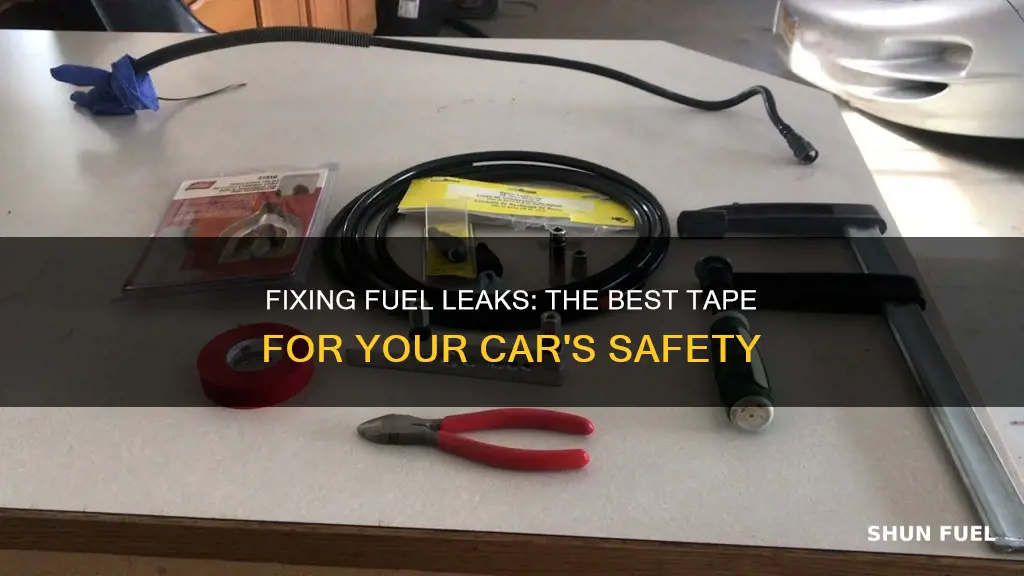

When dealing with a fuel line leak, it's crucial to use the right type of tape to ensure a secure and effective repair. The choice of tape depends on the specific requirements of the leak and the material of the fuel line. For example, silicone-based tapes are commonly used for their flexibility and resistance to heat and chemicals, making them ideal for sealing fuel lines. However, other types of tapes, such as metal-backed tapes or specialized automotive repair tapes, may be more suitable depending on the severity of the leak and the specific conditions of the vehicle. In this guide, we'll explore the various options available and provide recommendations to help you choose the best tape for your fuel line repair.

What You'll Learn

- Tape Material: Choose the right tape for fuel line leaks, considering adhesive strength and compatibility with the fuel

- Tape Thickness: Opt for thin, flexible tape to avoid damage to the fuel line and ensure a secure seal

- Tape Adhesion: Ensure the tape has strong adhesion to create a tight seal and prevent fuel leakage

- Tape Flexibility: Select a flexible tape that can conform to the fuel line's shape and withstand movement

- Tape Repair Time: Quick-drying tape is ideal for immediate repairs, minimizing downtime and potential hazards

Tape Material: Choose the right tape for fuel line leaks, considering adhesive strength and compatibility with the fuel

When dealing with fuel line leaks, selecting the appropriate tape is crucial to ensure a secure and effective repair. The primary consideration is the adhesive strength of the tape, which must be strong enough to create a reliable seal and prevent further leaks. For fuel line repairs, a tape with a high-performance adhesive is ideal, capable of withstanding the pressure and movement associated with fuel flow. Look for tapes specifically designed for automotive or industrial applications, as these are formulated to adhere well to various surfaces and provide excellent bonding.

The material of the tape is another critical factor. Rubber-based tapes are commonly used for fuel line repairs due to their flexibility and ability to conform to the shape of the fuel line. This flexibility is essential to accommodate the natural movement and expansion of the fuel line, ensuring a long-lasting repair. Additionally, rubber tapes are resistant to fuel degradation, meaning they won't break down or become brittle over time, providing a durable solution.

For a more permanent fix, consider using a tape made from a fabric-based material, such as glass cloth or polyester. These tapes offer superior strength and durability, making them suitable for more severe leaks or high-pressure applications. The fabric provides excellent tear resistance and can handle the rigors of fuel line repairs, ensuring a robust and long-lasting solution. However, it's important to note that fabric tapes may be less flexible, so careful application is required to avoid damaging the fuel line.

In terms of compatibility, it's essential to choose a tape that is compatible with the fuel type. Some fuels, like gasoline or diesel, have different properties that may require specific tape formulations. For instance, tapes designed for gasoline applications should be able to withstand the volatile nature of the fuel without compromising the seal. Always refer to the manufacturer's guidelines or seek expert advice to ensure the chosen tape is compatible with the fuel in question.

