Auto hot rod fuel line leaks can be a frustrating and potentially dangerous issue for vehicle owners. To address this problem effectively, it's essential to understand the causes and implement preventive measures. This guide will provide a comprehensive overview of how to stop fuel line leaks, covering topics such as identifying the source of the leak, choosing the right materials for repairs, and ensuring proper installation techniques. By following these steps, you can ensure that your hot rod's fuel system remains reliable and safe.

| Characteristics | Values |

|---|---|

| Identify the Source | Locate the specific fuel line that is leaking. This could be a damaged hose, a cracked fitting, or a weakened connection. |

| Inspect for Damage | Carefully examine the fuel line for any visible signs of damage, such as cracks, punctures, or corrosion. |

| Tighten Connections | Ensure all connections are secure and tightened according to manufacturer specifications. Use the appropriate tools for tightening. |

| Replace Worn Components | If the fuel line is damaged beyond repair, replace it with a new one of the same size and material. |

| Use Fuel Line Repair Kit | Consider using a fuel line repair kit, which typically includes a sealant and a clamp, to temporarily stop leaks. This is a quick fix but may require further permanent solutions. |

| Reinforce the Line | In some cases, reinforcing the fuel line with a protective sleeve or wrap can provide additional strength and prevent future leaks. |

| Check for Contamination | Ensure that the fuel system is free from contamination, as this can lead to corrosion and weakening of the fuel line. |

| Regular Maintenance | Perform regular maintenance checks on the fuel system to identify and address potential issues before they become major problems. |

| Consult a Mechanic | If the leak persists or you are unsure about the cause, consult a professional mechanic for a thorough inspection and expert advice. |

What You'll Learn

- Identify the Source: Inspect the fuel line for damage, corrosion, or connections that may be loose

- Tighten Connections: Use appropriate tools to ensure all connections are secure and tightened to the correct specifications

- Replace Worn Components: Replace any damaged or worn-out parts like o-rings, gaskets, and fuel line itself

- Use Fuel Line Sealant: Apply a high-temperature sealant to prevent leaks and improve fuel line flexibility

- Regular Maintenance: Schedule routine inspections to catch issues early and prevent future leaks

Identify the Source: Inspect the fuel line for damage, corrosion, or connections that may be loose

When dealing with fuel line leaks in an auto hot rod, a thorough inspection is crucial to pinpoint the source of the issue. Start by visually examining the fuel lines for any signs of damage, such as cracks, punctures, or frayed ends. These physical imperfections can be caused by various factors, including age, wear and tear, or even accidental impacts during the vehicle's lifetime. Look for any visible corrosion along the length of the fuel lines, especially at points where they are exposed to the elements or in areas prone to moisture accumulation. Corrosion can weaken the fuel line material, making it more susceptible to leaks.

Pay close attention to the connections between the fuel lines and various components, such as the fuel pump, carburetor, or fuel tank. Over time, these connections can become loose due to vibration or improper installation. A loose connection may result in a gap between the fuel line and the fitting, allowing fuel to seep out. Ensure that all connections are tight and secure, using the appropriate tools to tighten any loose fittings. It's also a good practice to double-check the tightness of these connections regularly, especially if the vehicle has been driven over rough terrain or experienced extreme weather conditions.

In addition to physical damage and corrosion, inspect the fuel lines for any signs of deterioration caused by the fuel itself. Over time, fuel can degrade, especially if it contains impurities or is exposed to high temperatures. This degradation can lead to the formation of varnish or sludge, which can clog the fuel lines and cause leaks. If you suspect fuel-related issues, consider using a fuel stabilizer or performing a fuel system flush to improve the fuel's quality and prevent further deterioration.

Remember, a systematic inspection is key to identifying the source of the fuel line leak. By carefully examining the fuel lines for damage, corrosion, and loose connections, you can pinpoint the specific areas that require repair or replacement. This targeted approach will help you effectively address the issue and prevent further leaks, ensuring the reliable operation of your auto hot rod's fuel system.

