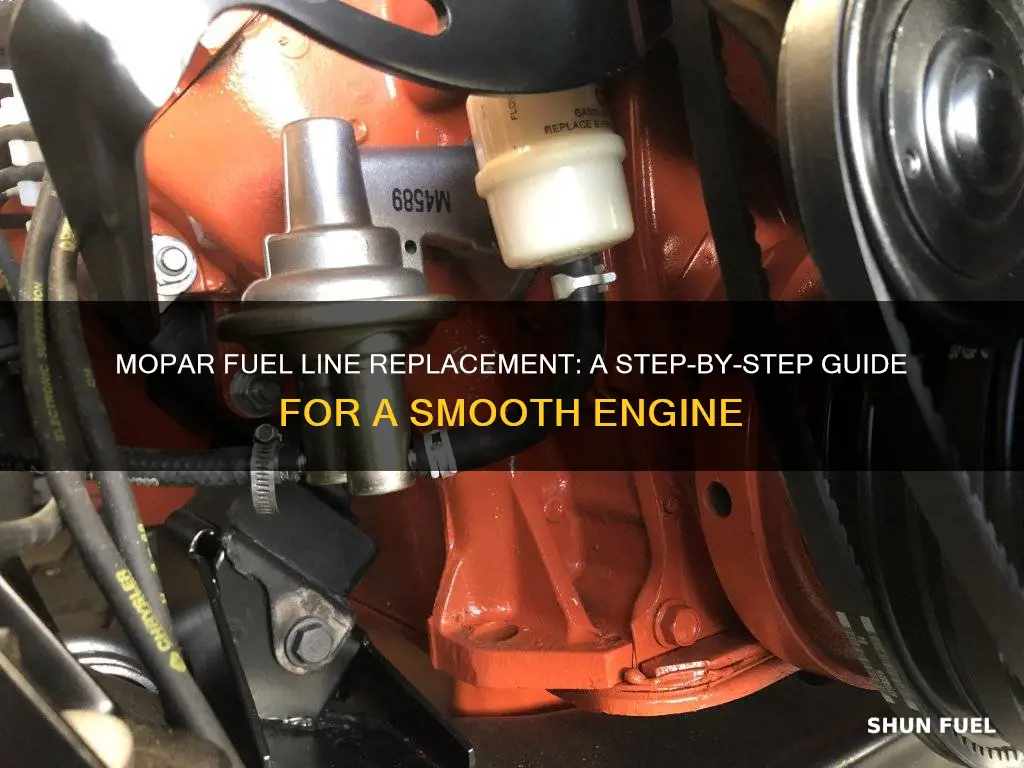

Running a new hard fuel line on a Mopar engine can be a rewarding project for any car enthusiast. This guide will provide a step-by-step process to ensure a successful installation, covering the necessary tools, materials, and techniques to achieve a reliable fuel delivery system. From preparing the components to making precise connections, this tutorial aims to simplify the process, ensuring your Mopar engine runs smoothly and efficiently with the new fuel line.

| Characteristics | Values |

|---|---|

| Fuel Type | Gasoline |

| Engine Type | Mopar |

| Line Material | Hard Plastic |

| Installation Process | Step-by-step guide available online |

| Tools Required | Wrench, pliers, fuel line cutter, primer |

| Time Required | Approximately 2-3 hours |

| Difficulty Level | Intermediate |

| Safety Precautions | Wear gloves and safety goggles; ensure engine is off and cooled before working |

| Common Issues | Leaks, improper fit, fuel contamination |

| Maintenance Tips | Regularly inspect for cracks or damage; replace if necessary |

What You'll Learn

- Fuel Line Inspection: Check for damage, cracks, and leaks before installation

- Fuel Line Routing: Route the line away from heat sources and sharp bends

- Fuel Line Fittings: Use the correct fittings and ensure tight connections

- Fuel Line Support: Secure the line with ties or clips to prevent movement

- Fuel Line Testing: Test for leaks and pressure after installation

Fuel Line Inspection: Check for damage, cracks, and leaks before installation

Before you begin the installation of a new hard fuel line for your Mopar vehicle, a thorough inspection is crucial to ensure the system's integrity and prevent potential issues. This process involves checking for any signs of damage, cracks, or leaks that could compromise the fuel system's performance and safety. Here's a step-by-step guide to inspecting the fuel line:

- Visual Inspection: Start by visually examining the existing fuel line. Look for any visible signs of wear, such as brittleness, softening, or discoloration. Check for cracks, punctures, or any other physical damage along the length of the line. Pay close attention to bends, fittings, and connections, as these areas are more susceptible to damage. If you notice any severe damage, it may indicate a need for replacement rather than just a repair.

- Flexibility Test: Fuel lines should be flexible to accommodate engine movement. Test the flexibility by gently bending the line at various points. It should yield without permanent deformation. If the line becomes stiff or breaks when bent, it could indicate internal damage or the need for replacement.

- Pressure Test: A pressure test is essential to identify potential leaks. Use a fuel pressure gauge and a small amount of compressed air to apply pressure to the fuel line. Check for any hissing sounds or fuel leakage around connections and fittings. Leaks can occur at damaged areas or where the line connects to the fuel pump, injectors, or tank. Address any leaks immediately, as they can lead to fuel loss and potential engine performance issues.

- Connection Inspection: Carefully inspect all connections, including the fuel pump, injectors, and the fuel tank. Ensure that all fittings are tight and secure. Over time, connections can loosen, leading to fuel leaks. Also, check for any signs of corrosion or damage around the connections, as this can affect the flow of fuel.

- Documentation: Document the condition of the fuel line before removal. Take notes on any issues found, such as specific locations of damage or leaks. This documentation will be valuable when deciding whether to replace or repair the line and can help in troubleshooting any future problems.

By following these inspection steps, you can identify potential issues with the fuel line before the new installation, ensuring a smoother and safer process for your Mopar vehicle. Regular maintenance and inspections are key to keeping your fuel system reliable and efficient.

Where to Find 1/4 Clear Fuel Lines: A Comprehensive Guide

You may want to see also

Fuel Line Routing: Route the line away from heat sources and sharp bends

When installing a new hard fuel line for your Mopar vehicle, proper routing is crucial to ensure optimal performance and longevity. One essential aspect of this process is to route the fuel line away from potential heat sources and sharp bends. Here's a detailed guide on how to achieve this:

Identify Heat Sources: Begin by thoroughly inspecting your vehicle's engine bay and surrounding areas. Locate any components that generate significant heat, such as the exhaust manifold, catalytic converter, or engine block. These heat sources can cause the fuel line to degrade over time. It's important to keep the fuel line at a safe distance from these areas to prevent damage.

Plan the Route: Before you start routing the fuel line, carefully plan its path. Aim to create a straight and smooth route that avoids any sharp bends or kinks. Consider the natural flow of the engine bay and try to utilize the available space efficiently. By keeping the route as straight as possible, you minimize the risk of stress and potential leaks.

Use Appropriate Materials: Ensure that the fuel line material is compatible with the fuel type and operating temperatures in your Mopar vehicle. Hard fuel lines are typically made of durable materials like steel or high-density polyethylene (HDPE) to withstand high pressure and temperature variations. Choose the appropriate size and thickness to handle the fuel flow requirements of your engine.

Route Away from Heat and Bends: As you begin routing the fuel line, maintain a safe distance from heat sources. Wrap the line around the engine bay, utilizing rubber or plastic grommets or protective sleeves to guide it. Avoid sharp bends by using elbows or bends that provide a gentle radius. This practice reduces the risk of stress concentrations, which can lead to cracks or leaks over time.

Secure and Protect: Secure the fuel line using appropriate ties or clips to keep it in place and prevent movement. Ensure that the line is not pinched or subjected to excessive pressure. Additionally, consider using heat shields or protective covers to further safeguard the fuel line from direct heat exposure. This extra layer of protection will contribute to the overall reliability of your fuel system.

