. Start the engine and monitor for any unusual noises or fuel odors, which could indicate a leak. If everything is functioning correctly, you've successfully bled the fuel system and prevented potential spills during the LS1 fuel line removal process.

Remember, when working with fuel, always prioritize safety and take the necessary precautions to avoid any accidents. This methodical approach to fuel drainage will help you maintain a clean and efficient fuel system for your LS1 engine.

Unleash Engine Power: Discover the Magic of Inline Fuel Catalysts

You may want to see also

Removal: Carefully cut and remove damaged or old fuel lines

When dealing with the removal of fuel lines on an LS1 engine, it's crucial to approach the task with precision and care. The LS1 engine, known for its high-performance capabilities, relies on a complex network of fuel lines to deliver gasoline to the engine's cylinders. Over time, these lines can become damaged or worn out, leading to potential fuel leaks and performance issues. The process of removing these fuel lines requires a methodical approach to ensure the engine remains intact and functional.

The first step in this process is to identify the specific fuel lines that need to be removed. LS1 engines typically have multiple fuel lines, each serving a different purpose. These lines can be found running from the fuel pump to the engine's fuel injectors. It's essential to understand the function of each line to avoid any accidental disconnections that could lead to starting issues.

Once the lines to be removed are identified, the next step is to carefully cut and disconnect them. Using a sharp, clean pair of fuel line cutters or a utility knife, carefully sever the damaged or old fuel lines. It's important to make clean, straight cuts to avoid any jagged edges that could cause further damage or injury. When cutting, ensure you are not cutting into any other vital components, such as the fuel pump or engine block.

After the lines are cut, it's crucial to remove any remaining connections or fittings. These connections are often made of metal or plastic and can be tightened or loosened by hand or with a small wrench. Carefully undo these fittings, being mindful of any fuel residue that may remain. Cleaning the area around the connections is essential to prevent any fuel from seeping into unwanted areas.

Finally, with the damaged or old fuel lines removed, it's important to inspect the surrounding area for any signs of damage or corrosion. This step ensures that the engine's overall health is maintained and that any potential issues are addressed promptly. Properly disposing of the removed fuel lines and keeping the work area clean is also an important part of the process to ensure a safe and efficient engine operation.

Fuel Line Removal: A Step-by-Step Guide for 2001 Buick Injector Maintenance

You may want to see also

Frequently asked questions

Removing fuel lines from an LS1 engine requires caution and a systematic approach. First, ensure the engine is cool and parked on a level surface. Locate the fuel lines, typically found near the fuel pump and injectors. Use a fuel line removal tool or a pair of adjustable pliers to carefully grip and pull the lines away from the engine block. Take note of the positions of the lines to ensure proper reinstallation.

Yes, you'll need a few essential tools. A fuel line removal tool, also known as a fuel line cutter or fuel line puller, is highly recommended for a clean and efficient removal process. These tools provide a firm grip and allow for controlled pulling without damaging the lines. Additionally, have a set of socket or wrenches to loosen any fuel line connectors and a new set of fuel lines for reinstallation.

If you encounter damaged or clogged fuel lines, it's crucial to address the issue before reinstalling. Start by inspecting the lines for any signs of damage, such as cracks or leaks. If damage is found, it's best to replace the entire line. For clogs, use a fuel line cleaner or a compressed air gun to blow through the line and remove any debris. Ensure all contaminants are cleared before proceeding with the reinstallation process.

It is generally recommended to replace the original fuel lines, especially if they show signs of wear or damage. Over time, fuel lines can degrade due to fuel exposure, heat, and mechanical stress. New fuel lines will provide a fresh and reliable connection, ensuring optimal fuel delivery to the engine. However, if the original lines are in good condition and show no signs of issues, they can be reused after thorough cleaning and inspection.