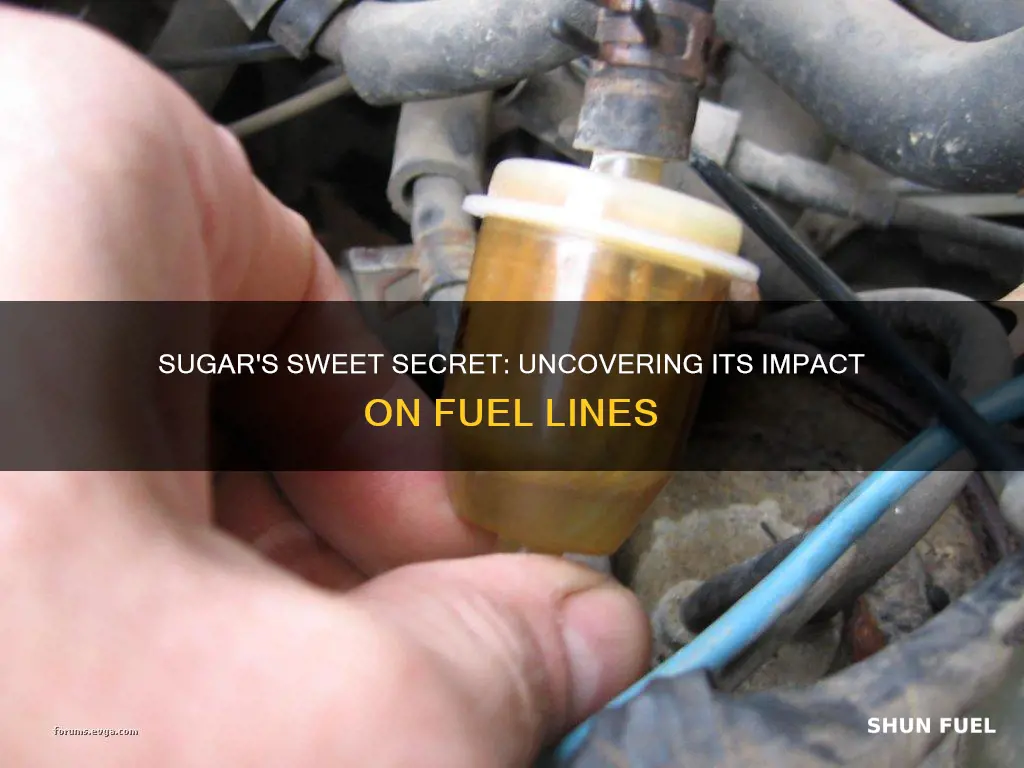

Sugar in a fuel line can have detrimental effects on vehicle performance and longevity. When sugar enters the fuel system, it can cause several issues. Firstly, it can lead to the formation of gum and varnish in the fuel lines and injectors, which can restrict fuel flow and reduce engine performance. Secondly, sugar can attract moisture, leading to the growth of microorganisms and the formation of acidic byproducts, which can corrode the fuel system components over time. This can result in fuel leaks, engine misfires, and even permanent damage to the engine. Understanding the potential risks and consequences of sugar contamination in the fuel line is crucial for vehicle owners to ensure optimal engine operation and longevity.

| Characteristics | Values |

|---|---|

| Corrosion | Sugar can accelerate the corrosion of metal fuel lines, leading to leaks and engine issues. |

| Fuel Contamination | It can cause contamination by attracting moisture and promoting microbial growth, which may block fuel filters. |

| Engine Performance | The presence of sugar can lead to reduced engine performance, misfires, and even engine failure over time. |

| Fuel Line Material | Different types of fuel lines may react differently to sugar, with some materials being more susceptible to damage. |

| Long-term Effects | Prolonged exposure to sugar in fuel lines can result in permanent damage, requiring replacement. |

| Maintenance | Regular maintenance, including fuel line inspections, is crucial to prevent sugar-related issues. |

What You'll Learn

- Sugar's Impact on Engine Performance: Sugar can cause fuel line blockages, leading to engine misfires and reduced power

- Corrosion and Sugar: Sugar accelerates corrosion in fuel lines, potentially damaging the fuel system and reducing fuel efficiency

