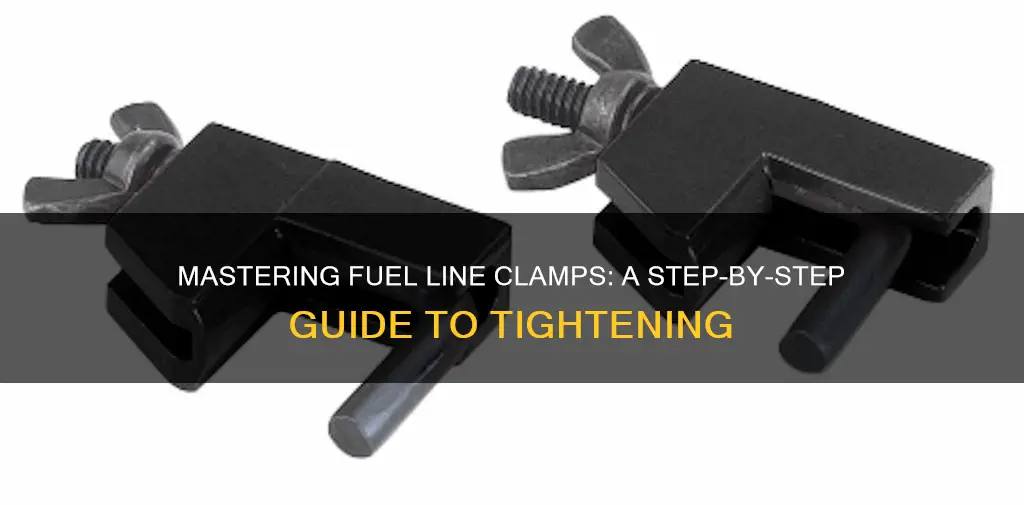

Tightening fuel line clamps is a crucial step in maintaining the integrity of your vehicle's fuel system. Over time, fuel lines can loosen due to vibrations and temperature changes, leading to potential fuel leaks and reduced engine performance. To ensure a secure and reliable connection, it's essential to know the proper technique for tightening these clamps. This guide will provide a step-by-step process, highlighting the importance of using the right tools and techniques to achieve a tight and secure clamp, ultimately protecting your vehicle's engine from potential damage caused by fuel leaks.

What You'll Learn

- Identify Clamp Type: Determine the type of clamp (e.g., metal, plastic) to ensure proper tightening

- Clean Clamp Surface: Remove dirt and debris from the clamp and fuel line to ensure a tight seal

- Use the Right Tools: Employ appropriate tools like a wrench or torque wrench for precise tightening

- Tighten in Stages: Tighten the clamp in stages, checking for tightness and proper alignment after each turn

- Test for Leaks: After tightening, inspect for any fuel leaks around the clamp to ensure a secure connection

Identify Clamp Type: Determine the type of clamp (e.g., metal, plastic) to ensure proper tightening

When dealing with fuel line clamps, identifying the type of clamp is crucial to ensure a secure and effective tightening process. The two primary types of clamps you'll encounter are metal and plastic. Each has its own set of advantages and considerations.

Metal clamps, typically made from materials like steel or aluminum, are known for their durability and strength. They are often used in high-pressure applications or in environments where corrosion resistance is essential. Metal clamps provide a robust and reliable hold, ensuring that fuel lines remain tightly secured. However, they can be more challenging to tighten due to their weight and rigidity. It's important to use the appropriate tools, such as a wrench or a hydraulic clamp puller, to apply the necessary force without causing damage to the fuel line or the clamp itself.

On the other hand, plastic clamps offer flexibility and ease of use. They are commonly made from materials like nylon or polypropylene, which provide a good balance of strength and flexibility. Plastic clamps are often used in applications where weight and cost are considerations. These clamps are generally easier to tighten by hand, making them more accessible for DIY enthusiasts or those with limited access to heavy-duty tools. However, it's essential to be cautious when tightening plastic clamps, as they may be more susceptible to damage if subjected to excessive force or heat.

To determine the type of clamp you're dealing with, carefully inspect the fuel line and the clamp itself. Look for any markings or labels that indicate the material. Sometimes, the color of the clamp can also provide a clue, as different colors may represent different materials. For example, a black clamp might be made of metal, while a clear or translucent clamp could be plastic. If you're unsure, consult the vehicle's manual or seek guidance from a professional mechanic who can provide specific recommendations based on your vehicle's make and model.

Identifying the clamp type is a critical step in the process of tightening fuel line clamps. By understanding the characteristics of metal and plastic clamps, you can choose the appropriate tightening methods and tools, ensuring a secure and reliable fuel line connection.

