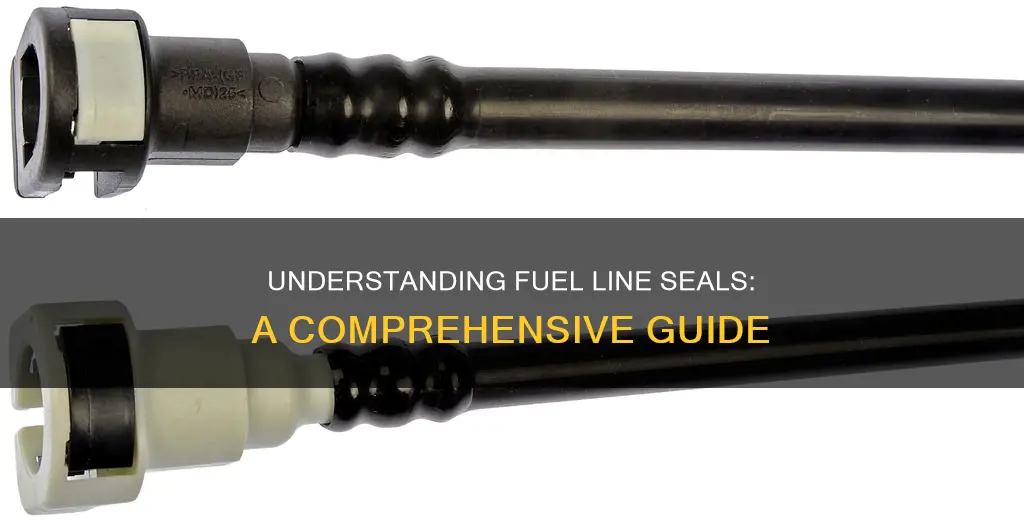

A fuel line seal is a crucial component in the automotive industry, specifically designed to prevent fuel leaks and ensure the efficient operation of a vehicle's fuel system. It is a small but vital part that acts as a barrier between the fuel lines and the engine, providing an effective seal to maintain the integrity of the fuel supply. This seal is typically made of durable materials such as rubber or silicone, which can withstand high temperatures and pressure, making it an essential safety feature in any vehicle's engine compartment.

What You'll Learn

- Materials: Fuel line seals are made from materials like rubber, silicone, or metal

- Design: They are designed to prevent fuel leaks and ensure a tight seal

- Installation: Proper installation is crucial to ensure the seal's effectiveness

- Maintenance: Regular inspection and replacement are recommended to maintain fuel system integrity

- Compatibility: Seals must be compatible with the specific fuel type and vehicle model

Materials: Fuel line seals are made from materials like rubber, silicone, or metal

Fuel line seals are an essential component in the automotive industry, designed to prevent leaks and ensure the safe operation of fuel systems. These seals are typically made from specific materials that offer durability, flexibility, and resistance to various environmental factors. The choice of material depends on the application and the specific requirements of the fuel system.

One of the most common materials used for fuel line seals is rubber. Rubber is known for its excellent elasticity and ability to withstand high temperatures and pressure. It is a cost-effective option and provides a reliable seal due to its inherent flexibility. Rubber seals can accommodate slight movements and vibrations in the fuel system, ensuring a tight seal without the risk of cracking or breaking. This material is widely used in various automotive applications, including gasoline and diesel engines.

Silicone is another popular choice for fuel line seals. Silicone rubber offers superior resistance to heat and chemicals, making it ideal for high-temperature environments. It is also highly flexible and can maintain its shape even under extreme conditions. Silicone seals are often used in high-performance vehicles or applications where the fuel system operates at elevated temperatures. This material's ability to resist aging and maintain its sealing properties over time makes it a reliable choice for long-lasting fuel system protection.

In some cases, metal seals are utilized for fuel line applications. Metal, such as stainless steel or aluminum, provides excellent strength and durability. Metal seals are often used in high-pressure systems or where a more rigid material is required. These seals offer a long-lasting solution and can withstand the harsh conditions of an engine compartment. However, metal seals may be less flexible and more prone to corrosion compared to rubber or silicone.

The choice of material for fuel line seals is crucial to ensure the longevity and reliability of the fuel system. Each material offers unique properties that cater to different requirements, such as temperature resistance, flexibility, and cost. Whether it's the versatility of rubber, the heat resistance of silicone, or the strength of metal, these materials play a vital role in maintaining the integrity of the fuel system and preventing potential leaks.