Lastly, consider the environmental conditions in which the repair will be made. Extreme temperatures or exposure to sunlight can affect the performance of the tape. In such cases, opt for a tape with a higher temperature resistance or one that is UV-stable to ensure the repair remains effective over time. By carefully selecting the tape material based on these factors, you can effectively address fuel line leaks and ensure the safety and reliability of your vehicle's fuel system.

Exploring the Consequences: What Happens When You Cut the Fuel Line

You may want to see also

Tape Thickness: Opt for thin, flexible tape to avoid damage to the fuel line and ensure a secure seal

When dealing with a fuel line leak, it's crucial to choose the right type of tape to ensure a temporary fix that is both effective and safe. One of the most important considerations is tape thickness. Opting for a thin, flexible tape is highly recommended to avoid any potential damage to the fuel line itself. The primary goal is to create a secure seal that can hold the leak in place without causing further harm.

Thicker tapes might seem more robust, but they can exert excessive pressure on the fuel line, potentially leading to further damage or even a complete rupture. The flexibility of the tape is equally important. A flexible tape will conform to the shape of the fuel line, ensuring a snug fit and a reliable seal. This is particularly crucial in areas where the fuel line might have some give or where it is tightly routed around other components.

The ideal tape should be thin enough to allow for easy application and removal without causing any permanent deformation to the fuel line. It should also be durable enough to withstand the pressure and heat associated with the fuel system. A good rule of thumb is to select a tape that is no thicker than 1/16th of an inch (approximately 0.0625 inches). This thickness ensures that the tape can provide a secure seal without risking the integrity of the fuel line.

Additionally, the tape should be made from a material that is compatible with the fuel being carried. Some fuels can be corrosive to certain types of tape, so it's essential to choose a tape that is specifically designed for fuel line repairs. Silicone-based tapes, for example, are often a good choice as they are resistant to many types of fuels and can provide a flexible, durable seal.

In summary, when addressing a fuel line leak, prioritize the use of thin, flexible tape to ensure a secure and safe temporary fix. This approach minimizes the risk of further damage to the fuel line and provides a reliable seal until more permanent repairs can be made. Always consider the specific requirements of your fuel system and choose materials that are compatible with the fuel in question.

Optimizing LS Swap Fuel Lines: A Comprehensive Guide

You may want to see also

Tape Adhesion: Ensure the tape has strong adhesion to create a tight seal and prevent fuel leakage

When dealing with a fuel line leak, it is crucial to use the right type of tape to ensure a secure and effective repair. The primary focus should be on tape adhesion, which is the tape's ability to create a tight seal and adhere strongly to the surface. This is essential to prevent any further fuel leakage and to ensure the safety of the vehicle.

The key to achieving a strong seal is to select a tape with a high-quality adhesive backing. Look for tapes specifically designed for automotive applications, as these are formulated to withstand the harsh conditions of a vehicle's environment. These tapes often feature a strong, rubber-based adhesive that can bond to various surfaces, including metal, plastic, and rubber. The adhesive should be able to withstand the pressure and movement that can occur within the engine compartment.

To ensure optimal adhesion, it is important to prepare the surface properly. Start by cleaning the area around the leak with a mild detergent and water solution to remove any dirt, grease, or debris. This step is critical, as any contaminants can interfere with the tape's ability to create a tight seal. After cleaning, ensure the surface is completely dry before applying the tape.

When applying the tape, follow the manufacturer's instructions carefully. Press the tape firmly onto the surface, ensuring full contact. The tape should be applied smoothly and evenly, without any wrinkles or bubbles. For best results, use a roller or a similar tool to apply pressure and ensure the tape adheres properly. This process will create a robust bond, providing an effective barrier against fuel leakage.

In summary, when addressing a fuel line leak, prioritize tape adhesion as the critical factor. Choose a tape with a strong adhesive, properly prepare the surface, and apply it with care to create a tight seal. This approach will help prevent further leaks and ensure the safe operation of your vehicle. Remember, using the right tools and materials is essential for a successful repair.

The Ultimate Guide to Choosing the Best 1-2 Fuel Line

You may want to see also

Tape Flexibility: Select a flexible tape that can conform to the fuel line's shape and withstand movement

When dealing with a fuel line leak, it's crucial to choose the right tape that offers flexibility and adaptability. The primary goal is to ensure a secure and long-lasting repair, and this is where flexibility comes into play. Opt for a tape that can easily conform to the intricate shape of the fuel lines, allowing it to fit snugly without any gaps or bunching. This flexibility is essential to create a seamless barrier that effectively seals the leak.