- Sugar's Effect on Fuel Stability: Sugar can cause fuel to degrade faster, leading to engine issues and reduced vehicle lifespan

- Sugar and Fuel Contamination: Sugar contamination in fuel can lead to engine knocking, reduced performance, and potential engine damage

- Sugar's Role in Fuel Line Clogs: Sugar residue can form blockages, causing fuel starvation, engine stalling, and potential engine damage

Sugar's Impact on Engine Performance: Sugar can cause fuel line blockages, leading to engine misfires and reduced power

Sugar, an unexpected culprit in the world of automotive maintenance, can have detrimental effects on engine performance when it finds its way into the fuel line. This seemingly innocuous substance can wreak havoc on an engine's efficiency and reliability. Here's an in-depth look at the impact of sugar on engine performance:

Fuel Line Blockages: When sugar enters the fuel line, it can cause significant blockages, especially in the smaller passages. Over time, sugar molecules can dissolve and spread throughout the fuel system, including the lines, injectors, and even the engine's internal components. This dissolution process results in the formation of sticky, gel-like substances that adhere to the walls of the fuel lines. As these substances accumulate, they create blockages, narrowing the passageways and restricting the flow of fuel. This reduced fuel flow directly impacts the engine's ability to operate optimally.

Engine Misfires: The presence of sugar in the fuel line can lead to a common yet frustrating issue: engine misfires. Misfires occur when the air-fuel mixture in the engine's cylinders fails to ignite properly, resulting in a lack of power and potential performance loss. The sticky sugar residue in the fuel lines can cause the fuel injectors to become clogged, leading to inconsistent fuel delivery. This inconsistency prevents the engine from achieving the precise air-fuel ratio required for efficient combustion, ultimately causing misfires.

Reduced Engine Power: The impact of sugar on engine performance is closely tied to the engine's power output. As sugar accumulates in the fuel line, it restricts the fuel supply, leading to a decrease in the engine's overall power. The engine may struggle to accelerate, and its performance might decline, especially during high-load conditions. This reduction in power can be attributed to the incomplete combustion of fuel, which is a direct consequence of the sugar-induced blockages and misfires.

Long-Term Engine Damage: Prolonged exposure to sugar in the fuel line can result in more severe consequences. Over time, the sugar can cause corrosion and deterioration of the fuel system components, including the injectors and engine internals. This corrosion may lead to permanent damage, such as blocked injectors or even engine failure. Regular maintenance and the use of fuel system cleaners can help mitigate these long-term effects, but the initial presence of sugar in the fuel line can set off a chain of events that requires careful attention and repair.

In summary, sugar's presence in the fuel line is a critical issue that can significantly impact engine performance. From fuel line blockages to engine misfires and reduced power, the consequences can be detrimental. Regular inspection and maintenance of the fuel system are essential to prevent sugar-related damage and ensure optimal engine operation.

Fuel Line Spray: Normal or Cause for Concern?

You may want to see also

Corrosion and Sugar: Sugar accelerates corrosion in fuel lines, potentially damaging the fuel system and reducing fuel efficiency

Sugar, an unexpected culprit in the realm of vehicle maintenance, can have a detrimental effect on fuel lines when present in fuel systems. This seemingly innocuous substance, often added to enhance flavor in gasoline, can accelerate corrosion within the fuel lines, leading to a cascade of issues. The presence of sugar in fuel can initiate a chemical reaction with the metal components of the fuel system, particularly those made of aluminum or steel. Over time, this reaction results in the formation of corrosive compounds that eat away at the fuel line walls.

The impact of this corrosion is twofold. Firstly, it can lead to a decrease in fuel efficiency. As the sugar-induced corrosion progresses, it narrows the fuel line, restricting the flow of fuel to the engine. This reduction in fuel supply means the engine has to work harder to achieve the same performance, resulting in decreased fuel economy. Secondly, the corrosion can cause physical damage to the fuel lines, potentially leading to leaks. These leaks not only waste fuel but also risk contaminating the engine's internal components, causing further performance issues.

