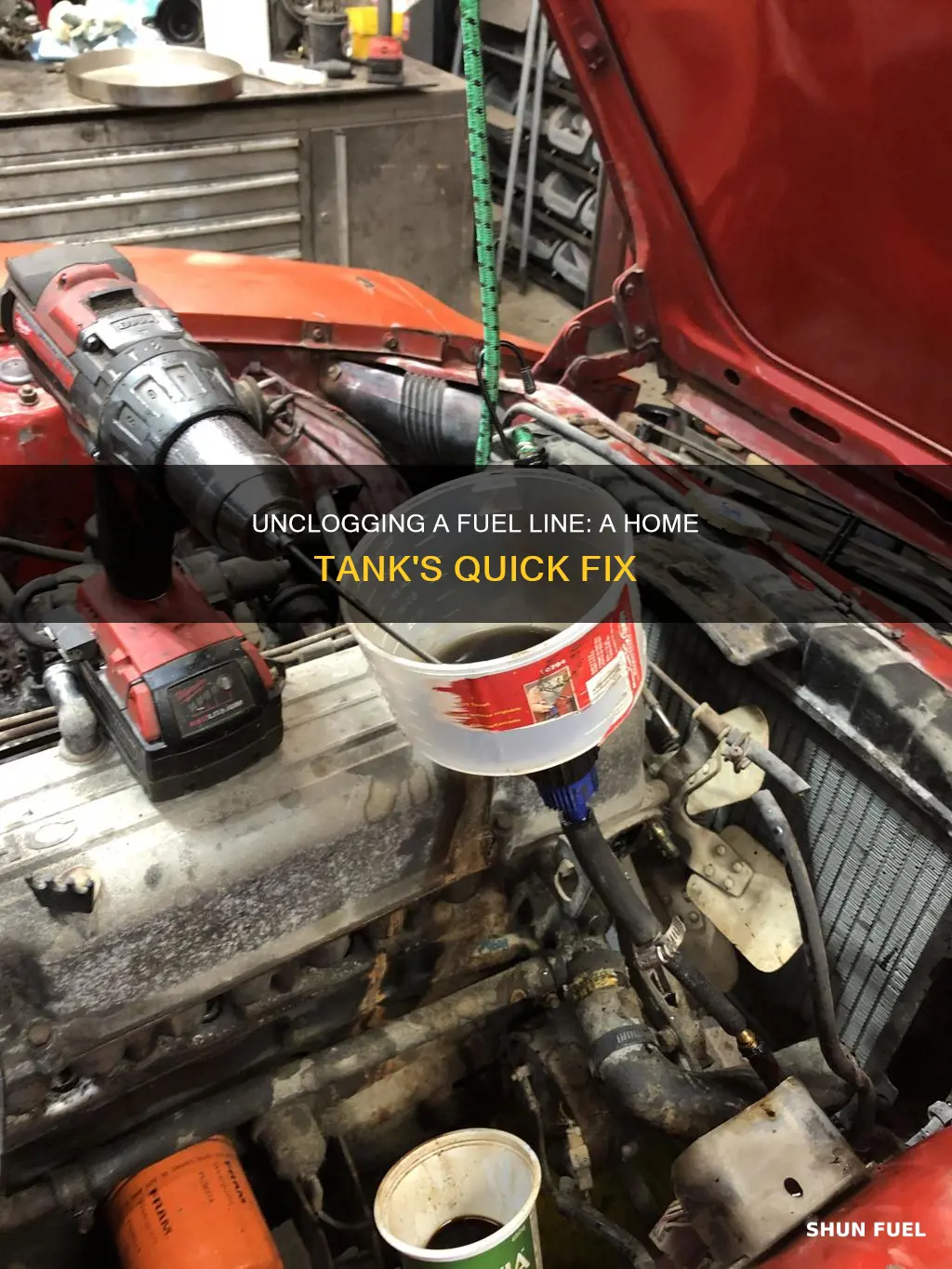

Unclogging a fuel line in a home tank can be a straightforward process if you follow the right steps. Start by ensuring the tank is empty and the fuel line is disconnected. Use a fuel line cleaner or a compressed air gun to clear any blockages. Inspect the line for any debris or clogs and clear them carefully. If the issue persists, consider consulting a professional for further assistance. Remember to always prioritize safety and wear protective gear when working with fuel.