Fixing Fuel Line Pinhole Leaks: A Step-by-Step Guide

You may want to see also

Tighten Connections: Use appropriate tools to ensure all connections are secure and tightened to the correct specifications

When dealing with fuel line leaks in an auto hot rod, one of the most critical steps is to ensure that all connections are tight and secure. This process requires the use of appropriate tools and a systematic approach to guarantee the integrity of the fuel system. Here's a detailed guide on how to tighten connections effectively:

Gather the Right Tools: Before you begin, make sure you have the necessary tools for the job. This includes a torque wrench, which is essential for applying the correct amount of force to each connection. Different components may require specific types of wrenches, such as open-end or box-end wrenches, depending on their design. Additionally, have a set of screwdrivers and pliers handy for any adjustments or tighteners you might encounter.

Locate the Connections: Identify all the connections in your fuel line system, including fuel injectors, pumps, and any fittings or hoses. These are typically found along the length of the fuel lines, where they are connected to various components of the engine. It's important to inspect each connection carefully, as leaks can occur at any point where there is a join or fitting.

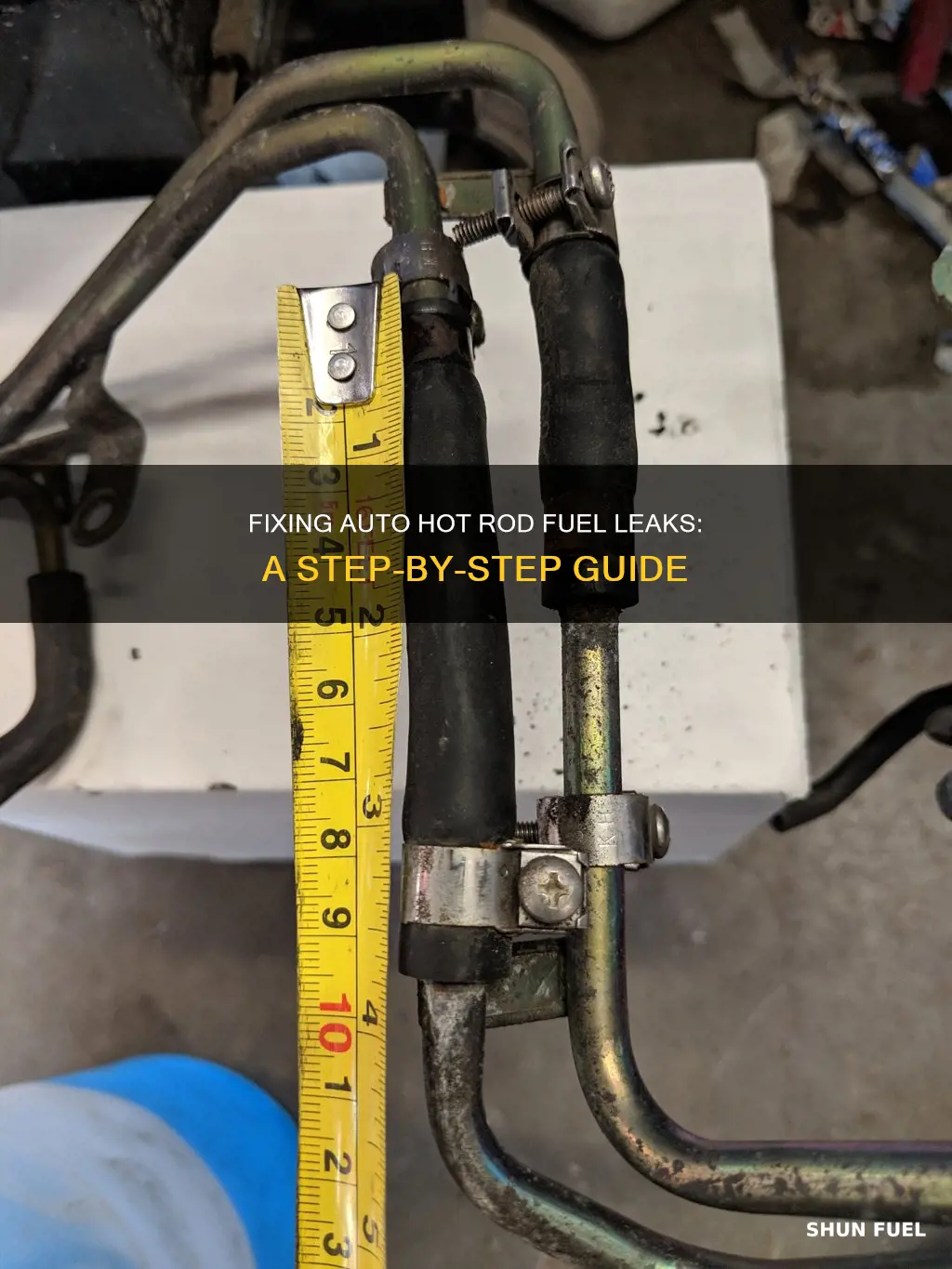

Tighten with Precision: Start tightening each connection using the appropriate tool. For example, if you have a fuel line connected to a pump, use the torque wrench to apply the specified torque value, which can usually be found in the vehicle's service manual. Ensure that you follow the manufacturer's guidelines for torque settings to avoid over-tightening, which can damage threads or components. For fittings and hoses, you might need to use a combination of tools, such as a hose clamp and a fitting wrench, to secure them properly.

Double-Check and Re-tighten: After tightening all connections, it's crucial to double-check your work. Loosen each connection slightly and then retighten it to ensure it is secure. This process helps to confirm that the initial tightening was effective and that there are no loose connections that could cause leaks. If any connections feel loose or require further tightening, do so gently but firmly, being careful not to overtighten.

