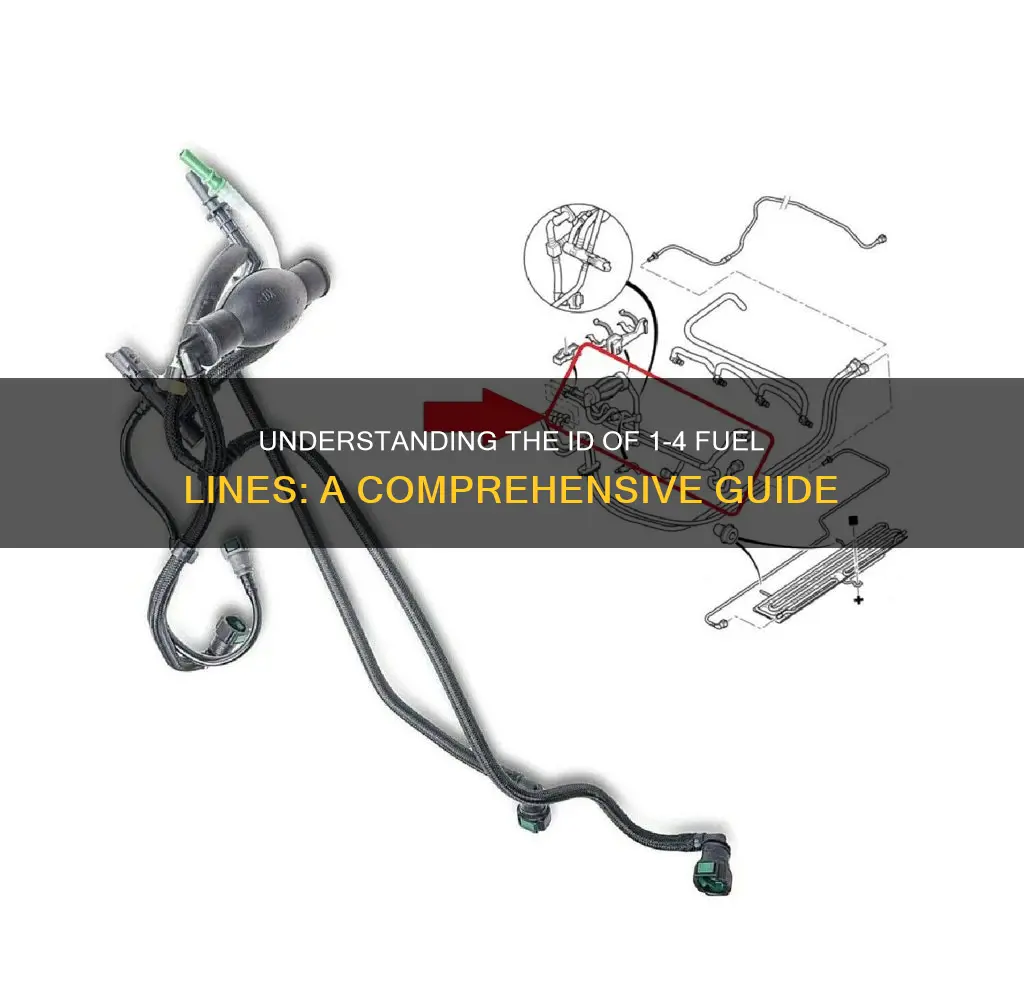

The ID of a 1-4 fuel line is a crucial component in the fuel system of an engine, specifically referring to the internal diameter of the fuel line. This measurement is essential for ensuring proper fuel flow and pressure, as it determines the size and capacity of the fuel line. Understanding the ID of the 1-4 fuel line is vital for engine maintenance, as it helps in selecting the correct fuel line for replacement or upgrade, ensuring optimal engine performance and reliability.