What You'll Learn

- Identify the Problem: Check for fuel line blockages, leaks, or damage

- Prepare the Tank: Ensure safety by draining fuel and disconnecting the line

- Locate the Clog: Use a fuel line cleaner or compressed air to clear blockages

- Clean and Inspect: Remove debris and inspect for further issues

- Reattach and Test: Securely reconnect the fuel line and test the system

Identify the Problem: Check for fuel line blockages, leaks, or damage

Before attempting to unclog a fuel line on your home tank, it's crucial to identify the problem at hand. This step is essential to ensure you're addressing the root cause and to prevent any further complications. Here's a detailed guide on how to check for fuel line blockages, leaks, or damage:

- Inspect the Fuel Line Visually: Start by visually inspecting the fuel line for any visible signs of damage or blockages. Look for kinks, bends, cracks, or any visible obstructions along the length of the fuel line. Fuel lines are typically made of rubber or plastic and can be susceptible to wear and tear over time. Check for any signs of deterioration, especially in areas where the line connects to the tank or the engine.

- Check for Leaks: Fuel line leaks can be a serious issue and often require immediate attention. Inspect the fuel line for any wet spots or signs of fuel seepage. Leaks can occur at connections, fittings, or where the line passes through the tank or engine compartments. If you notice any leaks, it's crucial to address them promptly to prevent fuel wastage and potential fire hazards.

- Inspect the Fuel Tank: Open the fuel tank cap and examine the interior for any signs of debris, rust, or blockages. Over time, sediment can accumulate at the bottom of the tank, and small particles may enter the fuel line. If you notice any significant buildup or debris, it could indicate a potential blockage further down the line.

- Listen for Fuel Flow: Use your ears to listen to the sound of fuel flowing through the line. If you notice a change in the sound or a complete absence of fuel flow, it may indicate a blockage. A complete blockage can be caused by clogs, debris, or a damaged fuel pump.

- Use a Fuel Line Inspection Camera (Optional): For more severe cases or if you suspect internal blockages, consider using a fuel line inspection camera. This camera can be inserted into the fuel line to provide a visual inspection of the interior. This method can help identify blockages, clogs, or damage that might not be visible to the naked eye.

Identifying the problem accurately is the first step towards resolving the issue. Once you've confirmed the presence of a blockage, leak, or damage, you can proceed with the appropriate unclogging or repair methods. Remember, if you're unsure or uncomfortable with any part of this process, it's always best to consult a professional mechanic to ensure the job is done safely and effectively.

Fuel Line MRI: Locating the Right Source

You may want to see also

Prepare the Tank: Ensure safety by draining fuel and disconnecting the line

Before you begin the process of unclogging a fuel line, it is crucial to prioritize safety. The fuel tank is a potentially hazardous component of your vehicle or equipment, and proper preparation is essential to avoid any accidents or mishaps. Here's a step-by-step guide to preparing the tank for the unclogging process:

- Drain the Fuel: The first and most critical step is to ensure that the fuel tank is empty. Clogged fuel lines can lead to fuel accumulation, which may cause pressure build-up and potential safety risks. To drain the fuel, locate the fuel drain valve, which is typically found at the bottom of the fuel tank. This valve is designed to release fuel from the tank. Open the valve and allow the fuel to flow into a suitable container or drain it into a designated fuel-draining system. Ensure that you have a proper container to collect the fuel, as it may contain contaminants or debris that have accumulated in the tank.

- Disconnect the Fuel Line: Once the tank is drained, proceed with disconnecting the fuel line. Locate the fuel line that connects the tank to the engine or fuel pump. This line is usually a flexible hose or a rigid tube. Carefully disconnect the line by removing any clamps or fittings that secure it in place. Take note of the position of the line to ensure proper reattachment later. When disconnecting, be cautious as fuel may still be present in the line, so handle it with care.