Final Inspection: Once you've tightened all the connections, perform a final inspection of the fuel line system. Check for any signs of damage, such as cracks or corrosion, especially around the connections. Ensure that there are no kinks or bends in the fuel lines that could restrict flow or cause leaks. This thorough inspection will help you identify any potential issues that may have been overlooked during the tightening process.

Choosing the Right Fuel Line for Your 2005 650 V2

You may want to see also

Replace Worn Components: Replace any damaged or worn-out parts like o-rings, gaskets, and fuel line itself

If you're dealing with fuel line leaks in your hot rod, it's crucial to identify and replace any worn-out components promptly. Here's a step-by-step guide to help you tackle this issue effectively:

- Inspect the Fuel Line: Start by carefully examining the fuel line for any visible signs of damage or wear. Look for cracks, punctures, or areas where the line has become brittle. Also, check for any signs of corrosion or deterioration, especially if the fuel line has been exposed to harsh environments or chemicals.

- Check O-Rings and Gaskets: O-rings and gaskets are critical components that seal connections and prevent fuel leaks. Inspect these parts for any signs of degradation or damage. Over time, o-rings and gaskets can dry out, become brittle, or develop cracks, leading to fuel leaks. If you notice any issues, it's essential to replace these components immediately.

- Replace O-Rings and Gaskets: When replacing o-rings and gaskets, ensure you use high-quality, compatible replacements. Follow the manufacturer's recommendations for the correct type and size of seals. Properly align and install the new o-rings and gaskets, ensuring they create a tight seal. Take your time with this step, as an improper installation can lead to future leaks.

- Repair or Replace the Fuel Line: If the fuel line itself is damaged or worn, it may need to be replaced. Carefully cut out the damaged section and prepare the ends for a new connection. Use a fuel line repair kit or a suitable adhesive to ensure a secure bond. Alternatively, if the damage is extensive, it might be more practical to replace the entire fuel line with a new one designed for your hot rod's specifications.

