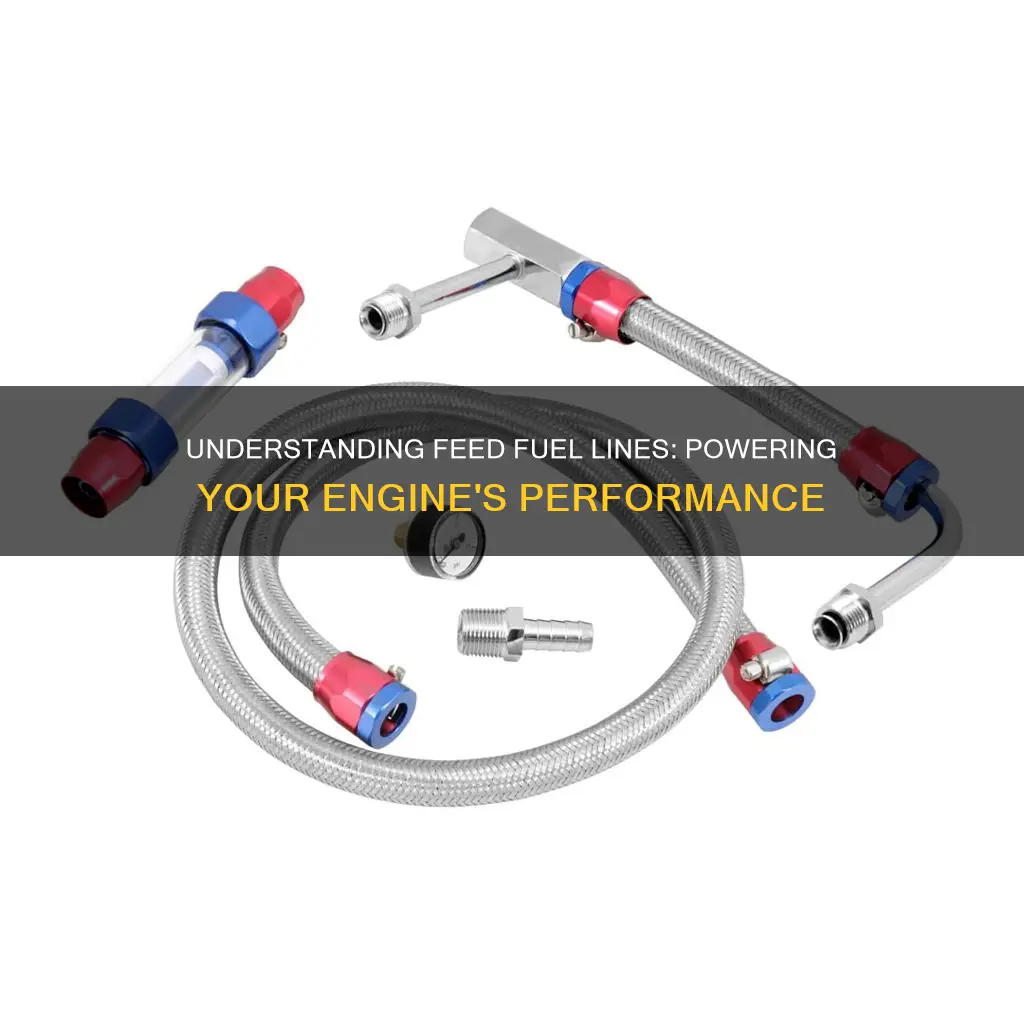

A feed fuel line is an essential component in the fuel system of an engine, playing a critical role in delivering fuel from the fuel tank to the engine's carburetor or fuel injection system. This line is designed to handle the high pressure required to ensure a steady and consistent fuel supply, which is crucial for optimal engine performance. The feed fuel line is typically made of durable materials like steel or rubber to withstand the corrosive nature of fuel and the engine's operating temperatures. Its primary function is to maintain a continuous flow of fuel, ensuring that the engine receives the necessary amount of fuel for combustion, thereby maximizing efficiency and power output. Understanding the role of the feed fuel line is vital for maintaining and troubleshooting fuel-related issues in various types of engines.

