Fuel lines are an essential component of any vehicle's engine, and proper maintenance is crucial to ensure optimal performance and safety. One common issue that car owners may encounter is the need to undo fuel line clips, which can be a challenging task without the right tools and knowledge. This guide will provide a step-by-step process to safely and effectively remove fuel line clips, ensuring that your vehicle's fuel system remains intact and functional. Understanding the process can save time and prevent potential damage to your car.

| Characteristics | Values |

|---|---|

| Method | Using a pair of pliers or a fuel line clip removal tool |

| Tools Required | Pliers, fuel line clip removal tool, or a flat-head screwdriver |

| Process | 1. Locate the fuel line clip. 2. Insert the tool between the clip and the fuel line. 3. Apply firm pressure to loosen the clip. 4. Carefully pull the clip away from the fuel line. |

| Precautions | Ensure you have the correct tool for the specific clip type. Be gentle to avoid damaging the fuel line. |

| Common Issues | Clips may be stuck due to corrosion or tight fits. Using the right tool can help overcome this. |

| Alternative | For stubborn clips, consider heating the clip slightly to make it more pliable before attempting to remove it. |

What You'll Learn

- Locate the fuel line clips: Identify the clips holding the fuel line in place

- Release the clips: Gently pull the clips apart to loosen their grip

- Inspect and clean: Check for damage and clean any debris

- Reattach with care: Securely reconnect the fuel line, ensuring a tight fit

- Test for leaks: Verify the system's integrity by checking for any leaks

Locate the fuel line clips: Identify the clips holding the fuel line in place

When working on a vehicle's fuel system, it's crucial to first identify the clips that secure the fuel line. These clips are typically small, metal or plastic fasteners that hold the fuel line in place, ensuring it remains taut and secure. They are often located at regular intervals along the length of the fuel line, providing support and preventing the line from sagging or coming loose.

To locate these clips, you'll need to inspect the fuel line carefully. Start by tracing the path of the fuel line from the fuel tank to the engine or other components it supplies. Look for any points where the line changes direction or where it is secured to other parts of the vehicle. The clips are usually visible and can be found at these junctures. They might be attached to the fuel line itself or to the surrounding components, such as the engine block or frame.

In some cases, the clips may be hidden behind other parts or under protective covers. If this is the case, you might need to remove some of the surrounding components to gain access. For example, you might need to take off a section of the engine cover or remove a few screws to expose the clips. Once you've identified their positions, you can proceed with the next steps in the process of undoing the clips.

It's important to note that the specific location of the clips can vary depending on the vehicle's make and model. Some vehicles might have more clips than others, and their placement can differ based on the design of the fuel system. Always refer to your vehicle's service manual or consult a professional mechanic if you're unsure about the location of the clips or how to proceed with the repair.

By carefully inspecting the fuel line and its surroundings, you can effectively locate the clips holding it in place. This knowledge is essential for safely and successfully undoing the clips and performing any necessary repairs or maintenance on the fuel system.

Perfect Fuel Line Size for Husqvarna 137 Chainsaw

You may want to see also

Release the clips: Gently pull the clips apart to loosen their grip

When dealing with fuel line clips, it's important to approach the task with care and precision. The goal here is to release the clips without causing any damage to the fuel lines or the surrounding components. Start by identifying the clips you need to remove. These clips are typically made of plastic or metal and are designed to hold the fuel line in place. Locate the clips along the length of the fuel line, ensuring you know which ones need to be loosened.

Gently grasp the clips with your fingers, taking care not to apply excessive force. The key is to loosen the grip of the clips without forcing them off. Begin by pulling the clips apart in a slow and controlled manner. You might feel some resistance as the clips start to release their hold. Be patient and apply a steady, gentle force. Avoid jerking or pulling too hard, as this can lead to damage or dislodgement of the clips.

As you pull, you may notice that the clips start to move apart, revealing the fuel line beneath. Continue this process until you have loosened all the clips along the desired section of the fuel line. Remember, the goal is to loosen the clips, not to remove them completely. You can use a small tool, such as a flathead screwdriver or a pair of pliers, to assist in the process if needed, but always exercise caution to avoid any accidental damage.