- Secure Connections: When replacing or repairing fuel lines, ensure all connections are tight and secure. Use fuel line clamps or fittings that provide a reliable seal. Avoid overtightening, as this can damage the fuel line. Regularly check and tighten connections, especially if your hot rod is used frequently or in challenging conditions.

Remember, addressing fuel line leaks promptly is essential for maintaining the performance and safety of your hot rod. By replacing worn-out components, you can ensure a reliable fuel supply and prevent potential engine issues caused by fuel leaks. Always refer to your vehicle's manual or consult with a professional mechanic for specific guidance tailored to your hot rod's make and model.

Mastering Fuel Line Removal: A Guide for 1993 F150 Owners

You may want to see also

Use Fuel Line Sealant: Apply a high-temperature sealant to prevent leaks and improve fuel line flexibility

If you're dealing with fuel line leaks in your hot rod, one effective solution is to use a high-temperature sealant. This method is particularly useful for addressing leaks in fuel lines, as it provides a durable and flexible barrier that can withstand the extreme conditions inside your engine bay. Here's a step-by-step guide on how to apply this sealant to prevent leaks and enhance the overall performance of your fuel lines:

Preparation: Before you begin, ensure that the engine is cool to the touch to avoid any burns. Gather the necessary supplies, including the high-temperature fuel line sealant, a clean cloth, and a small brush or applicator tool. It's crucial to work in a well-ventilated area or outdoors to avoid inhaling any fumes.

Cleaning and Inspection: Start by thoroughly cleaning the fuel line where the leak is occurring. Use a degreaser or a mild solvent to remove any dirt, grease, or old sealant. Rinse the area with clean water and allow it to dry completely. Inspect the fuel line for any visible damage or cracks, as these areas may require additional attention.

Application: Begin by cutting a small piece of high-temperature sealant tape or using a liquid sealant. For tape, ensure it is the correct size to cover the affected area. Apply the sealant liberally to the fuel line, ensuring complete coverage of the damaged section. For liquid sealants, follow the manufacturer's instructions for application. Use the brush or applicator to spread the sealant evenly, creating a smooth and continuous layer.

Flexibility and Reinforcement: One of the key advantages of using a high-temperature sealant is its ability to improve fuel line flexibility. After application, allow the sealant to cure according to the manufacturer's guidelines. Once cured, gently flex the fuel line to ensure it moves freely. This step is crucial to guarantee that the sealant adheres well and doesn't restrict the fuel line's movement, which could lead to future leaks.

Testing and Final Touches: After the sealant has cured, start the engine and test for leaks. If no leaks are detected, you've successfully addressed the issue. However, if any minor leaks persist, reapply the sealant and allow it to cure again. For a more permanent solution, consider replacing the affected fuel line section with a new, high-quality part to ensure long-term reliability.

By following these steps, you can effectively use a high-temperature sealant to prevent fuel line leaks and improve the overall performance and longevity of your hot rod's fuel system. Remember, regular maintenance and prompt attention to any leaks can save you from potential engine damage and costly repairs.

Engine's Strange Noises: When Fuel Line Issues Speak

You may want to see also

Regular Maintenance: Schedule routine inspections to catch issues early and prevent future leaks

Regular maintenance is a crucial aspect of vehicle ownership, especially when it comes to preventing fuel line leaks in your beloved hot rod. By implementing a routine inspection schedule, you can stay ahead of potential problems and ensure the longevity of your car's fuel system. Here's a comprehensive guide to help you understand why and how to schedule these inspections:

Identifying Potential Issues: Fuel lines are vital components that carry gasoline from the tank to the engine. Over time, these lines can develop cracks, become brittle, or suffer from corrosion, leading to leaks. Routine inspections allow you to identify these issues early on. Start by visually examining the fuel lines for any visible damage, such as cracks, brittleness, or signs of corrosion. Look for puddles of fuel around the engine bay, which could indicate a leak. Additionally, check for any signs of deterioration, such as frayed or exposed lines, especially where they connect to the fuel tank and engine.