Saab 01 Fuel Line: Return Line Mystery Solved

You may want to see also

Design: They are designed to prevent fuel leaks and ensure a tight seal

The design of fuel line seals is a critical aspect of their functionality, especially in the context of preventing fuel leaks and ensuring a tight seal. These seals are meticulously crafted to fit specific fuel lines, taking into account the unique dimensions and contours of each line. This precision is essential because it allows the seal to create a secure barrier around the fuel line, effectively preventing any potential leaks. The design often incorporates a combination of materials, such as rubber or silicone, which are known for their flexibility and resilience. This flexibility is crucial as it enables the seal to adapt to slight movements and vibrations that occur within the engine system, ensuring a consistent and reliable seal over time.

One of the key design features is the presence of a raised or textured surface around the perimeter of the seal. This design element serves multiple purposes. Firstly, it provides a physical barrier that directly contacts the fuel line, creating a tight seal. Secondly, the texture can help to create a more secure grip, preventing the seal from shifting or moving under pressure. This is particularly important in high-pressure fuel systems where the seal must withstand significant force without compromising its integrity.

In addition to the material and texture, the design of fuel line seals often includes a series of grooves or channels. These grooves are strategically placed to allow for the passage of fuel while maintaining a tight seal. The design ensures that the fuel flows efficiently through the line without any leaks, while also providing a physical barrier that prevents contaminants from entering the system. This dual functionality of allowing fuel flow and blocking leaks is a testament to the intricate design considerations that go into creating these seals.

Furthermore, the design of fuel line seals often takes into account the operating conditions of the vehicle. For example, seals used in high-performance engines may require a more robust design to withstand extreme temperatures and pressures. In such cases, the seal might incorporate additional layers of material or a more durable composition to ensure its longevity and reliability. This customization in design ensures that the fuel line seal is tailored to the specific demands of the vehicle's fuel system.

In summary, the design of fuel line seals is a complex and critical process that focuses on preventing fuel leaks and ensuring a tight seal. Through the use of specific materials, textures, and grooves, these seals are engineered to provide a secure barrier around fuel lines, allowing for efficient fuel flow while blocking potential leaks. The design considerations also take into account the operating conditions of the vehicle, ensuring that the seal is reliable and durable in various environments.

Optimizing Fuel Flow: Choosing the Right Fuel Line Diameter for Horsepower

You may want to see also

Installation: Proper installation is crucial to ensure the seal's effectiveness

The installation process of a fuel line seal is a critical step to ensure its effectiveness and prevent potential issues. Proper installation involves several key steps that should be followed meticulously to guarantee a secure and reliable seal. Firstly, it is essential to inspect the fuel line and ensure it is free from any damage or debris. This initial check helps identify any potential issues that might affect the seal's performance. Once the fuel line is confirmed to be in good condition, the next step is to clean the area where the seal will be applied. This cleaning process ensures that there are no contaminants or residues that could interfere with the seal's functionality.

When installing the fuel line seal, it is crucial to follow the manufacturer's guidelines. These instructions are designed to provide the most effective and secure method of installation for the specific seal being used. Typically, the seal is positioned over the fuel line, ensuring it covers the entire length of the line. It should be firmly pressed onto the line, creating a tight seal. This process might require the use of specialized tools or techniques to ensure the seal is applied with the correct amount of pressure. Over-tightening can damage the fuel line, while under-tightening may result in an ineffective seal.

After the seal is in place, it is essential to check for any signs of leakage. This can be done by applying a small amount of fuel to the seal and observing if any fuel drips or seeps through. If any leakage is detected, the installation process should be repeated, ensuring the seal is properly seated and tightened. Additionally, it is recommended to inspect the seal periodically, especially after any maintenance or repair work, to ensure its continued effectiveness.

In some cases, additional measures might be required to enhance the seal's performance. This could include the use of sealants or tape to provide extra protection against fuel leakage. These supplementary steps are particularly important in high-pressure or high-temperature environments, where the fuel line seal must withstand more demanding conditions. Proper installation and regular maintenance will contribute to the overall reliability and longevity of the fuel system.

In summary, the installation of a fuel line seal is a precise and critical process. It requires attention to detail, adherence to manufacturer guidelines, and a thorough understanding of the fuel system. By following these steps, one can ensure that the fuel line seal effectively prevents fuel leakage, contributing to the overall safety and performance of the vehicle's fuel system. Regular maintenance and inspections are also vital to identify and address any potential issues promptly.

Fuel Line Faults: Common Issues and Solutions

You may want to see also

Maintenance: Regular inspection and replacement are recommended to maintain fuel system integrity

Maintaining the integrity of your fuel system is crucial to ensure optimal engine performance and longevity. One critical component that often requires attention is the fuel line seal. These seals play a vital role in preventing fuel leaks and maintaining the overall health of your vehicle's engine. Regular maintenance and inspection are essential to identify and replace worn-out or damaged seals, ensuring a reliable and efficient fuel system.