Once you've loosened the clips, you'll have more flexibility to work on the fuel line or make any necessary adjustments. This step is crucial in ensuring that you can access the fuel line for maintenance, repairs, or any other tasks without causing unnecessary strain or damage. Always take your time and be mindful of the clips' position to avoid any potential issues.

T100 Fuel Line Guide: Choosing the Right Option

You may want to see also

Inspect and clean: Check for damage and clean any debris

When dealing with fuel line clips, it's crucial to inspect and clean the components thoroughly to ensure a successful undoing process. Begin by carefully examining the fuel line clips for any signs of damage or wear. Look for cracks, bends, or any visible deterioration that might indicate the clips are no longer functional or secure. Pay close attention to the clips' condition, as they play a vital role in holding the fuel lines in place. If you notice any damage, it's essential to replace the affected clips to maintain the integrity of the fuel system.

Next, focus on the fuel lines themselves. Inspect the lines for any debris, dirt, or grime that might have accumulated over time. This debris can interfere with the clips' ability to grip the fuel lines tightly. Use a soft-bristled brush or a small, clean cloth to gently remove any visible dirt or contaminants. Ensure that you clean the entire length of the fuel lines, paying extra attention to areas where the clips are attached, as these spots might have more debris buildup.

As you clean, be mindful of the fuel line's material and color. Different types of fuel lines may have varying cleaning requirements. For instance, some lines might be made of rubber, while others could be constructed from a flexible plastic. Always refer to the manufacturer's guidelines or consult a professional if you're unsure about the specific cleaning method for your fuel lines. The goal is to restore the fuel lines to their original condition, ensuring they are free from any obstructions that could hinder the undoing process.

Once you've completed the inspection and cleaning, take a moment to reassess the fuel line clips. Check if the clips are now easier to manipulate due to the cleaned fuel lines. The process of undoing the clips might require some patience, especially if they have become stiff or corroded over time. Remember, the goal is to create a smooth and unobstructed environment for the clips to release their grip on the fuel lines.

In summary, inspecting and cleaning the fuel line clips and their associated components is a critical step in the process of undoing them. By carefully examining for damage, removing debris, and ensuring the fuel lines are clean, you create the necessary conditions for a successful undoing. This thorough approach helps prevent further complications and ensures the overall health and functionality of the fuel system.

Freezing Fuel: The Impact of Water in Fuel Lines

You may want to see also

Reattach with care: Securely reconnect the fuel line, ensuring a tight fit

Reattaching a fuel line can be a delicate process, and it's crucial to follow the correct steps to ensure a secure and safe connection. Here's a comprehensive guide on how to carefully reconnect the fuel line, ensuring a tight and reliable fit:

Step 1: Prepare the Components

Before you begin, make sure you have all the necessary tools and components ready. You'll need a new set of fuel line clips (or you can reuse the original ones if they are in good condition), a fuel line (if you need to replace it), and a wrench or fuel line tool. Inspect the fuel line for any signs of damage or wear. If it's old or damaged, consider replacing it to ensure optimal performance. Clean the fuel line and the clips to remove any dirt or debris that might interfere with the connection.

Step 2: Locate the Fuel Line Clips

Identify the fuel line clips that hold the fuel line in place. These clips are typically located along the length of the fuel line, often at regular intervals. Carefully inspect the clips for any signs of damage or wear. If a clip is broken or damaged, replace it with a new one. Ensure that the new clips are the correct size and shape for your fuel line.

Step 3: Loosen the Existing Clips

Using the appropriate tool, carefully loosen the existing fuel line clips. Turn the clips counterclockwise to release their grip on the fuel line. Be gentle but firm to avoid damaging the fuel line or the clips themselves. Take note of the position of the clips to ensure you can reattach them correctly.