| Characteristics | Values |

|---|---|

| Material | Steel, Aluminum, Plastic |

| Diameter | 1.4 mm |

| Length | Varies based on application |

| Color | Typically black or blue |

| Compatibility | Specific to vehicle models |

| Function | Connects fuel pump to the engine |

| Pressure Rating | Designed for fuel system pressure |

| Temperature Range | Suitable for engine operating temperatures |

| Flexibility | May be flexible or rigid |

| Installation | Requires precise fitting |

What You'll Learn

- Fuel Line Identification: Understanding the unique ID for a specific fuel line

- Fuel Line Components: Exploring the parts that make up the fuel line

- Fuel Line Routing: How fuel lines are strategically routed in a vehicle

- Fuel Line Maintenance: Tips for keeping the fuel line in optimal condition

- Fuel Line Diagnostics: Methods for identifying and fixing fuel line issues

Fuel Line Identification: Understanding the unique ID for a specific fuel line

Fuel lines are an essential component of any vehicle's fuel system, responsible for transporting fuel from the tank to the engine. Each fuel line is uniquely identified to ensure proper installation and maintenance. The identification process is crucial, as it helps mechanics and car owners quickly locate and access specific fuel lines, especially in complex engine systems. When dealing with a 1.4-liter fuel line, understanding its unique identifier is vital for accurate diagnosis and repair.

The ID of a 1.4 fuel line typically refers to the specific fuel line's part number or code, which is assigned by the vehicle manufacturer. This identifier is often a combination of letters and numbers, providing a unique reference for that particular fuel line. For instance, a common format might be 'FL-14A,' where 'FL' indicates the fuel line, '14' could represent the engine size or model, and 'A' might denote a specific variant or configuration. This coding system ensures that the correct fuel line is used during repairs and replacements.

Identifying the correct fuel line ID is crucial for several reasons. Firstly, it ensures that the appropriate fuel line is installed in the right location, as different fuel lines may have varying diameters, lengths, and connections. Secondly, the ID helps in troubleshooting, as mechanics can quickly narrow down potential issues by referring to the specific fuel line's documentation. For example, if a 1.4 fuel line is leaking, knowing its exact ID allows technicians to access the relevant repair manuals and procedures.

To locate the unique ID for a 1.4 fuel line, one should consult the vehicle's service manual or the manufacturer's website. These resources provide detailed diagrams and part numbers for each fuel line. Alternatively, online forums and communities dedicated to vehicle maintenance can offer valuable insights and experiences from other car owners, who may share their knowledge of specific fuel line IDs.

In summary, understanding the unique ID of a 1.4 fuel line is essential for proper maintenance and repairs. This identification process ensures that the correct fuel line is used, facilitating efficient troubleshooting and minimizing potential errors. By following the manufacturer's guidelines and utilizing available resources, car owners and mechanics can easily identify and work with specific fuel lines, contributing to the overall reliability and performance of the vehicle's fuel system.

Understanding the Role of the Diesel Leak Off Fuel Line

You may want to see also

Fuel Line Components: Exploring the parts that make up the fuel line

A fuel line is an essential component of any vehicle's fuel system, responsible for transporting fuel from the tank to the engine. It is a network of pipes and hoses that ensures a continuous and controlled supply of fuel to the engine, allowing it to run efficiently. Understanding the components of a fuel line is crucial for maintenance and troubleshooting, as each part plays a specific role in the overall functionality of the fuel system.

The primary components of a fuel line include the fuel pump, fuel filter, and various hoses and pipes. The fuel pump is a critical element, located within the fuel tank or close to it. Its primary function is to draw fuel from the tank and deliver it under pressure to the engine. This pump ensures that the fuel is supplied at the required pressure, which is essential for optimal engine performance. The pump's efficiency and longevity are vital to the vehicle's overall reliability.

Connected to the fuel pump is the fuel filter, which serves as a protective barrier. It is designed to remove impurities and contaminants from the fuel before it reaches the engine. Over time, the fuel filter may become clogged with dirt, water, or debris, leading to reduced engine performance. Regular maintenance, including replacing the fuel filter at recommended intervals, is necessary to ensure the fuel line's efficiency and prevent potential engine damage.

The fuel line itself consists of several hoses and pipes that connect the various components. These hoses are typically made of rubber or a flexible material to accommodate the movement of the vehicle. The pipes, often made of metal or rigid plastic, provide a sturdy pathway for fuel transport. Each hose and pipe is designed to withstand the pressure and temperature changes associated with fuel, ensuring a safe and efficient flow.

In addition to these main components, some fuel lines may include additional parts such as fuel pressure regulators, fuel injectors, and return lines. These extra elements contribute to the precise control and distribution of fuel within the engine. Understanding the specific configuration of a vehicle's fuel line is essential for mechanics and enthusiasts alike, as it allows for accurate diagnosis and maintenance of the fuel system.