- Safety Precautions: While working on the fuel system, it is essential to take safety precautions. Wear protective gear, such as gloves and safety goggles, to protect your hands and eyes from potential fuel spills or splashes. Ensure that the work area is well-ventilated to avoid inhaling fuel vapor. Keep a fire extinguisher nearby, as fuel is highly flammable. Additionally, turn off the engine and disconnect the battery to eliminate any electrical hazards.

- Inspect the Tank (Optional): If you have access to the fuel tank, it is a good idea to inspect it for any visible signs of damage, corrosion, or debris. This step is especially important if the tank has been in use for a prolonged period. Look for any signs of rust, leaks, or blockages that might have contributed to the clogged fuel line. Cleaning the tank, if necessary, can be done using appropriate fuel system cleaners and following the manufacturer's guidelines.

By following these preparation steps, you ensure a safe and controlled environment for unclogging the fuel line. Remember, working with fuel requires caution and attention to detail to prevent any accidents or further complications.

Optimizing Fuel Flow: Choosing the Right Fuel Line Size for DSM

You may want to see also

Locate the Clog: Use a fuel line cleaner or compressed air to clear blockages

To effectively unclog a fuel line in your home tank, the first step is to locate the blockage. This process involves a systematic approach to ensure you address the issue thoroughly. Start by inspecting the fuel line for any visible signs of blockage, such as debris or clogs. If you notice any visible obstructions, use a fuel line cleaner to dissolve and remove them. Fuel line cleaners are designed to break down and eliminate blockages, making them an effective tool for this task.

If the blockage is not visible, you can use compressed air to clear the fuel line. Compressed air is a powerful tool for removing clogs and can be particularly useful for hard-to-reach areas. Begin by attaching a compressed air canister to the fuel line, ensuring a secure connection. Then, gently apply the air pressure to the line, working from one end to the other. This process helps to dislodge any blockages and clear the path for fuel flow.

When using compressed air, it's essential to be cautious and methodical. Apply the air pressure steadily and avoid sudden bursts, as this can cause the fuel to spray out unexpectedly. Work the air through the line in sections, ensuring you cover the entire length. Pay attention to any areas where the fuel line bends or changes direction, as these spots are common sites for blockages.

After applying the compressed air, inspect the fuel line again to ensure the blockage has been cleared. If you still notice any signs of obstruction, repeat the process with the fuel line cleaner. This two-step approach ensures a thorough cleaning and increases the chances of completely removing the clog.

Remember, when dealing with fuel lines, it's crucial to take your time and be thorough. Properly locating and clearing blockages will not only improve fuel flow but also contribute to the overall safety and efficiency of your home's fuel system.

Mastering Small Engine Fuel Line Stretching: A Comprehensive Guide

You may want to see also

Clean and Inspect: Remove debris and inspect for further issues

When it comes to dealing with a clogged fuel line in a home tank, the first step is to ensure that you have the necessary tools and safety precautions in place. Start by gathering the required equipment, such as a fuel line cleaner, a fuel filter, a funnel, and a container for any collected debris. It's crucial to wear protective gear, including gloves and safety goggles, to safeguard yourself from any potential fuel-related hazards.

Begin by removing the fuel line from the tank. This process might vary depending on the specific setup of your fuel system, so it's essential to consult the manufacturer's instructions or seek professional guidance if needed. Carefully detach the fuel line, ensuring you have a clear understanding of its connections and the direction of the flow. Once removed, you'll be able to access the interior of the fuel tank.

Inside the fuel tank, you'll likely encounter various debris and contaminants that have accumulated over time. Use the funnel to carefully pour the fuel line cleaner into the tank, allowing it to circulate and dissolve any blockages. Ensure that you follow the instructions on the cleaner's packaging for the correct dosage and contact time. After the specified duration, drain the tank, collecting any dislodged debris in the container.