Step 4: Remove the Fuel Line

Once the clips are loosened, carefully remove the fuel line from the vehicle. Slide the fuel line out of the clips, being mindful of any connections or fittings along the way. If the fuel line is stubborn, you may need to apply some gentle force, but be careful not to twist or kink the line.

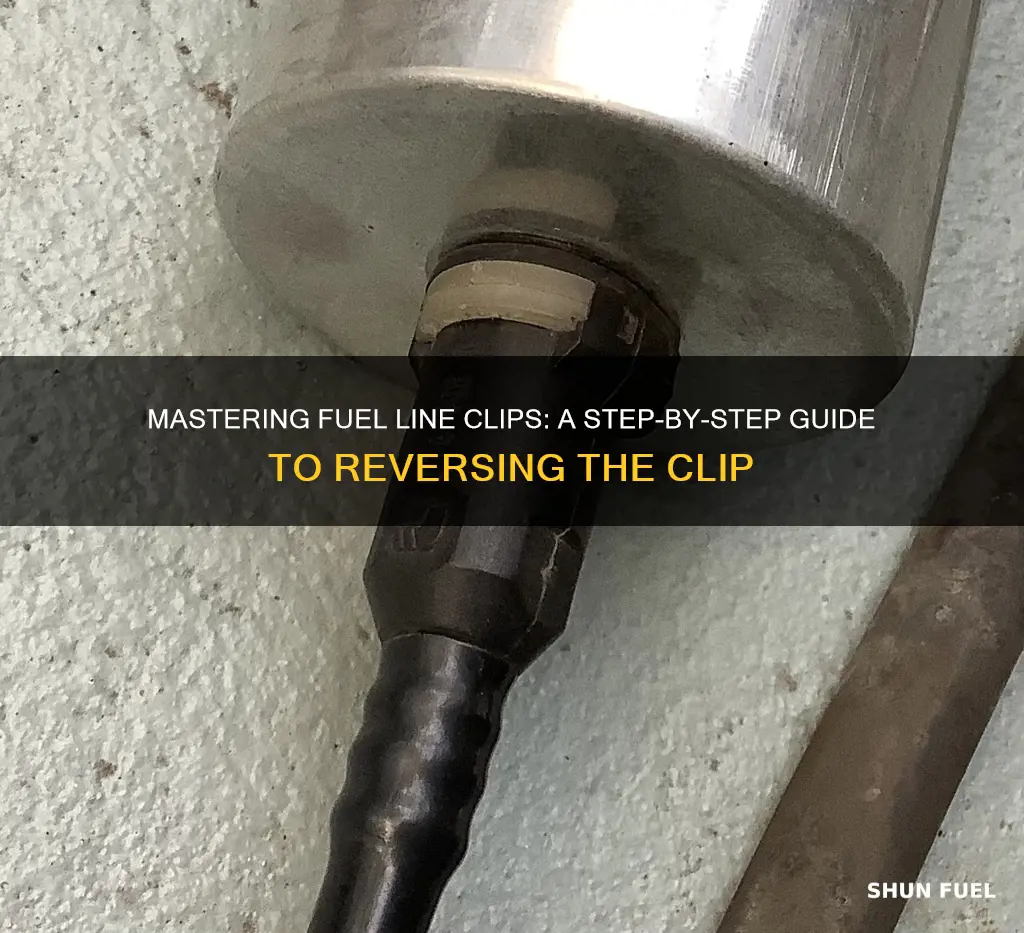

Step 5: Reattach with Care

Now, it's time to reattach the fuel line. Start by positioning the fuel line through the new clips, ensuring it is aligned correctly. Push the fuel line into the clips, one by one, until it is fully inserted. Tighten the clips securely by turning them clockwise with the appropriate tool. Ensure that each clip is tightened evenly and securely to provide a tight fit.

Step 6: Final Checks

After reattaching the fuel line, perform a few crucial checks. First, inspect the connections for any leaks. Even a small drip can indicate a loose connection. If you notice any leaks, tighten the clips further or consider replacing the fuel line if it's significantly damaged. Additionally, test the fuel line's flexibility and movement to ensure it is functioning correctly.

