Boat fuel lines play a critical role in ensuring a reliable and efficient fuel supply to the engine. The direction and layout of these lines can significantly impact performance and safety. Understanding the principles of direct vs. indirect fuel lines is essential for boat owners and enthusiasts, as it can affect fuel flow, pressure, and overall engine operation. This discussion will explore the advantages and disadvantages of both direct and indirect fuel line configurations, providing insights into how they influence the overall performance and maintenance of marine vessels.

What You'll Learn

- Boat Fuel Lines: Materials, design, and installation of fuel lines for boats

- Direct Injection: Fuel delivery systems that inject fuel directly into the engine cylinders

- Fuel Pump Location: Placement of fuel pumps in boats for efficient fuel supply

- Fuel Line Routing: Best practices for organizing and routing fuel lines in a boat

- Fuel Line Maintenance: Cleaning, inspection, and repair techniques for boat fuel lines

Boat Fuel Lines: Materials, design, and installation of fuel lines for boats

Boat fuel lines are a critical component of any vessel's fuel system, ensuring efficient and safe fuel delivery to the engine. The design, materials, and installation of these lines are essential to prevent fuel leaks, maintain performance, and ensure the longevity of the boat's engine. Here's an overview of the key aspects:

Materials:

Fuel lines for boats are typically made from specialized materials designed to withstand the harsh marine environment. The most common materials include:

- High-Density Polyethylene (HDPE): This is a lightweight, flexible, and durable plastic that is resistant to fuel degradation and UV radiation. HDPE fuel lines are often used for their ability to handle high-pressure fuel systems.

- Reinforced Rubber: Rubber fuel lines are reinforced with fibers or braids to provide additional strength and flexibility. They are known for their excellent resistance to fuel leaks and can handle a wide range of temperatures.

- Braided Stainless Steel: For high-performance boats, braided stainless steel fuel lines are often preferred. This material offers superior strength, flexibility, and corrosion resistance, making it ideal for demanding marine applications.

Design Considerations:

The design of boat fuel lines involves several factors to ensure optimal performance and safety:

- Diameter and Routing: Fuel lines should be sized appropriately based on the boat's engine requirements and the flow rate of fuel. Proper routing is crucial to avoid sharp bends or kinks, which can restrict fuel flow and cause engine issues.

- Flexibility: Lines must be flexible to accommodate the vessel's movement during operation and storage. This is especially important for boats with limited space or those that experience significant vibration.

- Compatibility: Ensure that the fuel lines are compatible with the type of fuel used (e.g., gasoline, diesel) and the engine's fuel system.

Installation Process:

Installing boat fuel lines requires careful planning and execution:

- Preparation: Before installation, ensure the boat's fuel system is clean and free of debris. Inspect the engine and existing fuel lines for any damage or leaks.

- Routing: Route the new fuel lines following the manufacturer's guidelines or the boat's design. Secure the lines using appropriate clamps or ties to prevent movement and potential damage.

- Connections: Use high-quality fuel line connectors that are compatible with the chosen material. Ensure a tight and leak-free connection at all joints.

- Testing: After installation, start the engine and check for any fuel leaks. Test the fuel system under various operating conditions to ensure proper functionality.

Proper installation and regular maintenance of boat fuel lines are essential to prevent fuel-related issues and ensure the boat's engine operates efficiently. It is recommended to consult the boat's manual or seek professional assistance for specific installation requirements.

Mastering Fuel Line Tool: A Comprehensive Guide to Efficient Maintenance

You may want to see also

Direct Injection: Fuel delivery systems that inject fuel directly into the engine cylinders

Direct injection is a fuel delivery system that has revolutionized engine performance and efficiency. Unlike traditional port fuel injection, where fuel is injected into the engine's intake manifold, direct injection involves injecting fuel directly into the engine cylinders. This process offers several advantages that contribute to improved engine performance and fuel economy.

In a direct injection system, fuel is precisely injected into the combustion chamber at the precise moment it is needed. This ensures that the fuel is mixed with the air at the optimal ratio, resulting in more efficient combustion. The direct injection process allows for a higher compression ratio, which means the engine can produce more power for a given displacement. This is particularly beneficial for high-performance engines, where maximizing power output is crucial.