Quick Disconnect Fuel Line Repair: A Step-by-Step Guide

You may want to see also

Clean Clamp Surface: Remove dirt and debris from the clamp and fuel line to ensure a tight seal

To ensure a secure and tight seal when tightening fuel line clamps, it is crucial to start with a clean and prepared surface. This process involves removing any dirt, debris, or contaminants that could interfere with the clamping mechanism. Here's a step-by-step guide to achieving this:

Step 1: Gather the Necessary Tools and Materials

Before you begin, ensure you have the right tools and materials. You will need a gentle cleaning agent suitable for fuel line cleaning, such as a specialized fuel line cleaner or a mild detergent. Additionally, have a soft cloth or brush, compressed air (if available), and a clean, dry rag ready for the process.

Step 2: Inspect the Clamp and Fuel Line

Carefully examine the fuel line clamp and the fuel line itself. Look for any visible dirt, rust, or debris accumulation. Pay attention to the areas where the clamp attaches to the fuel line, as these spots are critical for a proper seal. Identify any potential issues, such as corrosion or excessive wear, which may require further action.

Step 3: Clean the Clamp Surface

Using the soft cloth or brush, gently wipe down the clamp surface, ensuring you cover all areas, including the threads and any grooves or ridges. Apply the cleaning agent to the cloth and carefully rub the clamp, removing any dirt or contaminants. Be thorough but gentle to avoid damaging the clamp or fuel line. If there is heavy buildup or corrosion, consider using a small wire brush or a specialized tool to carefully remove it without compromising the clamp's integrity.

Step 4: Remove Debris from the Fuel Line

With the clamp cleaned, focus on the fuel line. Use compressed air to blow out any loose debris or dirt from the fuel line's interior. Ensure you direct the air carefully to avoid pushing debris further into the line. If necessary, use a small brush or a compressed air nozzle to reach into the fuel line and remove any stubborn particles. This step is crucial to prevent any foreign matter from interfering with the clamping process.

Step 5: Rinse and Dry

After cleaning, rinse the clamp and fuel line with clean water to remove any remaining cleaning agent. Ensure there is no residue left behind. Then, allow the components to air dry completely. This step is essential to prevent moisture from affecting the clamping process and the overall seal.

By following these steps, you can ensure that the clamp surface and fuel line are clean and prepared, allowing for a tight and secure connection when tightening the fuel line clamps. This process is fundamental to maintaining a reliable and safe fuel system in vehicles or machinery.

Simplifying Fuel Pump Line Removal: A Guide for 1998 Plymouth Grand Voyager Owners

You may want to see also

Use the Right Tools: Employ appropriate tools like a wrench or torque wrench for precise tightening

When it comes to tightening fuel line clamps, using the right tools is crucial to ensure a secure and reliable connection. The process requires precision and attention to detail to avoid over-tightening or under-tightening, which can lead to potential issues. Here's a guide on how to employ the appropriate tools for this task:

Start by gathering the necessary tools. A standard wrench, preferably a adjustable wrench, is a common tool used for tightening fuel line clamps. It allows for a customizable grip, ensuring you get a firm hold on the clamp. However, for more precise work, a torque wrench is highly recommended. This tool measures the force applied during tightening, ensuring the clamp is secured with the correct amount of torque. The ideal torque value can vary depending on the fuel line and vehicle, so it's essential to consult your vehicle's manual or a professional for guidance.

Before beginning, inspect the fuel line clamp and the surrounding area. Ensure that the clamp is in good condition and free from any damage or corrosion. Cleaning the clamp and the fuel line can also be beneficial, especially if there is any debris or dirt present. This step ensures a proper connection and prevents any potential leaks.

Now, locate the fuel line clamp and position the wrench or torque wrench accordingly. For a wrench, you'll typically need to grip the clamp and apply force in a clockwise direction. For torque wrenches, follow the manufacturer's instructions to set the desired torque value. Apply the force gradually and steadily, ensuring that you don't overtighten the clamp. Over-tightening can damage the fuel line or clamp, leading to potential leaks or even a broken connection.

Remember, the goal is to achieve a tight and secure connection without forcing it. Take your time and use the tools to guide your tightening process. If you're using a torque wrench, ensure that the specified torque value is reached but not exceeded. This approach guarantees that the fuel line clamp is tightened appropriately, providing a reliable seal and preventing any fuel leaks.

Air Bubbles in Diesel Fuel Lines: A Cause for Concern?

You may want to see also

Tighten in Stages: Tighten the clamp in stages, checking for tightness and proper alignment after each turn

When working with fuel line clamps, a methodical approach is essential to ensure a secure and effective installation. Tightening the clamp in stages is a smart technique that allows for precise adjustments and helps avoid over-tightening, which can lead to damage. Here's a step-by-step guide on how to tighten fuel line clamps effectively:

Start by placing the fuel line clamp in the desired position, ensuring it is centered and aligned with the fuel line. Use a wrench or a specialized tool designed for tightening clamps to begin the tightening process. Take the first few turns by hand, feeling for resistance and ensuring the clamp is snug. This initial tightening sets the foundation for the subsequent stages.