The mechanism behind this corrosion is a complex interplay of chemistry. When sugar is present in the fuel, it can react with the metal surfaces, forming acidic compounds. These acids then corrode the metal, leading to the breakdown of the fuel line material. The process is accelerated by the presence of moisture, as water can act as a catalyst for these chemical reactions. Over time, this can result in the formation of rust and other corrosive byproducts that compromise the structural integrity of the fuel lines.

Preventing this issue is relatively straightforward. Regularly using fuel additives that neutralize the acidic byproducts of sugar corrosion can help. Additionally, maintaining a clean fuel system is crucial. This includes routine fuel line inspections and replacements to catch any early signs of corrosion. For those who frequently use their vehicles in harsh conditions or with sugary fuels, more frequent maintenance may be necessary to ensure the longevity of the fuel system.

In summary, while sugar might be added to enhance the taste of gasoline, its presence in fuel lines can lead to significant problems. The acceleration of corrosion not only damages the fuel system but also negatively impacts fuel efficiency and performance. Awareness of this issue is the first step towards implementing preventive measures, ensuring that vehicles remain reliable and efficient over their lifespan.

Choosing the Right Fuel Line: Size Matters!

You may want to see also

Sugar's Effect on Fuel Stability: Sugar can cause fuel to degrade faster, leading to engine issues and reduced vehicle lifespan

Sugar, when present in fuel, can have detrimental effects on the stability and performance of the fuel system, particularly in vehicles. This is primarily due to the nature of sugar as a carbohydrate, which can undergo chemical reactions when exposed to certain conditions, leading to the degradation of the fuel.

One of the primary concerns is the process of hydrolysis, where sugar molecules break down into simpler sugars and acids. When fuel containing sugar is stored or transported, especially under conditions of high temperature and humidity, the sugar can undergo hydrolysis, producing organic acids and other byproducts. These acids can then corrode the fuel tank, fuel lines, and other fuel system components, leading to potential engine damage. The presence of these acids can also cause the fuel to become more acidic, which can further accelerate the degradation process.

The degradation of fuel due to sugar content can result in several engine issues. Firstly, the fuel's performance and efficiency can be significantly reduced. As the sugar breaks down, it can form gums and varnish-like substances that clog fuel injectors, carburetor jets, and passages, leading to poor fuel atomization and incomplete combustion. This can result in reduced power, increased fuel consumption, and even engine misfires. Additionally, the presence of these byproducts can cause the fuel to become more viscous, making it harder for the engine to draw and atomize the fuel, further exacerbating the performance issues.

Over time, the continuous presence of sugar in the fuel can lead to the deterioration of the vehicle's overall lifespan. The constant exposure to sugar-related degradation can cause premature wear and tear on engine components, leading to increased maintenance requirements and potential costly repairs. The fuel system, including the fuel tank, lines, and injectors, may require more frequent replacements or repairs, reducing the vehicle's overall reliability and longevity.

To mitigate these issues, it is essential to ensure that fuel used in vehicles is free from sugar or any other contaminants that could cause degradation. Proper fuel storage and handling practices, such as using compatible containers and maintaining appropriate temperatures, can help minimize the risk of sugar-related degradation. Regular fuel system maintenance and inspections can also help identify and address any issues caused by sugar contamination, ensuring optimal engine performance and vehicle longevity.

Chevy Fuel Tank: Understanding the Lines and Connections

You may want to see also

Sugar and Fuel Contamination: Sugar contamination in fuel can lead to engine knocking, reduced performance, and potential engine damage

Sugar contamination in fuel is a serious issue that can have detrimental effects on engine performance and longevity. When sugar enters the fuel system, it can cause a range of problems, from reduced power and efficiency to potential engine damage. This contamination often occurs due to improper fuel storage, especially in regions where fuel is not treated with the same rigor as in more developed markets.

One of the primary concerns with sugar in fuel is its ability to cause engine knocking, also known as 'pinging' or 'pre-ignition'. This occurs when the air-fuel mixture in the engine's cylinders ignites prematurely, leading to a rapid and uncontrolled burning of the fuel. The result is a loud knocking sound and a loss of power. Sugar in the fuel can act as a catalyst for this phenomenon, as it lowers the flash point of the fuel, making it more susceptible to ignition at lower temperatures. Over time, this can lead to engine damage, including the destruction of engine components such as pistons and valves.