| Characteristics | Values |

|---|---|

| Purpose | Delivers fuel from the fuel tank to the engine, ensuring a continuous supply of fuel for combustion. |

| Function | Acts as a conduit for the high-pressure fuel, allowing it to flow from the tank to the injectors or carburetor. |

| Material | Typically made of durable materials like steel, aluminum, or brass to withstand fuel pressure and temperature variations. |

| Design | Often features a flexible design to accommodate engine movement and vibrations, ensuring a secure connection. |

| Location | Usually positioned near the engine, running alongside the fuel tank or under the vehicle's body. |

| Pressure Rating | Designed to handle the specific fuel pressure requirements of the engine, ensuring efficient fuel delivery. |

| Compatibility | Specific to the vehicle's engine type and fuel system, requiring precise matching to ensure optimal performance. |

| Maintenance | Regular inspection for leaks, damage, or clogs is essential to prevent engine issues. |

| Lifespan | The lifespan can vary depending on usage, maintenance, and environmental factors, but it typically lasts several years. |

| Common Issues | Can develop leaks, clogs, or damage over time, leading to fuel delivery problems and potential engine misfires. |

What You'll Learn

- Fuel Delivery: The feed fuel line delivers gasoline from the tank to the engine

- Pressure Regulation: It regulates pressure to ensure optimal engine performance

- Filtration: Fuel lines often include filters to remove contaminants

- Flexibility: Designed to be flexible to accommodate engine movement

- Durability: Built to withstand high pressure and temperatures

Fuel Delivery: The feed fuel line delivers gasoline from the tank to the engine

The feed fuel line is a critical component in the fuel delivery system of an engine, responsible for transporting gasoline from the fuel tank to the engine's combustion chamber. This process is essential for the engine to operate efficiently and produce power. Here's a detailed explanation of its function:

In an internal combustion engine, fuel is required to ignite and create power. The feed fuel line, often made of durable materials like rubber or plastic, connects the fuel tank, which stores the gasoline, to the engine's fuel injection system or carburetor. Its primary role is to ensure a continuous and controlled supply of gasoline to the engine during operation. When the engine is running, the fuel pump, located within the tank or in the engine compartment, draws gasoline from the tank and pressurizes it. This pressurized fuel is then directed through the feed fuel line to the engine.

The design of the feed fuel line includes various features to ensure optimal performance. It is typically equipped with a filter to remove any contaminants or impurities from the fuel, ensuring clean gasoline reaches the engine. Additionally, the line may have a check valve or a series of valves to prevent fuel from flowing back into the tank when the engine is not running, maintaining a one-way flow. This design also helps to maintain pressure and ensures that the engine receives the required amount of fuel for efficient combustion.

As the fuel travels through the feed fuel line, it passes through various components like the fuel pump, lines, and injectors (in the case of fuel injection engines). These components work together to meter and distribute the gasoline precisely to each cylinder, ensuring optimal engine performance. The feed fuel line's diameter and length are carefully calculated to minimize pressure loss and maintain the required fuel flow rate, especially during acceleration or high-load conditions.

In summary, the feed fuel line is a vital link in the fuel delivery process, facilitating the transfer of gasoline from the tank to the engine's combustion chamber. Its design and construction are optimized to provide a reliable and efficient fuel supply, contributing to the overall performance and longevity of the engine. Understanding the role of this component is essential for maintaining and troubleshooting fuel-related issues in various types of engines.

Duramax Fuel Line Diameter: 2003 Specs Revealed

You may want to see also

Pressure Regulation: It regulates pressure to ensure optimal engine performance

The feed fuel line plays a crucial role in maintaining the proper pressure of the fuel system, which is essential for optimal engine performance. This component is designed to manage the fuel pressure and ensure it meets the engine's requirements. When the engine is running, it demands a precise amount of fuel at a specific pressure to operate efficiently. The feed fuel line acts as a regulator, adjusting the pressure to match the engine's needs. This regulation is vital because it prevents the engine from receiving too much or too little fuel, which could lead to poor performance or even damage.