The dynamic nature of fuel lines, especially in vehicles with moving parts, demands a tape that can withstand motion. The tape should be able to move with the fuel lines without becoming tight or restrictive, ensuring it doesn't hinder the vehicle's performance. Look for tapes with a good stretch and recovery ability, which will enable them to adapt to the fuel lines' natural movement. This feature is particularly important in high-vibration environments, where the fuel lines experience constant stress.

Flexibility also contributes to the overall durability of the repair. A flexible tape can better absorb shocks and vibrations, reducing the risk of damage or detachment over time. It allows the tape to conform to any minor imperfections or irregularities on the fuel lines, creating a tight seal. This is especially beneficial in areas where the fuel lines are exposed to extreme temperatures or harsh conditions, as the tape can adapt and maintain its integrity.

In addition to flexibility, consider the material's adherence to the fuel lines. The tape should have a strong adhesive backing that can create a reliable bond, ensuring the leak is effectively sealed. Look for tapes with a high-quality adhesive that can withstand the fuel's corrosive properties and the overall operating conditions of the vehicle. This combination of flexibility and strong adhesion will result in a robust and long-lasting repair.

When selecting the tape, keep in mind that the fuel lines may have varying diameters and shapes. A flexible tape will allow for a customized fit, accommodating these differences without compromising the seal. This adaptability is key to a successful repair, ensuring the tape stays in place and effectively prevents further leaks. By prioritizing flexibility, you can achieve a secure and reliable solution for your fuel line leak.

Fuel Injector Line Maintenance: Is Cleaning Necessary?

You may want to see also

Tape Repair Time: Quick-drying tape is ideal for immediate repairs, minimizing downtime and potential hazards

When dealing with a fuel line leak, time is of the essence, and having the right tools and materials on hand can make all the difference. In such urgent situations, quick-drying tape is an invaluable asset. This specialized type of tape is designed to adhere rapidly to surfaces, providing an immediate and effective solution to seal leaks. The rapid drying time is crucial as it minimizes the time the fuel is exposed to the air, reducing the risk of fire or explosion, which are significant hazards associated with fuel leaks.

The primary benefit of quick-drying tape is its ability to act swiftly. As soon as it comes into contact with the fuel line, it forms a tight, cohesive seal, effectively blocking the leak. This immediate action is essential to prevent further fuel loss and potential damage to the vehicle's engine. By minimizing the time the fuel is in contact with the air, the risk of combustion is significantly lowered, ensuring a safer environment for both the vehicle and its occupants.

In addition to its rapid action, quick-drying tape is also highly durable. Once applied, it creates a robust barrier that can withstand the pressure and movement associated with fuel lines. This durability ensures that the repair is not only quick but also long-lasting, providing peace of mind that the leak has been effectively addressed. The tape's strength and flexibility also allow it to conform to the unique shape of the fuel line, ensuring a perfect fit and a secure seal.

Furthermore, the use of quick-drying tape is a convenient and accessible solution. It requires no special skills or tools for application, making it easy for anyone to use in an emergency. The tape is typically designed for ease of use, with a user-friendly adhesive that ensures a simple and quick application process. This accessibility is vital when every second counts, allowing for a swift response to the fuel line leak.

In summary, quick-drying tape is an essential tool for addressing fuel line leaks promptly and safely. Its rapid drying time, durability, and ease of use make it an ideal choice for immediate repairs, helping to minimize downtime and potential hazards associated with fuel leaks. Having this type of tape readily available in your emergency kit can provide valuable protection and peace of mind when dealing with such critical situations.

When Fuel Lines Detach: Understanding the Consequences and Solutions

You may want to see also

Frequently asked questions

For temporary fixes, a rubber-based repair tape or a fuel-resistant tape is ideal. These tapes are designed to withstand the harsh conditions of fuel exposure and can provide an effective seal to prevent further leaks.

While duct tape is versatile, it is not recommended for fuel line repairs. Duct tape may not adhere well to the fuel line material and could lose its grip over time, leading to potential leaks. It's best to use specialized tapes for this purpose.

For permanent solutions, consider using a fuel-line repair tape or a high-temperature silicone tape. These tapes are specifically engineered to withstand the heat and pressure of fuel systems, ensuring a long-lasting repair. Look for tapes with a strong adhesive and a flexible material that can conform to the fuel line's shape.

Yes, in some cases, a temporary fix can be achieved by using a rubber gasket or a piece of rubber tubing. These can be cut to size and secured in place with tape. However, for a more permanent solution, it's best to consult a professional mechanic who can recommend the appropriate repair method.

Ensure the surface is clean and dry before applying the tape. Remove any old tape or debris to create a strong bond. Apply the tape firmly, ensuring good contact with the fuel line. Consider using a primer or an adhesive specifically designed for the chosen tape material to enhance the bond. Regularly inspect and reapply the tape as needed to maintain the integrity of the repair.