One of the key benefits of direct injection is the ability to optimize fuel usage. By injecting fuel directly into the cylinders, the system can control the fuel-air mixture more accurately. This results in better fuel atomization and mixing, ensuring that the combustion process is more complete and efficient. As a result, engines with direct injection can achieve higher fuel efficiency, reduced emissions, and improved overall performance.

Direct injection systems also offer improved low-end torque and smoother power delivery. The precise fuel injection timing allows for better control over the combustion process, resulting in a more responsive engine. This is especially noticeable during acceleration, where the engine delivers a strong, linear power response. Additionally, the direct injection system can provide better cold-start performance due to the precise fuel-air mixture control, ensuring that the engine starts efficiently even in cold conditions.

In summary, direct injection is a fuel delivery system that has transformed engine technology. Its ability to inject fuel directly into the cylinders offers numerous advantages, including improved power output, enhanced fuel efficiency, and better overall performance. This technology is widely used in modern vehicles, especially in high-performance engines, and continues to evolve, pushing the boundaries of engine capabilities.

Mantis Tiller Fuel Lines: Location Guide for Easy Access

You may want to see also

Fuel Pump Location: Placement of fuel pumps in boats for efficient fuel supply

The placement of fuel pumps in boats is a critical aspect of ensuring efficient fuel supply and optimal performance. When designing or modifying a boat's fuel system, understanding the optimal locations for fuel pumps is essential to avoid potential issues and ensure a reliable fuel supply. Here's a detailed guide on the placement considerations:

Engine Bay Placement: One of the most common and practical locations for fuel pumps in boats is within the engine bay. This placement offers several advantages. Firstly, it allows for easy access to the fuel lines, making maintenance and repairs more convenient. By locating the pump near the engine, you minimize the length of the fuel lines, reducing the risk of fuel degradation and ensuring a fresh supply directly to the engine. Additionally, placing the pump in the engine bay provides better protection from external elements, as it is typically enclosed and shielded from weather conditions.

Below Deck or Transom Mounting: For larger boats or those with specific design requirements, fuel pumps can be strategically placed below deck or on the transom. Below-deck mounting is ideal for boats with limited engine bay space, as it utilizes the available space efficiently. This location also provides a more discreet installation, reducing the risk of fuel spillage in case of a leak. Transom-mounted pumps are often used in smaller boats or those with inboard engines, where space constraints might make engine bay placement challenging.

Consider Pump Capacity and Flow Rate: When deciding on the placement, it's crucial to consider the pump's capacity and flow rate. The pump should be sized appropriately to handle the boat's fuel requirements. Insufficient pump capacity can lead to inadequate fuel supply, affecting engine performance. Additionally, ensure that the pump's flow rate matches or exceeds the engine's demand to maintain optimal fuel pressure and distribution.