In the context of pressure regulation, the feed fuel line incorporates a pressure-regulating valve or mechanism. This valve is strategically positioned along the fuel line and is designed to control the flow of fuel. When the engine's demand for fuel increases, the valve opens wider, allowing more fuel to pass through and maintain the required pressure. Conversely, if the engine's demand decreases, the valve restricts the fuel flow, ensuring the pressure remains stable. This dynamic process is a critical aspect of the fuel system's functionality.

The pressure regulation process is particularly important during engine startup. When the engine is cold, it requires a higher pressure to ignite the fuel efficiently. The feed fuel line's pressure regulation mechanism ensures that the fuel pressure is increased to the necessary level, facilitating a smooth and reliable start. As the engine warms up, the pressure regulation adjusts to maintain the optimal pressure, promoting efficient combustion and overall engine performance.

Furthermore, the feed fuel line's pressure regulation feature contributes to fuel economy. By precisely controlling the fuel pressure, the engine can operate at its most efficient state, burning fuel more effectively. This results in better fuel economy, as the engine doesn't waste fuel by running at suboptimal pressures. This aspect is especially beneficial for vehicles, as it can lead to cost savings and reduced environmental impact.

In summary, the feed fuel line's primary function is to regulate pressure, ensuring the engine receives the right amount of fuel at the appropriate pressure. This regulation is vital for engine performance, fuel efficiency, and longevity. Understanding the role of the feed fuel line in pressure management highlights its significance as a critical component in the overall fuel system design.

Visual Guide: Sleeved Fuel Lines Explained

You may want to see also

Filtration: Fuel lines often include filters to remove contaminants

Fuel lines play a crucial role in the efficient delivery of fuel from the tank to the engine, and one of their essential functions is filtration. Over time, fuel can become contaminated with various impurities, such as water, dirt, and debris, which can lead to performance issues and potential damage to the engine. To address this, fuel lines are often equipped with filters, which serve as a barrier to trap and remove these contaminants, ensuring that only clean fuel reaches the engine.

The filtration system in a fuel line typically consists of a filter element, usually made of a fine mesh or pleated media, designed to capture particles and impurities. This filter element is strategically placed within the fuel line, often near the fuel pump or at a point where contaminants are more likely to accumulate. As fuel flows through the line, the filter traps any solid or liquid particles, preventing them from entering the engine.

The design of these filters is crucial for their effectiveness. They are often designed with a specific capacity to handle a certain volume of contaminants before requiring replacement or cleaning. Some filters are reusable and can be cleaned and reinstalled, while others are designed for single-use and need to be replaced entirely when clogged. Regular maintenance, including checking and replacing filters, is essential to ensure the fuel system's longevity and optimal performance.

In addition to physical filters, some fuel lines may also incorporate electronic fuel management systems. These systems use sensors and computers to monitor fuel quality and adjust the fuel flow accordingly. By continuously analyzing the fuel's properties, these systems can detect contaminants and make real-time adjustments to maintain the desired fuel-air mixture.

By incorporating filters into fuel lines, vehicles can ensure that the engine receives a consistent supply of clean fuel. This not only improves engine performance but also extends the lifespan of the engine and other fuel-related components. Proper maintenance, including regular filter checks and replacements, is vital to keeping the fuel system in optimal condition.

Unleash Your Engine's Potential: Understanding the 8AM Fuel Line

You may want to see also

Flexibility: Designed to be flexible to accommodate engine movement

The feed fuel line is a critical component in any engine system, and its flexibility is an essential feature that often goes unnoticed. This design aspect is crucial for ensuring the efficient and reliable operation of the engine, especially in high-performance applications. The primary purpose of this flexibility is to accommodate the natural movement and vibration of the engine during operation.

Engines are complex machines with numerous moving parts, and as they run, these components experience a significant amount of stress and movement. The feed fuel line, which connects the fuel pump to the engine's fuel injectors or carburetor, is no exception. It must be able to move and flex with the engine's various motions without compromising the fuel supply. This flexibility is designed to absorb the vibrations and movements, ensuring that the fuel is delivered consistently and accurately to the engine's combustion chambers.