The presence of sugar in fuel can also lead to reduced engine performance. As sugar accumulates in the fuel system, it can form deposits on the internal surfaces of the engine, including the fuel injectors and combustion chamber. These deposits can restrict the flow of fuel, air, and the resulting mixture, leading to incomplete combustion. This, in turn, results in reduced power, lower fuel efficiency, and increased emissions. In extreme cases, the engine may stall or experience difficulty starting due to the poor quality of the fuel.

Furthermore, sugar contamination can have long-term effects on the engine's overall health. The deposits formed by sugar can lead to increased engine wear and tear, as the engine works harder to overcome the restrictions in the fuel system. Over time, this can result in the need for more frequent engine maintenance and potential major repairs. In some cases, the engine may require a complete overhaul or even replacement due to the extensive damage caused by sugar contamination.

To prevent these issues, it is crucial to ensure that fuel is stored and handled properly. This includes using appropriate fuel containers, keeping fuel in a cool and dry environment, and using fuel stabilizers when necessary. Regular engine maintenance, such as fuel filter changes and engine inspections, can also help identify and mitigate the effects of sugar contamination. By being proactive and addressing potential fuel quality issues, vehicle owners can ensure their engines perform optimally and have a longer lifespan.

Clogged Fuel Line: How It Affects Your Car's Performance

You may want to see also

Sugar's Role in Fuel Line Clogs: Sugar residue can form blockages, causing fuel starvation, engine stalling, and potential engine damage

Sugar, an ingredient often overlooked in the context of vehicle maintenance, can have a significant impact on fuel lines and overall engine performance. When present in fuel, sugar residue can lead to a series of detrimental effects, primarily due to its ability to form blockages within the fuel system. These blockages are a result of the sugar's interaction with other components, particularly ethanol, which is commonly added to gasoline.

The process begins with the evaporation of ethanol, leaving behind sugar residue. This residue then adheres to the walls of the fuel lines, gradually building up over time. As the sugar molecules bond with ethanol, they create a sticky, gel-like substance that can easily clog fuel filters, injectors, and even the fuel pump itself. The clogs are insidious because they are not always visible, and by the time they are detected, significant damage may have already occurred.

One of the most immediate consequences of these blockages is fuel starvation. As the sugar residue accumulates, it narrows the fuel lines, reducing the flow of fuel to the engine. This can lead to engine misfires, reduced power, and even complete engine stall during operation. In extreme cases, the engine may not start at all, requiring a thorough cleaning of the fuel system to resolve the issue.

Over time, the presence of sugar residue can cause more severe damage. The constant narrowing of fuel lines and the pressure exerted by the engine's fuel pump can lead to the erosion of these delicate components. This erosion may result in leaks, further exacerbating the fuel starvation problem and potentially causing engine damage. In some instances, the fuel pump may become so clogged that it requires replacement, leading to costly repairs.

To prevent these issues, it is crucial to ensure that the fuel used in vehicles is free from sugar residue. Regular fuel system maintenance, including the use of fuel additives designed to break down sugar, can help mitigate the problem. Additionally, keeping the vehicle's fuel system clean and well-maintained can significantly reduce the risk of sugar-related blockages and ensure optimal engine performance.

Fuel Pump Upgrade: Big Line Solutions for Your Chevy Yukon

You may want to see also

Frequently asked questions

Sugar, when added to fuel lines, is primarily used as an octane booster. It helps to increase the fuel's resistance to engine knock and pinging, which can occur when the fuel-air mixture in the engine ignites too quickly, causing damage to the engine over time.

By adding sugar to the fuel, it can improve engine performance and efficiency. This is because sugar can act as a fuel additive, enhancing the combustion process and allowing for better engine operation, especially in high-performance vehicles or those running on lower-octane fuels.

While sugar can provide benefits, there are some considerations. Overuse of sugar can lead to fuel system issues, such as clogging or contamination, which may require professional cleaning or replacement of fuel line components. Additionally, sugar can attract moisture, so proper storage and usage are essential to prevent any adverse effects.