By following these instructions, you can ensure that your Mopar vehicle's fuel line is properly routed, away from heat sources and sharp bends, resulting in a reliable and efficient fuel supply. Remember, taking the time to plan and execute the routing process correctly will contribute to the long-term performance and durability of your vehicle's fuel system.

Will Heet Unfreeze Fuel Line? A Comprehensive Guide

You may want to see also

Fuel Line Fittings: Use the correct fittings and ensure tight connections

When dealing with fuel lines, especially in a classic car like the Mopar, it's crucial to use the right fittings and ensure secure connections to maintain optimal performance and safety. Here's a detailed guide on how to approach this task:

Understanding the Importance of Proper Fittings:

Fuel lines are responsible for transporting fuel from the tank to the engine, and any compromise in their integrity can lead to serious issues. Using incorrect fittings can result in fuel leaks, reduced performance, and even potential fire hazards. Mopar vehicles, known for their classic style and powerful engines, demand precision and attention to detail when it comes to fuel system maintenance.

Identifying the Right Fittings:

Start by referring to the Mopar vehicle's manual or seeking guidance from a reputable mechanic. They will provide specific recommendations for fuel line fittings compatible with your car's make and model. Look for fittings that are designed to withstand the pressure and temperature variations associated with fuel systems. Common types include barbed fittings, compression fittings, and quick-connect fittings, each with its own advantages and use cases.

Assembly and Connection Techniques:

- Barbed Fittings: These are commonly used for fuel lines. Ensure the barbed end is inserted into the corresponding hole, and then tighten the nut securely. Use a wrench to avoid over-tightening, which can damage the fitting.

- Compression Fittings: These require a ferrule to be compressed over the fuel line. Slide the ferrule onto the line, then insert the fitting and tighten it. Again, be cautious not to overtighten.

- Quick-Connect Fittings: These are convenient for temporary connections or when replacing sections of fuel lines. Simply push the fitting onto the line and ensure a snug fit.

Ensuring Tight Connections:

The key to a successful fuel line installation is a tight, leak-free connection. Here's how to achieve that:

- Cleanliness is Key: Ensure all surfaces are clean and free of debris. Use a cloth or brush to remove any dirt or old fuel residue.

- Thread Seal Tape or Tape: Apply a thin layer of thread seal tape (also known as pipe dope) to the threads of the fittings and fuel line ends. This provides an extra layer of protection against leaks.

- Tighten Securely: Use the appropriate tools to tighten the fittings. A ratchet or wrench should be applied in a controlled manner, ensuring the fitting is secure but not over-tightened.

- Test for Leaks: After assembly, start the engine and check for any fuel leaks. If any are found, tighten the connections further or re-evaluate the fitting type.

By following these steps and paying close attention to the quality of your connections, you can ensure that your Mopar's fuel lines are reliable and perform optimally. Remember, when working with fuel, safety and precision are paramount.

Mastering the Fuel Line Removal: A Guide for Chrysler PT Cruiser Owners

You may want to see also

Fuel Line Support: Secure the line with ties or clips to prevent movement

When installing a new hard fuel line for your Mopar vehicle, ensuring the fuel line is securely supported is crucial to prevent any potential issues and maintain optimal performance. One of the key steps in this process is to secure the fuel line with ties or clips to minimize movement and potential damage. Here's a detailed guide on how to achieve this:

Start by identifying the optimal locations for securing the fuel line. Typically, you'll want to attach the ties or clips at regular intervals along the length of the fuel line. These points should be chosen carefully, considering the line's flexibility and the potential for movement due to engine vibrations. Avoid securing the line too close to sharp bends or areas where it might rub against other components, as this could lead to premature wear and potential leaks.

Using ties or clips specifically designed for fuel lines is essential. These accessories are typically made of durable materials that can withstand the harsh conditions inside the engine bay. You can find these ties or clips at auto parts stores or online retailers specializing in Mopar accessories. Ensure you get the appropriate size and type for your fuel line diameter to ensure a secure and snug fit.