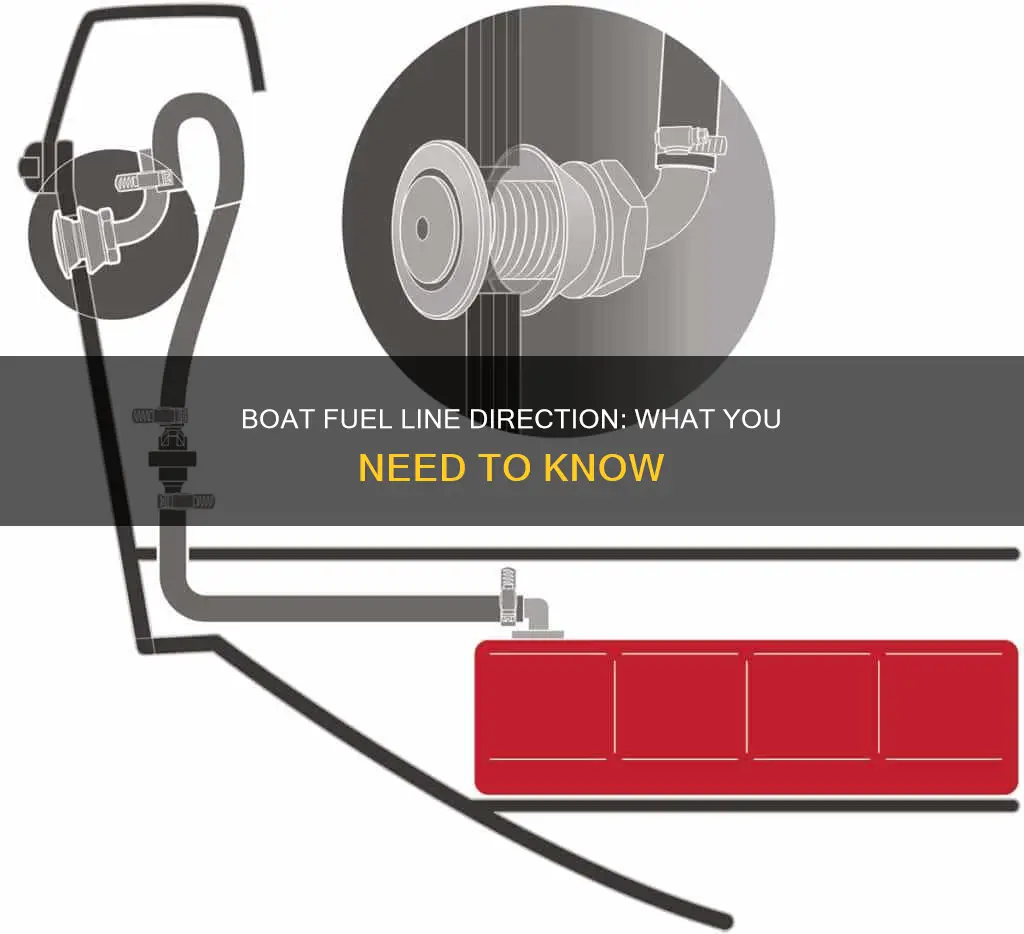

Fuel Line Routing: Proper fuel line routing is essential to prevent fuel contamination and ensure efficient fuel delivery. Fuel lines should be routed away from heat sources, such as exhaust systems or engine components, to maintain fuel temperature and prevent potential issues like fuel line cracking. Keep the lines as short as possible to minimize the risk of air bubbles and ensure a consistent fuel supply.

Regular Maintenance and Inspection: Regardless of the fuel pump location, regular maintenance and inspection are vital. Check for any signs of fuel line damage, leaks, or contamination. Keep the fuel pump and lines clean to prevent debris buildup, which can restrict fuel flow. Regularly inspect the fuel system for any potential issues, especially in areas with limited access, to ensure the system's longevity and reliable performance.

Unclipping the Ford Pink Fuel Line: A Step-by-Step Guide

You may want to see also

Fuel Line Routing: Best practices for organizing and routing fuel lines in a boat

When it comes to boat fuel line routing, organization and proper routing are crucial for optimal performance and safety. Here are some best practices to ensure efficient fuel line management:

- Plan the Route: Before starting the installation, carefully plan the path of the fuel lines. Consider the layout of your boat's engine compartment, the location of fuel tanks, and the proximity to other components. Aim for a route that minimizes bends and twists, as sharp turns can lead to fuel pressure issues and potential leaks. A well-planned route will also make future maintenance and repairs more accessible.

- Use Proper Materials: Choose fuel lines made from high-quality materials suitable for marine environments. Look for lines with a durable outer covering that can withstand the elements, including UV exposure, temperature fluctuations, and potential abrasion. Ensure the inner material is compatible with the type of fuel your boat uses to prevent any chemical reactions that could compromise the line's integrity.

- Secure and Protect: Properly secure the fuel lines to prevent movement and potential damage. Use appropriate clamps, ties, or brackets to attach the lines to the boat's structure, ensuring they are tight enough to eliminate slack but not so tight that they cause stress on the lines. Protect the fuel lines from sharp edges, protruding components, and potential impact areas to avoid punctures or damage.

- Keep It Clean and Dry: Fuel lines should be kept free from dirt, debris, and moisture. Use filters to prevent contaminants from entering the fuel system. Regularly inspect the lines for any signs of corrosion or damage, especially in areas where the lines pass through bulkheads or other structural members. Keep the lines dry to avoid rust and ensure the fuel's quality.

- Consider Future Upgrades: When routing fuel lines, think ahead to potential future modifications or upgrades. Allow enough space for additional lines or components, such as fuel pumps or filters. Proper planning will make it easier to accommodate changes without re-routing the entire system.