By following these steps with care and precision, you can successfully reattach the fuel line, ensuring a tight and secure connection. Remember, taking your time and being meticulous during this process will contribute to the overall reliability and safety of your vehicle's fuel system.

Fuel Line Removal: A Step-by-Step Guide for LBZ Owners

You may want to see also

Test for leaks: Verify the system's integrity by checking for any leaks

To ensure the proper functioning and safety of your vehicle's fuel system, it's crucial to verify its integrity by checking for any leaks. This process is essential, especially after any work involving the fuel lines or system. Here's a step-by-step guide to testing for leaks:

- Gather the Necessary Tools and Materials: Before you begin, ensure you have the required tools and materials. You'll need a fuel system pressure tester, which can be rented or purchased from most auto parts stores. Additionally, have some clean rags or paper towels ready to wipe up any spills.

- Park in a Well-Ventilated Area: Choose a safe and open space to work on your vehicle. Park it in a well-ventilated area, preferably outdoors, to avoid inhaling any potential fuel vapors. Ensure the engine is cool to the touch before proceeding.

- Locate the Fuel System Components: Familiarize yourself with the fuel system's components. Locate the fuel tank, fuel lines, and the fuel pump. Identify the pressure regulator and the fuel injectors or carburetor (depending on your vehicle's setup).

- Disconnect the Negative Battery Terminal (Optional): For added safety, you can disconnect the negative battery terminal to prevent any accidental electrical discharges while testing. This step is optional but recommended for added precaution.

- Apply the Pressure Tester: Attach the pressure tester to the fuel line, typically near the fuel pump or the pressure regulator. Turn on the engine and allow it to idle. Operate the pressure tester according to the manufacturer's instructions. You should hear a hissing sound if there are any leaks. If you hear a continuous hiss, it indicates a significant leak.

- Check for Visual Leaks: While the engine is idling, visually inspect the fuel system for any signs of leaks. Look for wet spots on the ground or any fuel that has seeped out. Check the fuel lines for any visible damage, cracks, or disconnections. Also, inspect the fuel tank and its connections for any signs of leakage.

- Tighten Connections and Reassemble: If you identify any leaks, carefully tighten the connections and ensure all components are properly reassembled. Make sure all fuel lines are securely attached and there are no sharp bends that could cause damage.

- Re-test and Verify: After making any necessary adjustments, re-test the fuel system using the pressure tester. Ensure that all leaks have been resolved. If you still detect leaks, further investigation and repairs may be required.

Remember, regular maintenance and testing of your vehicle's fuel system are vital to prevent potential hazards and ensure optimal performance. By following these steps, you can effectively verify the integrity of your fuel system and address any issues promptly.

Powerful Engine Demands: Choosing the Right Fuel Line for 1200HP

You may want to see also

Frequently asked questions

Fuel line clips are small metal or plastic fasteners used to secure fuel lines to various components in an engine bay. They help to keep the fuel lines in place and prevent them from moving or rubbing against other parts, which could lead to damage or fuel leaks.

Undoing a fuel line clip typically involves using a pair of pliers or a small adjustable wrench. Locate the clip you want to remove and insert the tool's jaws or grip into the clip's opening. Apply gentle but firm pressure to loosen and remove the clip. Be careful not to damage the fuel line during this process.

Yes, fuel line clips can often be reused. Ensure that the clip is not damaged or bent, as this could affect its ability to hold the fuel line securely. Clean the clip if necessary and reattach it to the fuel line, following the same procedure as when initially installing it.

If a fuel line clip is stubborn and won't budge, you can try applying a small amount of fuel line solvent or a similar lubricant to the clip and the surrounding area. Allow it to soak for a few minutes, then gently try to remove it again. Be cautious not to over-tighten or force the clip, as it may damage the fuel line.

While a standard set of pliers or a wrench is usually sufficient, you might find a fuel line removal tool or a specialized clip removal tool useful in certain situations. These tools are designed to grip and remove clips without damaging the fuel line. They can be especially helpful for tight or hard-to-reach clips.