After the initial tightening, it's crucial to inspect the clamp's position and tightness. Check for any visible gaps or misalignments. If the clamp is not properly aligned, it may not provide the necessary support and could lead to fuel leaks over time. Use a straight edge or a ruler to verify the clamp's straightness and ensure it is centered around the fuel line.

Now, continue tightening the clamp in small increments. For each turn, observe the clamp's movement and the fuel line's response. The goal is to achieve a secure hold without applying excessive force. After each turn, stop and inspect the clamp's tightness and alignment once more. This iterative process allows for fine-tuning and ensures the clamp is neither too tight nor too loose.

As you progress, you'll develop a sense of when the clamp is properly tightened. The key is to be gentle yet firm, ensuring the clamp doesn't strip the threads of the fuel line or the clamp itself. Remember, the objective is to create a tight, leak-free seal while maintaining the integrity of the fuel line.

By tightening the clamp in stages and regularly checking its tightness and alignment, you can achieve a professional-grade installation. This methodical approach ensures that the fuel line clamp is secure, properly aligned, and less likely to cause any issues in the future. It's a simple yet effective technique that every mechanic or DIY enthusiast should master.

Mastering the Art of Installing Steel Fuel Lines: A Comprehensive Guide

You may want to see also

Test for Leaks: After tightening, inspect for any fuel leaks around the clamp to ensure a secure connection

When tightening fuel line clamps, it's crucial to ensure a secure and leak-free connection to prevent any potential hazards. After tightening the clamps, the next step is to conduct a thorough inspection for any fuel leaks. This process is essential to guarantee the safety and efficiency of your vehicle's fuel system. Here's a detailed guide on how to perform this test:

Start by visually inspecting the area around the clamp. Look for any signs of fuel leakage, which could appear as small droplets or a steady stream of fuel. Often, leaks will be visible as a dark, oily stain on the ground or nearby surfaces. Pay close attention to the clamp's interface with the fuel line and any other components it connects to. Even a small crack or gap can allow fuel to escape. If you notice any fuel, it's a clear indication that the clamp may not be tight enough or that there's an issue with the connection.

Use a simple yet effective method to test for leaks. Apply a small amount of diesel or fuel-safe dye around the clamp, ensuring it's evenly distributed. You can use a syringe or a small brush for this purpose. Allow the vehicle to idle or run for a few minutes to ensure the fuel circulates. Then, inspect the area again. If there's a leak, the dye will flow towards it, making it easier to identify. This method is particularly useful for hard-to-reach areas.

For a more comprehensive test, you can use a fuel pressure gauge. This tool measures the pressure in the fuel system and can help detect leaks. Start the engine and allow it to reach a steady operating temperature. Then, connect the gauge to the fuel line, ensuring a secure connection. Gradually increase the engine's speed and listen for any hissing or whistling sounds, which could indicate a leak. If you hear any unusual noises, it's essential to investigate further and check for any visible signs of fuel escaping.

Remember, a proper inspection is crucial for your safety and the longevity of your vehicle's fuel system. Always take the time to thoroughly tighten and test fuel line clamps to prevent any potential accidents or costly repairs. Regular maintenance and attention to these details will ensure your vehicle's performance and reliability.

The Ultimate Guide to Choosing the Best Marine Fuel Line

You may want to see also

Frequently asked questions

Fuel line clamps are essential for securing fuel lines and preventing leaks. Over time, they can loosen due to vibration, heat, or regular use. Look for signs of wear, such as cracks, corrosion, or if the clamp no longer fits snugly around the fuel line. If you notice any of these issues, it's important to tighten the clamp promptly.

Tightening a fuel line clamp typically requires a few basic tools. You'll need a wrench or a pair of channel locks to apply the necessary force. Ensure you have the correct size and type of wrench for the clamp's bolt or nut. It's also a good idea to have a rag or gloves to protect your hands and provide a better grip.

While a regular wrench can be used, it's not always the best option. Regular wrenches may not provide the necessary leverage or grip to tighten the clamp effectively. It's recommended to use a specialized tool like a fuel line clamp wrench, which is designed to fit the clamp's shape and provide a secure grip.

The amount of force required can vary depending on the clamp and fuel line. As a general guideline, tighten the clamp by hand first to feel for resistance. Then, using your wrench, apply firm pressure in a clockwise direction until the clamp is secure. Avoid over-tightening, as it can damage the fuel line or clamp.

Yes, here are a few tips:

- Always tighten the clamp in a counterclockwise direction to ensure it is secure.

- Check for any obstructions or interference that might prevent the clamp from tightening properly.

- After tightening, inspect the clamp to ensure it is still intact and not damaged.

- If you're unsure, consult a professional mechanic or refer to your vehicle's manual for specific instructions.