With the tank cleaned, it's time to inspect the fuel line and tank for any further issues. Carefully examine the fuel line for any signs of damage, cracks, or corrosion. Check for any visible blockages or obstructions that might have caused the clog. Inspect the tank's interior for any rust, corrosion, or debris buildup that could impact fuel quality. If any issues are identified, address them accordingly, which may involve replacing damaged parts or further cleaning.

Remember, regular maintenance and cleaning of the fuel system are essential to prevent clogs and ensure optimal performance. By following these steps, you can effectively clean and inspect the fuel line and tank, addressing any existing issues and taking preventive measures to avoid future clogs.

Understanding Torquing: Stages Fuel Line Maintenance

You may want to see also

Reattach and Test: Securely reconnect the fuel line and test the system

Once you've unclogged the fuel line and ensured the issue is resolved, the next crucial step is to reattach and thoroughly test the system. This process involves carefully reconnecting the fuel line to its original position and then conducting a series of tests to ensure the fuel flow is restored and functioning correctly. Here's a step-by-step guide to help you through this process:

Reattachment: Start by locating the fuel line, which is typically a flexible hose or a rigid tube, and identify its connection points. One end is attached to the fuel tank, and the other connects to the engine's fuel injection system or the carburetor. Carefully detach the clogged section, ensuring you don't damage the surrounding components. Now, reattach the fuel line by aligning the connectors and securing them with the appropriate fasteners or clips. Make sure the connection is tight and secure to prevent any leaks.

Testing the System: After reattachment, it's essential to test the fuel system to ensure everything is functioning as it should. Here's how you can do it:

- Fuel Pump Test: Start the engine and listen for the fuel pump's operation. It should be audible and running for a few seconds as the engine cranks. If the pump doesn't come on or runs intermittently, it might indicate a problem with the pump or its electrical connections.

- Engine Crank Test: Attempt to start the engine. If it starts easily and runs smoothly, the fuel system is likely functioning correctly. However, if the engine struggles to start or stalls immediately, it could be a sign of fuel delivery issues.

- Pressure Check: Use a fuel pressure gauge to check the pressure in the fuel line. The pressure should be within the manufacturer's specified range. Low pressure might suggest a clogged fuel filter or a faulty pump, while high pressure could indicate a potential leak or issue with the fuel injectors.

- Visual Inspection: Inspect the fuel line for any signs of damage, cracks, or leaks. Ensure there are no kinks or obstructions that could affect fuel flow.

Troubleshooting: If the engine doesn't start or exhibits unusual behavior during the test, you may need to investigate further. Check for any error codes or warning lights on the dashboard, as these can provide valuable insights into potential issues. Additionally, inspect the fuel filter and consider replacing it if it hasn't been done recently, as a clogged filter can restrict fuel flow.

By following these steps, you can ensure that the fuel line is securely reattached and that the entire fuel system is operating optimally, minimizing the chances of future clogs or issues. Remember, proper maintenance and regular checks can help prevent such problems and keep your fuel system reliable.

Fixing Fuel Leaks: The Best Tape for Your Car's Safety

You may want to see also

Frequently asked questions

Unclogging a fuel line can be a straightforward process if you follow these steps. First, locate the fuel line, which is typically a flexible tube connecting the fuel tank to the engine. Use a fuel line cleaner or a compressed air can to blow out any debris or clogs. If the clog is more severe, you may need to remove the fuel line and clean it with a fuel line cleaner. Ensure you follow safety precautions and wear protective gear when handling fuel.

Fuel lines can become clogged due to various reasons. Over time, fuel can accumulate contaminants like water, sediment, or varnish, which can lead to clogs. Additionally, physical obstructions, such as debris or small objects, may enter the fuel line and cause blockages. Regular maintenance and fuel stabilization treatments can help prevent clogs, but if issues arise, addressing them promptly is essential to avoid potential engine problems.

Using a plunger is not recommended for unclogging a fuel line. Fuel lines are designed to handle fuel pressure and are not meant to be unclogged using a plunger, which can cause damage to the line or the fuel tank. Instead, opt for safe and effective methods like using a fuel line cleaner or compressed air to clear the clog. If the clog is severe, it's best to consult a professional mechanic to avoid any potential risks associated with fuel system repairs.