- Label and Document: Clearly label the fuel lines to identify their purpose and location. This is essential for quick identification during maintenance or repairs. Document the routing and any specific requirements, such as pressure ratings or fuel compatibility, to ensure future work aligns with the original setup.

By following these best practices, you can ensure that your boat's fuel lines are properly organized, routed efficiently, and well-maintained, contributing to the overall reliability and longevity of your vessel. Remember, a well-planned fuel line system is a critical aspect of boat ownership and operation.

Fixing a Steel Fuel Line: A Step-by-Step Guide

You may want to see also

Fuel Line Maintenance: Cleaning, inspection, and repair techniques for boat fuel lines

Boat fuel lines are an essential component of any vessel's propulsion system, and proper maintenance is crucial to ensure optimal performance and longevity. Over time, these lines can accumulate dirt, debris, and contaminants, leading to reduced fuel efficiency, engine performance issues, and potential safety hazards. This guide will provide an in-depth look at fuel line maintenance, covering cleaning, inspection, and repair techniques to keep your boat's fuel system in top shape.

Cleaning Fuel Lines:

Regular cleaning is vital to remove built-up contaminants and ensure smooth fuel flow. Start by disconnecting the fuel lines from the engine and fuel tank. Use a fuel line cleaner or a mixture of vinegar and water to flush the lines. Insert a flexible brush or a specialized fuel line cleaner tool into the lines to dislodge any stubborn deposits. For hard-to-reach areas, consider using compressed air to blow out any remaining debris. Rinse the lines thoroughly with clean water to remove any cleaning agent residue.

Inspection Techniques:

Regular visual inspections are key to identifying potential issues early on. Look for any signs of damage, such as cracks, leaks, or corrosion. Inspect the fuel lines for any bends or kinks that might restrict fuel flow. Check for visible contamination or discoloration, which could indicate the presence of water or fuel degradation. Pay attention to the connections and fittings; ensure they are tight and secure. If you notice any wear and tear or suspect a problem, it's best to consult a professional for further assessment.

Repair and Replacement:

In some cases, fuel lines may require repair or replacement. For minor leaks, you can use fuel line repair kits, which typically involve inserting a flexible repair sleeve over the damaged area and clamping it in place. For more severe damage, it's best to replace the entire fuel line. When replacing, ensure you use the correct size and type of fuel line for your boat's engine. Always disconnect the fuel supply before making any repairs or replacements to prevent fuel spills and potential hazards.

Preventative Measures:

To minimize the need for extensive maintenance, consider implementing preventative measures. Use fuel stabilizers to prevent fuel degradation, especially during extended storage periods. Keep the boat's fuel tank relatively full to minimize the risk of water accumulation. Regularly check and clean the fuel filter to prevent contaminants from entering the system. By taking these proactive steps, you can significantly extend the life of your fuel lines and overall engine performance.

Remember, proper fuel line maintenance is essential for the safe and efficient operation of your boat's engine. By following these cleaning, inspection, and repair techniques, you can ensure that your fuel lines remain in optimal condition, providing reliable performance on the water.

Choosing the Right Fuel Line for Effective Brake Bleeding

You may want to see also

Frequently asked questions

The fuel line direction in a boat engine is crucial for efficient fuel delivery and combustion. It ensures that the fuel flows in a specific path, allowing for proper atomization and mixing with air, which optimizes engine performance and fuel efficiency.

The direction of the fuel line can affect engine power, acceleration, and overall performance. Proper alignment ensures that the fuel is delivered to the engine at the right pressure and temperature, resulting in better engine response and reduced chances of fuel-related issues like stalling or misfires.

Yes, in some cases, the fuel line direction can be adjusted or modified. This might be necessary if the original setup is causing performance issues or if the boat's fuel system requires an upgrade. However, it should be done by a qualified marine mechanic to ensure compatibility and avoid potential engine damage.

Issues can arise if the fuel line is not routed correctly, leading to potential problems like fuel leaks, reduced engine power, or even engine damage. Common issues include kinks, bends, or improper connections in the fuel line, which can cause fuel starvation or inefficient combustion.

It is recommended to consult the boat's owner's manual or seek professional advice from a marine mechanic. They can provide specific guidance based on your boat's make and model, ensuring that the fuel line direction is optimized for your engine's performance and longevity.