Over time, fuel line seals can deteriorate due to various factors, including age, temperature fluctuations, and the corrosive nature of fuel. When these seals fail, it can lead to several issues. One of the most common consequences is fuel leakage, which can cause engine misfires, reduced power, and even potential safety hazards. Additionally, a compromised fuel line seal may result in fuel contamination, as impurities in the fuel can enter the system, leading to clogged injectors or carburetor issues.

To maintain the integrity of your fuel system, it is recommended to perform regular inspections. Start by visually examining the fuel lines for any signs of damage, cracks, or corrosion. Pay close attention to areas where the lines connect to the engine block, as these points are more susceptible to wear. Look for any signs of fuel leakage, such as wet spots on the ground or a sweet odor, which could indicate a compromised seal. If you notice any issues, it is crucial to address them promptly to prevent further damage.

In addition to visual inspections, it is beneficial to use specialized tools and techniques to assess the condition of the fuel line seals. This may include using a fuel pressure gauge to check for leaks or employing a diagnostic scanner to identify any error codes related to the fuel system. Professional mechanics often utilize these methods to ensure a thorough evaluation. When performing inspections, it is also essential to consider the age of the seals, as older seals may require replacement even if no visible damage is observed.

Regular replacement of fuel line seals is a proactive approach to maintaining your vehicle's fuel system. By replacing worn-out seals, you can prevent potential issues and ensure the engine operates efficiently. It is advisable to use high-quality replacement seals that are compatible with your vehicle's make and model. When replacing seals, ensure you follow the manufacturer's guidelines and consider consulting a professional mechanic to guarantee proper installation.

Understanding the Choke Fuel Line: A Car's Essential Component

You may want to see also

Compatibility: Seals must be compatible with the specific fuel type and vehicle model

When it comes to fuel line seals, compatibility is a critical factor that cannot be overlooked. These seals are designed to prevent fuel leaks and ensure the safe operation of a vehicle's fuel system. The primary concern with compatibility is ensuring that the seal material can withstand the unique properties of the fuel being used and the specific vehicle model's design.

Different types of fuel, such as gasoline, diesel, or alternative fuels like ethanol blends, have distinct chemical compositions and properties. For instance, ethanol-blended fuels can be more corrosive, requiring seals with enhanced resistance to prevent degradation. Similarly, the design of the vehicle's fuel system, including the shape and material of the fuel lines, can vary significantly between different models and manufacturers. This variation in fuel system design means that the fuel line seals must be tailored to fit and function optimally within the specific vehicle's architecture.

To ensure compatibility, it is essential to consider the manufacturer's recommendations and specifications for the fuel type and vehicle model in question. Automotive manufacturers often provide detailed guidelines on the appropriate types of seals and materials to use. These recommendations are based on extensive testing and research to ensure the safety and reliability of the vehicle's fuel system. Using the correct compatible seals is crucial to maintaining the integrity of the fuel system and preventing potential hazards associated with fuel leaks.

In some cases, vehicle manufacturers may specify the use of original equipment manufacturer (OEM) seals or provide specific part numbers for compatible seals. These OEM-approved seals are designed to meet the exacting standards of the vehicle's fuel system, ensuring a perfect fit and optimal performance. Using non-compatible or generic seals can lead to potential issues, such as fuel leaks, reduced engine performance, or even safety hazards.

In summary, compatibility is the cornerstone of effective fuel line sealing. It requires a thorough understanding of the fuel type, vehicle model, and the specific requirements of the fuel system. By selecting the right compatible seals, vehicle owners and mechanics can ensure the longevity and reliability of the fuel system, contributing to a safer and more efficient driving experience. Always refer to the vehicle's manual or consult with automotive experts to determine the appropriate seals for a particular fuel type and vehicle model.

Fuel Lines: Powering Your Snowmobile's Performance and Efficiency

You may want to see also

Frequently asked questions

A fuel line seal is a component designed to prevent fuel leaks in vehicles. It is typically made of a durable material such as rubber or silicone and is used to seal the connection between the fuel line and the engine, ensuring that fuel is delivered efficiently without any spills or emissions.

The fuel line seal is usually found where the fuel line connects to the engine block or the fuel injection system. It is an essential part of the vehicle's fuel system, often located near the engine or under the car's hood.

This seal creates a tight, waterproof barrier around the fuel line, preventing any fuel from escaping. It is designed to withstand high pressure and temperature changes, ensuring the fuel system's integrity. Over time, seals may degrade, requiring replacement to maintain optimal vehicle performance.

A damaged or faulty fuel line seal can lead to fuel leaks, which may cause engine misfires, reduced performance, and potential safety hazards. Regular inspection and timely replacement of seals are crucial to prevent costly engine repairs and ensure the vehicle's overall reliability.