Repairing a leaking fuel line is a crucial task for vehicle owners to ensure their engines run efficiently and safely. A leaking fuel line can lead to engine misfires, reduced performance, and potential environmental hazards. This guide will provide a step-by-step approach to fixing a leaking fuel line, covering the necessary tools, safety precautions, and the process of replacing or repairing the damaged section. By following these instructions, you can effectively address the issue and restore your vehicle's optimal performance.

What You'll Learn

- Identify the leak: Inspect the fuel line for visible damage, corrosion, or signs of fuel leakage

- Turn off the fuel supply: Stop the fuel flow by disconnecting the fuel line or turning off the fuel valve

- Drain the fuel tank: Empty the fuel tank to prevent further spillage and potential hazards

- Repair or replace: Depending on the damage, either repair the fuel line or replace it with a new one

- Test and re-fuel: After the repair, test the system to ensure no leaks and refuel the vehicle

Identify the leak: Inspect the fuel line for visible damage, corrosion, or signs of fuel leakage

When dealing with a leaking fuel line, the first step is to identify the source of the issue. This requires a thorough inspection of the fuel line itself, as well as the surrounding areas where it connects to other components. Start by visually examining the fuel line for any visible damage, such as cracks, punctures, or tears. Look for signs of corrosion, especially in areas where the line is exposed to the elements or in regions where it has been damaged by previous incidents. Even small cracks or pinholes can lead to significant fuel loss, so pay close attention to these details.

Check for any signs of fuel leakage around the connections and fittings. Over time, these connections can loosen or corrode, leading to leaks. Inspect the fuel line for any discolored or wet spots, which could indicate fuel seepage. It's also important to look for any signs of fuel accumulation, such as a sweet odor or a sticky residue, which may suggest a hidden leak. If you notice any of these indicators, it's crucial to investigate further to pinpoint the exact location of the leak.

In addition to visual inspection, listen for any unusual sounds coming from the fuel line. A hissing or bubbling noise could be a sign of fuel under pressure, indicating a potential leak. Feel the fuel line for any vibrations or pulsations, which might suggest a restricted flow or a leak. These sensory cues can provide valuable information about the nature and location of the problem.

If you're unable to identify the leak through visual inspection alone, consider using a fuel line inspection kit. These kits often include specialized dyes or indicators that can be injected into the fuel system. When the fuel line is leaking, the dye will be drawn to the affected area, making it visible and easier to pinpoint. This method can be particularly useful for hidden leaks or those that are not immediately apparent.

Remember, a careful and methodical inspection is key to identifying the source of the fuel line leak. By combining visual cues, sensory observations, and specialized tools, you can effectively locate the problem and proceed with the necessary repairs.

Mastering Fuel Line Maintenance: A Guide to Priming Bulb Replacement

You may want to see also

Turn off the fuel supply: Stop the fuel flow by disconnecting the fuel line or turning off the fuel valve

When dealing with a leaking fuel line, one of the most crucial steps is to turn off the fuel supply to prevent further damage and potential hazards. This process involves stopping the flow of fuel to the engine, which can be achieved through a few different methods.

The first approach is to disconnect the fuel line. Locate the fuel line, which is typically a rubber or plastic hose, and carefully detach it from the fuel tank and the engine. Ensure you identify the correct connections and use the appropriate tools if needed. By removing the fuel line, you effectively cut off the primary source of fuel to the engine, stopping the leak. This method requires caution to avoid spills and potential fuel wastage.

Alternatively, you can turn off the fuel valve, also known as the fuel shut-off valve. This valve is usually located near the fuel tank or along the fuel line. It is designed to control the flow of fuel and can be turned clockwise to shut off the supply. Locate the valve and use a wrench or a suitable tool to turn it, ensuring it is securely closed. This method provides a quick and effective way to stop the fuel flow without completely disconnecting the line.

It is important to note that turning off the fuel supply is a temporary measure and should be followed by a thorough inspection and repair of the leaking fuel line. Ignoring this step could lead to continued fuel leaks, potential engine damage, and safety risks. Once the fuel supply is stopped, you can proceed with the necessary repairs, ensuring a safe and efficient resolution to the leaking fuel line issue.

Aztek Fuel Disconnect: Step-by-Step Guide to Removing the Center Line

You may want to see also

Drain the fuel tank: Empty the fuel tank to prevent further spillage and potential hazards

If you're dealing with a leaking fuel line, one of the most critical steps is to drain the fuel tank to prevent further spillage and potential hazards. This process involves safely removing the fuel from the tank to mitigate the risk of fire, environmental damage, and other dangers associated with fuel leaks. Here's a step-by-step guide to help you through this process:

Step 1: Safety First

Before you begin, ensure you are working in a well-ventilated area and away from any open flames or sparks. Fuel is highly flammable, so it's essential to eliminate any potential ignition sources. Additionally, wear protective gear, including gloves and eye protection, to safeguard yourself from any fuel splashes or spills.