To secure the fuel line, thread the ties or clips through the line's protective covering, being careful not to damage the inner fuel-carrying tube. Tighten the ties or clips firmly but gently to hold the line in place without causing any kinks or bends that could restrict fuel flow. It's important to maintain a consistent tension along the entire length of the line to ensure an even support.

Remember, the goal is to provide support without restricting the fuel line's natural movement. Over-tightening can lead to unnecessary stress on the line, potentially causing it to fail prematurely. Regularly inspect the secured fuel line during and after the installation process to ensure it remains intact and secure.

By following these steps and paying close attention to fuel line support, you'll ensure a successful and reliable installation of your new hard fuel line for your Mopar vehicle. This attention to detail will contribute to the overall performance and longevity of your engine's fuel system.

Replacing the Fuel Line: A Step-by-Step Guide for the FS55R

You may want to see also

Fuel Line Testing: Test for leaks and pressure after installation

After installing a new hard fuel line for your Mopar vehicle, it is crucial to conduct thorough testing to ensure optimal performance and prevent potential issues. Here's a step-by-step guide on how to test the fuel line for leaks and pressure:

Leak Testing:

- Park your vehicle on a level surface and allow the engine to cool down. This is important to avoid any potential hazards from hot engine components.

- Locate the fuel line connections, typically found under the hood or near the fuel tank. Use a fuel line inspection kit or a simple piece of rubber tubing to temporarily cover the connections.

- Start the engine and turn it off immediately if any fuel is observed dripping or leaking from the covered connections. This simple test will help identify any potential issues with the installation.

- If no leaks are detected, you can further test the system by temporarily disconnecting the fuel line at various points and checking for any fuel flow. Use a clear container to catch any fuel that might escape, and ensure the engine is off during this process.

- Reattach the fuel line connections securely and double-check for any visible signs of leaks.

Pressure Testing:

- Ensure your vehicle's engine is off and in a stable condition.

- Locate the fuel pump and its electrical connection. You might need to access the engine compartment from below to find the pump.

- Disconnect the fuel pump's electrical connector and temporarily block the fuel line to create a closed system. This can be done using a piece of rubber tubing or a temporary block.

- Use a fuel pressure gauge to measure the pressure at the fuel pump. The gauge should read a specific value, typically around 45-60 psi (pounds per square inch) for Mopar vehicles. Refer to your vehicle's manual for the correct pressure range.

- If the pressure is not within the specified range, there might be an issue with the fuel pump or the fuel pressure regulator. In such cases, further investigation and potential repairs are necessary.

- Reattach the electrical connector and ensure the fuel line is secure. Start the engine and check for any unusual noises or behavior.

Remember, proper testing ensures the longevity of your vehicle's fuel system and helps identify any potential issues early on. Always refer to your Mopar vehicle's manual for specific instructions and recommendations regarding fuel line installation and testing.

Unclogging the Fuel Flow: A Guide to Removing Tight Fuel Lines

You may want to see also

Frequently asked questions

Replacing the fuel line is essential for maintaining optimal engine performance and safety. Over time, fuel lines can degrade due to heat, fuel contamination, or physical damage, leading to potential fuel leaks, reduced power, and even engine failure.

Look out for signs like fuel odors in the cabin, engine misfires, reduced power, or unusual noises from the fuel system. If you notice any of these symptoms, it's best to have the fuel line inspected by a professional mechanic.

The process involves removing the old fuel line, cleaning the fuel system, and installing the new hard fuel line. This requires careful disassembly of the engine and fuel system components. It's recommended to follow a detailed repair manual or seek professional assistance to ensure a proper installation.

Yes, you'll need various tools such as wrenches, sockets, fuel line cutters, and crimping tools. It's also advisable to have a fuel line inspection kit to identify any potential issues with the existing fuel lines before replacement.

While it is possible to replace the fuel line yourself, especially if you have experience with engine repairs, it is highly recommended to have a professional mechanic perform the task. This ensures a proper and safe installation, adhering to the manufacturer's guidelines.