In high-performance engines, the flexibility of the feed fuel line becomes even more critical. These engines often operate at higher RPMs and generate more power, leading to increased stress on all components. The fuel line must be able to handle the rapid acceleration and deceleration cycles, as well as the intense heat generated by the engine. By being flexible, it can adjust to these changes, maintaining a steady fuel flow even under extreme conditions.

This flexibility is typically achieved through the use of specialized materials and construction techniques. The fuel line is often made from high-quality, durable materials that can withstand the engine's environment while still retaining their flexibility. This might include rubber compounds, flexible hoses, or even braided materials that can move and bend without kinking or breaking. The design may also incorporate various bends and loops to allow for natural engine movement, ensuring that the fuel line remains taut and secure without being overly rigid.

In summary, the flexibility of the feed fuel line is a vital design consideration that enables engines to operate efficiently and reliably. It ensures that the fuel supply remains consistent, even in the face of engine movement and vibration. This feature is particularly important in high-performance applications, where the engine's demands can be extreme, and the fuel line must adapt accordingly to provide optimal performance. Understanding this aspect of engine design highlights the intricate relationship between various components and their role in delivering power.

EFI Fuel Line Options: Exploring the Best Choices for Performance

You may want to see also

Durability: Built to withstand high pressure and temperatures

The feed fuel line is a critical component in any engine system, especially those that rely on fuel injection. Its primary function is to deliver fuel from the fuel tank to the engine's fuel injectors with precision and efficiency. This line is designed to withstand the demanding conditions within an engine bay, including high pressure and varying temperatures.

In terms of pressure, feed fuel lines are engineered to handle the intense forces generated by the engine's operation. The fuel system operates under significant pressure to ensure a consistent and rapid flow of fuel to the injectors. This high-pressure environment requires a robust feed line that can maintain its structural integrity without compromising performance. The line's construction often includes layers of durable materials, such as high-strength polymers or reinforced rubber, which can withstand the pressure without bending, kinking, or leaking.

Temperature is another critical factor in the durability of feed fuel lines. Engines generate a lot of heat, and the fuel lines must be able to operate effectively across a wide temperature range. Extreme temperatures can cause materials to expand or contract, potentially leading to damage or failure. To combat this, manufacturers use materials with specific thermal properties. For example, some lines are made with flexible, temperature-resistant polymers that can handle the intense heat without becoming brittle or losing their shape. Others may incorporate insulation to protect against cold temperatures, ensuring the fuel remains in a usable state even in freezing conditions.

The design of the feed fuel line also plays a crucial role in its durability. Engineers consider factors such as bend radius, flexibility, and overall length to ensure the line can navigate the engine bay without stress or strain. A well-designed line will have a smooth, continuous path, reducing the risk of damage from sharp bends or sharp objects. Additionally, the line's connections and fittings are critical; they must be sealed properly to prevent fuel leaks and ensure a long-lasting, reliable connection.

In summary, the feed fuel line's durability is essential for its functionality and the overall performance of the engine. Its ability to withstand high pressure and temperatures ensures a consistent fuel supply, contributing to efficient combustion and optimal engine operation. By utilizing appropriate materials and careful design, engineers create feed fuel lines that can endure the harsh engine environment, providing reliable performance over extended periods.

Air in Paperstroke Return Fuel Line: A Cause for Concern?

You may want to see also

Frequently asked questions

A feed fuel line is an essential component in an engine's fuel system, responsible for delivering fuel from the fuel tank to the carburetor or fuel injection system. It ensures a continuous and controlled supply of fuel to the engine, allowing for efficient combustion and optimal performance.

The feed fuel line, as mentioned, carries fuel from the tank to the engine, while the return line, also known as the fuel return line, transports unused fuel from the carburetor back to the tank. This separation ensures that only the required amount of fuel is supplied to the engine, preventing wastage and maintaining a healthy fuel-to-air mixture.

Yes, a damaged or leaking feed fuel line can lead to significant engine problems. If the line is compromised, fuel may leak, causing potential hazards such as fuel contamination and fire risks. Additionally, a leak can result in a loss of power, poor engine performance, and even engine stall due to insufficient fuel supply. Regular inspection and maintenance of the fuel lines are crucial to prevent such issues.