Step 2: Locate the Fuel Tank

Identify the fuel tank on your vehicle. It is typically located beneath the vehicle, along the frame rail. In some cases, it might be in the trunk or behind the rear seat. Consult your vehicle's manual if you're unsure of its exact location.

Step 3: Drain the Fuel Tank

- Park the vehicle on a level surface and engage the parking brake.

- Locate the fuel drain valve, which is usually a small opening on the bottom of the fuel tank. It might be covered with a rubber plug or a small cap.

- Insert a suitable drain pan or container beneath the drain valve to catch the fuel as it drains.

- Open the drain valve and allow the fuel to flow out slowly. This process may take some time, depending on the amount of fuel in the tank.

- Continue draining until the fuel flow slows to a trickle, ensuring you capture all the fuel.

Step 4: Secure the Fuel Line

Once the tank is empty, it's crucial to secure the fuel line to prevent any further leaks. Clean the fuel line and inspect it for any signs of damage or corrosion. If necessary, replace the fuel line with a new one. Ensure all connections are tight and secure.

Step 5: Test and Reassemble

After draining and securing the fuel line, test the vehicle to ensure there are no further leaks. If the issue is resolved, carefully reassemble any components you removed during the repair process.

Remember, working with fuel requires caution and attention to detail. Always follow safety guidelines and, if you're unsure, consult a professional mechanic to ensure the job is done safely and effectively.

Fuel Line Leaks: Signs and Solutions for Cracked Lines

You may want to see also

Repair or replace: Depending on the damage, either repair the fuel line or replace it with a new one

When dealing with a leaking fuel line, it's crucial to assess the damage and decide whether to repair or replace the affected component. The decision depends on the extent of the leak and the overall condition of the fuel line. Here's a step-by-step guide to help you make an informed choice:

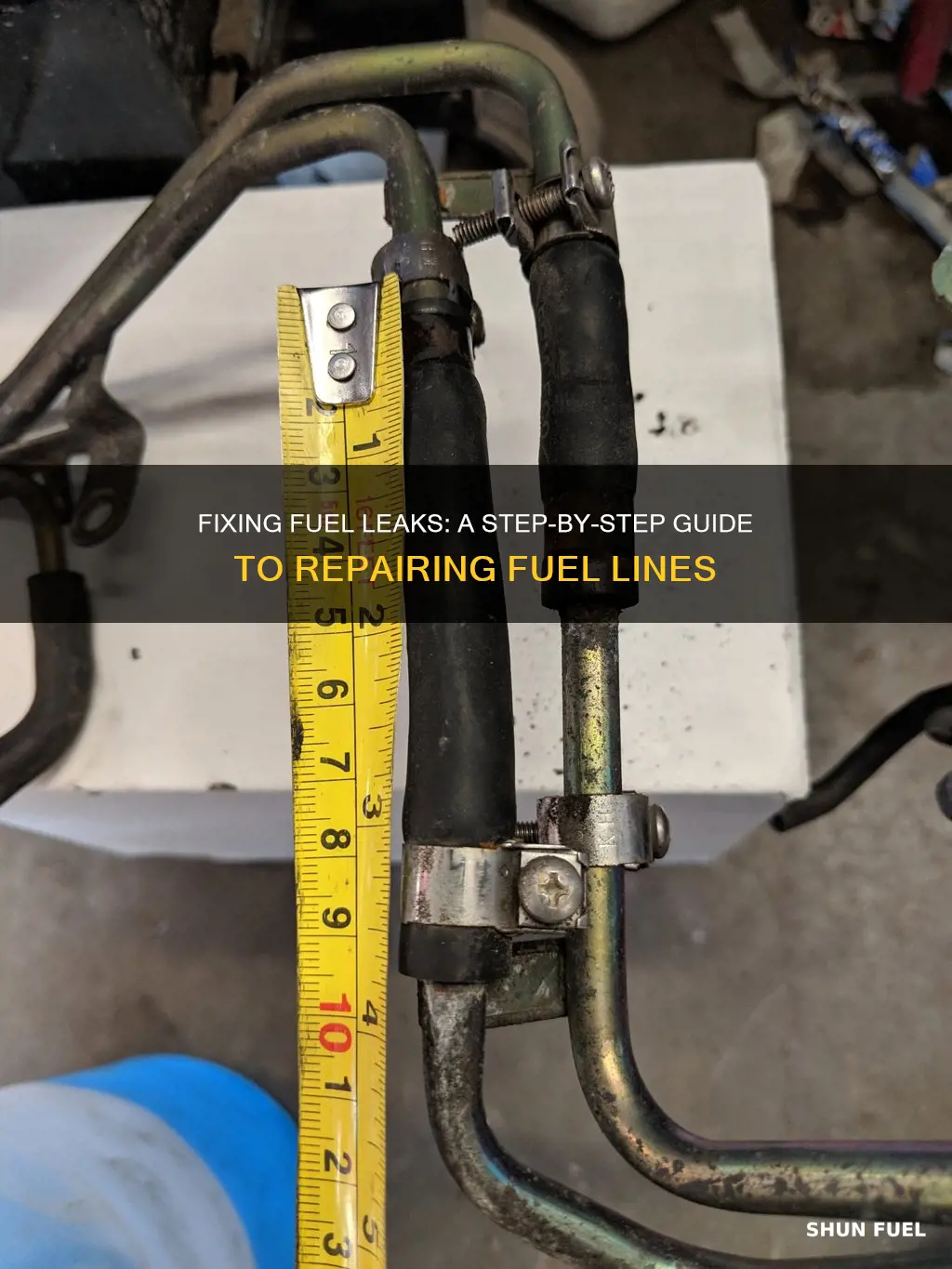

Assess the Damage: Start by inspecting the fuel line thoroughly. Look for any visible signs of damage, such as cracks, punctures, or corrosion. Check for wet spots or fuel residue around the line, as these could indicate a leak. If the damage is localized and the line appears intact elsewhere, repair might be a viable option. However, if the leak is widespread or the line is severely compromised, replacement is necessary.

Consider the Cause: Understanding why the fuel line is leaking is essential. Common causes include age-related deterioration, impact damage from accidents or collisions, or improper installation. If the leak is due to wear and tear, repair may be possible by replacing affected sections. In cases of impact damage or incorrect installation, the entire line might need to be replaced to ensure safety and prevent further issues.

Repair Process: If you decide to repair, the following steps can guide you:

- Gather the necessary tools and materials, including fuel line repair tape, clamps, and any specific tools required for your vehicle.

- Locate the leak and ensure the fuel supply is turned off.

- Carefully cut out the damaged section, ensuring you don't damage surrounding components.

- Clean the affected area and apply primer to create a secure bond.

- Wrap the repair tape around the cut ends, ensuring it's secure and covers the entire damaged area.

- Reattach the fuel line and secure it with clamps.

- Test the system to ensure there are no further leaks.

Replacement Procedure: Replacing the fuel line is a more extensive task:

- Purchase a new fuel line that is compatible with your vehicle.

- Locate the old line and disconnect it from the fuel tank and engine.

- Carefully route the new line, ensuring it is not pinched or damaged during installation.

- Secure the new line with clamps and connectors, following the manufacturer's instructions.

- Test the fuel system to ensure proper functionality and no leaks.

Remember, when dealing with fuel lines, safety is paramount. Always work on a level surface, wear protective gear, and ensure proper ventilation. If you're unsure about any step, consult a professional mechanic to ensure the job is done correctly and safely.

Chevy Equinox Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Test and re-fuel: After the repair, test the system to ensure no leaks and refuel the vehicle

After completing the fuel line repair, it's crucial to thoroughly test the system to ensure there are no leaks and that the vehicle is safe to operate. Here's a step-by-step guide to testing and refueling:

Step 1: Visual Inspection

Start by visually inspecting the fuel line and the surrounding areas for any signs of damage or disconnection. Look for any visible cracks, punctures, or loose connections. Pay close attention to the repair area to ensure it is clean and free of debris. This initial inspection will help you identify any potential issues that may have been missed during the repair process.

Step 2: Pressure Test

Connect a pressure gauge to the fuel line, ensuring it is securely attached. Turn on the vehicle's ignition but do not start the engine. Gradually increase the pressure in the fuel system using a hand pump or a specialized fuel pressure tester. Monitor the gauge to check for any drops in pressure, which could indicate a leak. If the pressure holds steady, it suggests the repair was successful. However, if there are any leaks, you may need to re-evaluate the repair and address the issue before proceeding.

Step 3: Leak Test

To perform a more comprehensive leak test, you can use a liquid leak detector or a soapy water solution. Apply the leak detector or a mixture of dish soap and water along the fuel line, especially at the repair site. Allow the vehicle to sit for a few minutes, then start the engine and observe for any bubbles or foam. If you notice any, it indicates a leak, and you should investigate further. This test is crucial to ensure the integrity of the repair.

Step 4: Refueling

Once you've confirmed that the fuel line is leak-free, it's time to refuel the vehicle. Ensure you use the correct fuel type recommended by the manufacturer. Fill the fuel tank until it is full, and then check the fuel gauge to confirm the correct level. After refueling, start the engine and let it run for a few minutes to ensure there are no immediate issues.

Step 5: Final Check

Before driving the vehicle, perform a final inspection to ensure everything is secure. Check all connections, including the fuel line to the engine and the fuel tank. Make sure there are no loose fittings or potential sources of future leaks. This final step provides peace of mind and ensures the safety of your vehicle.

Remember, proper testing and refueling procedures are essential to guarantee the success of the repair and the overall safety of your vehicle. Always follow manufacturer guidelines and consult a professional if you have any doubts or concerns during the process.

Honda Rancher 420 Fuel Line Removal: A Step-by-Step Guide

You may want to see also