Unveiling the 1967 Ford LTD's Fuel Line Route

You may want to see also

Fuel Line Routing: How fuel lines are strategically routed in a vehicle

Fuel line routing is a critical aspect of vehicle design, ensuring efficient and safe fuel delivery to the engine. The strategic placement and routing of fuel lines are essential to maintain optimal performance and prevent potential issues. When designing the fuel system, engineers consider various factors to ensure the fuel lines are routed correctly and securely.

In a typical vehicle, fuel lines are made of flexible materials like rubber or plastic and are designed to withstand the challenges of the automotive environment. These lines are routed from the fuel tank, usually located at the rear or front of the vehicle, to the engine compartment. The primary goal is to provide a direct and unobstructed path for fuel flow while minimizing potential hazards.

One common routing method is to run the fuel lines along the vehicle's frame or beneath the floor pan. This approach provides structural support and protection from potential road debris. The lines are often secured using clips or brackets to prevent movement and ensure they remain in place during various driving conditions. Proper routing helps avoid sharp bends or kinks that could restrict fuel flow or cause damage over time.

In some cases, fuel lines may be routed through the engine compartment, where they are closer to the engine and easier to access for maintenance. Here, the lines are typically protected by metal or plastic shields to guard against engine components and potential impacts. The routing should be carefully planned to avoid interference with other engine parts and to maintain a neat and organized appearance.

Additionally, fuel line routing must consider the vehicle's overall design and available space. In compact or sports cars, space is limited, requiring creative routing solutions. Engineers might utilize flexible hoses and innovative bends to navigate around obstacles while ensuring the lines remain secure and free from potential damage. Proper routing also contributes to a clean and professional-looking interior.

In summary, fuel line routing is a meticulous process that requires careful planning and consideration of various factors. By strategically placing and securing the fuel lines, engineers ensure efficient fuel delivery, optimal engine performance, and a safe driving experience. Understanding the principles of fuel line routing is essential for anyone working on vehicle fuel systems, as it directly impacts the vehicle's overall functionality and longevity.

Troubleshooting Fuel Line Issues: Signs and Solutions

You may want to see also

Fuel Line Maintenance: Tips for keeping the fuel line in optimal condition

Fuel lines are an essential component of any vehicle's fuel system, and proper maintenance is crucial to ensure optimal performance and longevity. Here are some tips to help you keep your fuel lines in top shape:

Regular Inspections: It is imperative to inspect your fuel lines regularly, especially if your vehicle is older or has been through harsh conditions. Look for any signs of damage, such as cracks, leaks, or corrosion. Check for any visible wear and tear, especially at the points where the fuel lines connect to the engine and the fuel tank. Even minor damage can lead to fuel leaks, which can be dangerous and costly to repair.

Keep It Clean: Over time, fuel lines can accumulate dirt, debris, and varnish, especially if your vehicle is used for off-road adventures or in dusty environments. Use a fuel line cleaner to remove any built-up contaminants. This process helps to ensure that the fuel lines remain clear and unobstructed, allowing for efficient fuel flow. Regular cleaning can also prevent the formation of varnish, which can restrict fuel flow and reduce engine performance.

Check for Leaks: Fuel line leaks are a common issue and can be caused by various factors, including age, damage, or improper installation. Inspect the fuel lines for any signs of leakage, especially around fittings and connections. If you notice any leaks, it's crucial to address them promptly. Start by tightening any loose connections and replacing any damaged sections. In some cases, you might need to seek professional help to ensure a proper repair.

Use the Right Fuel: Different fuels have different properties, and using the wrong type can impact the fuel lines' condition. Always use the fuel recommended by the manufacturer. Higher-octane fuels might not be necessary for your vehicle and could potentially damage the fuel system, including the lines. Ensure that the fuel you use is clean and free of contaminants to maintain the overall health of your fuel system.

Protect from Heat and Vibration: Fuel lines are susceptible to damage from extreme temperatures and vibrations. Park your vehicle in shaded areas to minimize direct sunlight exposure, which can cause fuel line degradation. Additionally, ensure that the fuel lines are securely mounted to prevent excessive vibration during operation. Proper insulation and mounting techniques can help protect the fuel lines from potential damage.