Professional Expertise: While visual inspections are essential, it's highly recommended to involve a professional mechanic for routine maintenance. Certified technicians have the expertise and tools to perform thorough inspections. They can use specialized equipment to detect leaks that might not be visible to the naked eye. During these inspections, mechanics will pressure-test the fuel system to ensure the lines can withstand the pressure and identify any weak points. They may also inspect the fuel pump and injectors to ensure they are functioning correctly and not contributing to potential leaks.

Preventive Measures: Regular maintenance is a proactive approach to preventing fuel line leaks. By catching issues early, you can avoid costly repairs and potential safety hazards. Mechanics will clean and replace any damaged gaskets or seals to ensure a tight and secure connection. They might also recommend using fuel line protectants to safeguard against corrosion and extend the life of the lines. Additionally, keeping your hot rod's engine and fuel system properly lubricated can prevent internal damage that could lead to fuel line issues.

Frequency of Inspections: The frequency of inspections may vary depending on your vehicle's age, usage, and maintenance history. As a general guideline, it is advisable to have a professional inspection at least once a year or every 10,000 miles. More frequent inspections might be necessary for older vehicles or those with a history of fuel system issues. Additionally, if you notice any unusual symptoms, such as strange noises, reduced engine performance, or fuel odor in the exhaust, it's crucial to have your vehicle inspected immediately.

By incorporating regular maintenance and inspections into your hot rod's care routine, you'll be taking a proactive approach to preventing fuel line leaks. This ensures that your classic car remains reliable and safe, allowing you to enjoy the thrill of the open road without unexpected breakdowns. Remember, proper maintenance is an investment in the long-term health of your vehicle.

Unrusting the Fuel Line: A Step-by-Step Guide to Removing Corroded Fittings

You may want to see also

Frequently asked questions

A leaking fuel line can be a serious issue and should be addressed immediately to prevent further damage and potential safety hazards. Here are the steps to fix it: First, locate the source of the leak by inspecting the fuel line for any cracks, punctures, or damage. Then, shut off the fuel supply to the engine and drain the remaining fuel from the system. Replace the damaged section of the fuel line with a new one, ensuring it is the correct size and type for your vehicle. Secure the new line with clamps or fittings, making sure there are no sharp bends or kinks. Finally, start the engine and check for any further leaks. If the issue persists, consider consulting a professional mechanic for further diagnosis.

Fuel lines can leak due to several reasons. Over time, the fuel lines may deteriorate due to exposure to heat, sunlight, and chemicals in the fuel. This can cause the lines to become brittle and crack. Additionally, fuel lines can be damaged by sharp objects, vibrations, or improper installation. Corrosion and mineral deposits inside the lines can also lead to leaks. It's important to regularly inspect the fuel lines and address any signs of damage or wear to prevent leaks.

Temporary fixes are possible, but it's crucial to understand that they are only a short-term solution. You can use a fuel line clamp or a temporary repair kit to seal the leak temporarily. These kits often include a rubber or epoxy compound that can be applied to the damaged area to create a temporary barrier. However, it's essential to get the fuel line replaced as soon as possible to avoid further complications and potential engine damage.

Preventive maintenance is key to avoiding fuel line issues. Here are some tips: Regularly inspect the fuel lines for any signs of damage, wear, or corrosion. Keep the fuel tank and lines clean by using a fuel stabilizer and changing the engine oil regularly. Ensure proper fuel filter installation and replacement. Avoid overfilling the fuel tank, as this can create pressure and potential leaks. Additionally, consider using a fuel line protector or shield to guard against sharp objects and vibrations.

Yes, there are several indicators that may suggest a fuel line problem. These include fuel leaks, engine misfires or stalling, reduced engine performance, strange noises from the engine, and a strong fuel odor inside the vehicle. If you notice any of these symptoms, it's advisable to have the fuel system inspected by a professional to identify and address the issue promptly.