By following these maintenance tips, you can ensure that your fuel lines remain in excellent condition, providing efficient fuel delivery to your engine. Regular care and attention to these seemingly small components can save you from potential breakdowns and costly repairs in the long run.

Ford Focus 2001 Fuel Line Breakdown: Essential Components Explained

You may want to see also

Fuel Line Diagnostics: Methods for identifying and fixing fuel line issues

Fuel lines are an essential component of any vehicle's fuel system, and diagnosing issues with them can be a complex task. Identifying and fixing fuel line problems is crucial to ensure optimal engine performance and prevent potential safety hazards. Here are some methods to help you tackle fuel line diagnostics:

Visual Inspection: The first step in diagnosing fuel line issues is a thorough visual inspection. Check the fuel lines for any visible signs of damage, such as cracks, leaks, or bulging. Look for corrosion or deterioration, especially if the lines are exposed to harsh weather conditions. Inspect the connections and fittings for tightness and any signs of leakage. This initial assessment can often reveal the source of the problem, making it easier to proceed with further diagnostics.

Pressure Testing: Fuel lines should maintain a certain pressure to ensure efficient fuel delivery. Conducting a pressure test can help identify issues with the fuel pump, lines, or injectors. Use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. Compare the readings with the manufacturer's specifications. Low pressure might indicate a faulty pump or clogged lines, while high pressure could suggest a malfunctioning pressure regulator. This test is particularly useful for diagnosing issues related to fuel delivery and performance.

Leak Detection: Fuel lines can develop leaks over time due to various factors, including age, corrosion, or physical damage. To identify leaks, spray a soapy water solution on the fuel lines and observe for any bubbles. Leaks will create bubbles as the fuel escapes. Pay attention to areas where the lines connect to the fuel tank, pump, or injectors. Additionally, use a fuel line dye or a specialized leak detection fluid to pinpoint the exact location of the leak. This method is crucial for ensuring the safety of the vehicle and preventing potential engine damage.

Engine Diagnostics: Modern vehicles are equipped with sophisticated engine control units (ECUs) that can provide valuable diagnostic information. When fuel line issues are suspected, connect a diagnostic scanner to the vehicle's ECU. This tool can retrieve error codes related to the fuel system, helping you identify specific problems. For example, a code related to fuel pressure regulation might indicate an issue with the fuel pump or lines. Engine diagnostics can also reveal performance issues that may be caused by fuel line problems, allowing for a more comprehensive assessment.

Fuel Pump Testing: The fuel pump is responsible for delivering fuel from the tank to the engine. Testing the pump's functionality is essential in fuel line diagnostics. Start by checking the pump's voltage and current draw using a multimeter. Ensure that the pump operates within the specified range. Additionally, listen for any unusual noises while the engine is running, as this could indicate a failing pump. Replacing the fuel pump if necessary will ensure a consistent fuel supply and improve overall engine performance.

Understanding Impulse Fuel Lines: Powering Chainsaws Efficiently

You may want to see also

Frequently asked questions

The ID or internal diameter of a 1.4 fuel line typically refers to the size or cross-sectional dimension of the fuel line. It is usually measured in inches or millimeters. For a 1.4 fuel line, the ID could be 1.4 inches or 14 millimeters, indicating the diameter of the fuel line.

To find the correct ID, you can refer to the vehicle's manual or the manufacturer's specifications. These sources will provide detailed information about the fuel system, including the dimensions of the fuel lines. Alternatively, you can consult a fuel line diagram or a trusted online resource that offers vehicle-specific fuel line specifications.

Using a fuel line with a different ID than the recommended one may not be compatible and could lead to issues. It's crucial to use the correct ID to ensure proper fuel flow and prevent potential engine problems. Always refer to the manufacturer's guidelines or seek professional advice if you're unsure about the compatibility of different fuel line IDs.

The common IDs for 1.4 fuel lines can vary depending on the vehicle make and model. Some common IDs include 3/8 inch, 1/2 inch, or 9mm. It's essential to identify the specific fuel line used in your vehicle to ensure you get the correct replacement or accessory.

In racing, fuel lines with specific IDs are often used to optimize fuel delivery and performance. The ID may vary based on the racing regulations and the engine's requirements. Racing teams often work closely with fuel line manufacturers to design custom solutions that meet the necessary specifications for high-performance applications.